Real-time monitoring system for full-automatic stamping production line

A real-time monitoring and production line technology, applied in the direction of comprehensive factory control, safety equipment, manufacturing tools, etc., can solve the problems of not meeting the environmental requirements of high-speed stamping production lines, slow work rhythm, etc., to reduce the floor area and the number of workers, and improve production Efficiency, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the patent of the present invention is described in detail below with reference to the accompanying drawings and specific examples:

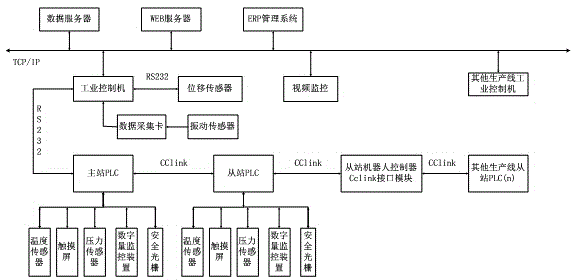

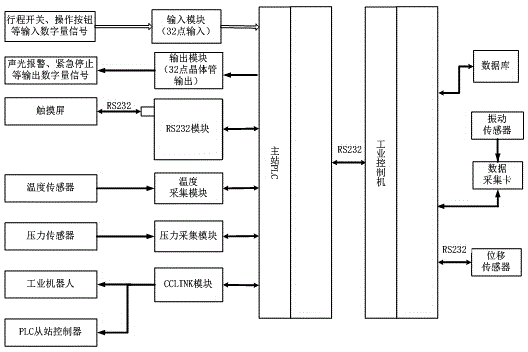

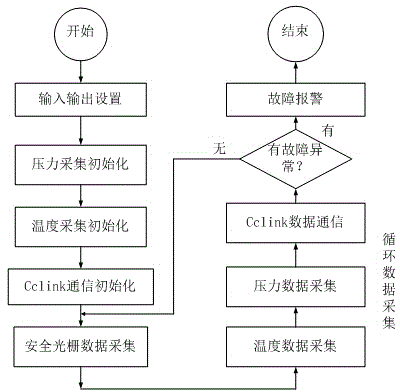

[0029] figure 1 It is a functional block diagram of a real-time monitoring system for a full-automatic stamping production line. The real-time monitoring system for a full-automatic stamping production line of the present invention is characterized in that it includes an industrial control machine and a master station PLC that controls the work of two stamping machines on the stamping production line. The signal input terminal of the PLC is respectively connected to the sensor and the pressure sensor installed on the stamping production line to detect the working temperature of the stamping machine, and the signal output terminal of the main station PLC is connected to the industrial control machine through the communication interface.

[0030] In this embodiment, the signal output end of the above-mentioned master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com