Ultraviolet/hot pressing curing type nano-printing method and stamping press

A nanoimprinting and curing technology, which is applied in the direction of optomechanical equipment, optics, instruments, etc., can solve the problem of difficult to achieve accurate replication of large-area nanopatterns, uneven residual layer of step exposure imprinting, and incomplete bonding of templates and substrates. In order to achieve the effect of stable and controllable imprinting process, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

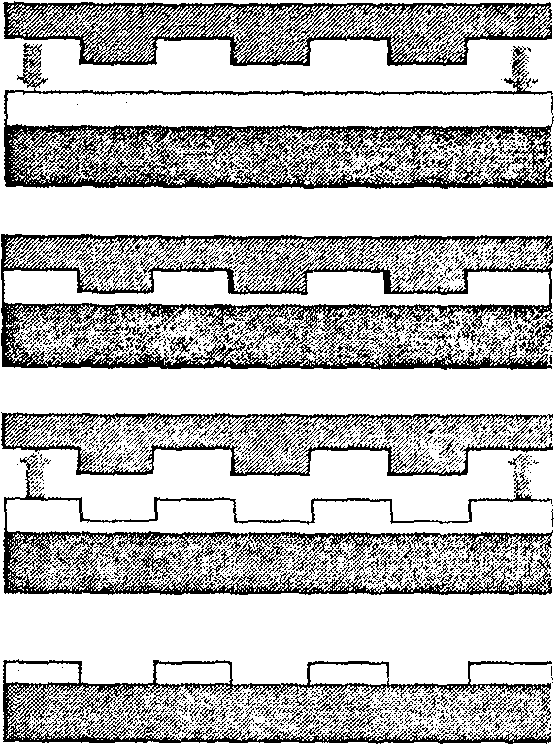

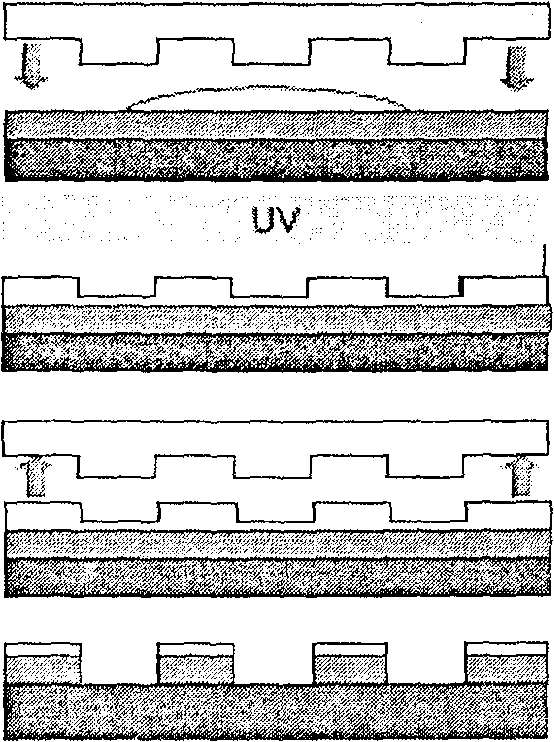

Method used

Image

Examples

Embodiment Construction

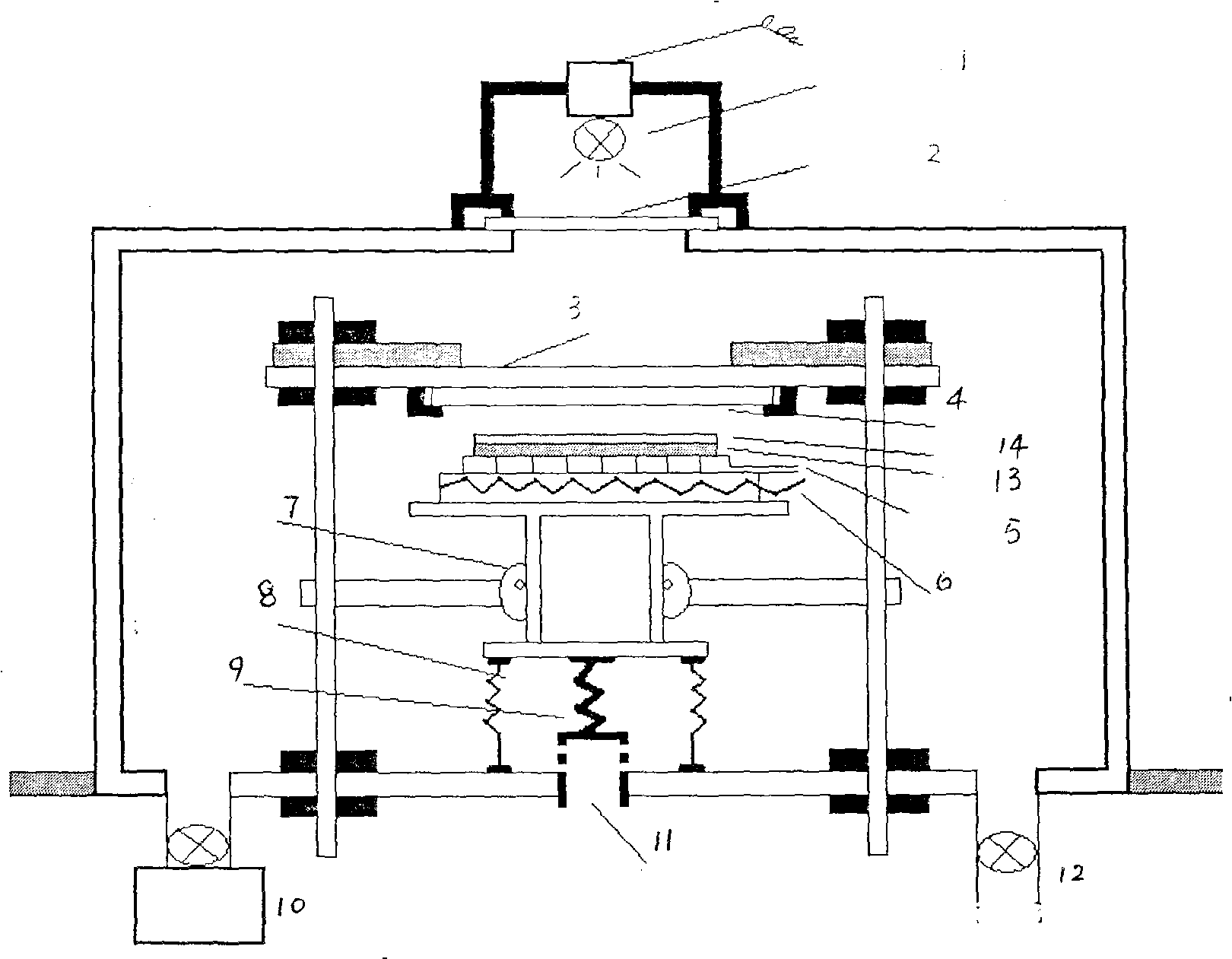

[0021] The means for realizing the object of the present invention and the specific implementation scheme can be divided into the following three parts to illustrate respectively:

[0022] (1) Design and development of the mechanical system of the nanoimprint machine

[0023] In the present invention, the mechanical system part of the nanoimprinting machine is the most critical and core part of the entire imprinting device, and it mainly involves the vacuum environment provided by the vacuum device for imprinting, and the imprinting implementation device (including an imprinting platform, a pressure generating device, Pressure transmission device, pressure control device, etc.), embossing reference surface device, imprinting leveling automatic adjustment device, vacuum suction device and other parts.

[0024] (1), vacuum system

[0025] The performance of the nanoimprint process in the present invention is carried out under vacuum conditions. According to the characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com