Patents

Literature

37results about How to "Simple and reliable control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

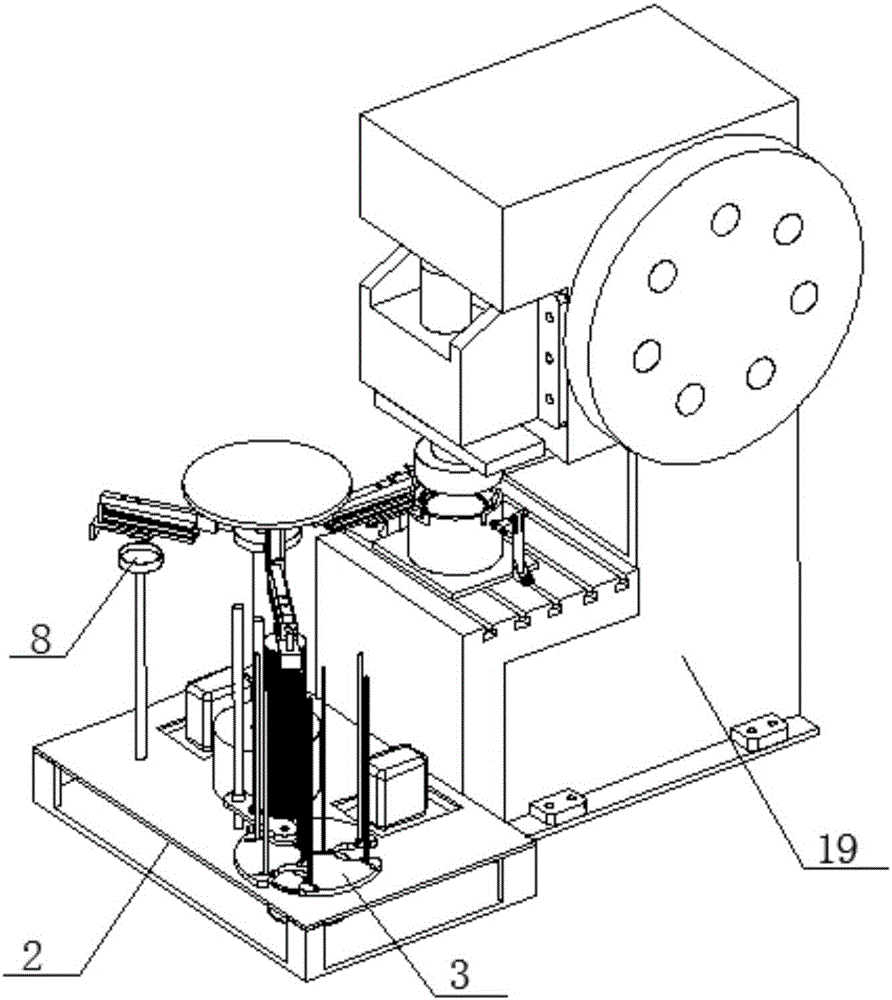

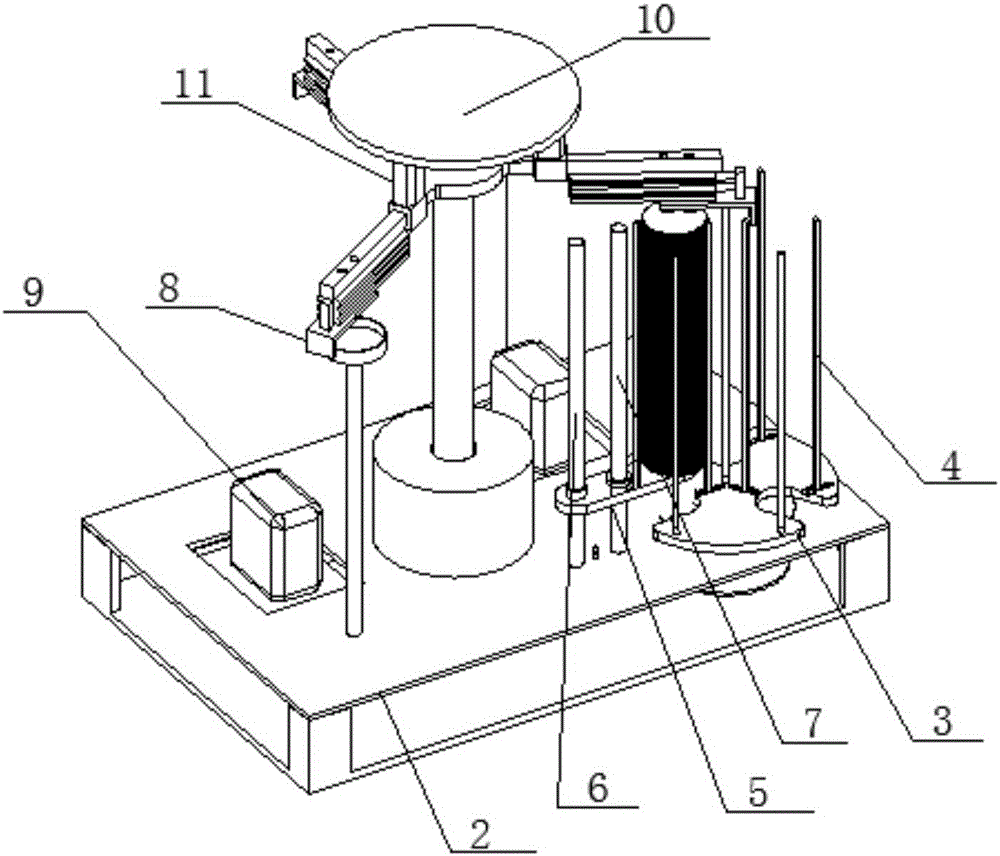

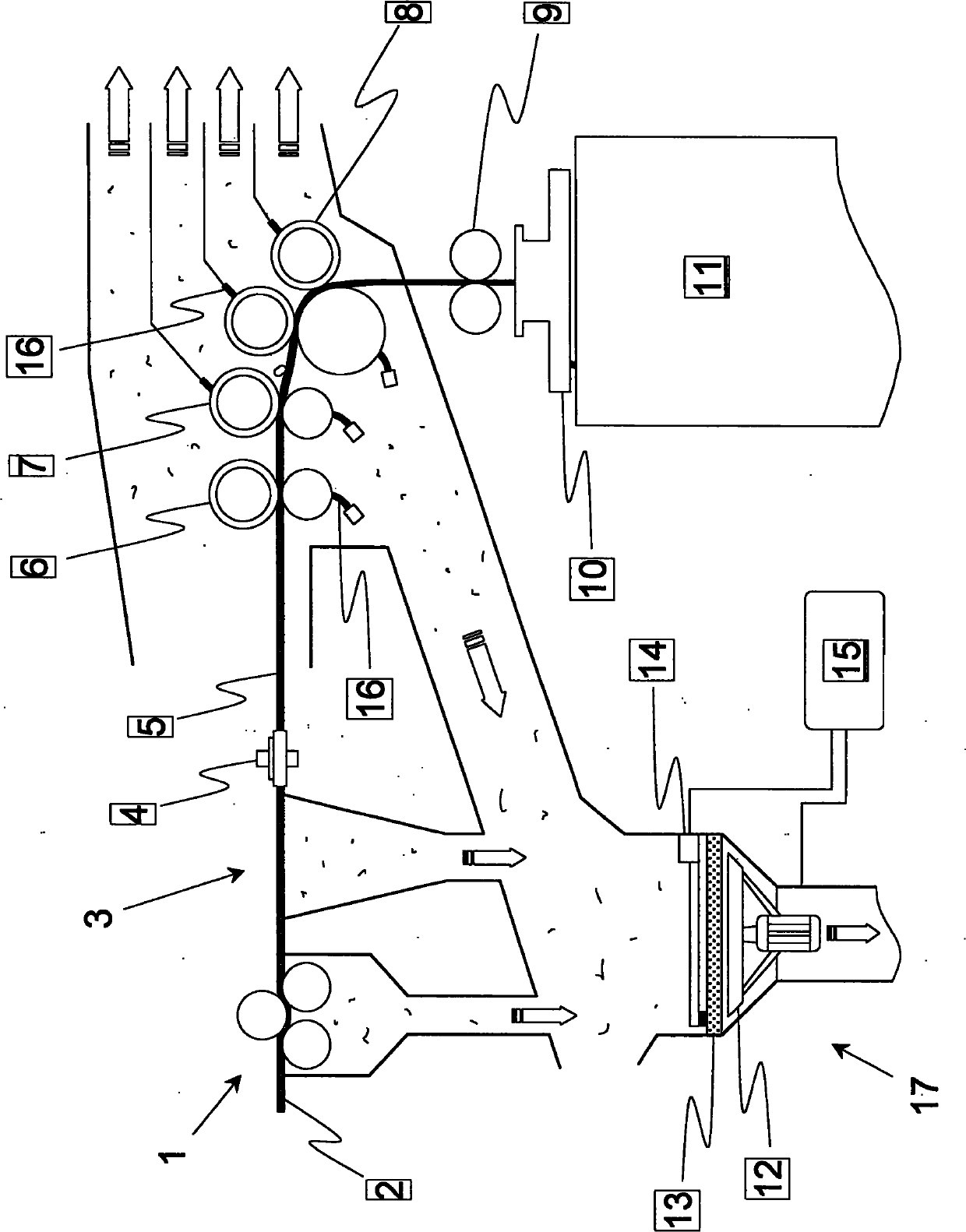

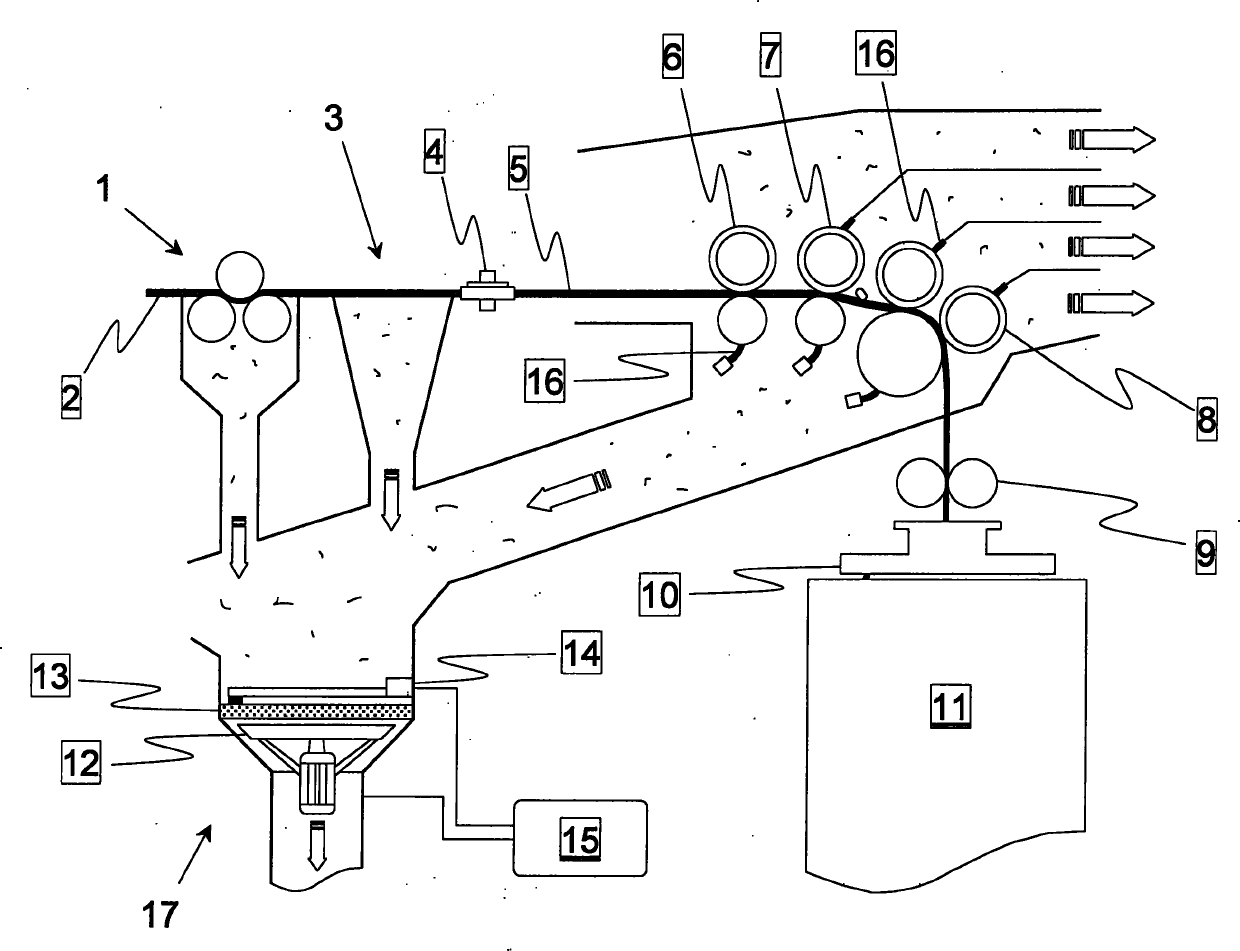

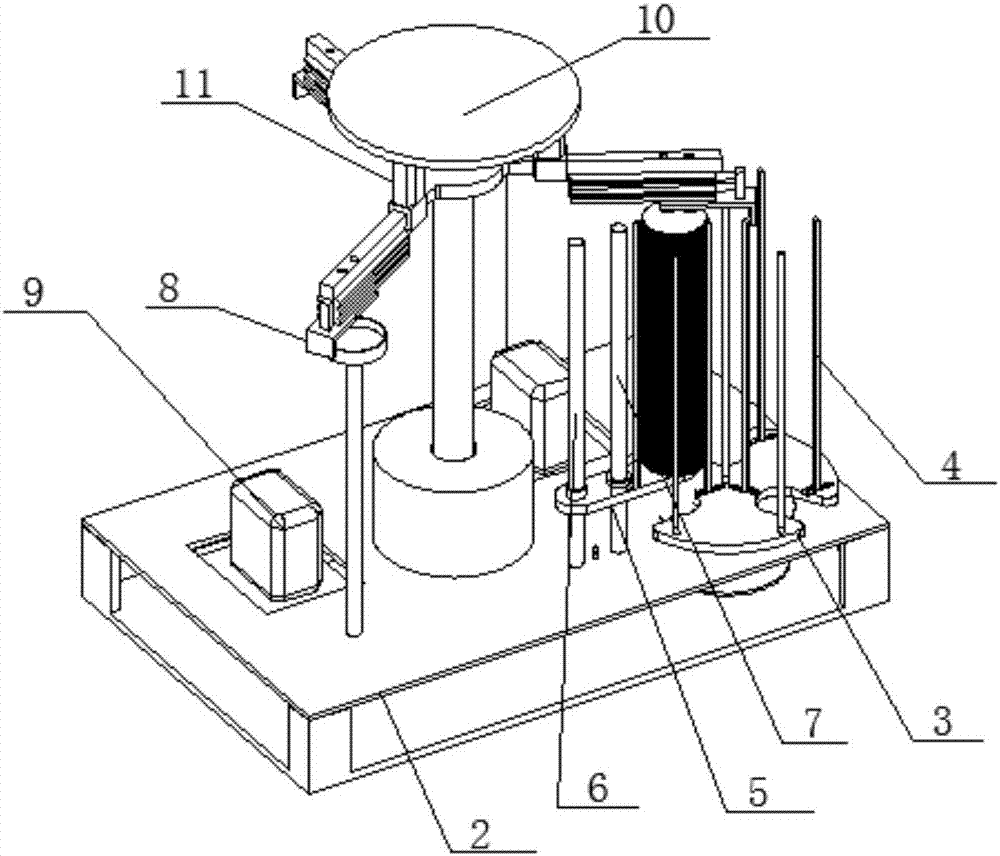

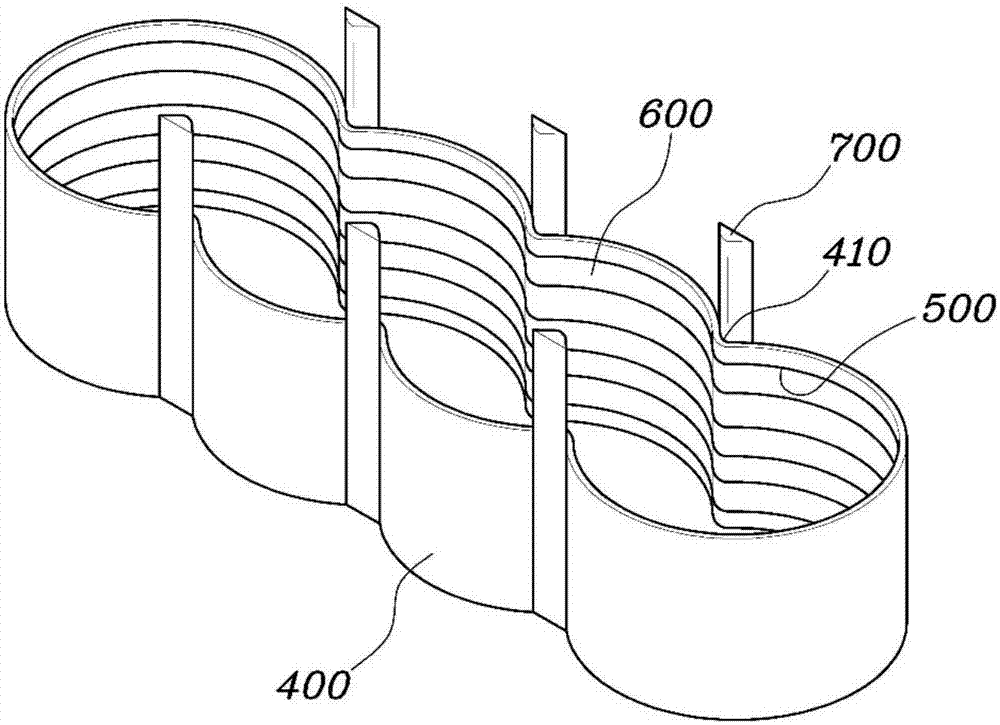

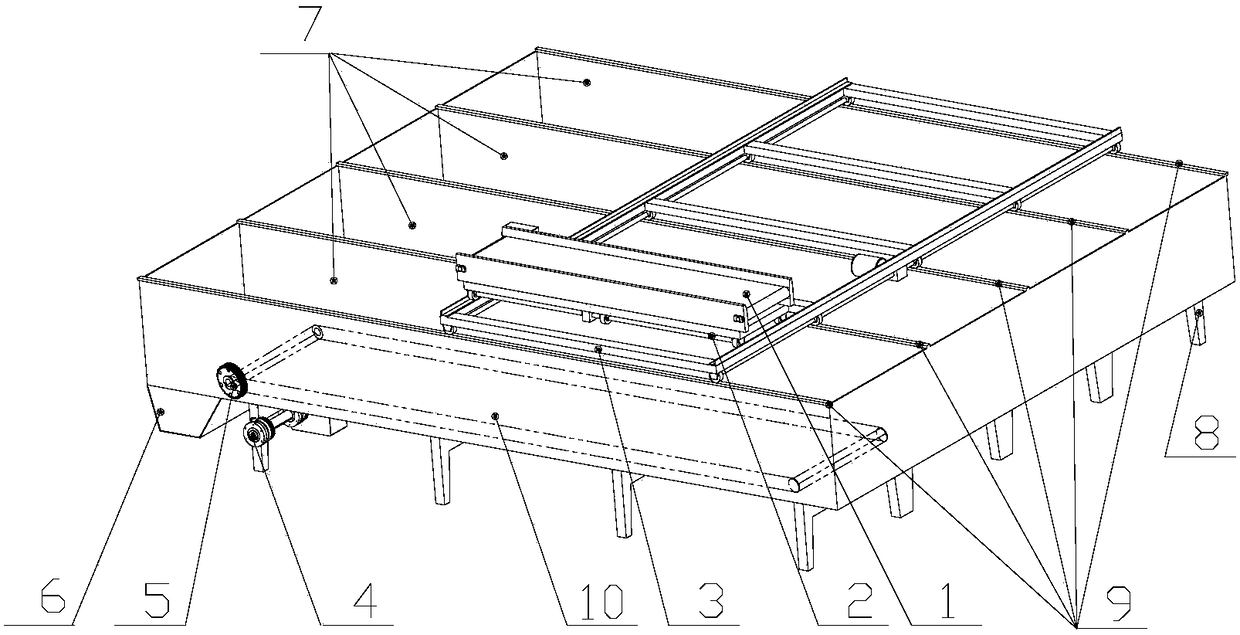

Rotary, continuous and automatic feeding mechanism of punching machine

ActiveCN105710246ASimple and reliable controlSimplify organizationMetal-working feeding devicesMetal working apparatusPunchingEngineering

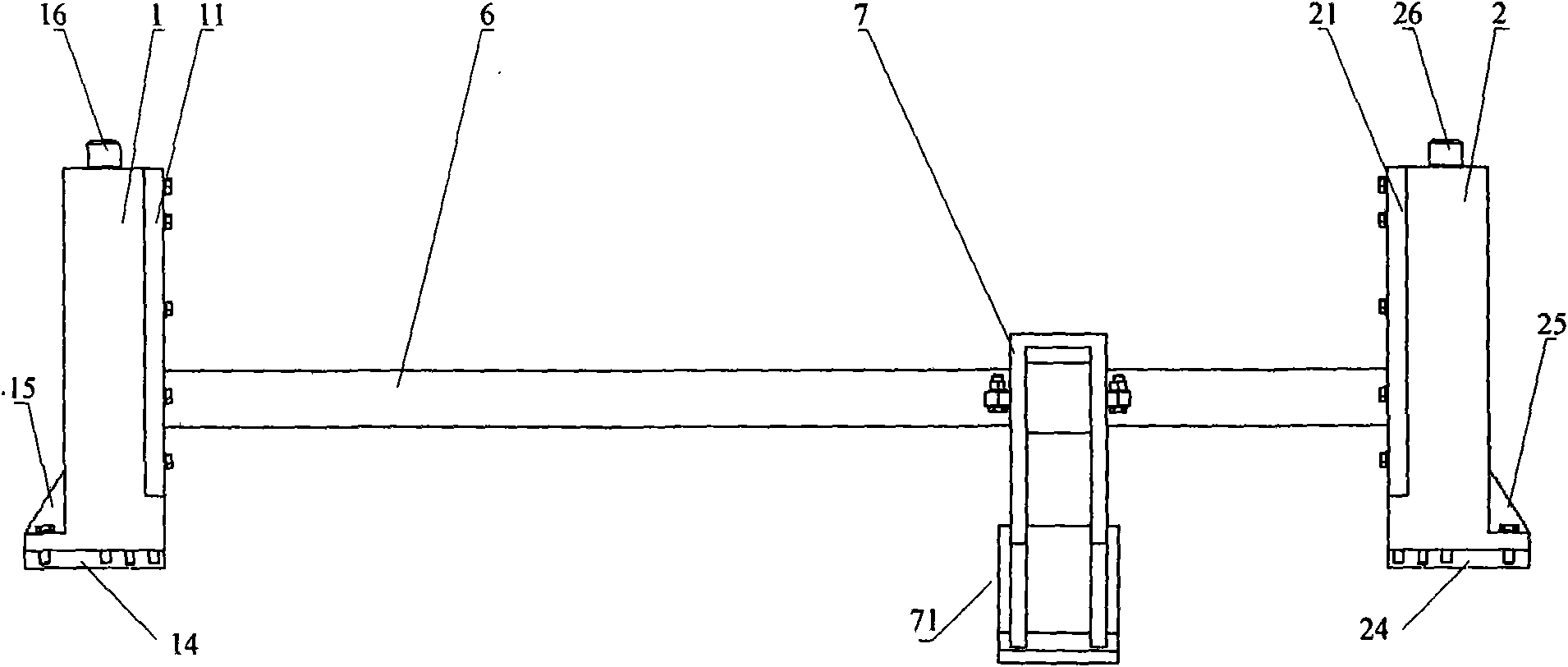

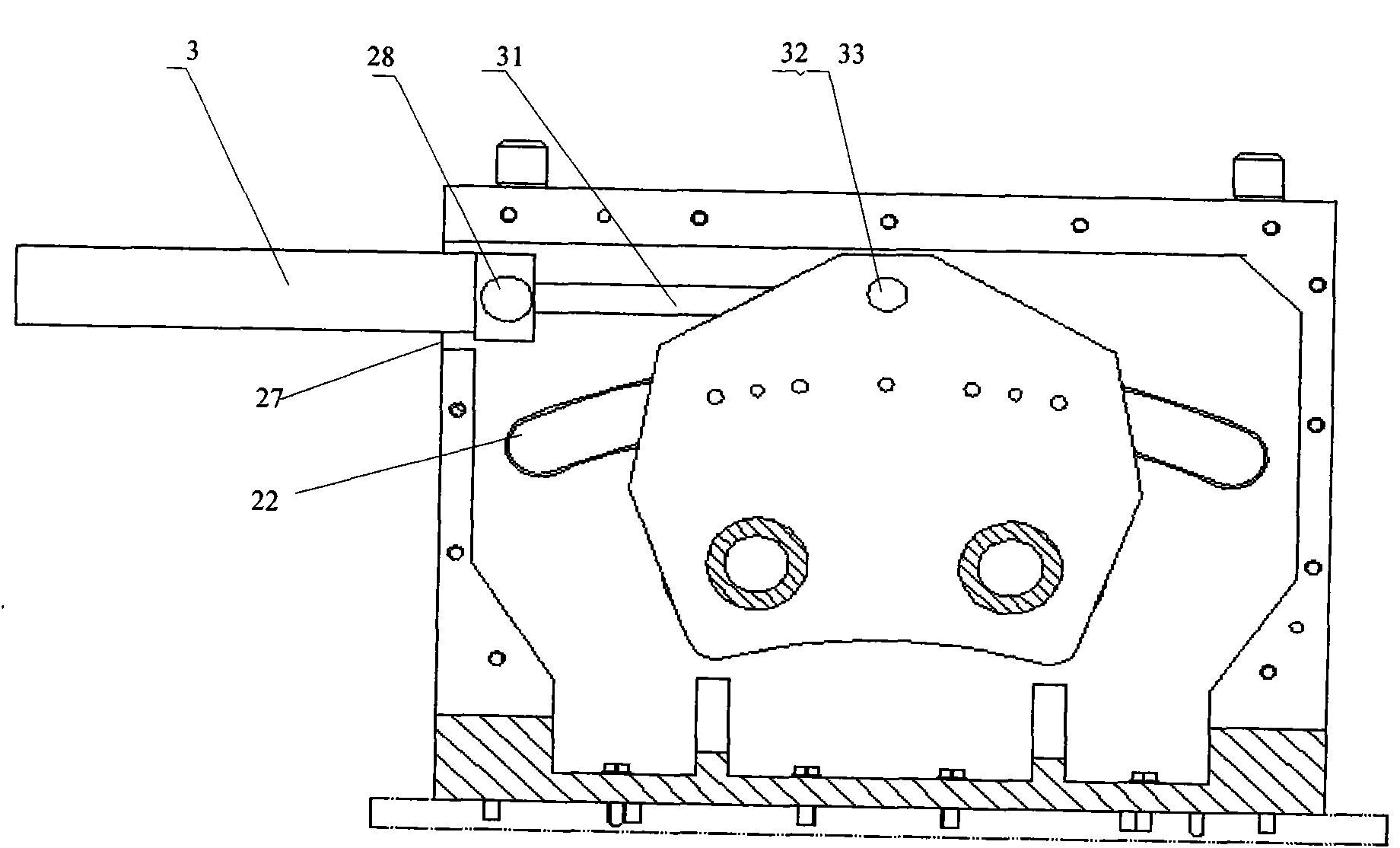

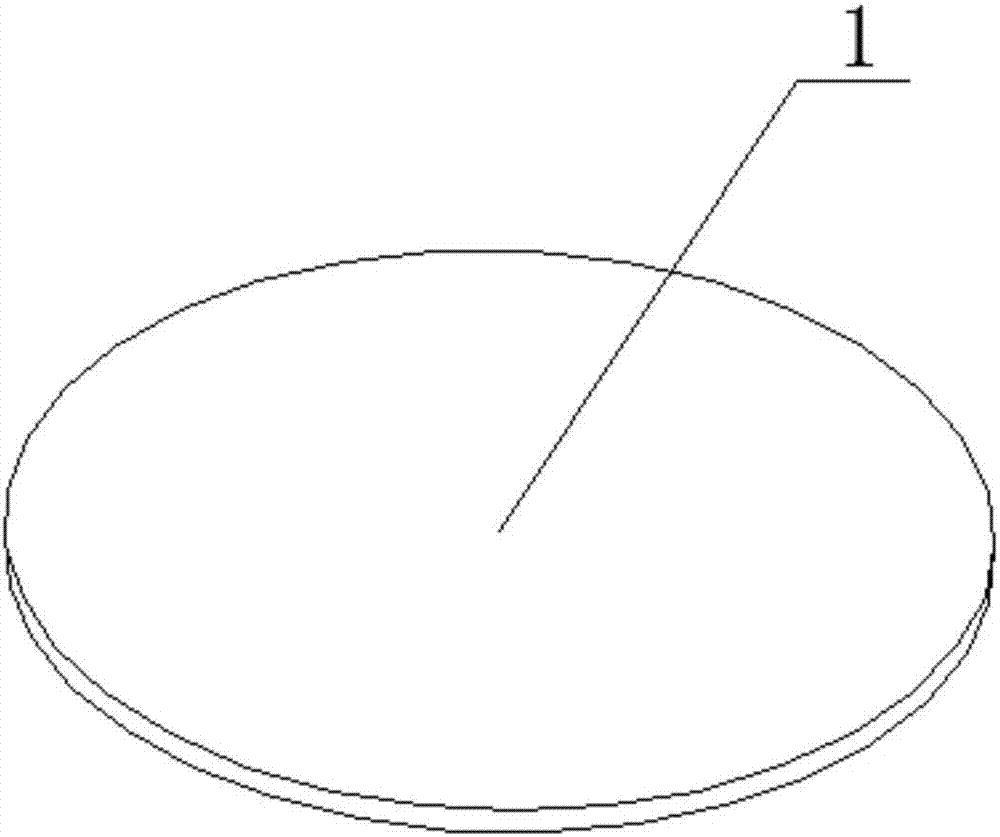

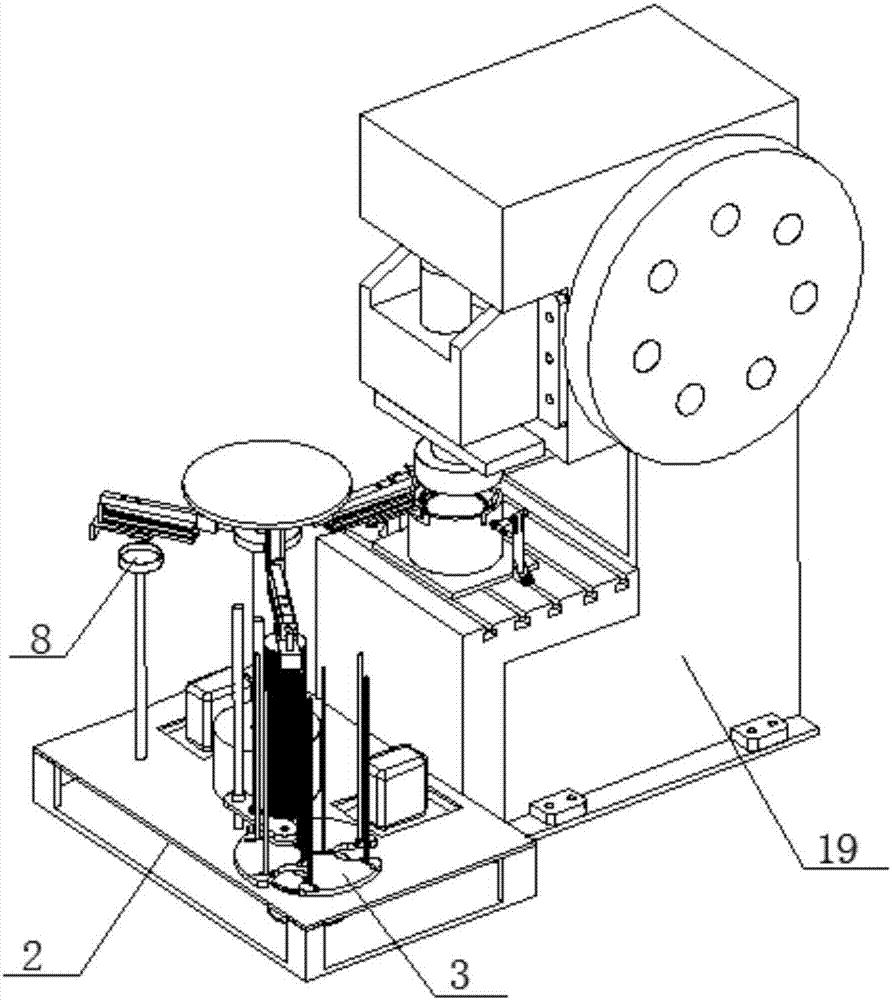

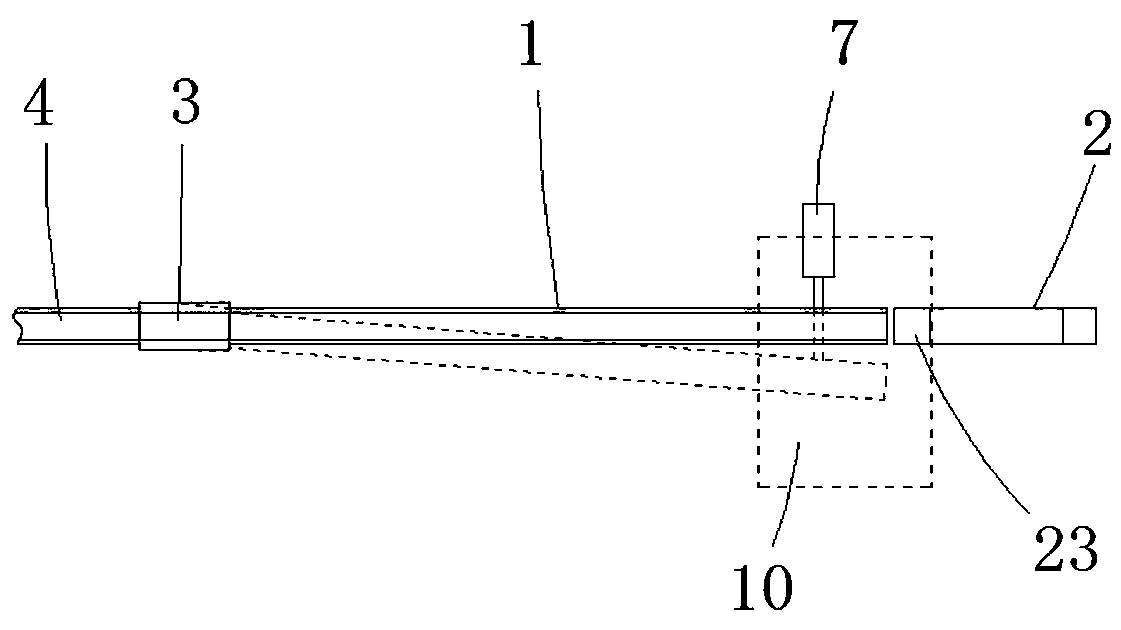

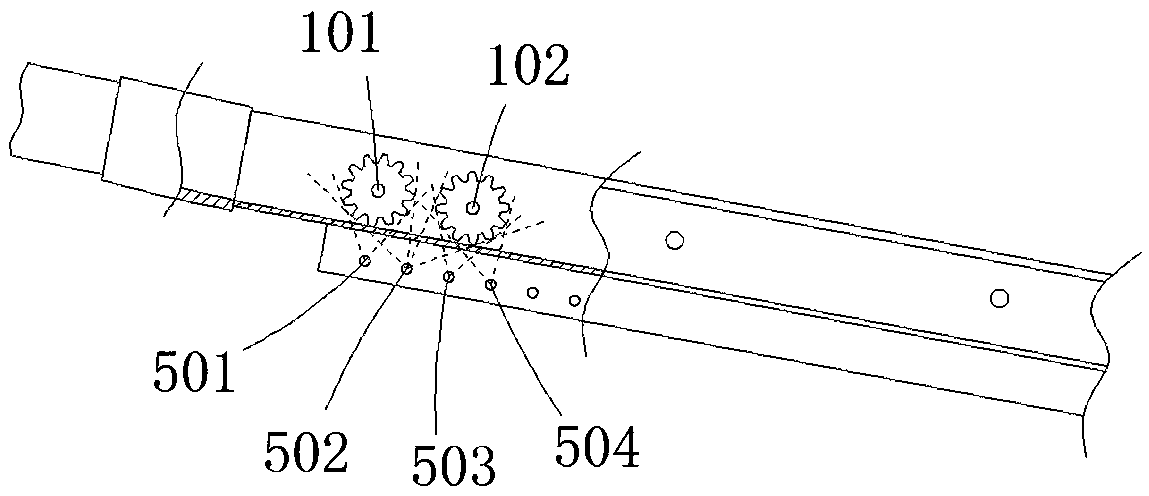

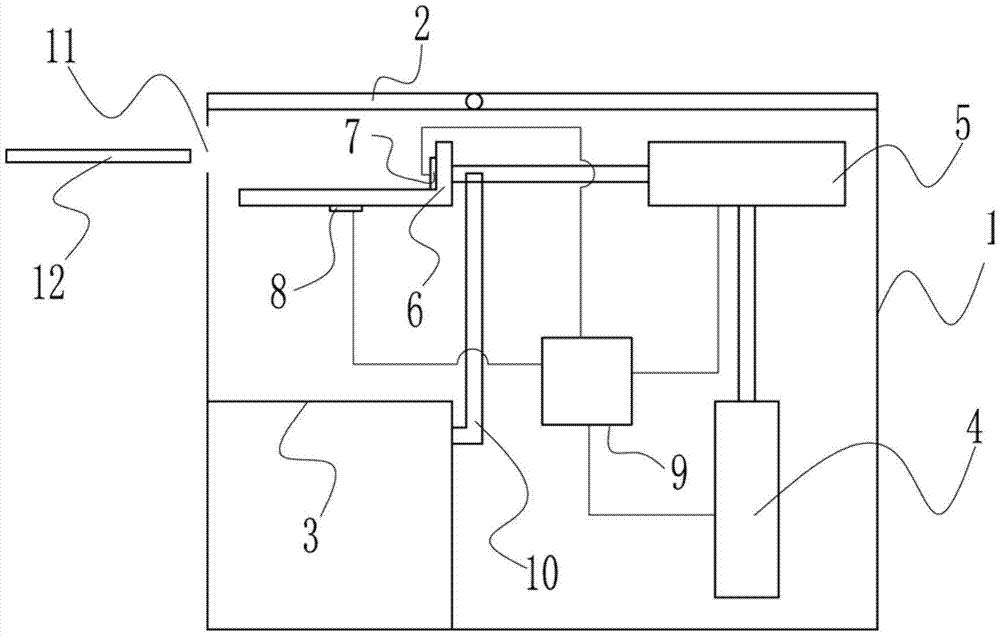

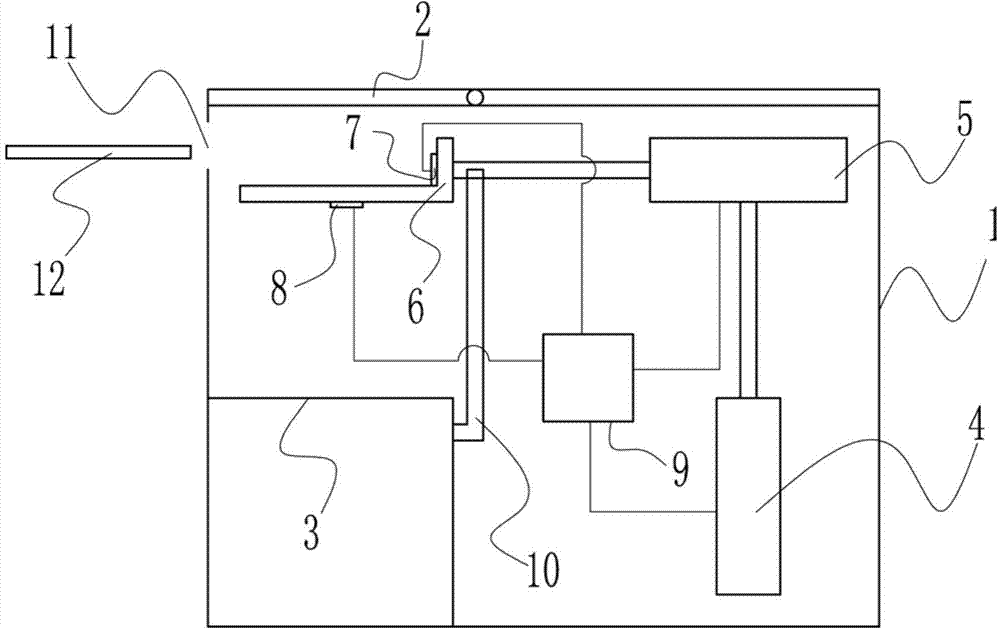

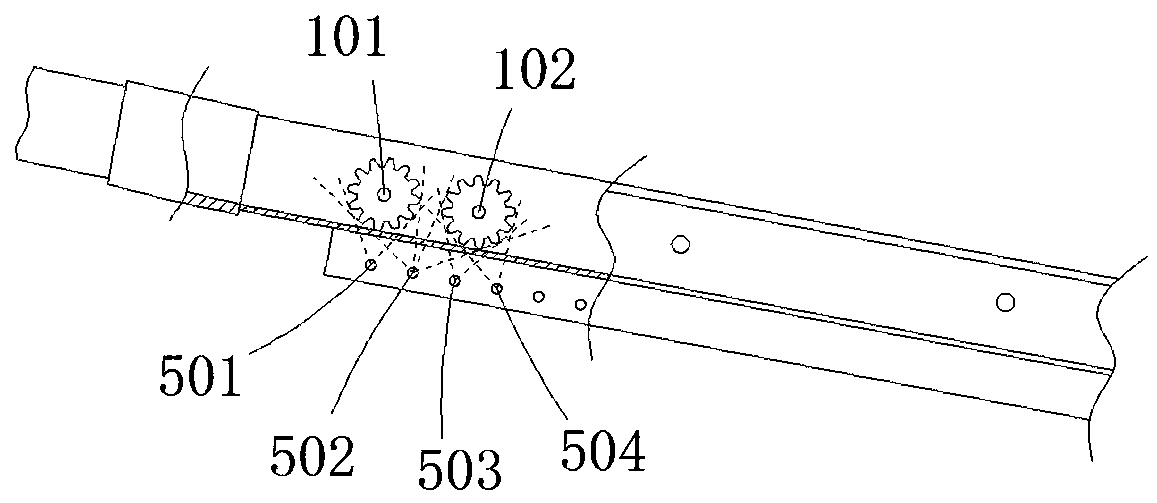

The invention discloses a rotary, continuous and automatic feeding mechanism of a punching machine. The feeding mechanism comprises a frame, a loading mechanism, a taking mechanism, a punching machine and a main controller, and is characterized by further comprising a detecting disc and a blank detection positioning mechanism; the loading mechanism, the taking mechanism and the detecting disc are all fixed on the frame; the loading mechanism, the detecting disc and the punching machine are fixed around the taking mechanism at intervals in sequence in the clockwise direction; and the distances of the loading mechanism, the detecting disc and the punching machine from the taking mechanism are equal. The mechanism performs two times of positioning for blanks to be machined through a positioning block above the loading mechanism and a mold cover out of a mold so as to guarantee precise placement of the blanks in a machining position, and prevents the mold damage caused by once sucking of multiple blanks by the taking mechanism through the detecting number of the detecting disc. In addition, when the blanks are put in the mold, a photoelectric detector on the punching machine can detect if the blanks are placed precisely, so that such problems as mold damage and punching safety are further guaranteed.

Owner:ZHEJIANG UNIV OF TECH

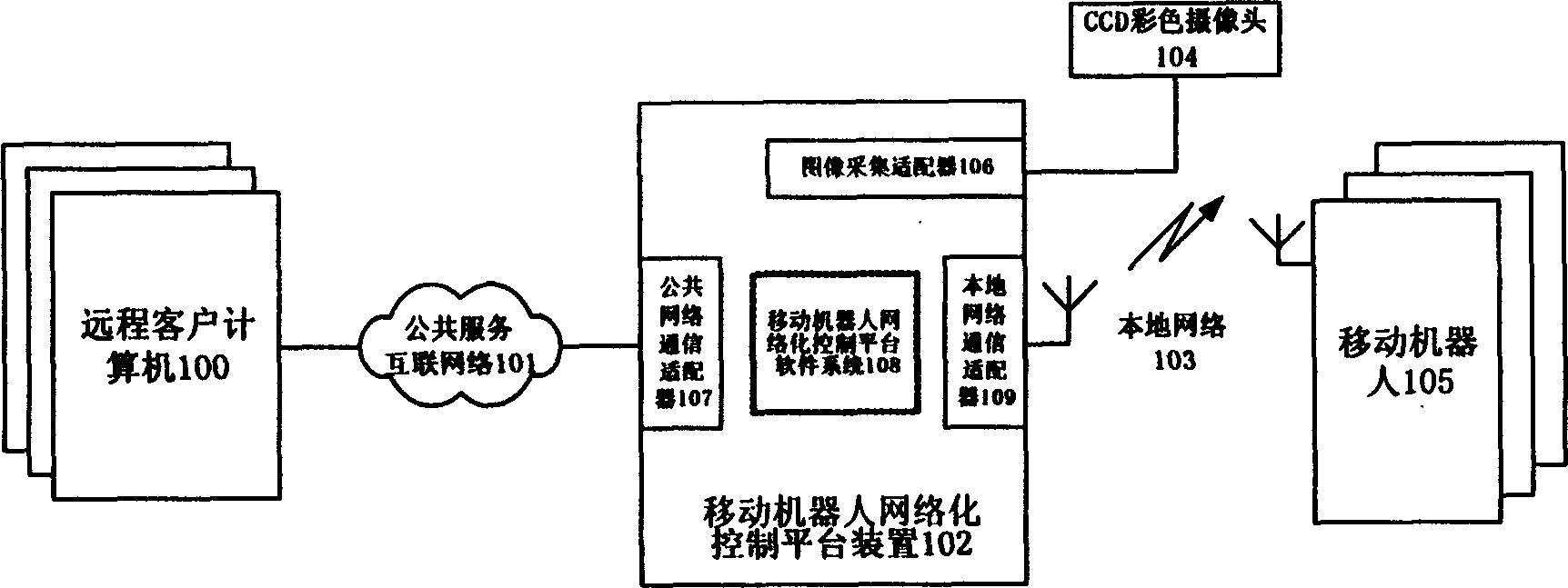

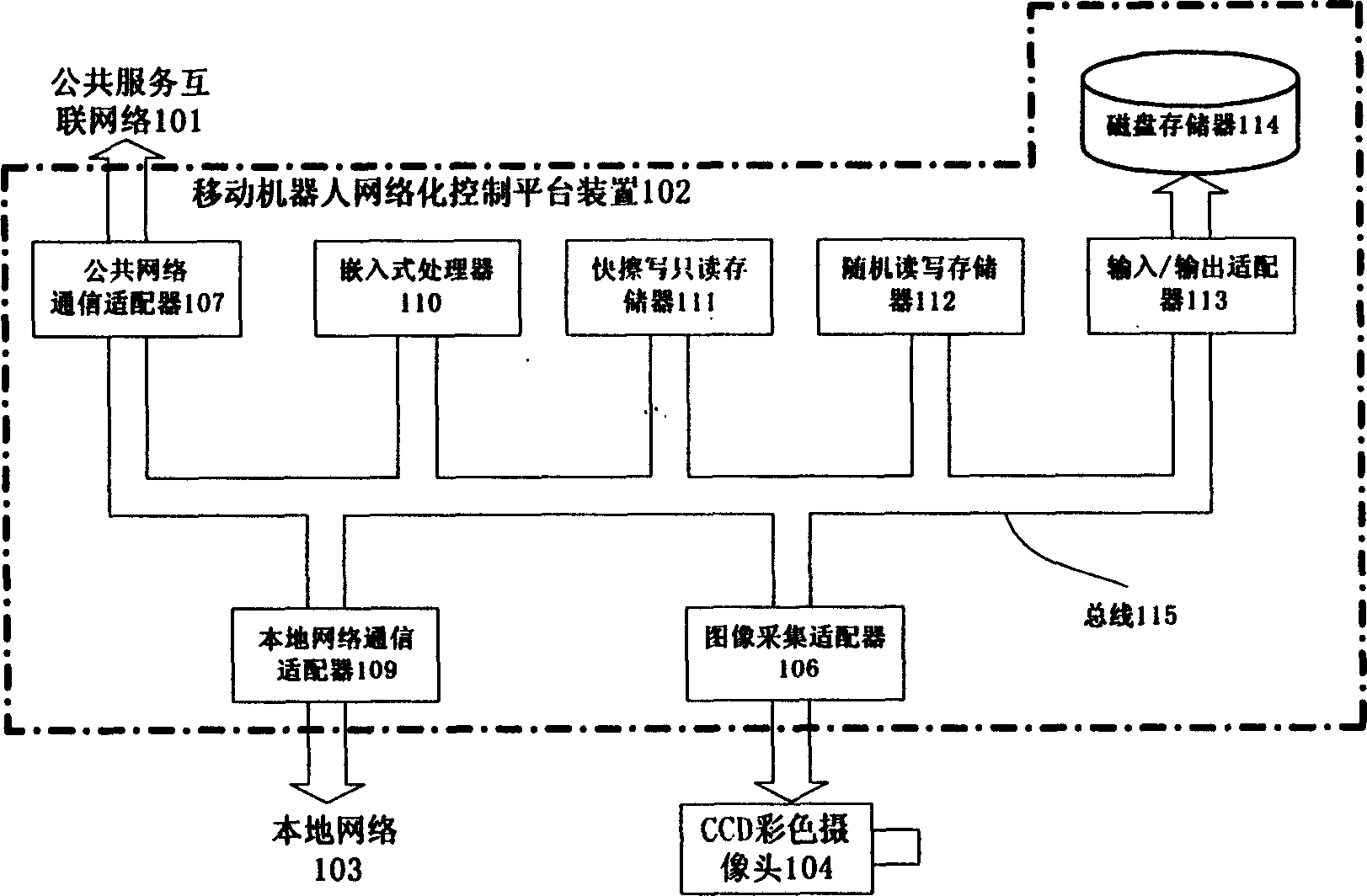

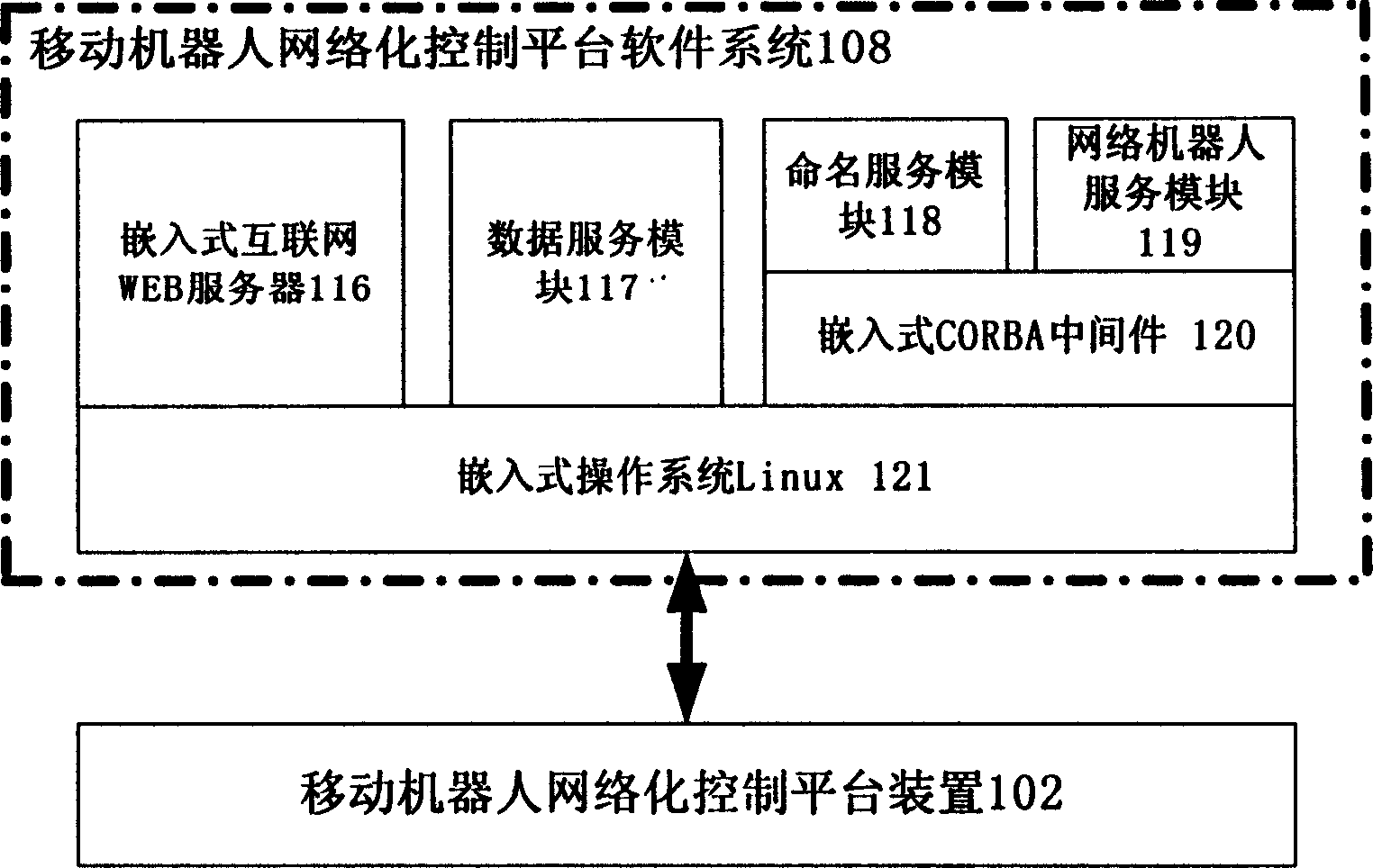

Mobile robot network control platform device

InactiveCN1556609AEnsure safetyGuaranteed automatic upgrade functionNetworks interconnectionOperational systemThe Internet

The invention relates to a mobile robot network control platform device which uses embedded server structure, applies to that the operator realizes the behavior control and information transmission of mobile robot on internet or local area network, makes the robot has plug and play automatic registering service and online control performance. The mobile robot network control platform device is an embedded device, the public network communication adapter, local network communication adapter, image gathering adapter, embedded processor, quick erasable read-only memory, random read and write memory, input and output adapter in the device are connected with the bus; the output end of the public network communication adapter is connected to the outer public service internet; the output end of the local network is connected to the outer local network; the output end of the image gathering adapter is connected to the CCD color camera head; the output end of the input and output adapter is connected with the magnetic memory; on which there arranges a embedded operation system software such as Linux.

Owner:SOUTHEAST UNIV

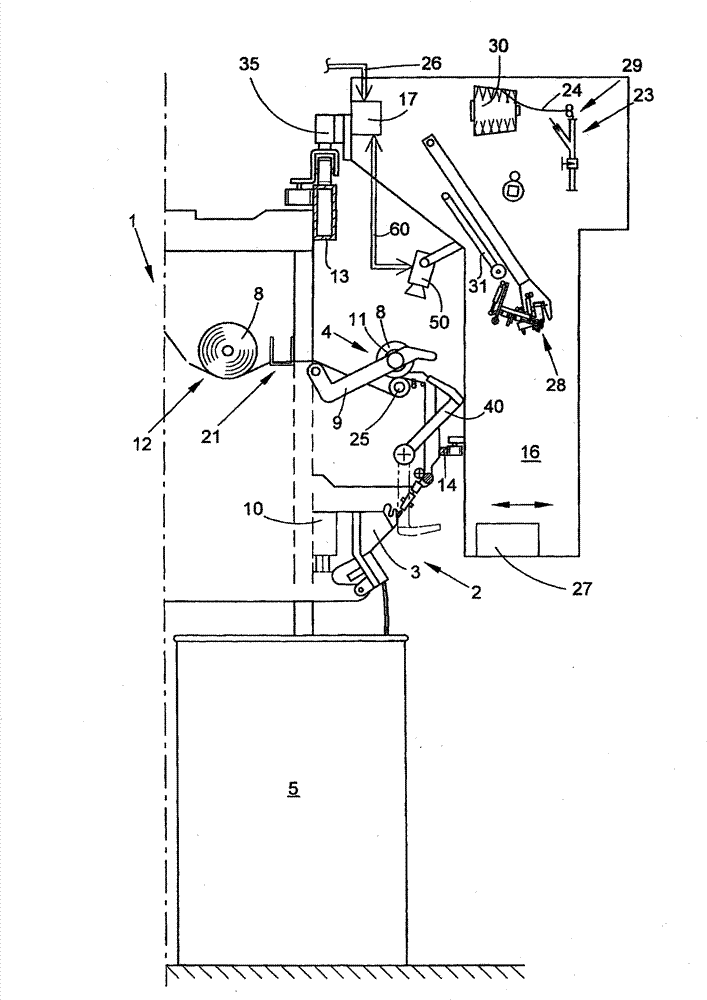

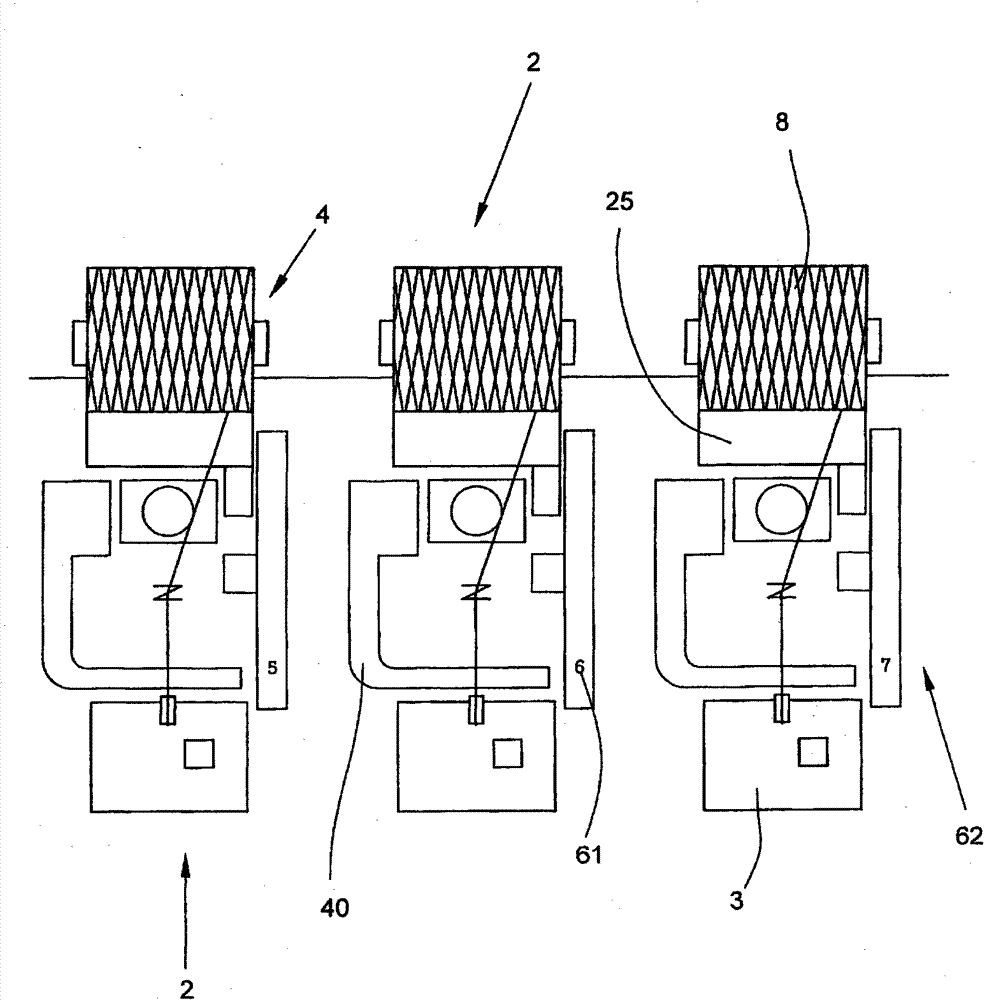

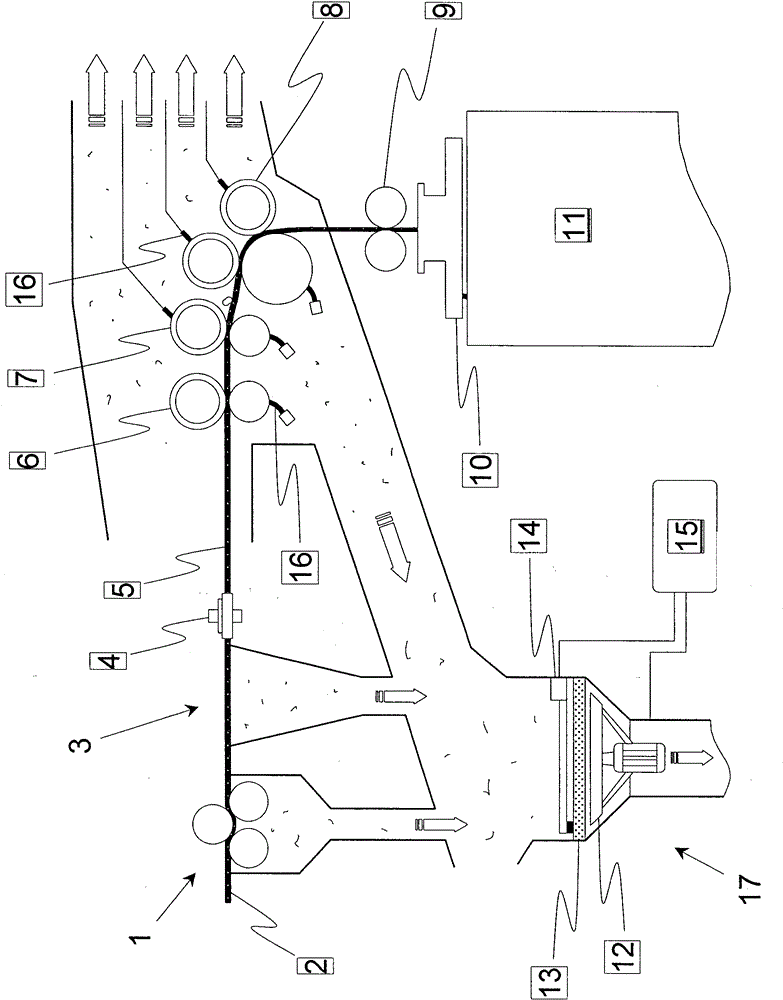

Spinning machine with suction apparatus and method for controlling suction apparatus of spinning machine

ActiveCN101994179AReduce speedGuaranteed volume flowFilament handlingDrafting machinesEngineeringRubbing

The present invention relates to a method for controlling a suction apparatus of a spinning machine, particularly a spinning or spinning preparing machine, e.g. a rubbing mill, a napping machine or a combing machine, wherein the suction apparatus (17) includes a ventilator (12) for generating air flow, a filter element (13) for filtering the air flow and a cleaning device for cleaning the filter element (13). According to the invention, rotational speed of the ventilator and an operating status of the cleaning device are coordinated by a controller (15). Furthermore, the invention describes a corresponding spinning machine having the suction apparatus (17), wherein the suction apparatus includes a ventilator (12) for generating air flow, a filter element (13) for filtering the air flow and a cleaning device for cleaning the filter element (13). The spinning machine is characterized in that the ventilator (12) and the cleaning device (14) is connected with the controller (15) of the spinning machine, such that the rotational speed of the ventilator and the operating status of the cleaning device are coordinated.

Owner:RIETER INGOLSTADT GMBH

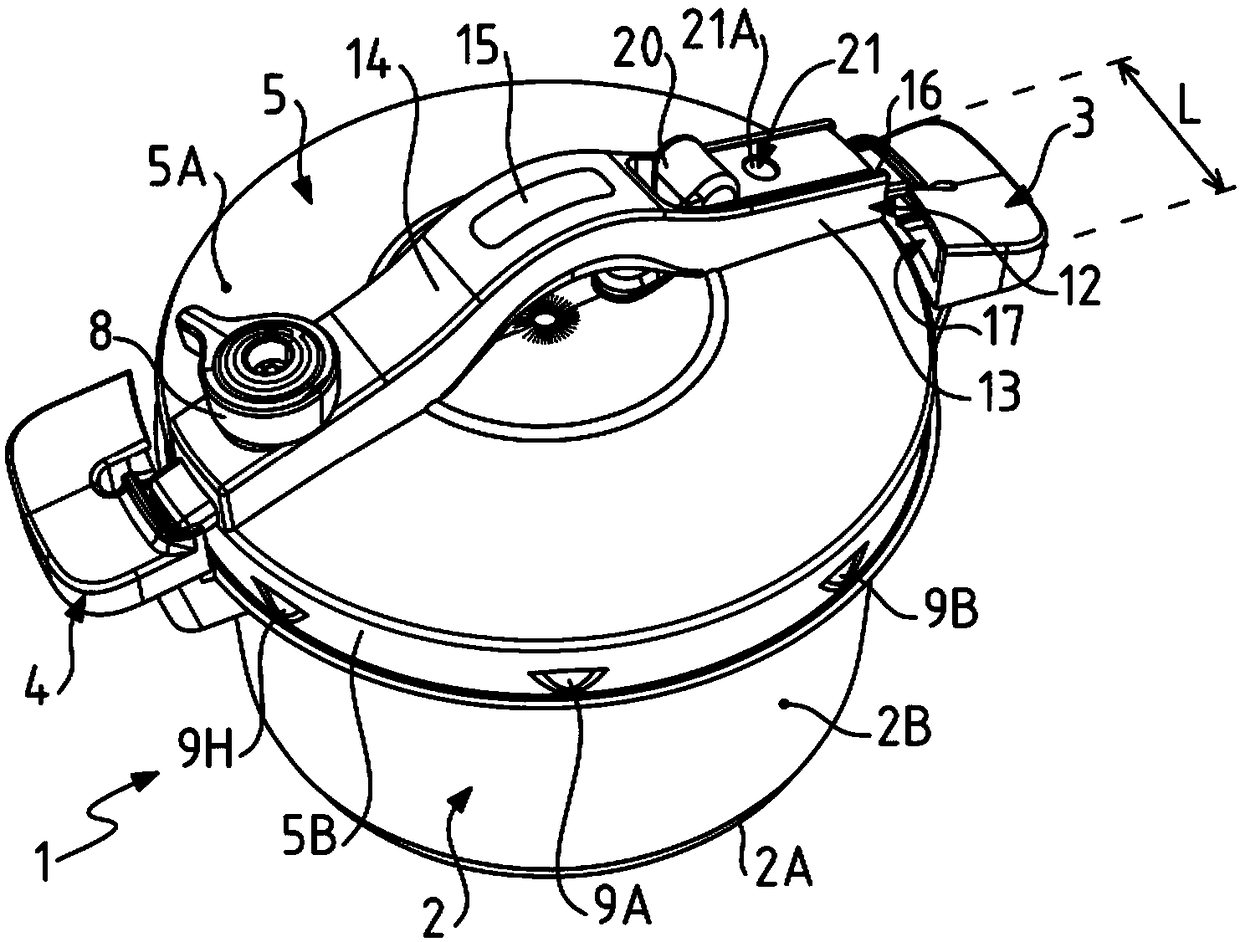

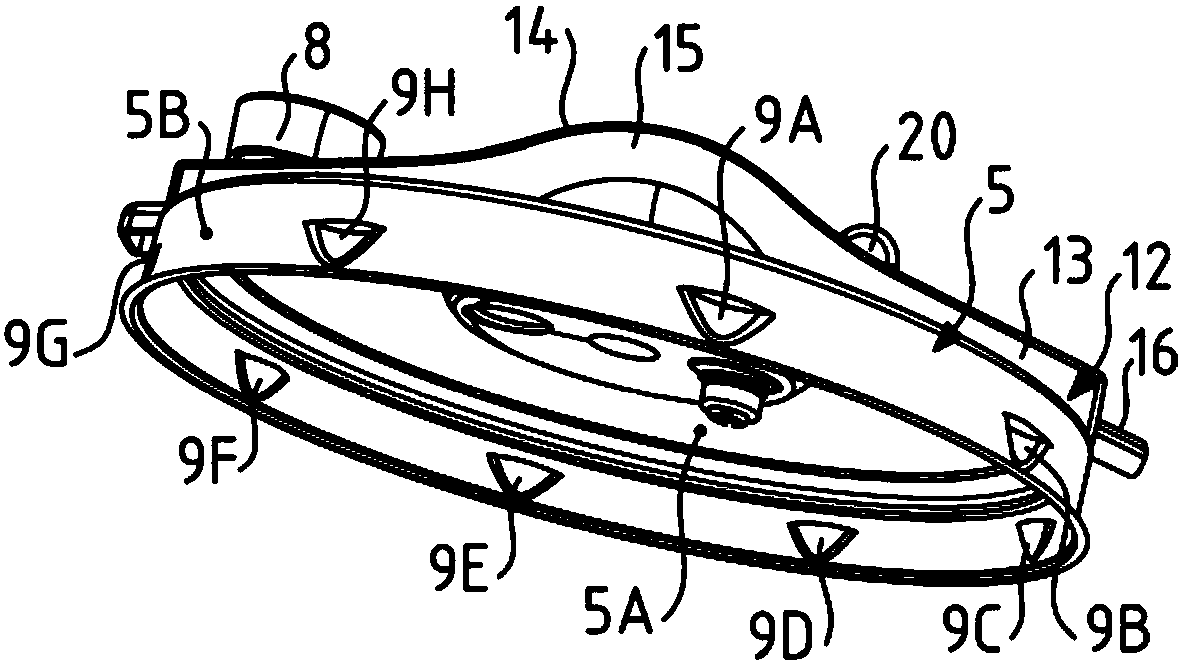

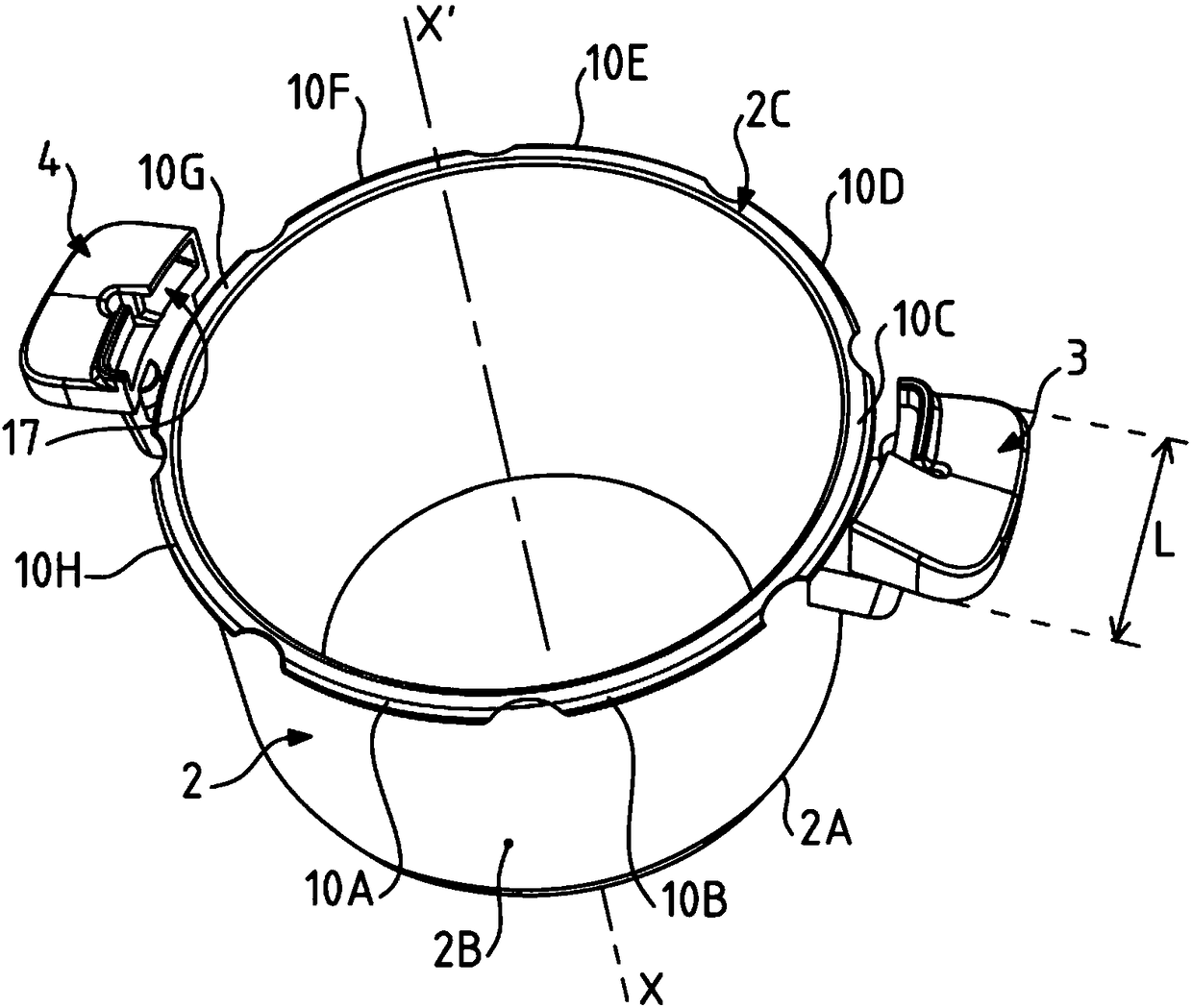

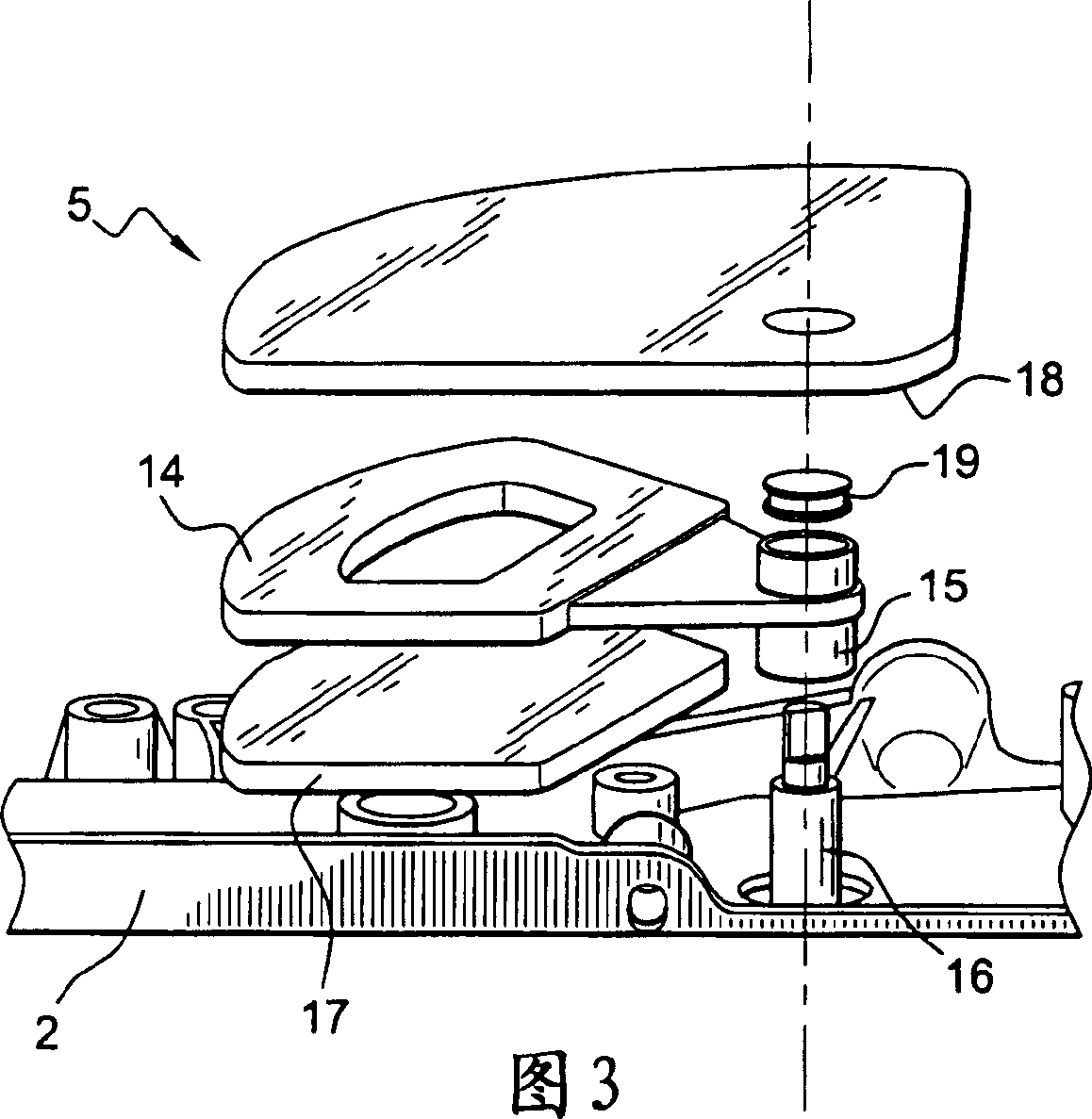

Buckle type pressure cooker and removable lock

ActiveCN108294613AReduce weightEasy to manufactureCooking-vessel lids/coversRefuse receptaclesEngineeringPressure cooking

A food pressure cooking utensil (1) comprises a bowl (2), a cover (5), and a buckle type locking system. The cooking utensil also comprises a safety element (12) including a main body (13) and a lock(16). The main body (13) is fixedly attached to the cover (5). The lock (16) is radially removable between an extension position and a retracted position relative to the main body (13). In the extension position, the lock (16) radially protrudes from the cover (5) and the main body (13). In the retracted position, the lock (16) retracts to the internal of the cover (5), so that when a locking system is in locking configuration, in one of the extension position and the retracted position, the lock (16) is connected with a complementary locking structure (17) supported by the bowl (2), and in the other one of the extension position and the retracted position, the lock (16) separates from the complementary locking structure (17).

Owner:SEB SA

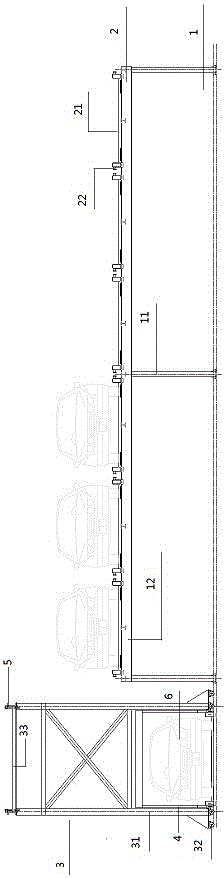

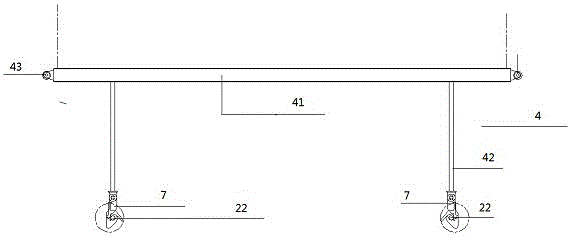

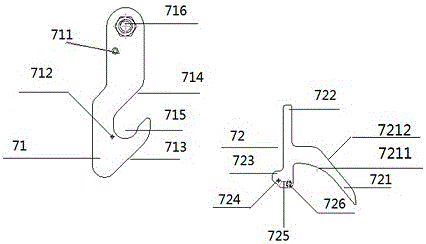

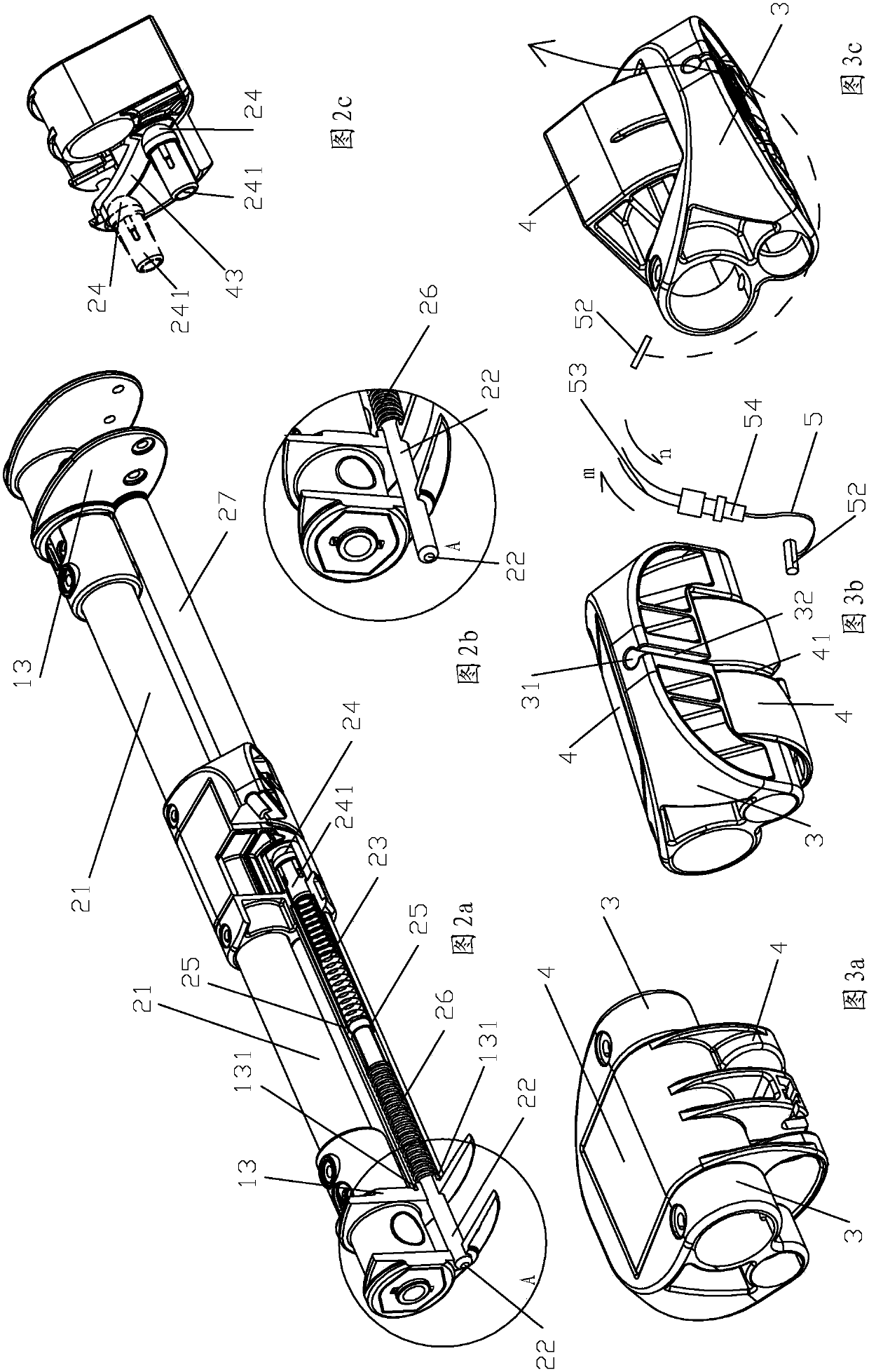

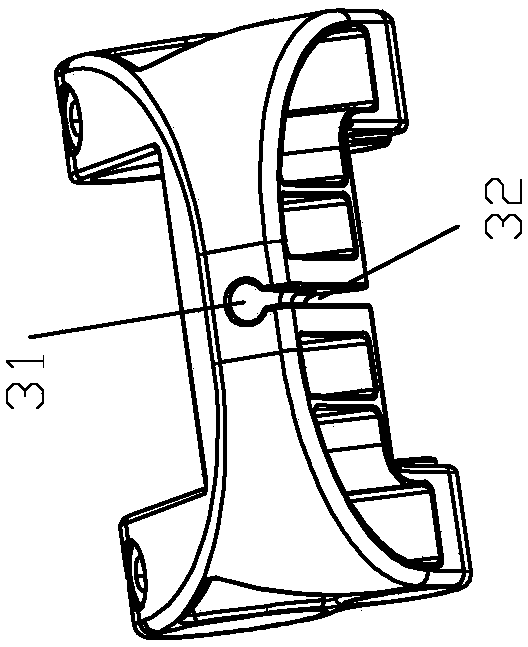

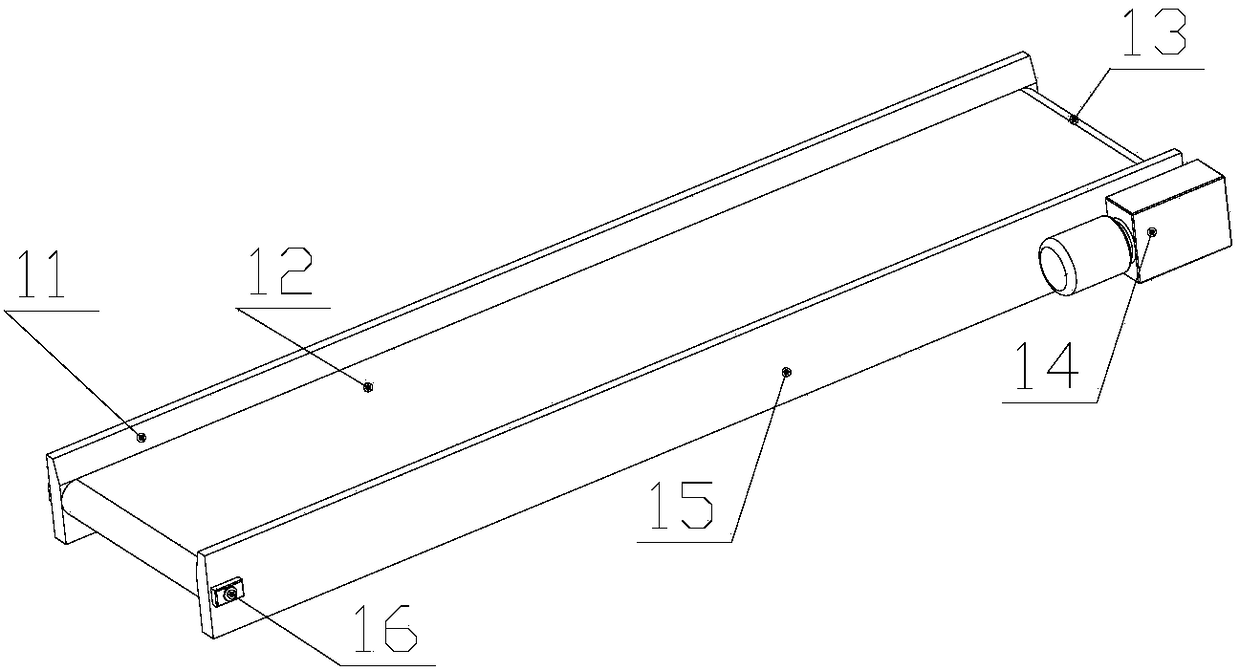

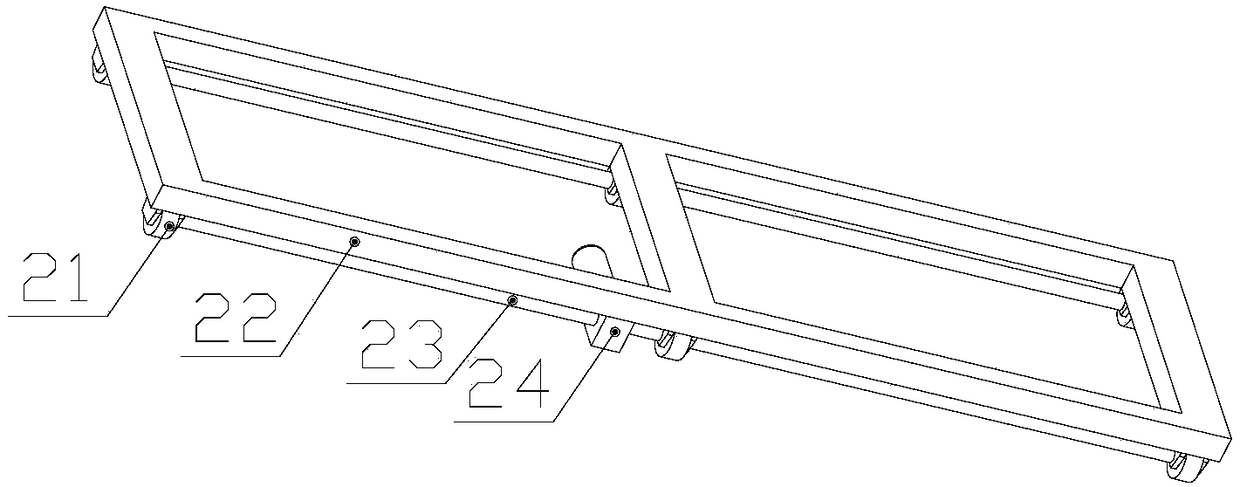

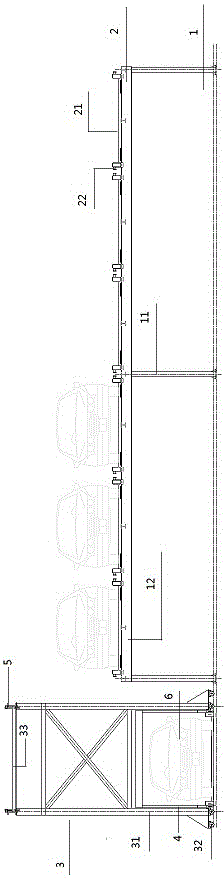

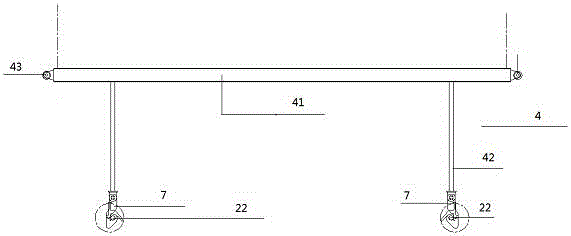

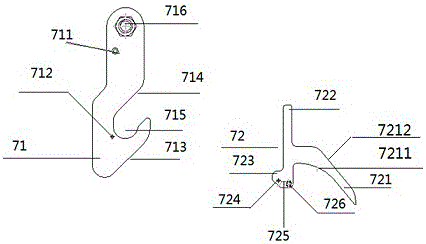

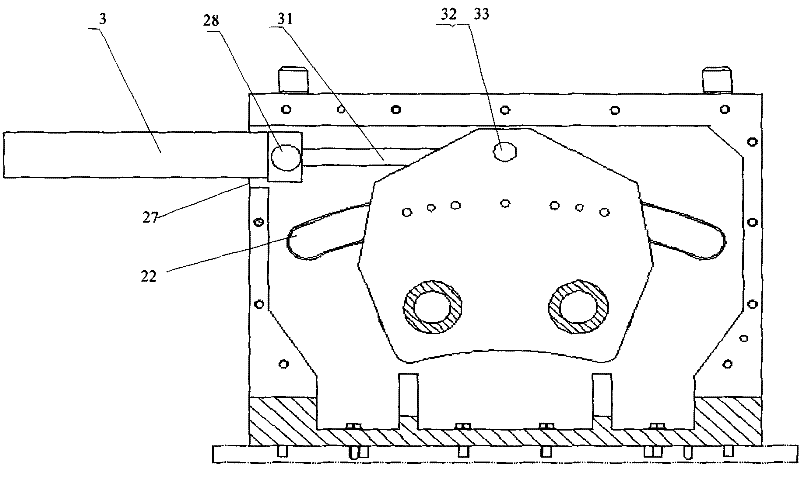

Stereoscopic parking equipment capable of achieving vehicle lifting through automatic grabbing device

Owner:深圳六点实业有限公司

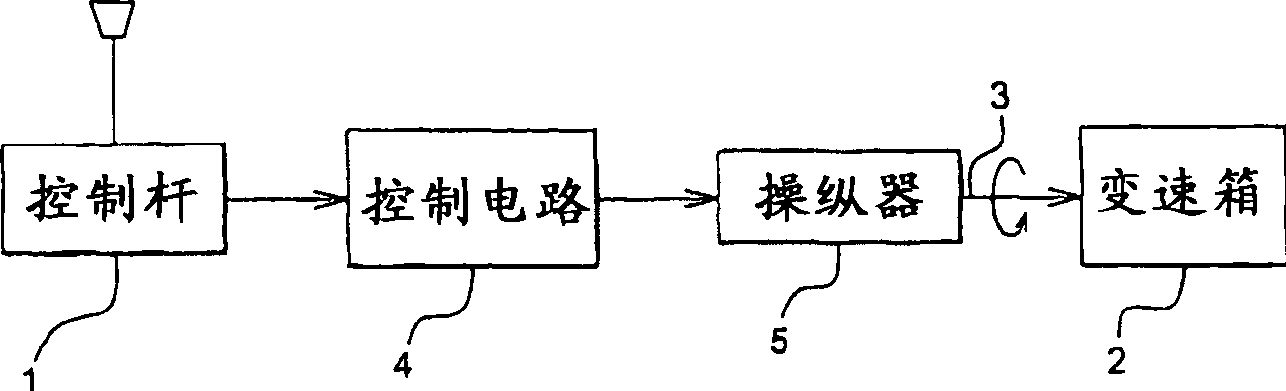

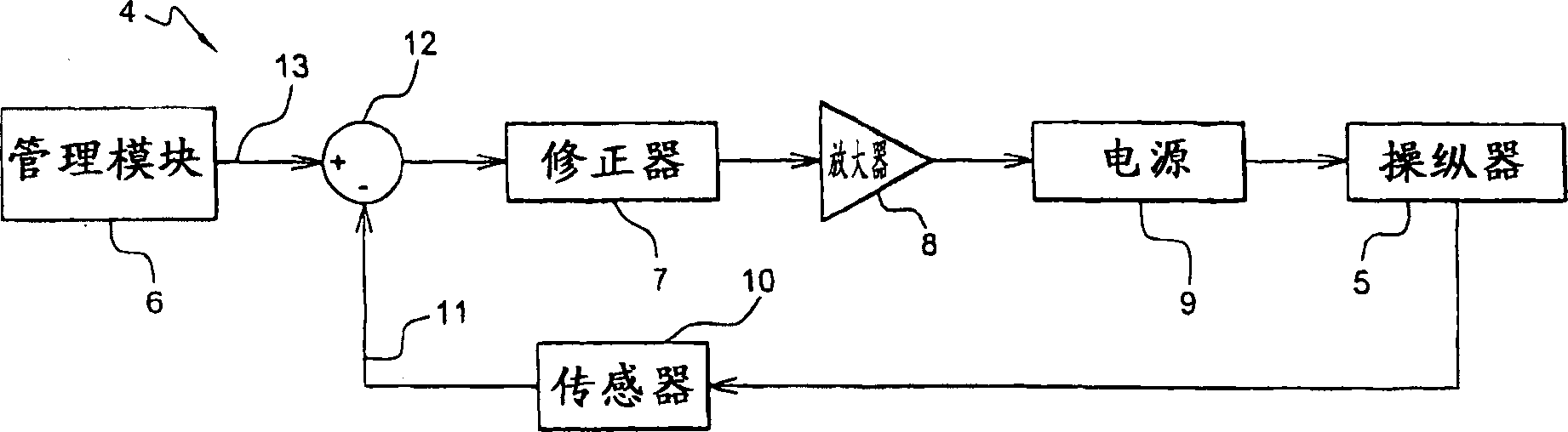

Control device of a transmission, especially for vehicles

InactiveCN1664418AReduce frictionReduce riskWindingsMagnetic circuit rotating partsMobile vehicleCylinder head

The device has a flat electric actuator (5) rotatably driving a selection axle (3) and having a flat coil (14) rotatably mounted around a fixed axis (16) between two flat permanent magnets (17, 18) carried by a cylinder head. A fitment (15) connects the coil to the selection axle. A power supply unit supplies electric current in any direction in the coil for turning the coil in any direction around the fixed axis.

Owner:TELEFLEX AUTOMOTIVE FRANCE

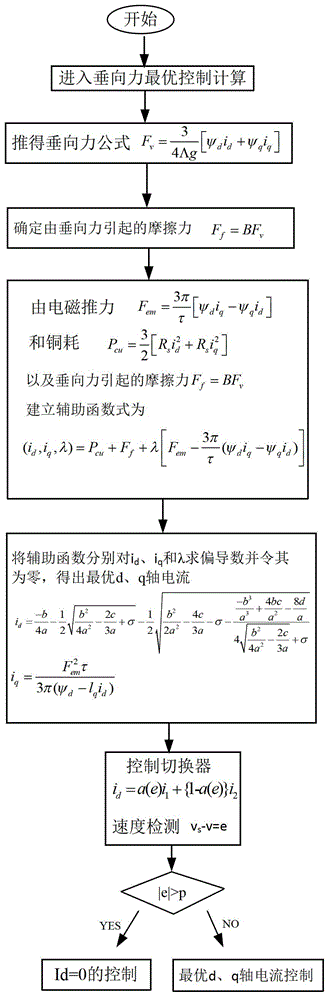

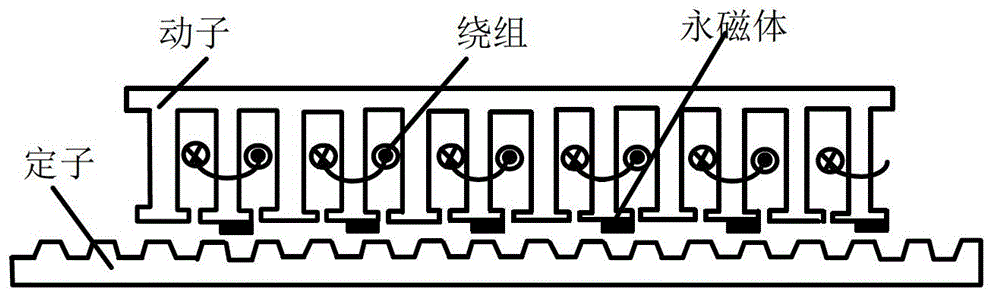

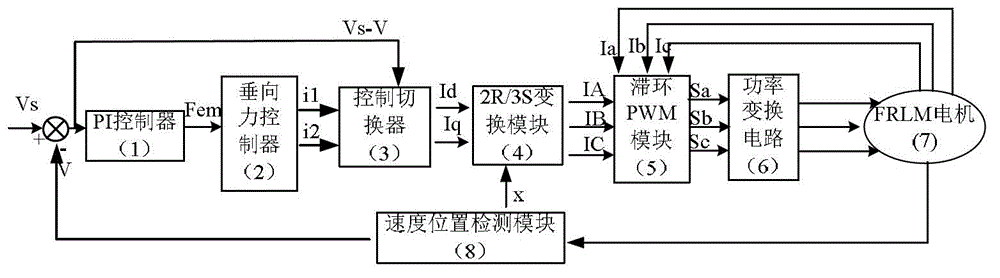

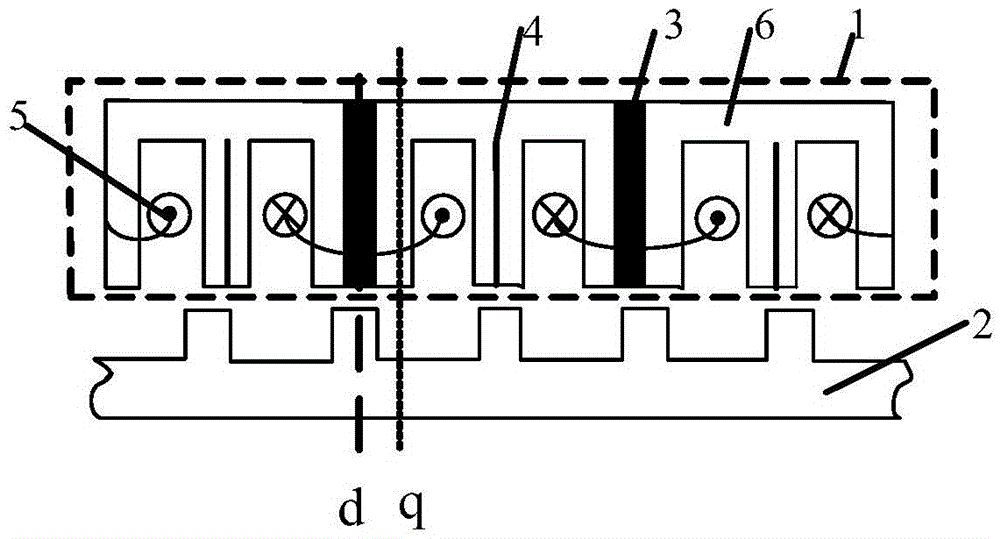

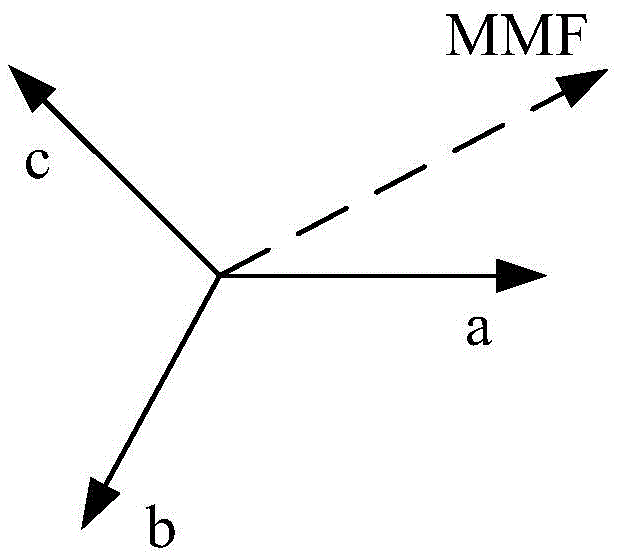

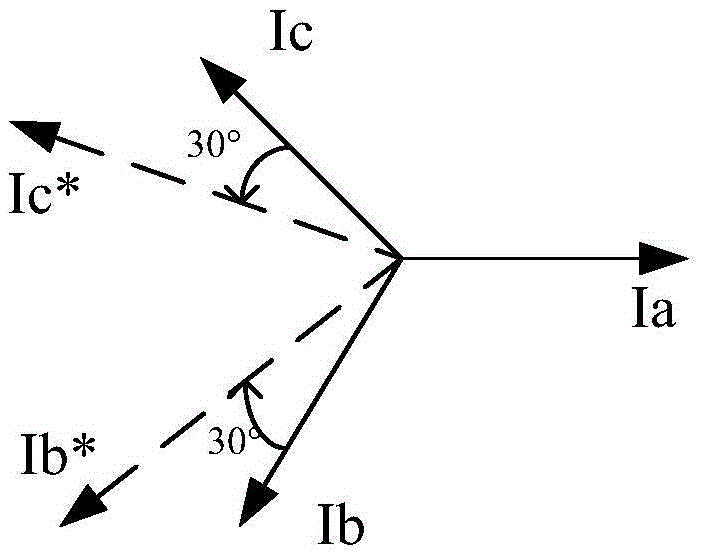

Vertical force control method of magnetic flux reverse permanent-magnet linear motor

ActiveCN103337998ASimple and reliable controlReduce vertical forceElectronic commutation motor controlAC motor controlPermanent magnet linear motorOptimal control

The invention discloses a vertical force control method of a magnetic flux reverse permanent-magnet linear motor. The method comprises a vertical force optimal algorithm and a control switcher, wherein the vertical force optimal algorithm comprises the steps of establishing an auxiliary function to obtain optimal d and q axis current, and obtaining minimum copper loss and vertical force under the condition of keeping push force unchanged during steady-state operation, so that the working efficiency and performance of the motor are improved; the control switcher adopts a control mode that the d axis current is zero in a dynamic stage, and adopts a vertical force optimal control mode in a steady stage. The method is rapid in response and easy to carry out.

Owner:指南者品牌管理(苏州)有限公司

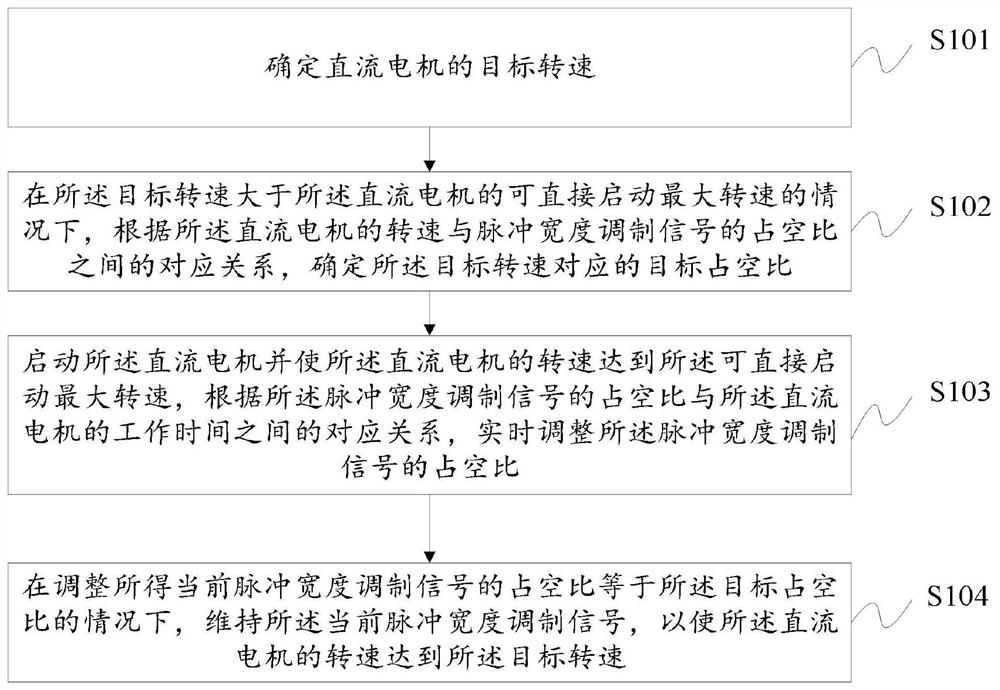

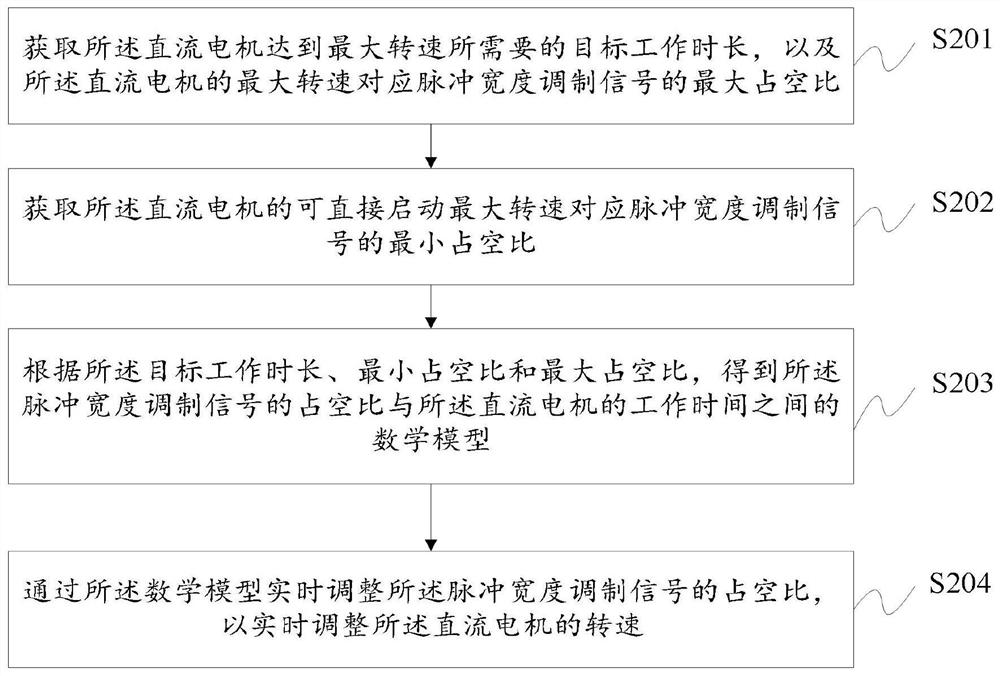

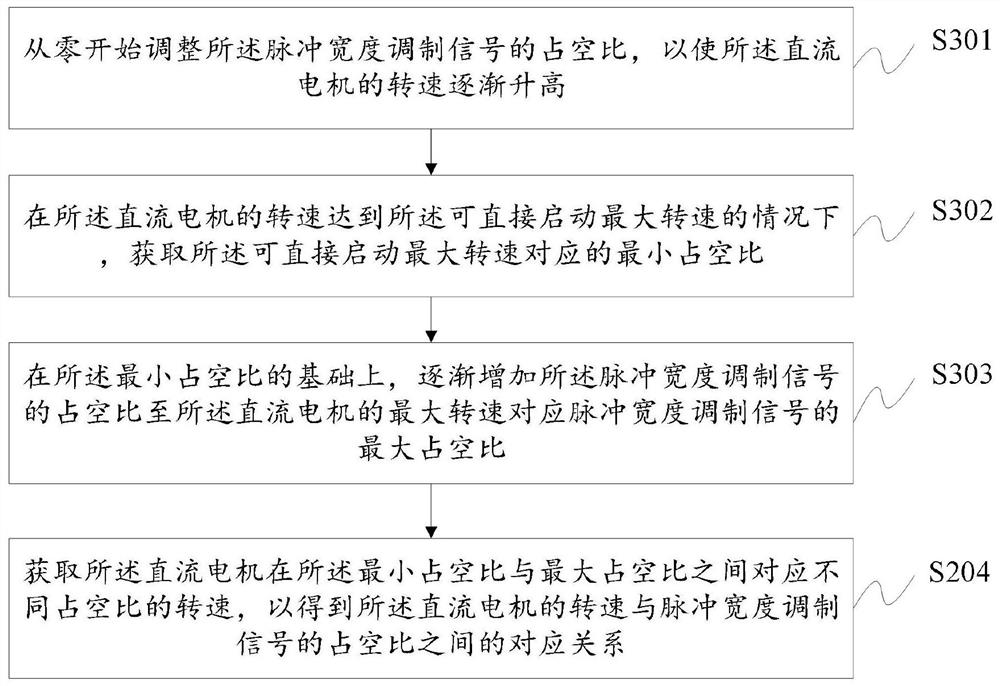

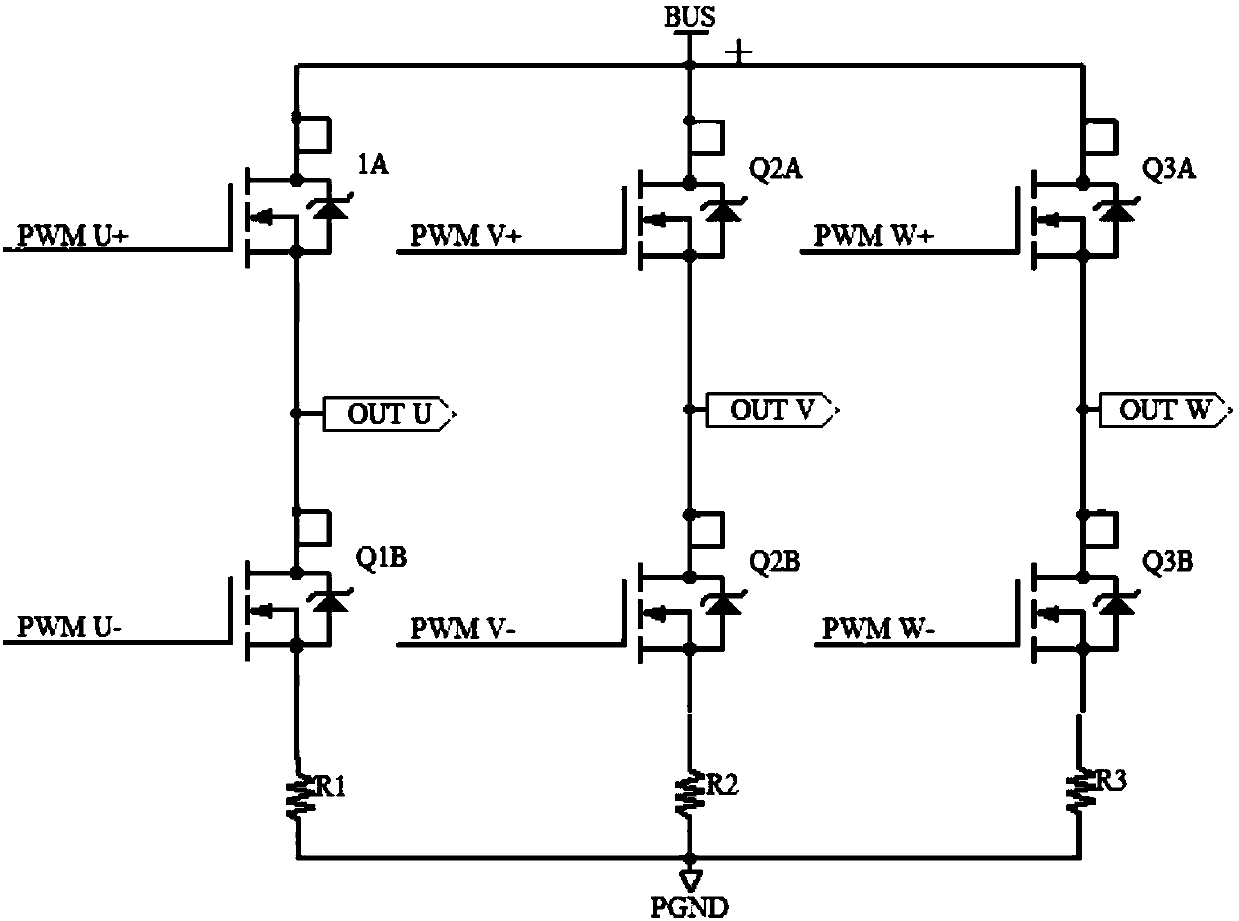

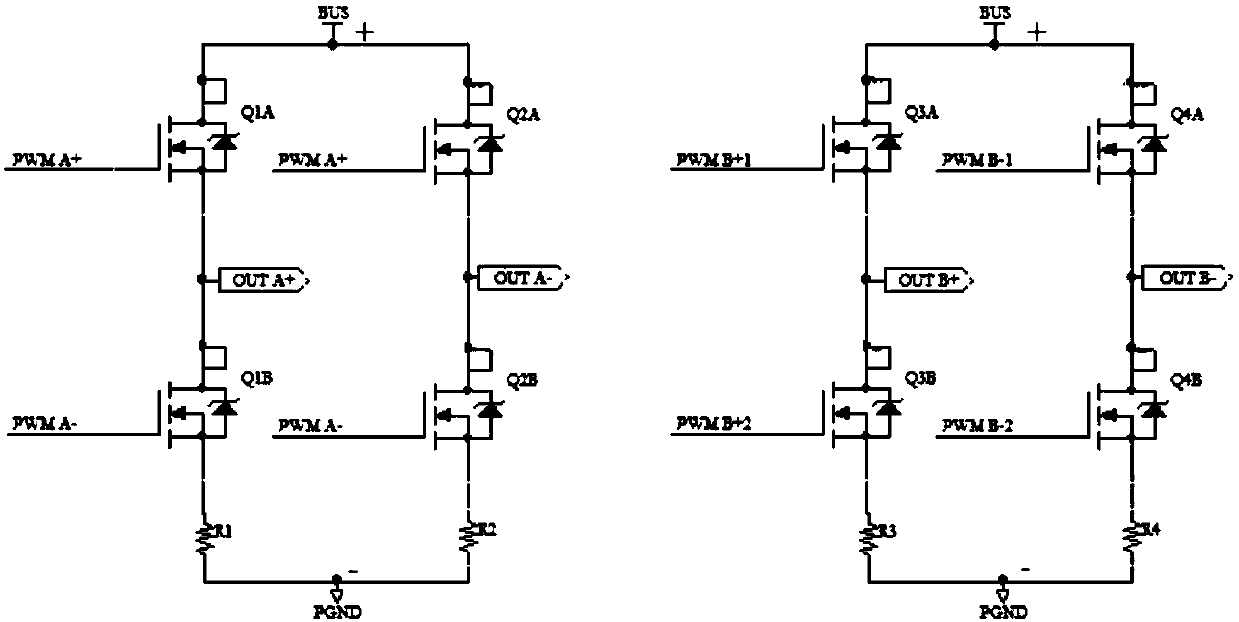

Control method and device for direct current motor and motor control system

ActiveCN113395024ASimple and reliable controlExtended service lifeField or armature current controlDC - Direct currentControl system

The invention relates to the technical field of motor driving, and discloses a control method for a direct current motor, which comprises the steps of determining a target rotating speed of the direct current motor; determining a target duty ratio corresponding to the target rotating speed according to a corresponding relation between the rotating speed of the direct current motor and the duty ratio of a pulse width modulation signal under the condition that the target rotating speed is greater than the maximum rotating speed of the direct current motor capable of being directly started; starting the direct current motor, enabling the rotating speed of the direct current motor to reach the maximum rotating speed capable of being directly started, and adjusting the duty ratio of the pulse width modulation signal in real time according to the corresponding relation between the duty ratio of the pulse width modulation signal and the working time of the direct current motor; and under the condition that the duty ratio of the obtained current pulse width modulation signal is adjusted to be equal to the target duty ratio, maintaining the current pulse width modulation signal so as to enable the rotating speed of the direct current motor to reach the target rotating speed.

Owner:QINGDAO HAIER BIOMEDICAL TECH CO LTD +1

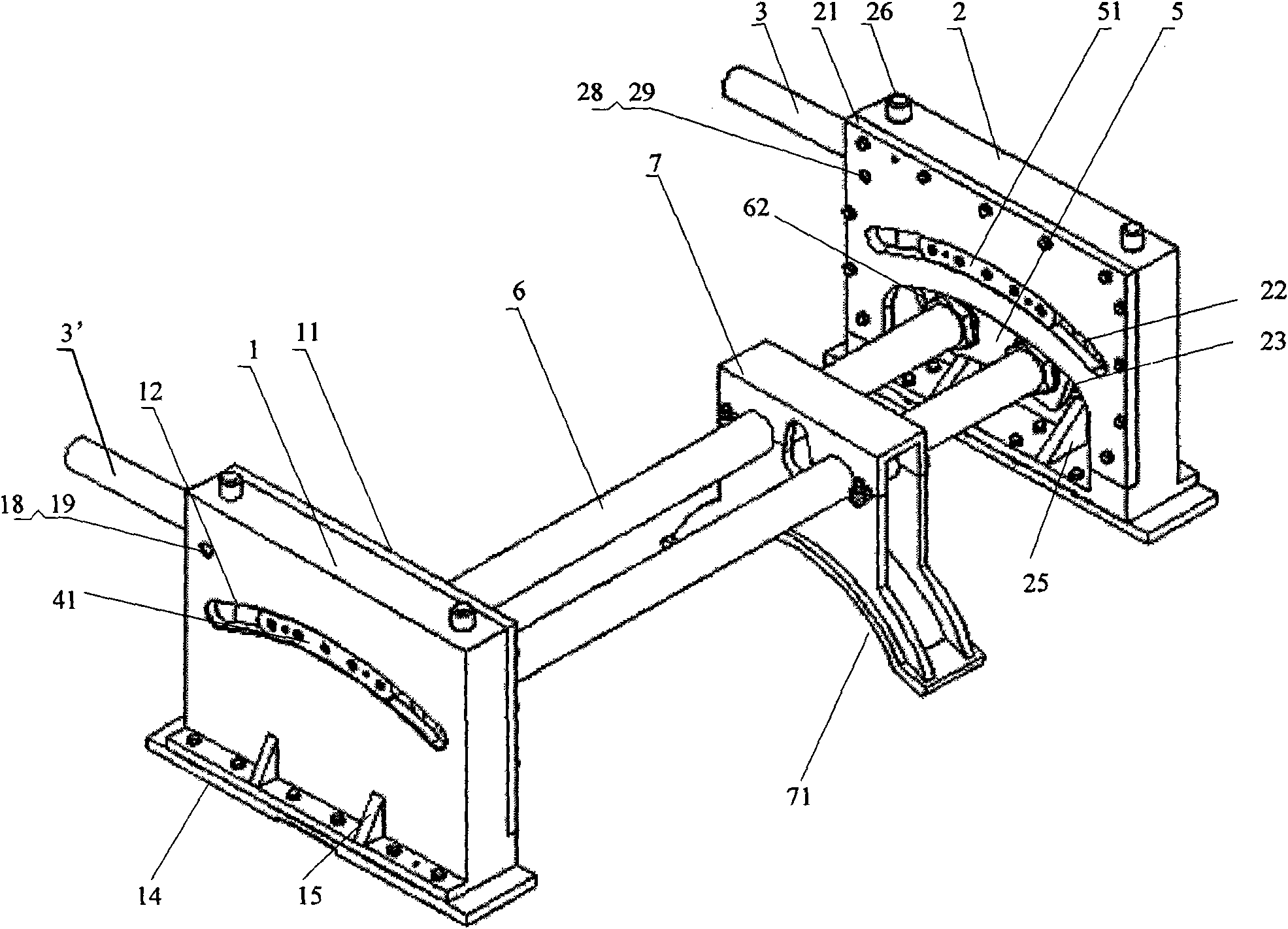

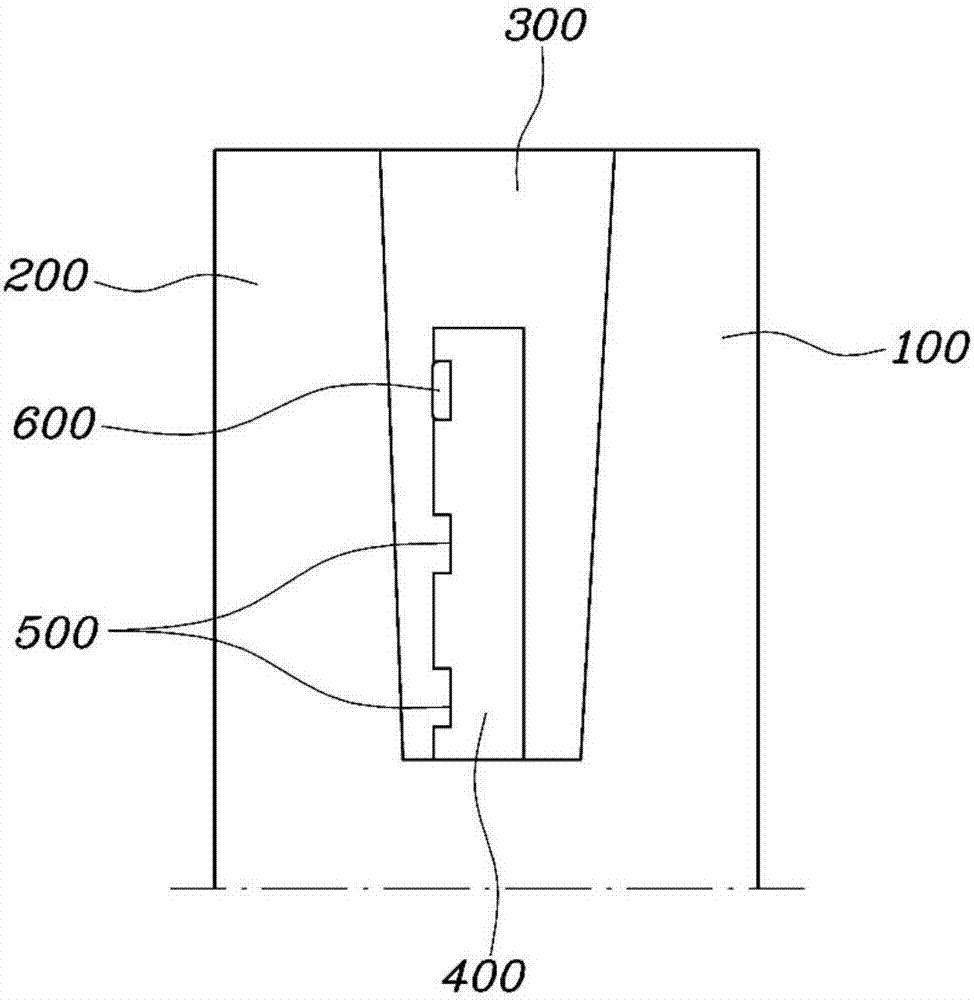

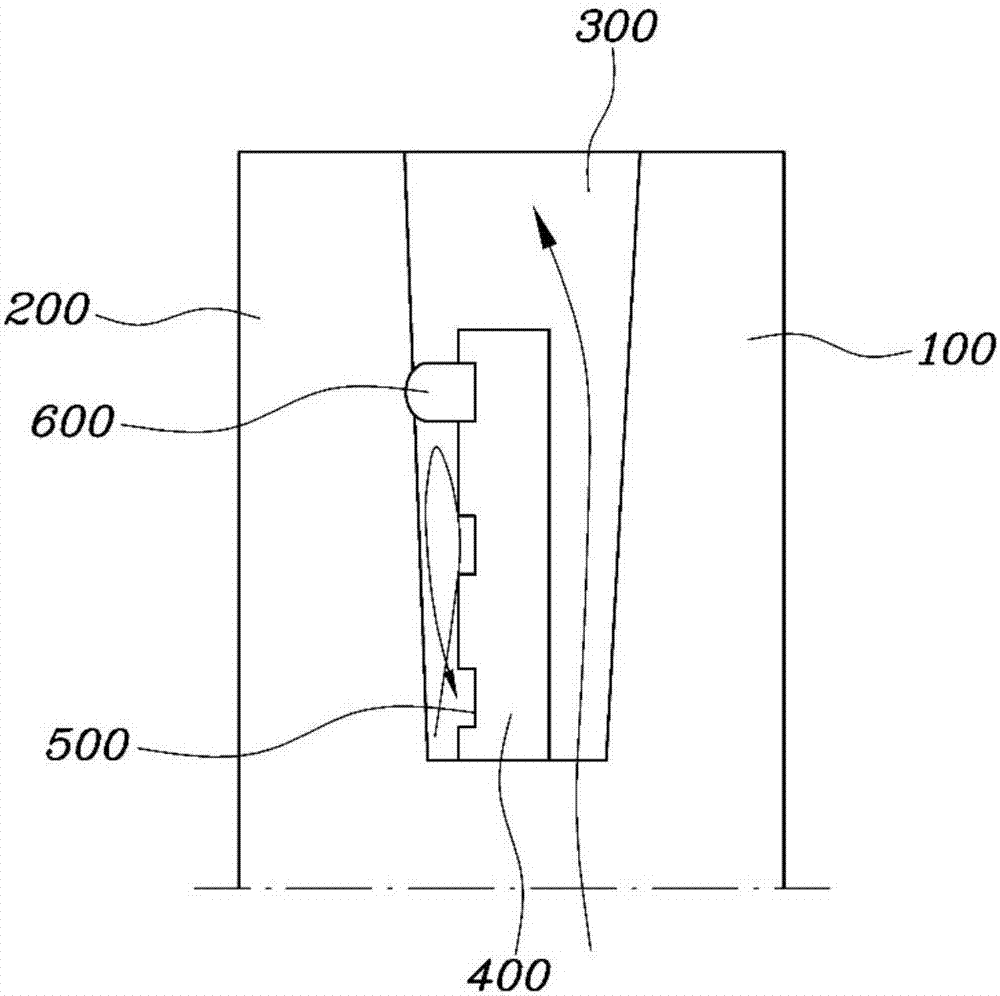

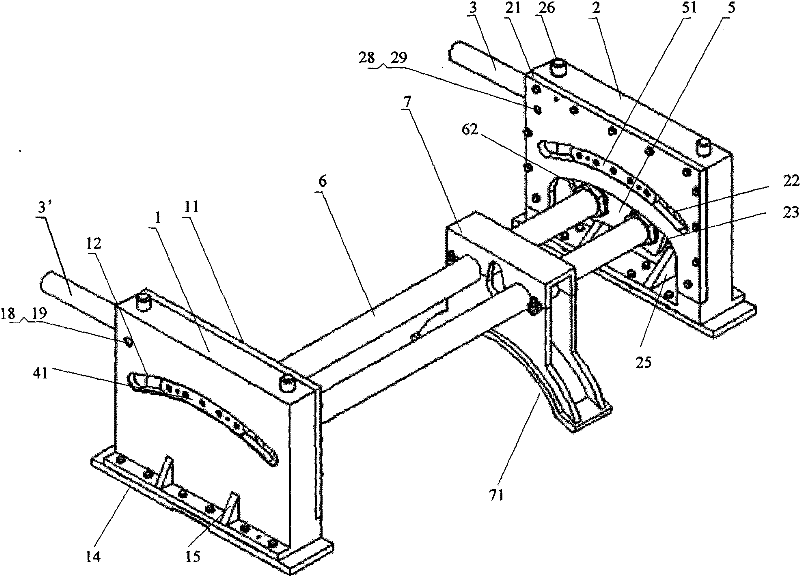

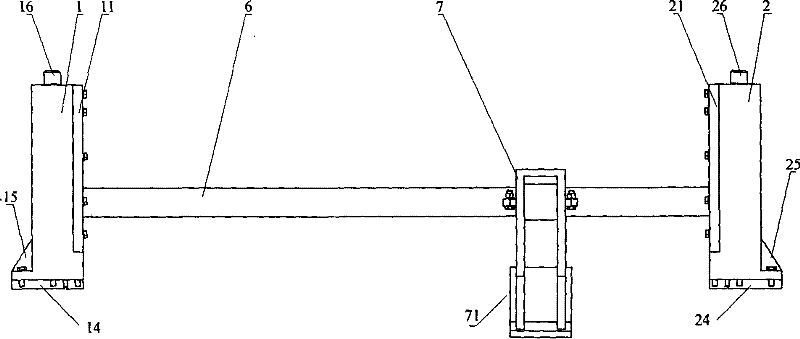

Control machine capable of carrying operation carrier to perform axial and circumferential motions relative to operation matrix

InactiveCN101929582ASimple and reliable controlImprove carrying capacityPipe laying and repairHydraulic cylinderEngineering

The invention relates to a control machine capable of carrying an operation carrier to perform axial and circumferential motions relative to an operation matrix, which comprises an outer frame and an inner frame, wherein the outer frame is connected with an external bearing matrix and comprises a left box and a right box; a left box bolted box cover is provided with a convex keyslot and a guide rail opening; a right box bolted box cover is provided with a convex keyslot and a guide rail opening; one side wall of the left box and one side wall of the right box are respectively provided with a hydraulic cylinder; the inner frame comprises a left rotator, a right rotator and a guide rail connected between the left and right rotators; the left and right rotators are respectively provided with a convex key; the convex key of the left rotator is clamped in the left box and the convex keyslot of the left box cover; the convex key of the right rotator is clamped in the right box and the convex keyslot of the right box cover; the left rotator is connected with a hydraulic cylinder piston rod arranged on the side wall of the left box; and the right rotator is connected with a hydraulic cylinder piston rod arranged on the side wall of the right box. The control machine of the invention realizes the axial and circumferential motions of the operation carrier relative to the operation matrix, has the advantages of high bearing capacity, and convenient and quick assembly and disassembly, and provides a simple-control and reliable pipeline local operation platform for subwater pipeline unmanned connection.

Owner:CHINA NAT OFFSHORE OIL CORP +3

A rotary continuous automatic feeding mechanism for a punching machine

ActiveCN105710246BSimple and reliable controlImprove securityMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention discloses a rotary, continuous and automatic feeding mechanism of a punching machine. The feeding mechanism comprises a frame, a loading mechanism, a taking mechanism, a punching machine and a main controller, and is characterized by further comprising a detecting disc and a blank detection positioning mechanism; the loading mechanism, the taking mechanism and the detecting disc are all fixed on the frame; the loading mechanism, the detecting disc and the punching machine are fixed around the taking mechanism at intervals in sequence in the clockwise direction; and the distances of the loading mechanism, the detecting disc and the punching machine from the taking mechanism are equal. The mechanism performs two times of positioning for blanks to be machined through a positioning block above the loading mechanism and a mold cover out of a mold so as to guarantee precise placement of the blanks in a machining position, and prevents the mold damage caused by once sucking of multiple blanks by the taking mechanism through the detecting number of the detecting disc. In addition, when the blanks are put in the mold, a photoelectric detector on the punching machine can detect if the blanks are placed precisely, so that such problems as mold damage and punching safety are further guaranteed.

Owner:ZHEJIANG UNIV OF TECH

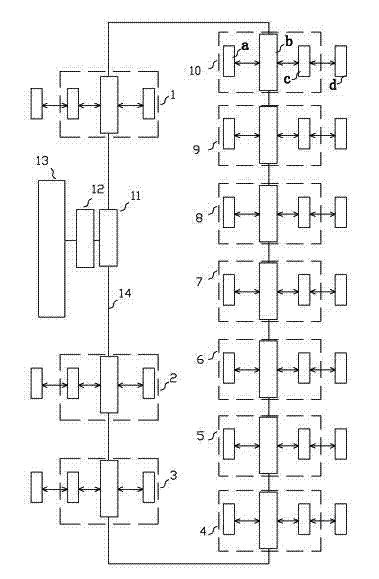

Control method of alumina production

InactiveCN102200771ARealize centralized monitoringRealize centralized managementTotal factory controlProgramme total factory controlFiberInformation control

The invention discloses a control method of alumina production. According to the method, a decentralised control system is used to carry out centralized control of the production process of each workshop. The decentralised control system comprises an information control center and central control rooms of each workshop. The information control center is provided with a host computer. Each central control room of the workshops is provided with a redundant data processor, a redundant data exchanger and a workshop monitoring terminal. The redundant data processor of each central control room of the workshops connects an annular fiber communication network through the redundant data exchanger of the central control room. The host computer comprises a plurality of monitors and a control terminal, and connects the annular fiber communication network through a network server. According to the method, the centralized control and centralized management of the data in the whole production process of alumina are realized, and safety production level and production efficiency are improved.

Owner:ZHENGZHOU ZHONGSHI CELL TECH

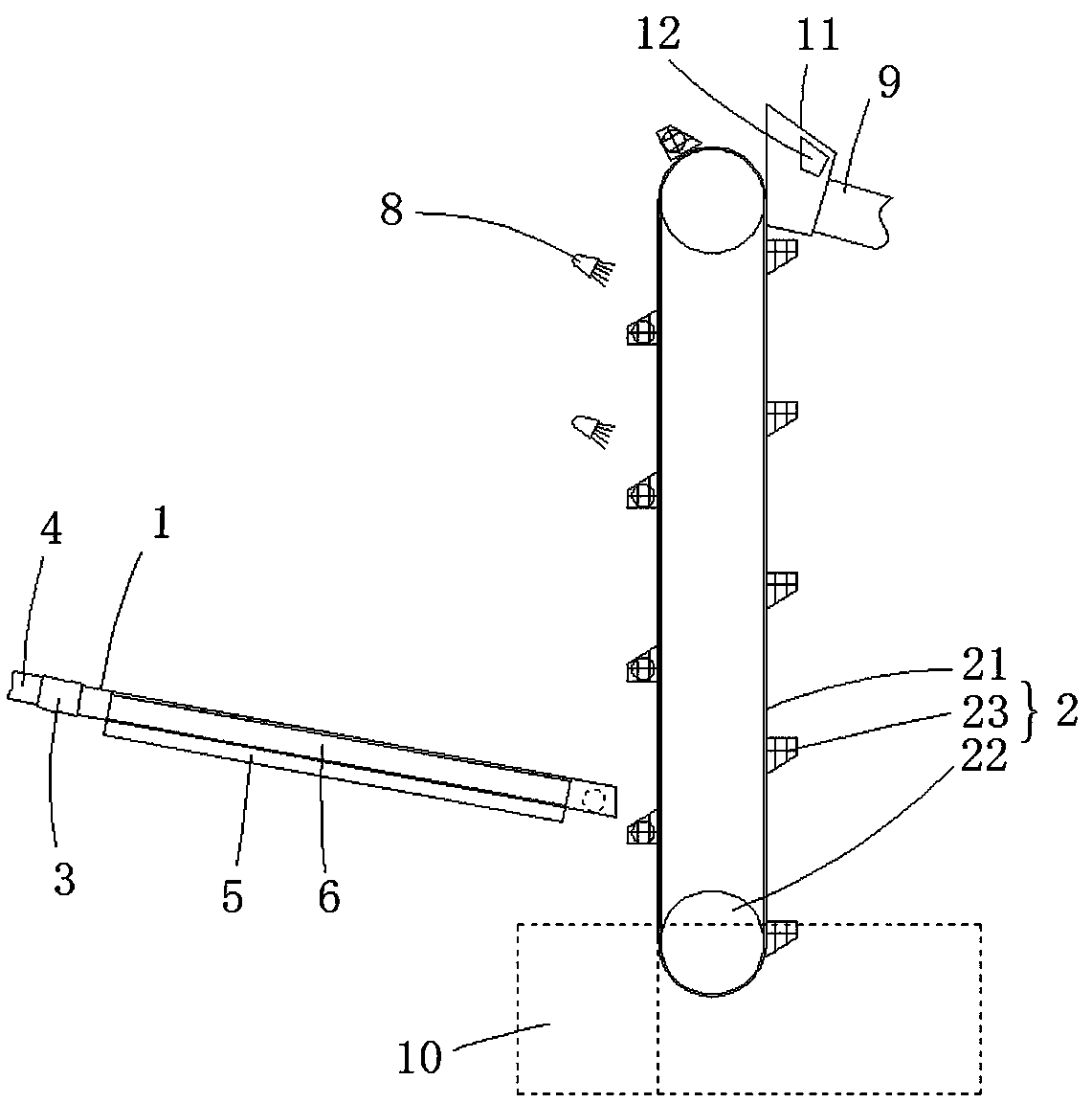

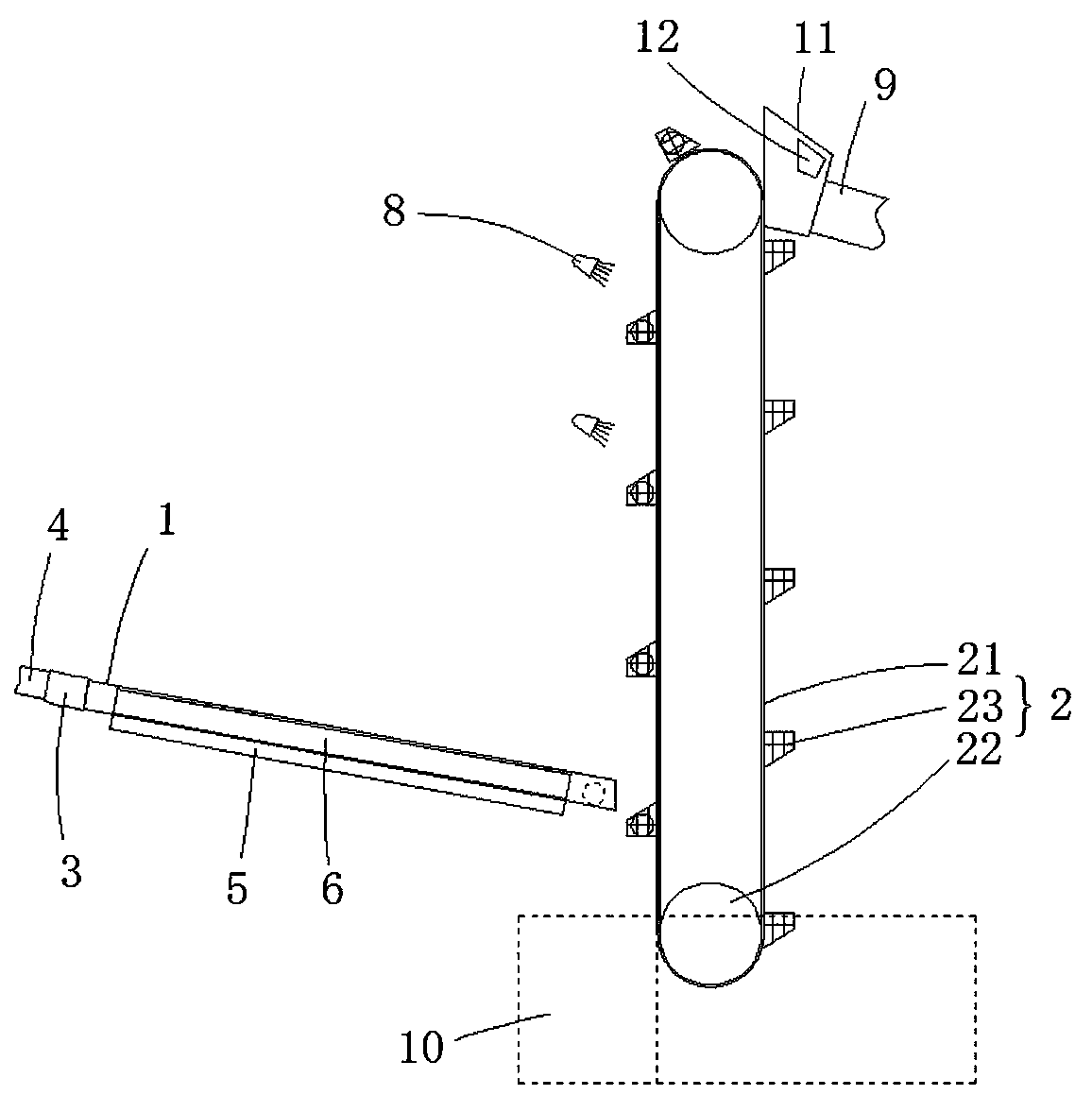

Appearance screening and cleaning integrated device for gears and work method of appearance screening and cleaning integrated device

InactiveCN108465650ASimple structureImprove work efficiencyDrying gas arrangementsCleaning using liquidsFace detectionChain structure

An appearance screening and cleaning integrated device for gears comprises a detection channel which is obliquely arranged, and a conveying chain structure which is vertically arranged. The detectionchannel is connected with a feeding port through a flexible piece, a tooth face detecting device is arranged at the bottom of the detection channel, end face detection devices are arranged on the twoside walls, and the detection channel is provided with a position changing drive device. The conveying chain structure comprises a circular movement chain, a set of chain wheels engaged with the chain, and a set of loading frames arranged on the chain, the chain wheels are connected with a chain wheel drive device, and the opening direction of the loading frames is consistent to the moving direction. The side, close to the detection channel, of the conveying chain structure is provided with a cleaning device, and a discharging channel is arranged at the upper end of the other side of the conveying chain structure. Tooth face and end face appearance detecting and screening and automatic qualified piece cleaning and unloading integrated actions are achieved, the integral structure is simple,the work efficiency is high, and the automation degree is high.

Owner:苏州聿知新机械科技有限公司

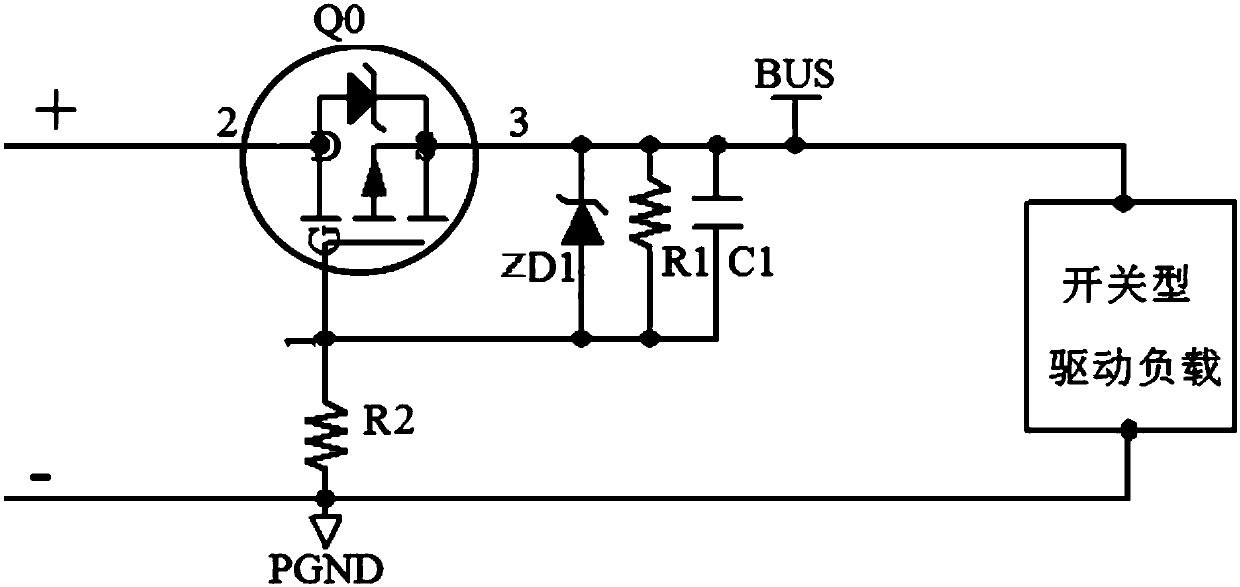

Low-voltage DC power supply driver power source anti-reverse-connection circuit based on PMOS transistor

PendingCN110098605ASimple and reliable controlEasy to implementEmergency protective circuit arrangementsCapacitanceLow voltage

The invention relates to a low-voltage DC power supply driver power source anti-reverse-connection circuit based on a PMOS transistor, whereby the reverse through short circuit of a switch-type driving load is avoided when a power source is reversely connected. The anti-reverse-connection circuit includes a PMOS transistor, a voltage stabilizing diode, a first resistor, a second resistor and a capacitor, wherein the drain of the PMOS transistor is connected to the positive pole of the power source; the source of the PMOS transistor is connected to the cathode of the voltage stabilizing diode,one end of the first resistor, one end of the capacitor and one end of the switch-type driving load; the gate of the PMOS transistor is connected to the anode of the voltage stabilizing diode, the other end of the first resistor, the other end of the capacitor and one end of the second resistor; the other end of the second resistor is connected to the negative side of the power source and the other end of the switch-type driving load. Compared with the prior art, the low-voltage DC power supply driver power source anti-reverse-connection circuit is easy and reliable to control, easy to implement, low in cost and the like.

Owner:SHANGHAI ANPU MINGZHI AUTOMATION EQUIP

Braker of electric opening device

InactiveCN1237213CSmooth brakingSimple and reliable controlSelf acting brakesOther shedding mechanismEngineeringDrive motor

The present invention provides a kind of electrically shedding device, which can avoid decent of heald frame in case of power failure of the driven motor to prevent damage of the heald frame and the warp. The electrically shedding device has shedding motion systems for the heald frames, and the shedding motion systems move to set press jointing members repeatedly and one pair of opposite holding members in the position capable of holding these press jointing members. At least on of the pair of holding members is provided with a driving part driving the holding member towards the press jointing direction. In power failure of the drive motor, the driving part acts to drive the holding members to move towards the holding direction, so that all the press jointed members are held between two holding members to maintain the heald frames against their motion.

Owner:TSUDAKOMA KOGYO KK

Split cooling apparatus for internal combustion engine

ActiveCN107304704ASmall sizeReduce weightLiquid coolingCoolant flow controlExternal combustion engineEngineering

The present disclosure provides a split cooling apparatus for an internal combustion engine, the apparatus including: a base inserted into a water jacket of a cylinder block, the base surrounding an outside of a cylinder along a shape of the cylinder; an insertion groove formed on the base by being depressed into an inner surface of the base; and a sealing member inserted into the insertion groove, wherein when a temperature of cooling water supplied into the water jacket reaches a preset temperature or higher, the sealing member expands so as to close a flow passage between the base and the cylinder, thereby increasing flow resistance of the cooling water and thus reducing a heat transfer rate of the cylinder.

Owner:HYUNDAI MOTOR CO LTD +1

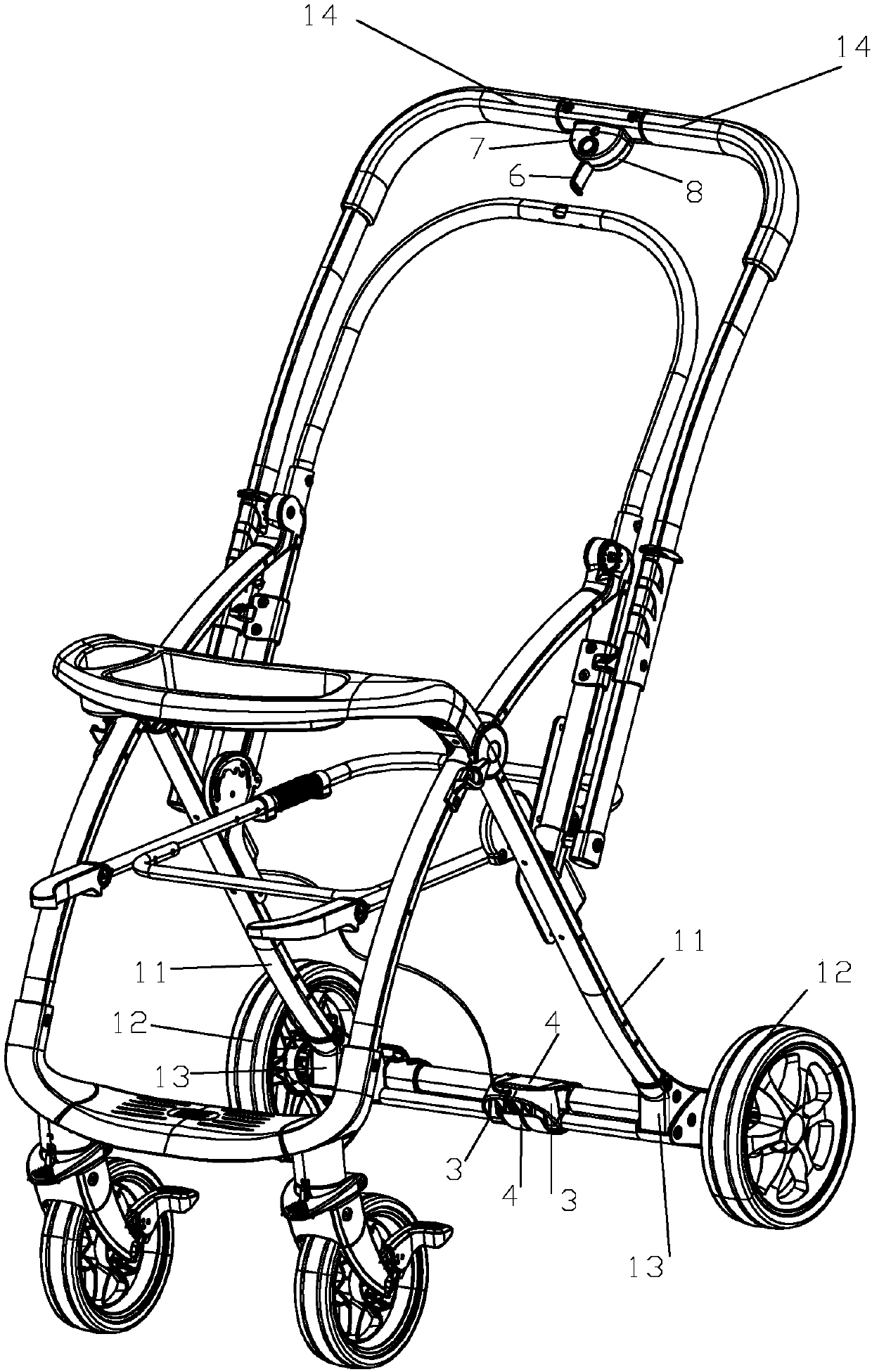

Single hand brake device of stroller

InactiveCN107792155AOverall small sizeSensitive and direct controlCarriage/perambulator accessoriesInfant StrollersParking brake

A single hand brake device of a stroller includes a brake arranged between back wheels at two sides, and a hand controller fixed on a pushing handle tube, wherein the brake and the hand controller areconnected through a metallic pulling rope; when a single hand rotates a wrench, the pulling rope retracts upward, an outer end of a metallic rod of the brake is inserted into an inner hole of the corresponding back wheel to achieve braking; when a finger presses a button of the hand controller, the pulling rope is loosed, the outer end of the metallic rod evacuates from the inner hole of the backwheel, and the braking state is unlocked; and for a stroller having a forward foldable pushing handle tube, quick braking and instant unlocking can be achieved whether a pushing person is in the backor the front of the stroller. The brake device can fully meet the linkage braking demand, and can satisfy the compulsive demand of a brake safety relevant standard of the baby stroller.

Owner:ANHUI SHUCHENG SANLE BABY CARRIAGE

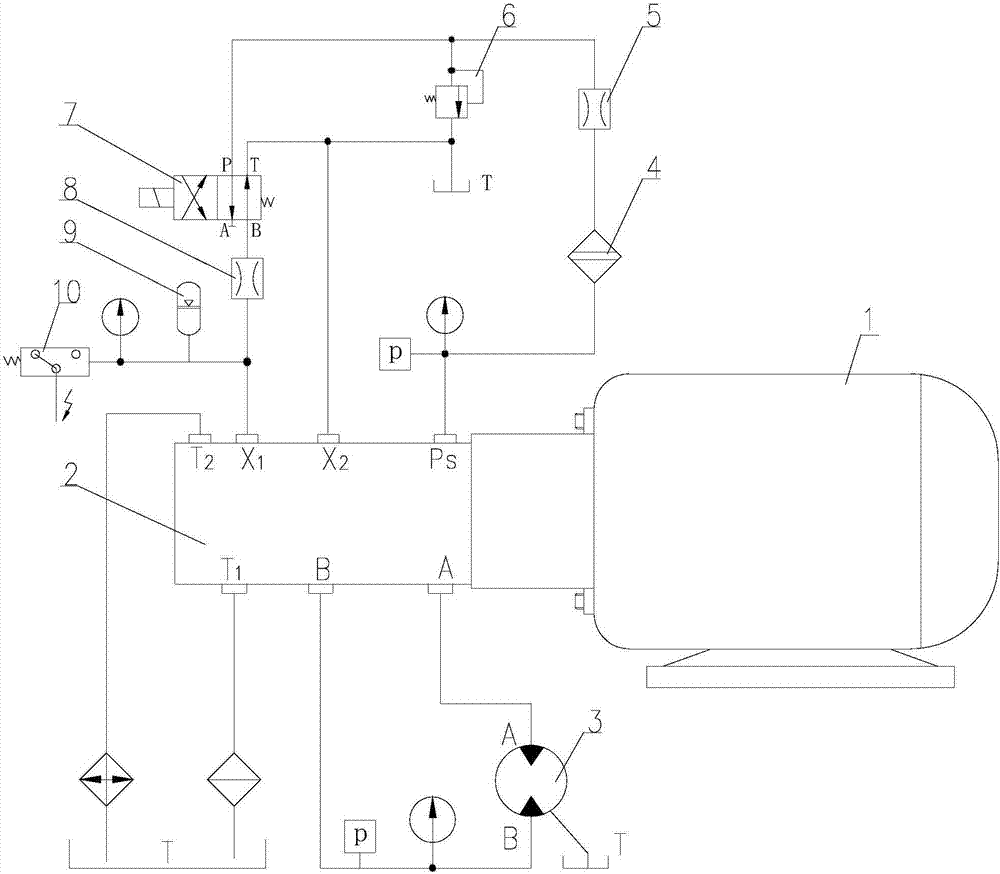

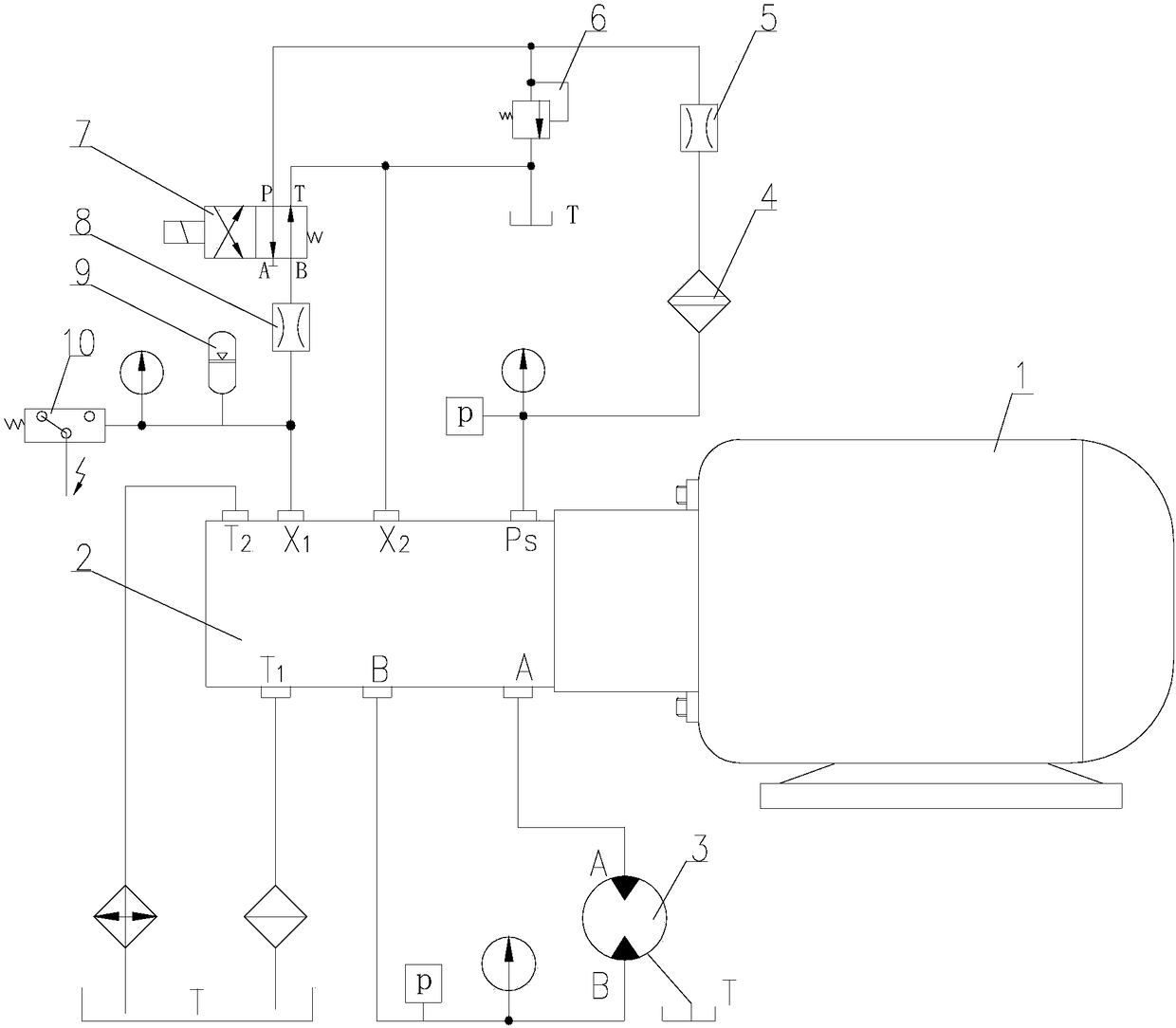

Cableway hydraulic driving system with pressure adjusted by energy accumulator

ActiveCN107044458AReduce electrical controlsSimple and reliable controlServomotor componentsServomotorsElectric machineElectrical control

The invention discloses a cableway hydraulic driving system with speed adjusted by an energy accumulator. The cableway hydraulic driving system consists of an electric machine, a variable-capacity oil pump, a motor and a hydraulic driving system, wherein the electric machine is connected with the variable-capacity oil pump; high-pressure oil ports A and B of the variable-capacity oil pump are connected with oil ports A and B of the motor; a hydraulic speed adjusting system comprises the variable-capacity oil pump; a filling pump opening PS in the variable-capacity oil pump is connected with a filter; the filter is connected with a throttling orifice of a pressure limiting valve bank; the throttling orifice of the pressure limiting valve bank communicates with the pressure limiting valve bank and a port P of a solenoid directional valve respectively; an oil return port of the pressure limiting valve bank, a port T of the solenoid directional valve and a pilot control port X2 of the variable-capacity oil pump are connected with an oil tank T; a port B of the solenoid directional valve is connected with the energy accumulator and a pilot control port X1 of the variable-capacity oil pump respectively through throttling orifices of the solenoid directional valve; and an oil inlet T1 and an oil outlet T2 of the variable-capacity oil pump communicate with the oil tank T. The cableway hydraulic driving system has the beneficial effects that the system is simple to control and is stable and reliable; the number of control valve banks and matched electrical control are reduced, costs are saved, and fault rate is reduced; and safety protection is complete.

Owner:XIANGTAN HENGXIN IND

Combined storage cabinet and control method thereof

PendingCN108263867AHigh speedSmall footprintConveyorsLoading/unloadingReciprocating motionEngineering

The invention relates to a combined storage cabinet and a control method thereof. The combined storage cabinet is characterized by comprising a conveying mechanism, a longitudinal walking mechanism, atransverse walking mechanism and a longitudinal guide rail, wherein the conveying mechanism is fixed to the upper portion of the transverse walking mechanism, the conveying mechanism and the transverse walking mechanism do transverse reciprocating motion on the upper portion of the longitudinal walking mechanism, and the longitudinal walking mechanism drives the conveying mechanism and the transverse walking mechanism to do longitudinal reciprocating motion on the longitudinal guide rail of the storage cabinet so that material distribution can be carried out. According to the combined storagecabinet, a plurality of storage cabinets can be combined very compactly, a material distribution vehicle and a bottom band are used for carrying out driving, less space is occupied, the storage amount is increased, the manufacturing cost, the running cost and the maintaining cost are reduced, control is more concise, in addition, the running cost is remarkably reduced, and the working efficiencyis improved.

Owner:QINHUANGDAO TOBACCO MACHINERY

Grabbing device of stereoscopic parking equipment

InactiveCN106481127ASimple and reliable controlAvoid interferenceParkingsEngineeringMechanical engineering

Owner:深圳六点实业有限公司

Upgrading method of gas turbine control system

ActiveCN111486006AIncrease typeReduce maintenance consumptionGas turbine plantsTurbine/propulsion fuel controlMode controlControl system

The invention discloses an upgrading method of a gas turbine control system. The upgrading method comprises the steps that the integrated gas turbine control system is introduced, control software isunified and centralized in a controller, and one set of PLC control system is used for achieving all control functions; brand-new control logic is used for controlling a gas turbine; the complex gas turbine control system is divided into multiple independent modules, and mode control is achieved according to the work condition state stepping sequence; multiple kinds of control algorithms are introduced into the control logic to optimize the gas turbine control system; and multiple independent modular command algorithms cover all states of a turbine generator set, and control of each equipmentadjusting component is expressed through a module equation. The existing gas turbine control system is modified and upgraded, the modular stepping process control logic and the advanced control algorithms are adopted for achieving the processes of starting, running and fuel switching control of the gas turbine, and meanwhile precise control of the process of fuel switching control is guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

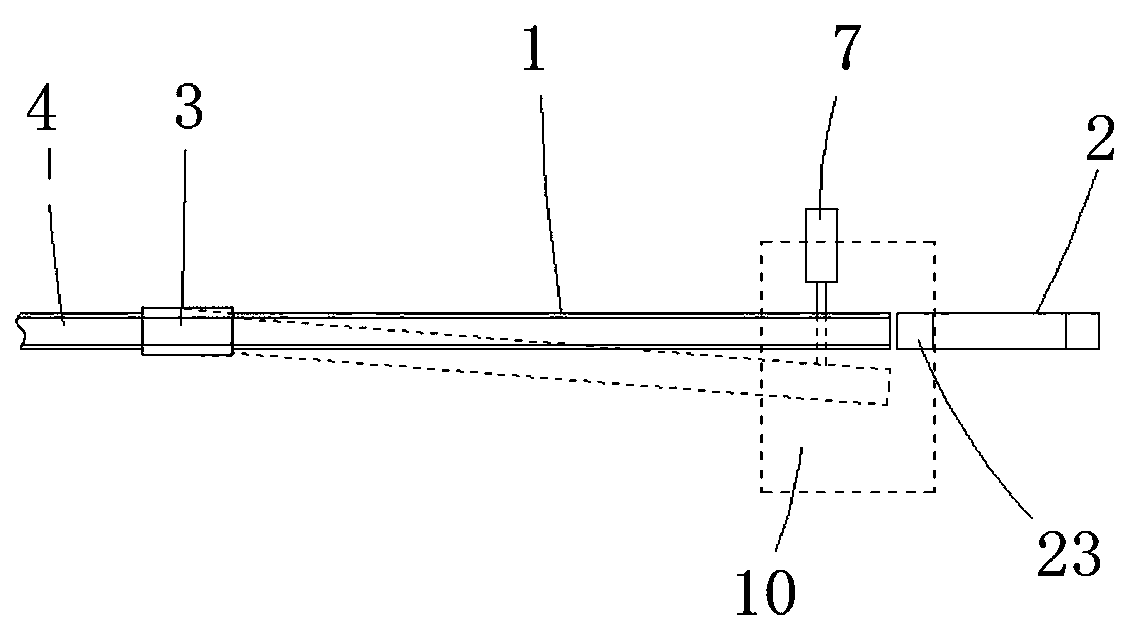

A fully automatic queuing box for medical examination

InactiveCN104758133BSimple structureEasy maintenanceNursing accommodationMedical recordControl system

The invention belongs to the technical field of medical technologies, relates to a full-automatic queuing box used for a medical examination, and aims at solving the technical problem by providing the full-automatic queuing box used for the medical examination. In order to solve the technical problem, the full-automatic queuing box used for the medical examination is provided, the full-automatic queuing box used for the medical examination comprises a box body, a box cover, a base, an upper-lower air cylinder, a left-right air cylinder, an L-shaped fork frame, a left-right pressure sensor, an upper-lower pressure sensor and a control system. In order to put a medical record note on the base accurately, a block bar is arranged on the base, the block bar is arranged on the upper portion of the right side of the base, and the block is located behind the L-shaped fork frame directly. According to the full-automatic queuing box used for the medical examination, the structure is simple, the maintenance and repair are convenient, and the production cost is low due to the fact that the number of parts is relatively few. The automation degree is high, and the automatic operation of the queuing box can be achieved.

Owner:秦爱林

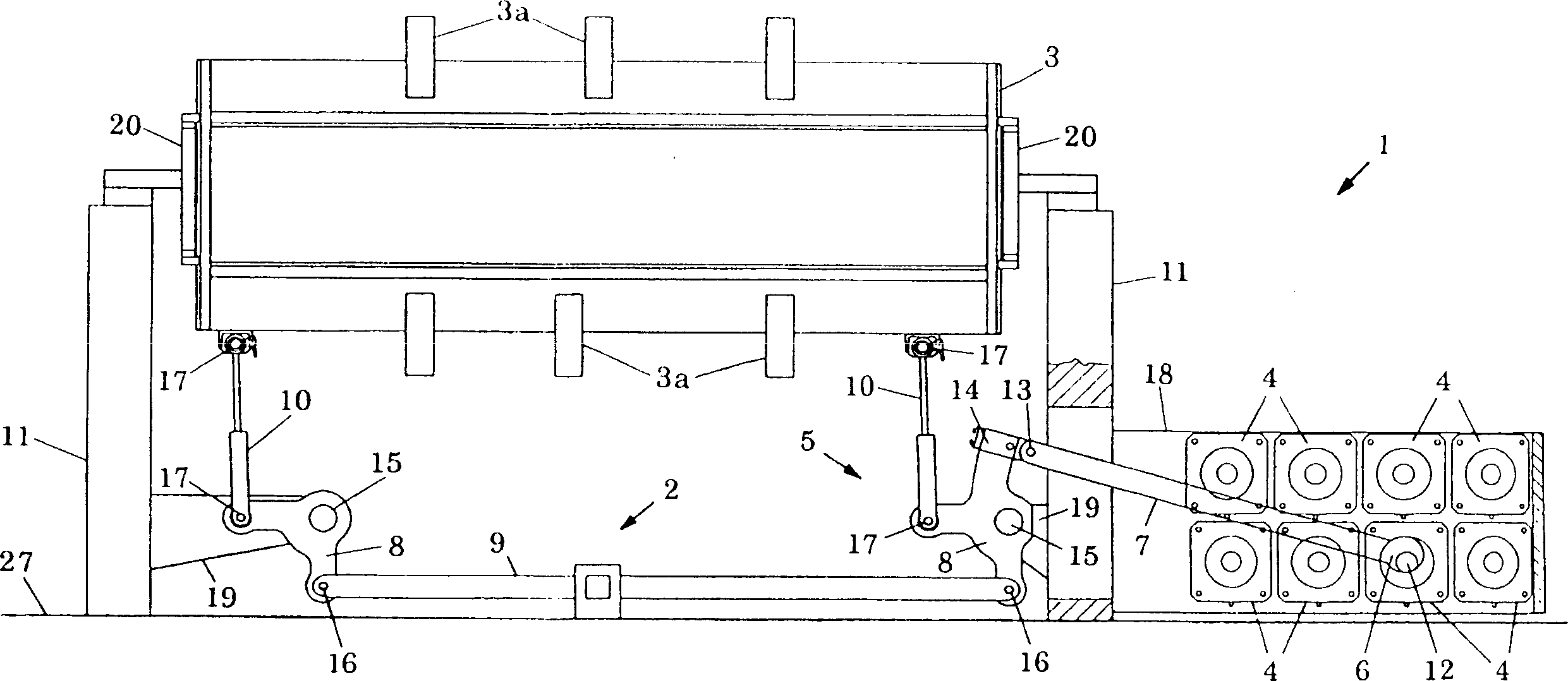

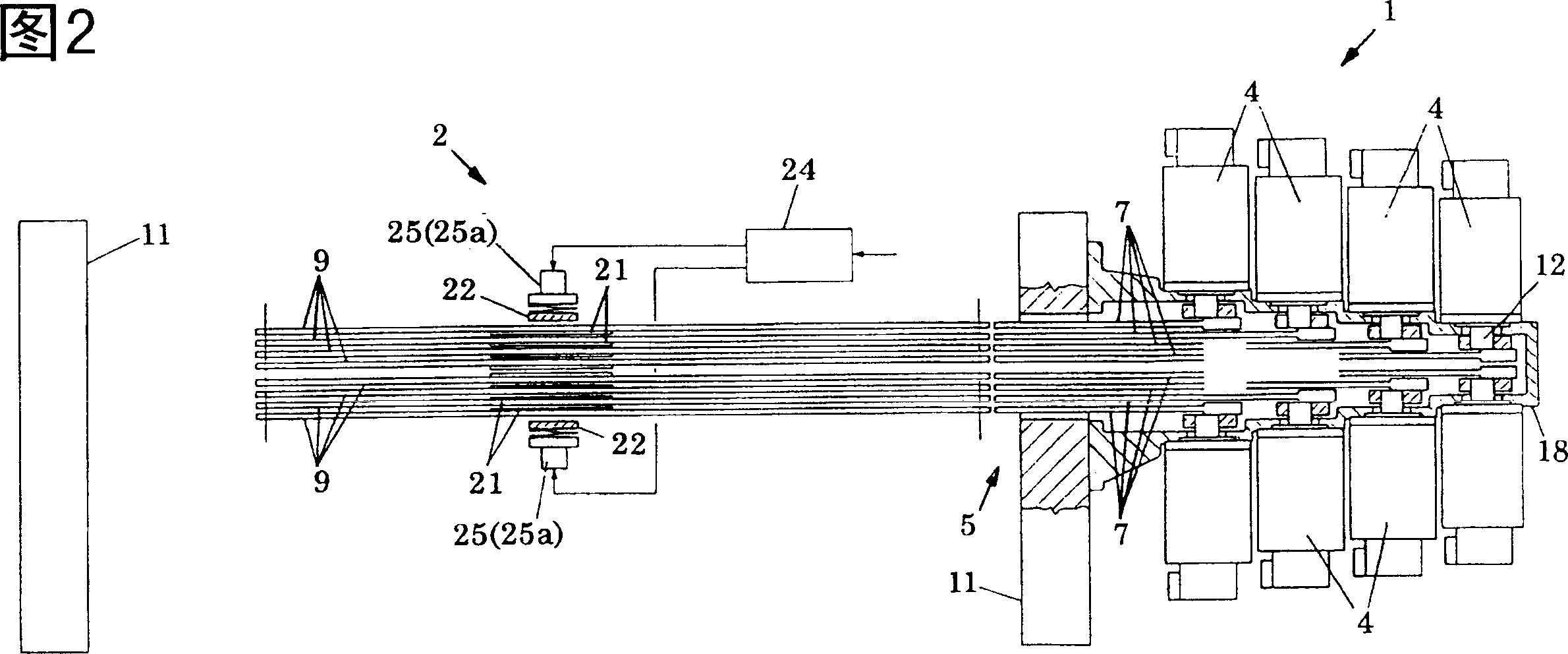

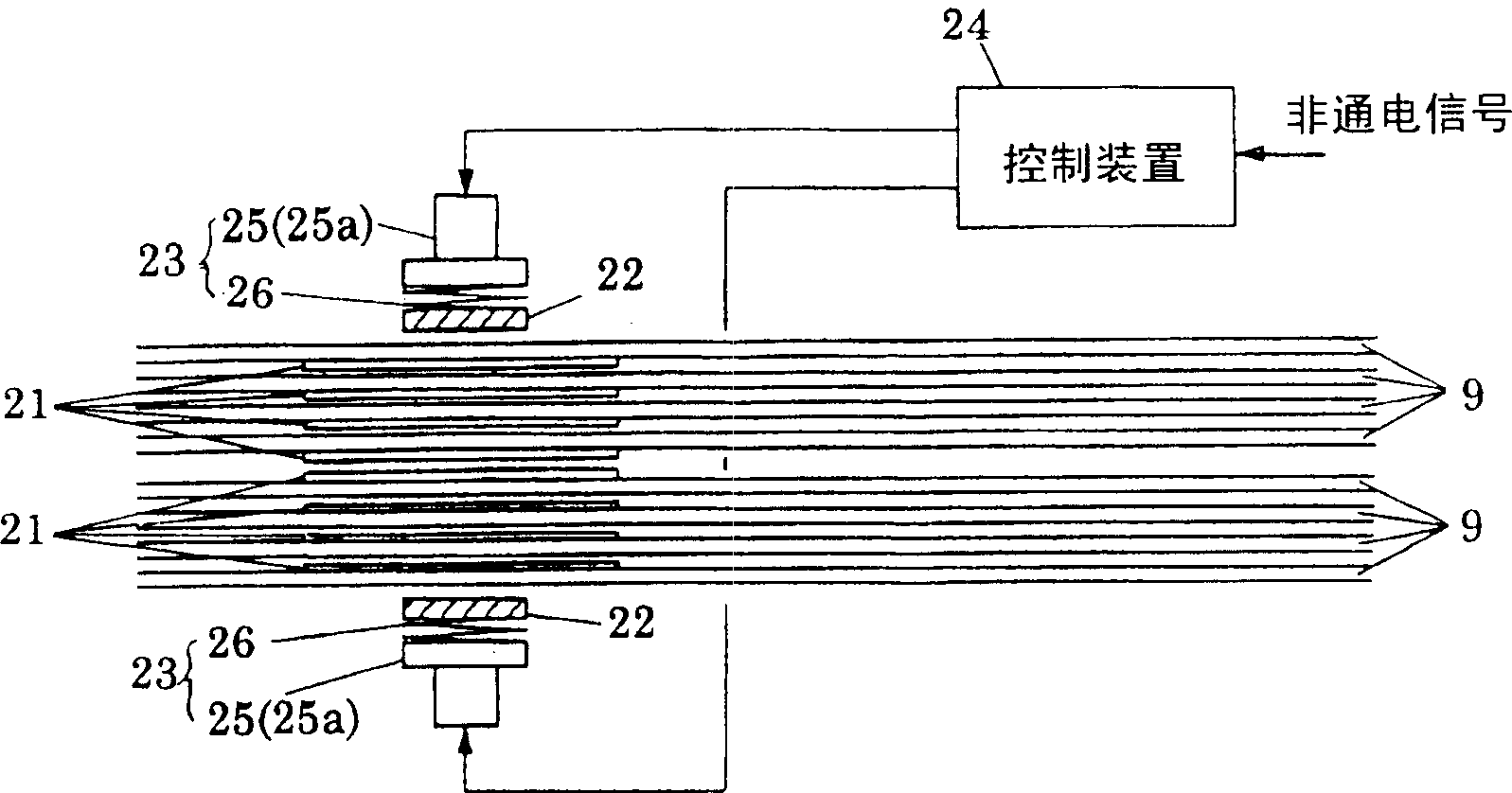

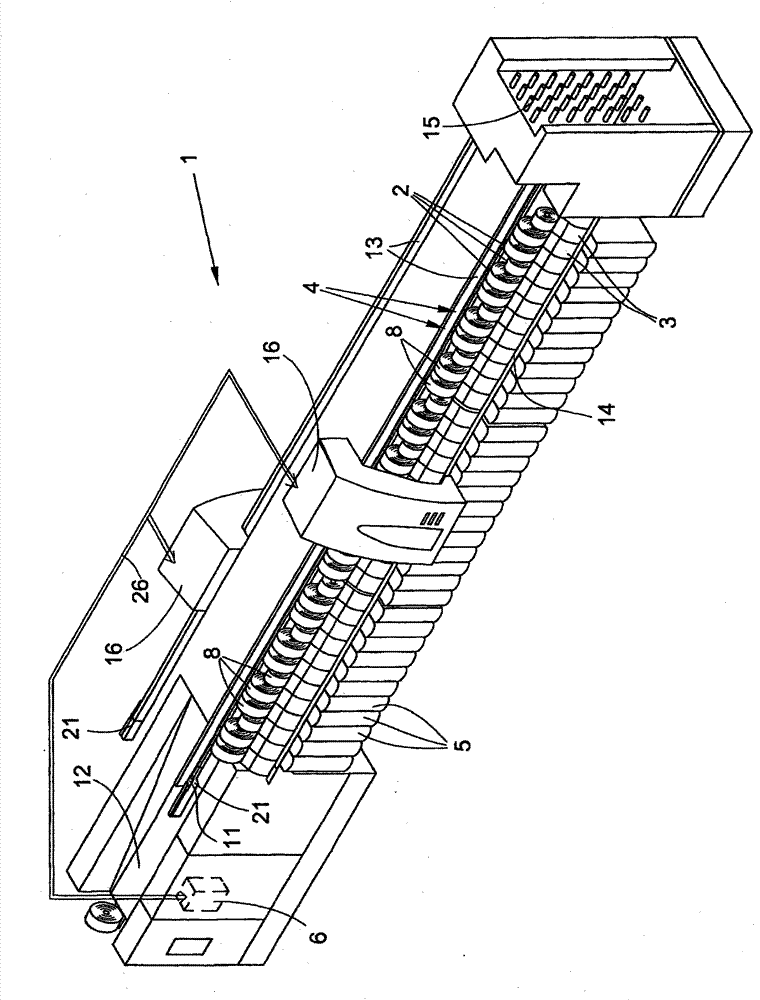

Textile machine having a moveable service unit

ActiveCN102066629BReduce in quantityImprove reliabilityPiercing arrangementsFilament handlingEngineeringMechanical engineering

The invention relates to a textile machine (1) having a plurality of work stations (2) and at least one service unit (16) that can be moved along the work stations (2) for operating and / or maintaining the individual work stations (2), wherein the at least one service unit (16) comprises at least one camera (50), and wherein the camera (50) is designed to produce images that include components of the service unit (16) and / or the work stations (2) and to transmit them to a control unit (17, 6, 10) of the textile machine (1) for detecting and evaluating the components and / or the current absolute or relative positions thereof, said control unit using the information obtained for controlling the service unit (16) and / or the work station (2) requiring operation and / or control. The invention further relates to a method for operating a textile machine (1) of said kind.

Owner:SAURER GERMANY GMBH & CO KG

Modular Fault Tolerant Flux Switching Permanent Magnet Linear Motor Control Method

ActiveCN103441640BSimple structureIncrease powerElectronic commutation motor controlAC motor controlElectric machineModularity

Owner:JIANGSU UNIV

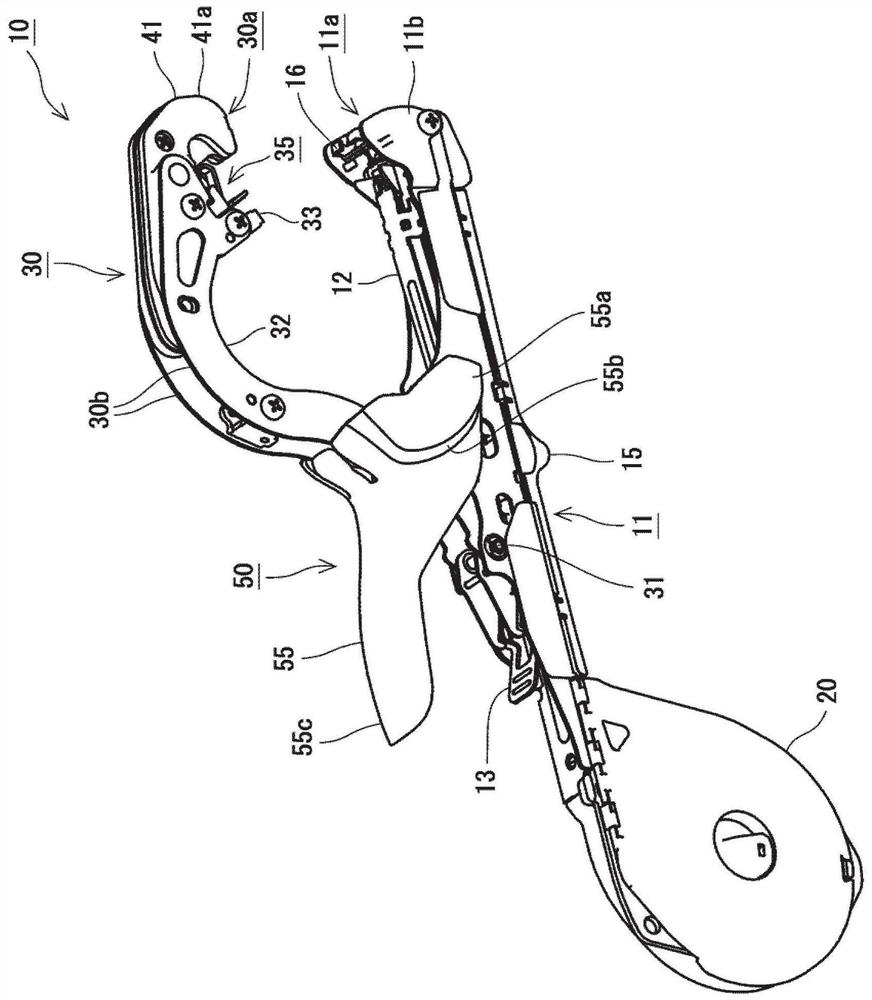

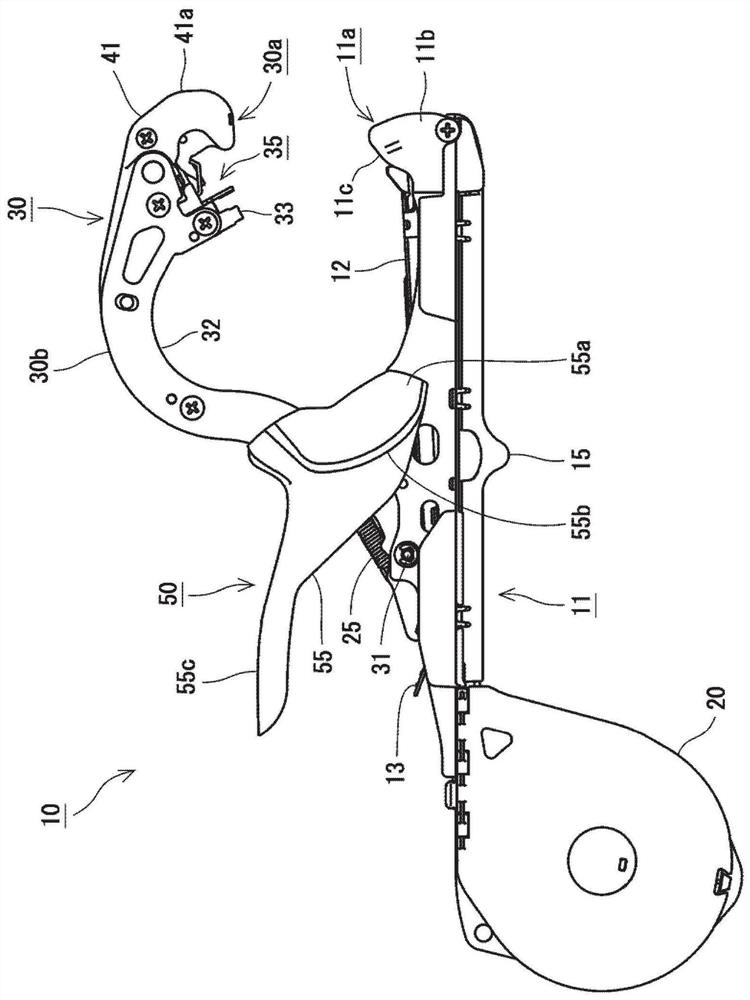

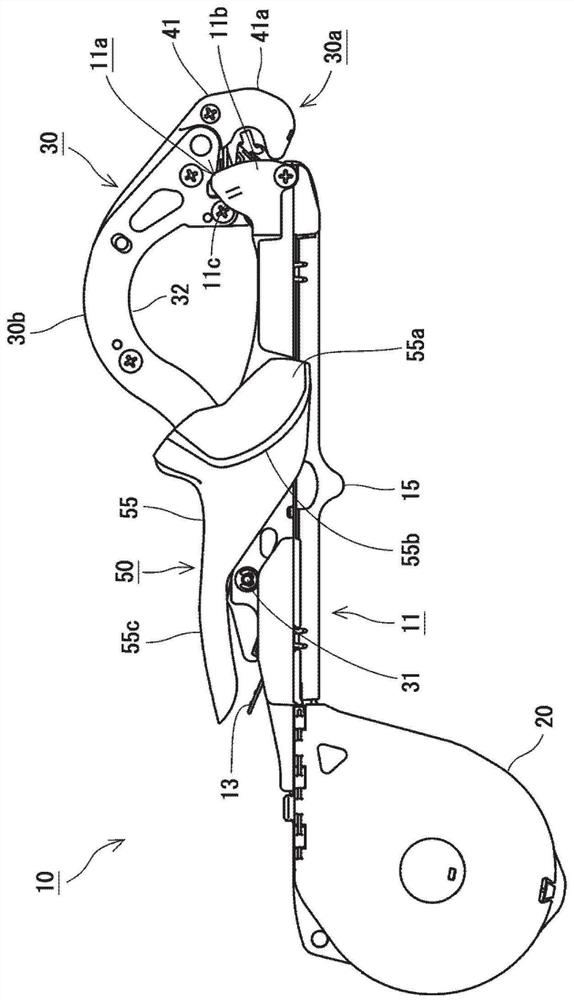

Horticultural strapping machine

ActiveCN107517774BUnrestricted movementHold unrestrictedBinding material applicationCultivating equipmentsEngineeringStructural engineering

The present invention provides a horticultural binding machine capable of preventing failure to pull out a belt even when no operator familiar with the gardening binding machine performs the work. The gardening strapping machine (10) has a main handle (11) capable of pulling out a belt (60) from a front end portion (11a), a clamp arm (30) mounted to be rotatable relative to the main handle (11), and a mounting The belt holding device (35) at the front end (30a) of the clamp arm (30) can bind the object to be bound (S) by alternately performing the holding action and the binding action. The gardening binding machine (10) has a movement limit The movement limiting unit limits the rotation of the clamp arm (30) from a predetermined position to the closing direction during the holding action.

Owner:MAX CO LTD

Spinning machine with suction apparatus and method for controlling suction apparatus of spinning machine

ActiveCN101994179BReduce speedGuaranteed volume flowFilament handlingDrafting machinesControl theoryFilter element

Owner:RIETER INGOLSTADT GMBH

Full-automatic queuing box used for medical examination

InactiveCN104758133ASimple structureEasy to maintainNursing accommodationPressure sensorMedical record

The invention belongs to the technical field of medical technologies, relates to a full-automatic queuing box used for a medical examination, and aims at solving the technical problem by providing the full-automatic queuing box used for the medical examination. In order to solve the technical problem, the full-automatic queuing box used for the medical examination is provided, the full-automatic queuing box used for the medical examination comprises a box body, a box cover, a base, an upper-lower air cylinder, a left-right air cylinder, an L-shaped fork frame, a left-right pressure sensor, an upper-lower pressure sensor and a control system. In order to put a medical record note on the base accurately, a block bar is arranged on the base, the block bar is arranged on the upper portion of the right side of the base, and the block is located behind the L-shaped fork frame directly. According to the full-automatic queuing box used for the medical examination, the structure is simple, the maintenance and repair are convenient, and the production cost is low due to the fact that the number of parts is relatively few. The automation degree is high, and the automatic operation of the queuing box can be achieved.

Owner:秦爱林

Gear detection and sorting device and working method thereof

InactiveCN108993928ASimple structureImprove work efficiencyOptically investigating flaws/contaminationSortingGear wheelChain structure

A gear detection and sorting device comprises an oblique detection channel and a vertical conveying chain structure, wherein the detection channel directly faces the conveying chain structure; the conveying chain structure is provided with a group of loading frames which are driven by the conveying chain structure to more circularly; the detection channel is connected with a feeding port through aflexible part and provided with a transposition driving device, the transposition driving device is arranged at one end, close to the conveying chain structure, of the detection channel, and one endof the detection channel can be driven by the transposition driving device to deviate from the conveying chain structure; a tooth surface detection device is arranged at the bottom of the detection channel, and end surface detection devices are arranged on two side walls respectively; the tooth surface detection device comprises a group of camera units axially arranged along the detection channel.Integrated actions of appearance detection and sorting of the tooth surface and end surfaces are realized, appearance detection of tooth surfaces with all tooth shapes is realized, the tooth surfaceand the end surfaces are detected simultaneously, besides, unqualified parts can be unloaded during dropping by offsetting the detection channel, and the working efficiency is high.

Owner:苏州聿知新机械科技有限公司

A control tool that carries the operating carrier to move axially and circumferentially relative to the operating base

InactiveCN101929582BSimple and reliable controlImprove carrying capacityPipe laying and repairHydraulic cylinderEngineering

A control tool that carries a working carrier to move circumferentially and axially relative to a working base, including an outer frame and an inner frame; the outer frame is connected to the outer receiving base, including left and right boxes, and the left box is screwed to the box cover to set a convex The keyway and guide rail opening, the right box is screwed to the box cover with convex keyway and guide rail opening, the side walls of the left and right boxes are separately equipped with hydraulic cylinders; the inner frame includes the left and right rotating bodies and the guide rails connected between the left and right rotating bodies. The convex key, the convex key of the left rotating body is buckled in the convex key groove of the left box and the left box cover, the convex key of the right rotating body is buckled in the convex key groove of the right box and the right box cover, and the left rotating body and the The piston rod of the hydraulic cylinder on the side wall of the left box is connected, and the right rotating body is connected to the piston rod of the hydraulic cylinder on the side wall of the right box; the axial and circumferential movement of the working carrier relative to the working base is realized, the bearing capacity is large, and installation and disassembly are easy. It is convenient and fast, and provides a simple and reliable pipeline local operation platform for unmanned connection of underwater pipelines.

Owner:CHINA NAT OFFSHORE OIL CORP +3

A method for upgrading a gas turbine control system

ActiveCN111486006BIncrease typeReduce maintenance consumptionGas turbine plantsTurbine/propulsion fuel controlMode controlControl system

The invention discloses an upgrading method of a gas turbine control system. The upgrading method comprises the steps that the integrated gas turbine control system is introduced, control software isunified and centralized in a controller, and one set of PLC control system is used for achieving all control functions; brand-new control logic is used for controlling a gas turbine; the complex gas turbine control system is divided into multiple independent modules, and mode control is achieved according to the work condition state stepping sequence; multiple kinds of control algorithms are introduced into the control logic to optimize the gas turbine control system; and multiple independent modular command algorithms cover all states of a turbine generator set, and control of each equipmentadjusting component is expressed through a module equation. The existing gas turbine control system is modified and upgraded, the modular stepping process control logic and the advanced control algorithms are adopted for achieving the processes of starting, running and fuel switching control of the gas turbine, and meanwhile precise control of the process of fuel switching control is guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A Cableway Hydraulic Driving System Using Accumulator to Regulate Pressure

ActiveCN107044458BReduce electrical controlsSimple and reliable controlServomotor componentsServomotorsElectric machineFuel tank

The invention discloses a cableway hydraulic driving system with speed adjusted by an energy accumulator. The cableway hydraulic driving system consists of an electric machine, a variable-capacity oil pump, a motor and a hydraulic driving system, wherein the electric machine is connected with the variable-capacity oil pump; high-pressure oil ports A and B of the variable-capacity oil pump are connected with oil ports A and B of the motor; a hydraulic speed adjusting system comprises the variable-capacity oil pump; a filling pump opening PS in the variable-capacity oil pump is connected with a filter; the filter is connected with a throttling orifice of a pressure limiting valve bank; the throttling orifice of the pressure limiting valve bank communicates with the pressure limiting valve bank and a port P of a solenoid directional valve respectively; an oil return port of the pressure limiting valve bank, a port T of the solenoid directional valve and a pilot control port X2 of the variable-capacity oil pump are connected with an oil tank T; a port B of the solenoid directional valve is connected with the energy accumulator and a pilot control port X1 of the variable-capacity oil pump respectively through throttling orifices of the solenoid directional valve; and an oil inlet T1 and an oil outlet T2 of the variable-capacity oil pump communicate with the oil tank T. The cableway hydraulic driving system has the beneficial effects that the system is simple to control and is stable and reliable; the number of control valve banks and matched electrical control are reduced, costs are saved, and fault rate is reduced; and safety protection is complete.

Owner:XIANGTAN HENGXIN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com