Pressing mechine, pressing method, and punched article

A processing device, pressure technology, applied in the field of punching products, can solve the problem of size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

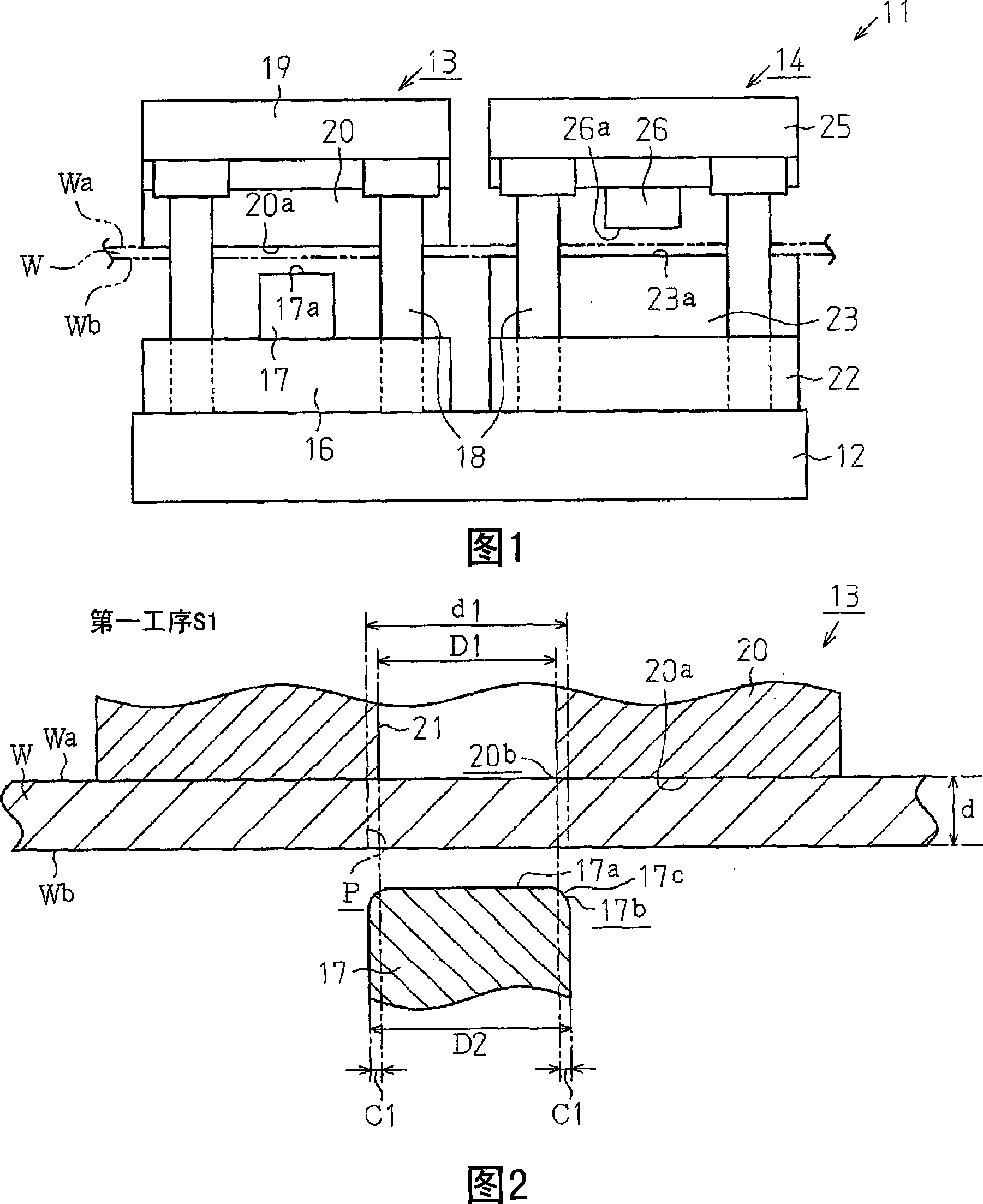

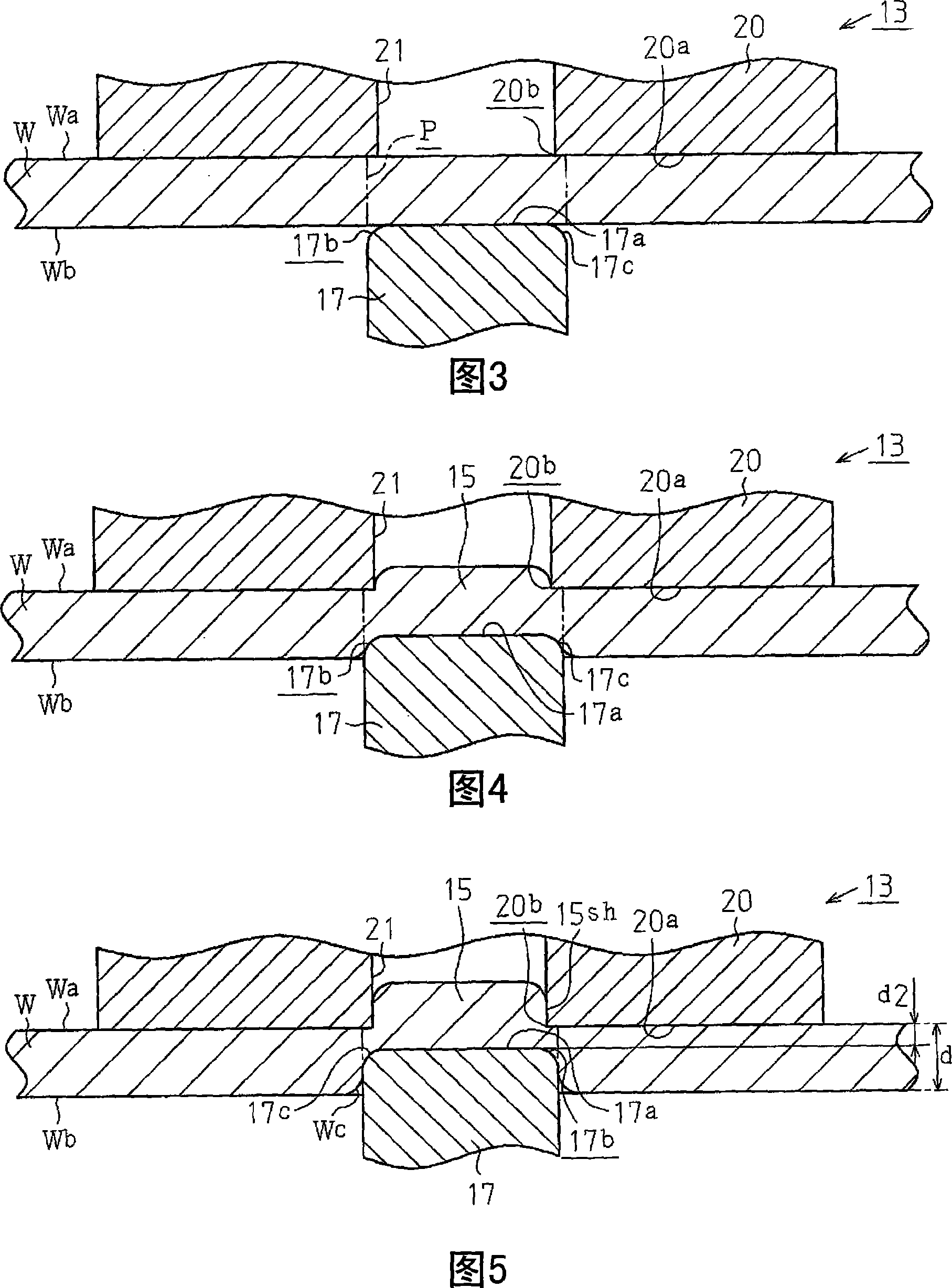

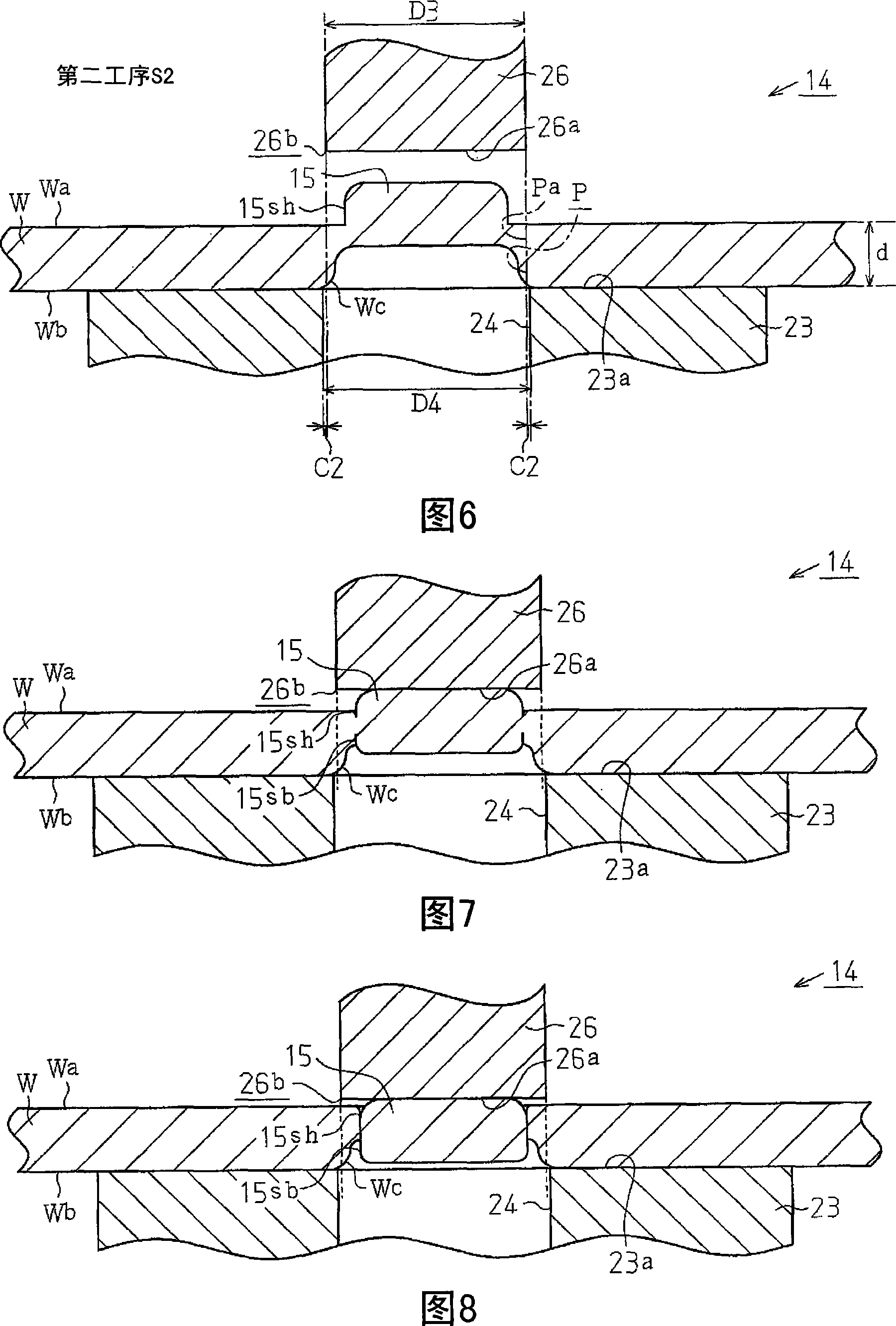

[0055] Next, with reference to FIGS. 1 to 12 , the first embodiment of the present invention will be described. The first embodiment is a press working device and a press working method used when punching out a punching body from a thicker plate.

[0056] As shown in FIG. 1 , in the press working device 11 of this embodiment, a first processing unit 13 and a second processing unit 14 are arranged side by side on a substrate 12 . In addition, the press processing device 11 uses each processing unit 13, 14 to form a through hole P (see FIG. 12 ) having a given shape (in this embodiment, the cross section is substantially circular) in the sheet W, and the sheet W (for example: A hot-rolled steel sheet (JISS PH440) for automobile structures is formed of a metallic material. That is, in the first processing unit 13, as shown in FIG. It has a shape that protrudes upward from the plate W. In the second processing unit 14, as shown in FIG. A through hole P is formed at the portion ...

no. 2 example

[0087] Next, a second embodiment of the present invention will be described based on FIGS. 13 to 19 . Furthermore, the second embodiment is slightly different from the first embodiment in terms of processing units. Therefore, in the following description, parts different from the first embodiment will be mainly described; members and structures that are the same as or corresponding to the first embodiment will be given the same reference numerals, and repeated description will be omitted.

[0088] The press working device 11 of this embodiment has a first working unit 13 and a second working unit 14 . In the first processing unit 13 , a first punch 17 is fixedly mounted on the lower die 16 , and a first die 20 corresponding to the first punch 17 is fixedly mounted on the lower surface side of the upper die 19 . The first punch 17 is formed in a substantially cylindrical shape, and also has a diameter dimension D2 of, for example, 30 mm.

[0089] In addition, as shown in FIG....

no. 3 example

[0107] Next, a third embodiment of the present invention will be described based on FIG. 20 . Furthermore, the third embodiment is slightly different from the first embodiment in terms of processing units. Therefore, the following description will mainly describe parts that are different from the first embodiment; members and structures that are the same as or corresponding to the first embodiment will be given the same reference numerals, and repeated description will be omitted.

[0108] The press working device 11 of the present embodiment has a first working unit 13 and a second working unit 14, and forms a steel plate having a given shape (in this embodiment, In this example, the through-hole P having a substantially circular cross-section), the plate W is formed of a metal material having a predetermined thickness (for example: 3mm). In this first processing unit 13 , a first punch 17 is fixedly mounted on the lower die 16 , and a first die 20 corresponding to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com