Movable-die type gantry numerical control press

A CNC punching machine, mobile technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of increasing the time for fast positioning in the Y direction, processing dead angle, instability, etc., to improve processing quality and reduce production The effect of reducing cost and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

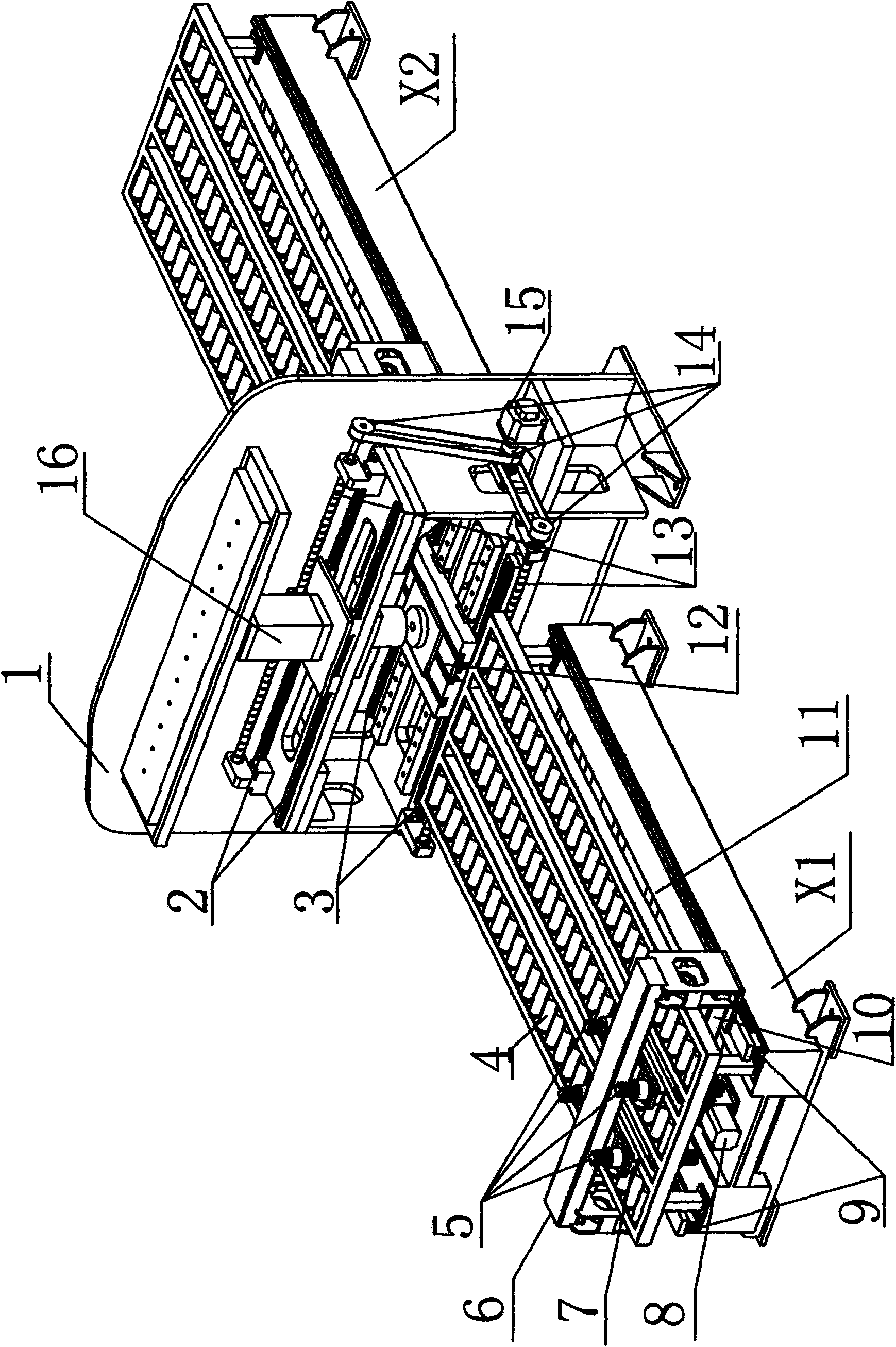

[0015] A specific embodiment of the present invention is a special numerical control punch for processing super long materials, including a punch body 1 and a feeder. The punch body 1 is provided with two sets of upper and lower linear guide rails 2, 3, and is equipped with a corresponding power mechanism. The power mechanism drives the die of the press body 1 to move along the Y axis through the screw 13 and the screw nut; the die is installed on the worktable 12 and the hydraulic cylinder 16 of the press body 1, and the worktable 12 and the hydraulic cylinder 16 respectively pass through the screw nut And the lead screw 13 is connected with the power mechanism. The punch body 1 is arranged between X1 and X2, and the worktable 11 can move back and forth along the Y axis. The structure of the feeder X1 and the feeder X2 are the same, such as X1, the worktable is equipped with several rollers 4 to reduce friction; it is equipped with a motor 8 and a ball screw 10 driven by the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com