Punching machine mold of metal button and method for processing metal button using the mold

A mold and button technology, applied in metal processing equipment, buttons, buttons, etc., can solve the problems of potential safety hazards and low production efficiency, and achieve the effects of eliminating potential safety hazards, ensuring quality, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

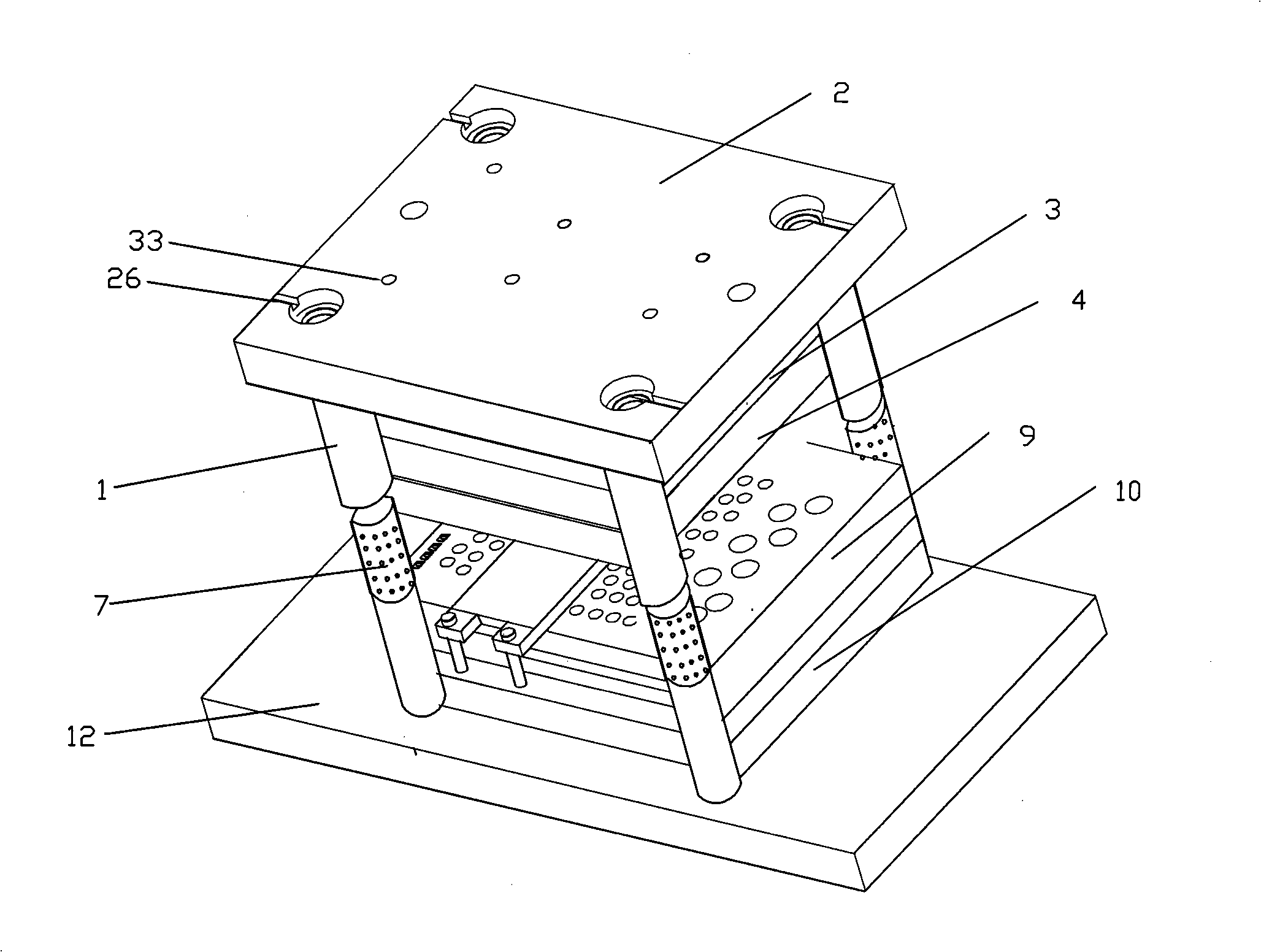

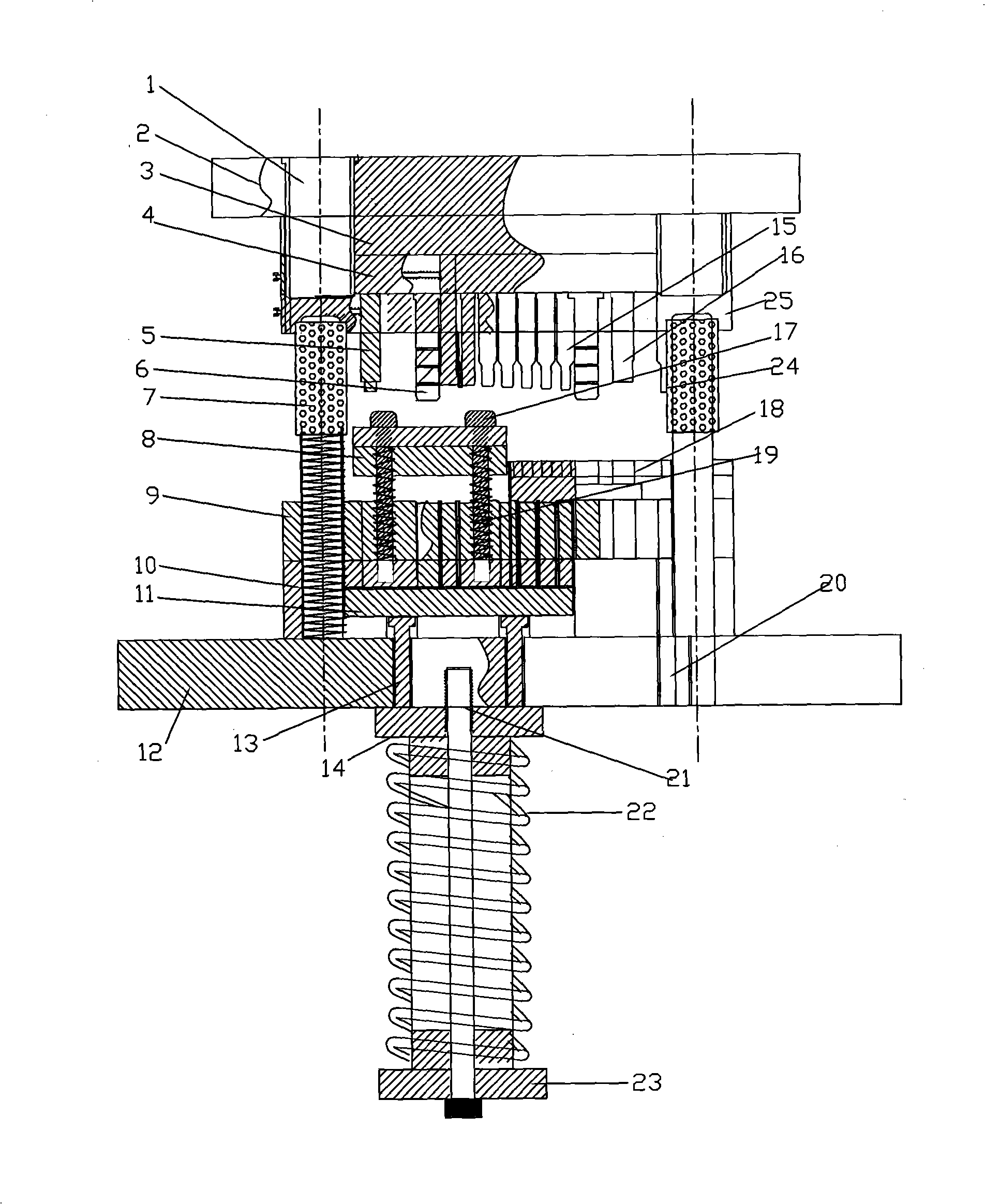

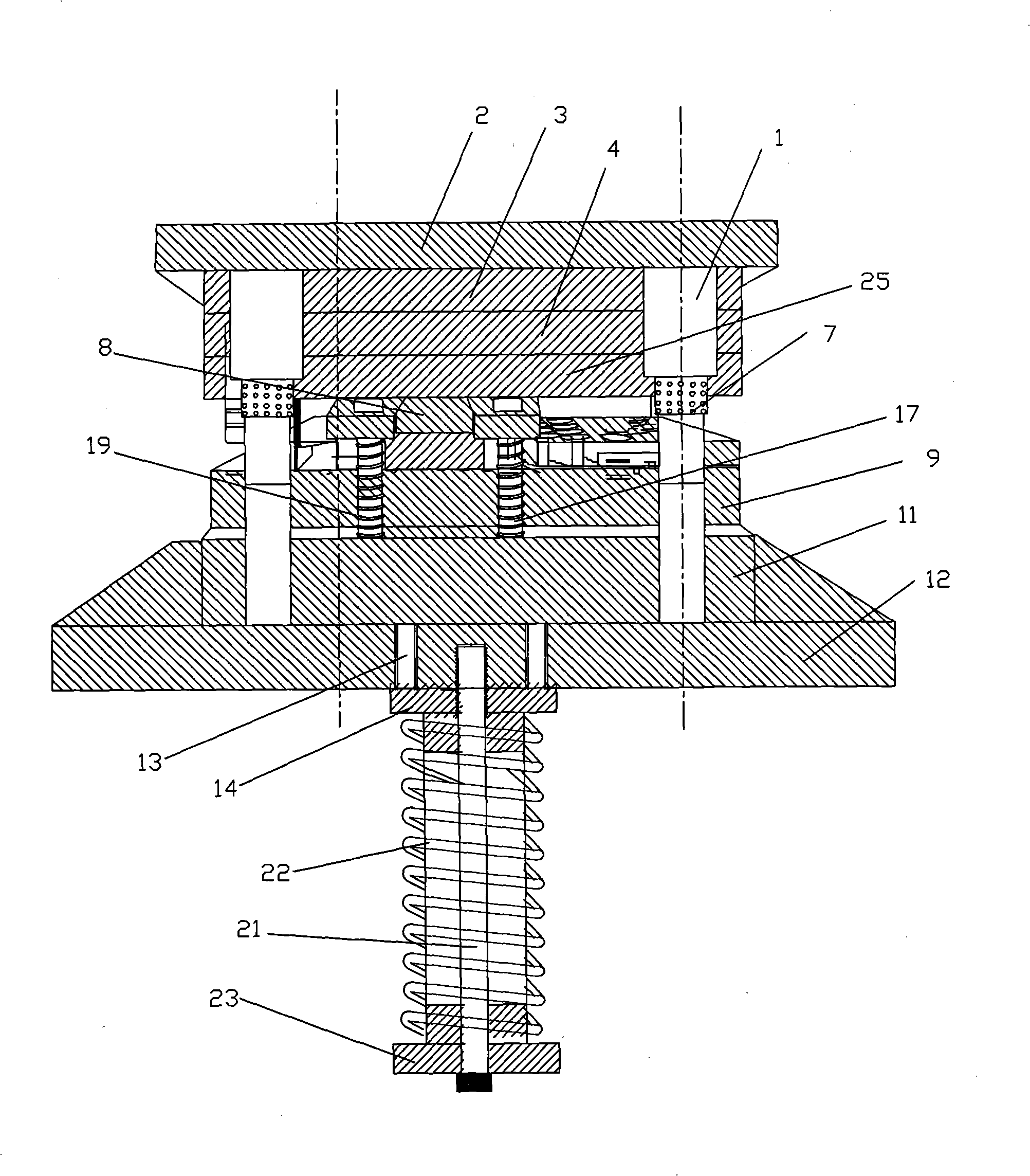

[0028] Please see attached figure 1 , attached figure 2 , attached image 3 , Mold among the present invention mainly comprises upper mold 8 and lower mold 29 two parts.

[0029] In this embodiment, the uppermost layer of the upper mold 28 is a top plate 2, and there may be a screw hole 33 on the top plate 2, and the top plate and the punch are fixedly installed together through the screw hole 33. 28 is fixedly installed on the punch press 27, a punch backing plate 3 is fixedly installed below the top plate 2, which mainly plays the role of buffer protection, and a punch fixing plate 4 is fixedly installed under the punch backing plate 3. It is fixedly installed on the punch fixing plate 4. What is used in this embodiment is a mold with one ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com