Method for manufacturing metal outer frame for panel display

A flat-panel display, metal frame technology, applied in metal casings, manufacturing tools, metal processing equipment, etc., can solve problems such as increased processing costs, alarming costs, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

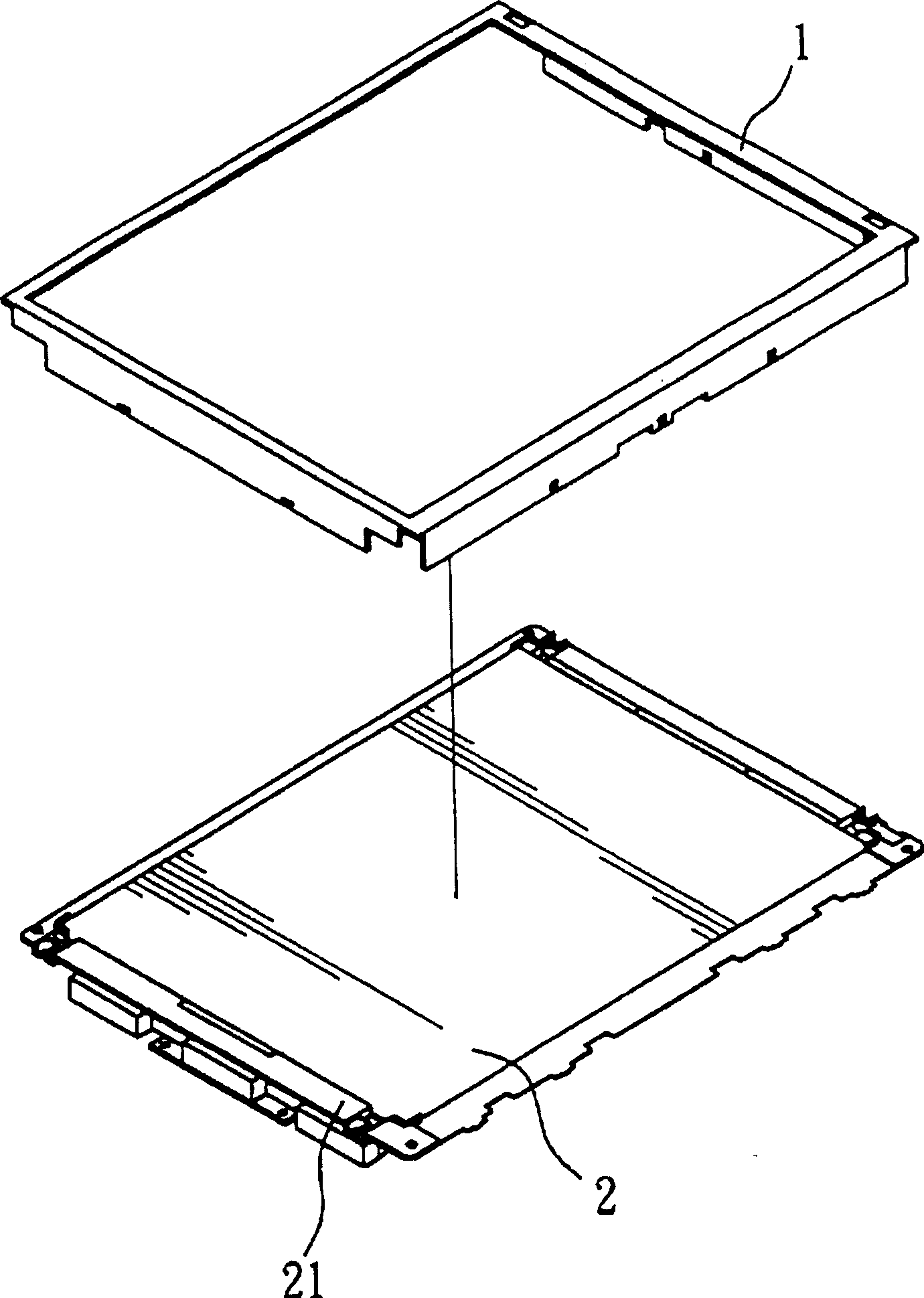

[0021] refer to Figure 3a to Figure 3e , which shows a method of manufacturing a metal frame according to a preferred embodiment of the present invention. In this example, the purpose of the metal frame is the same as figure 1 The same figure is used to fix a backlight module of a flat panel display, but in other applications, the metal frame can also be used to fix a display panel or other components of a flat panel display. In addition, in this embodiment, the overall structure of the metal frame is the same as figure 1 As shown, it is roughly the same, except that it has to use a completely novel manufacturing method to achieve the purpose of saving material and processing costs.

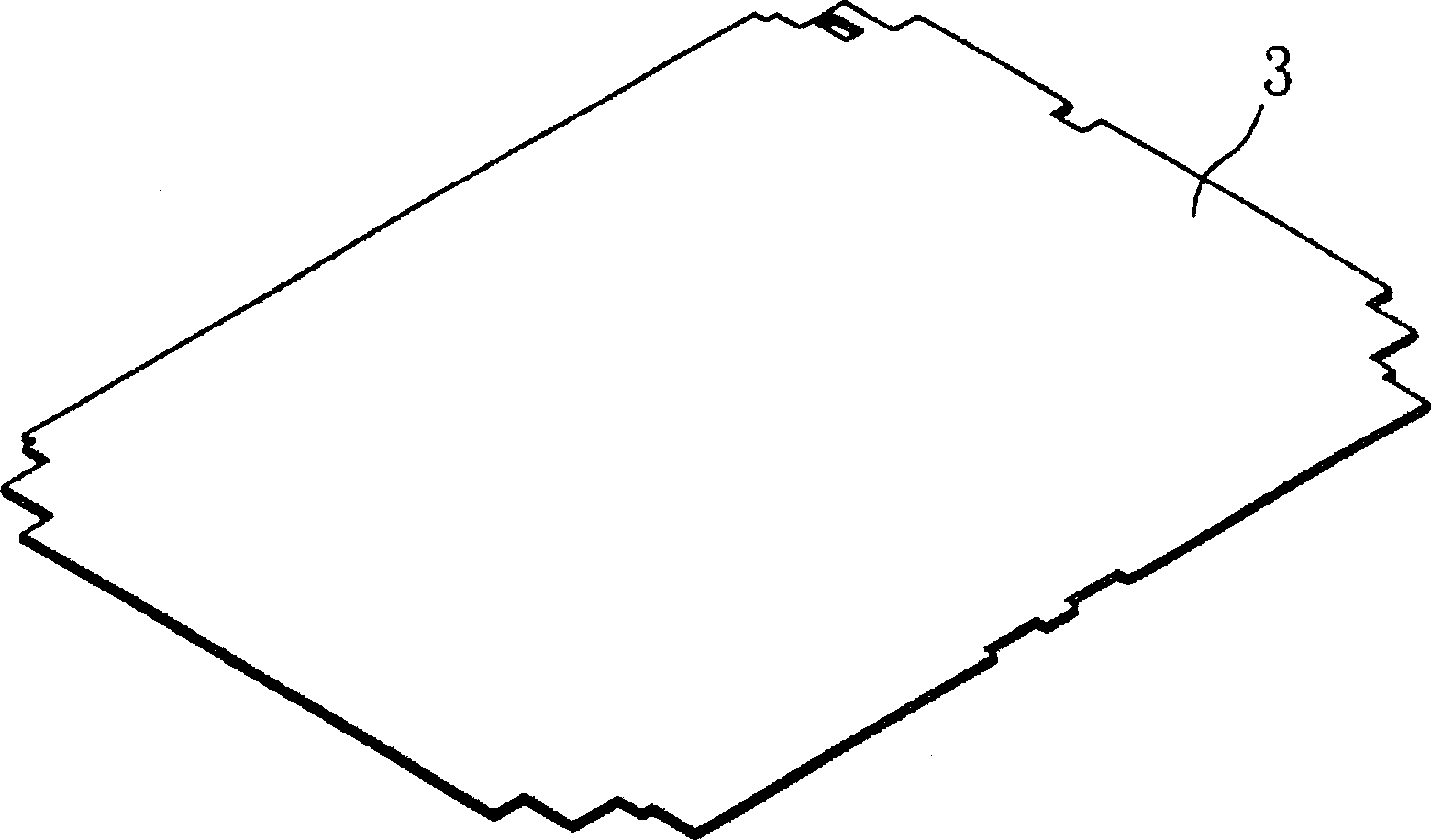

[0022] refer to Figure 3a , first provide a plurality of plates 5 as raw materials to be processed, these plates 5 can be processed from coils or sheets, and the material of the plates 5 is metal, such as iron, stainless steel, aluminum, tinplate, mild steel or galvanized steel plate etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com