Method for processing harmonic reducer flexible wheel

A technology of harmonic reducer and processing method, which is applied in the field of harmonic reducer, can solve problems such as heavy economic burden, achieve the effect of reducing economic burden and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in conjunction with specific embodiments.

[0037] A processing method for a harmonic reducer flexible wheel, including the following process steps, specifically:

[0038] a. Cut the bar for blanking;

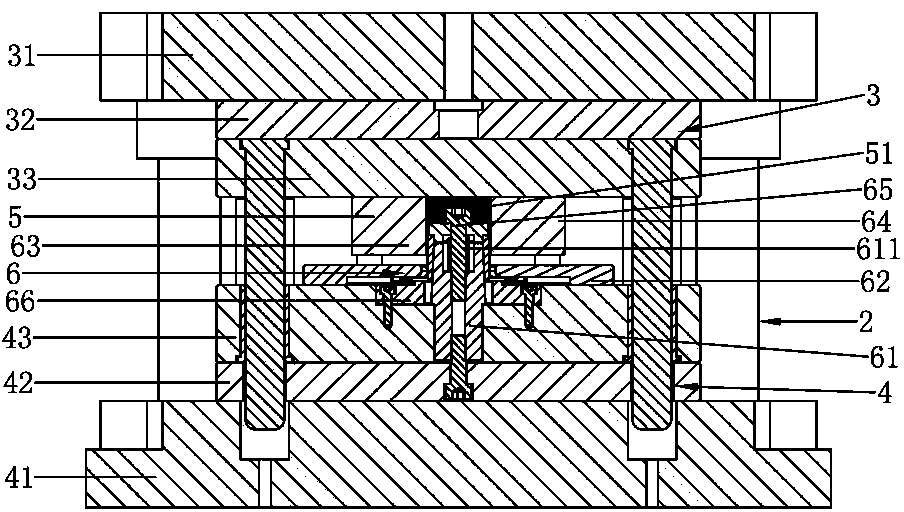

[0039] b. Heat the bar to 800°C-1150°C, and forge and shape the bar through a forging die;

[0040] c. Carry out normalizing heat treatment to the flexspline blank after forging and shaping. The normalizing temperature is 900°C-920°C and keep warm for 3 hours. After heat preservation, the flexspline blank is air-cooled to room temperature with the furnace;

[0041] d. Place the flexspline blank after normalizing heat treatment on the spinning machine for spinning treatment;

[0042] e. Turning the flexible spline blank after spinning through CNC lathe;

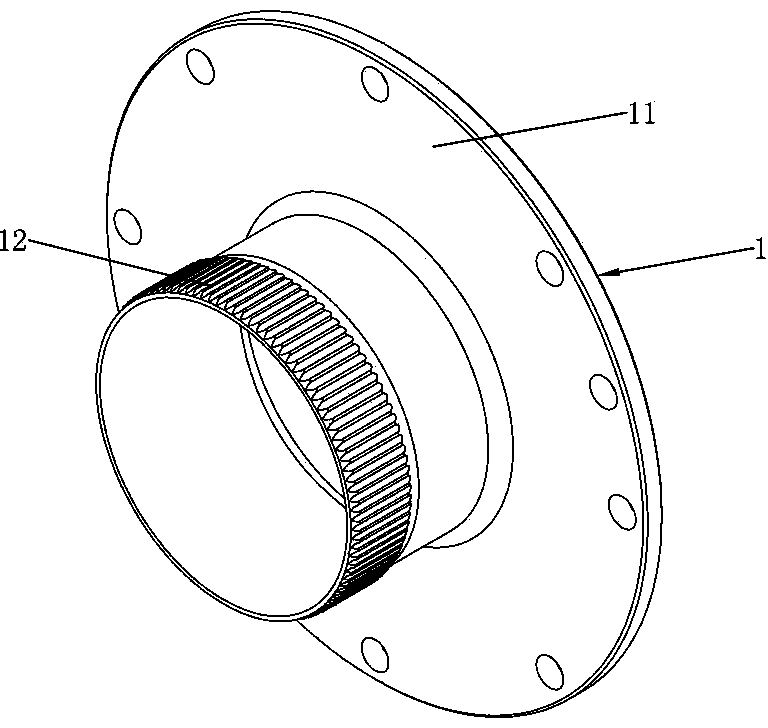

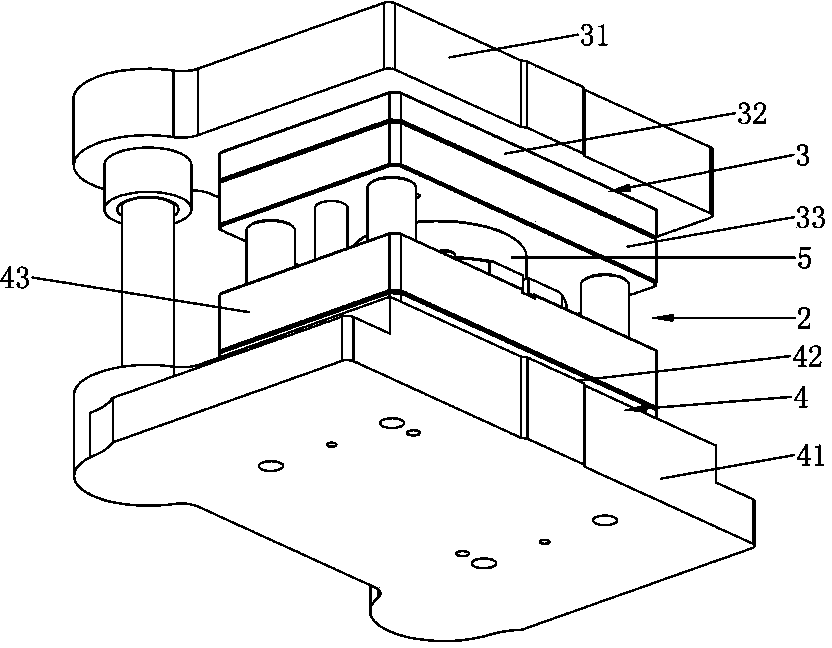

[0043] f. The flexspline blank after turning is processed by CNC milling machine for gear shaping, and the CNC milling machine processes the outline of the external ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com