Braker of electric opening device

A technology of opening device and braking device, applied in the direction of automatic brake, brake type, other opening mechanism, etc., can solve the problem of unable to obtain braking force and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiment of the invention

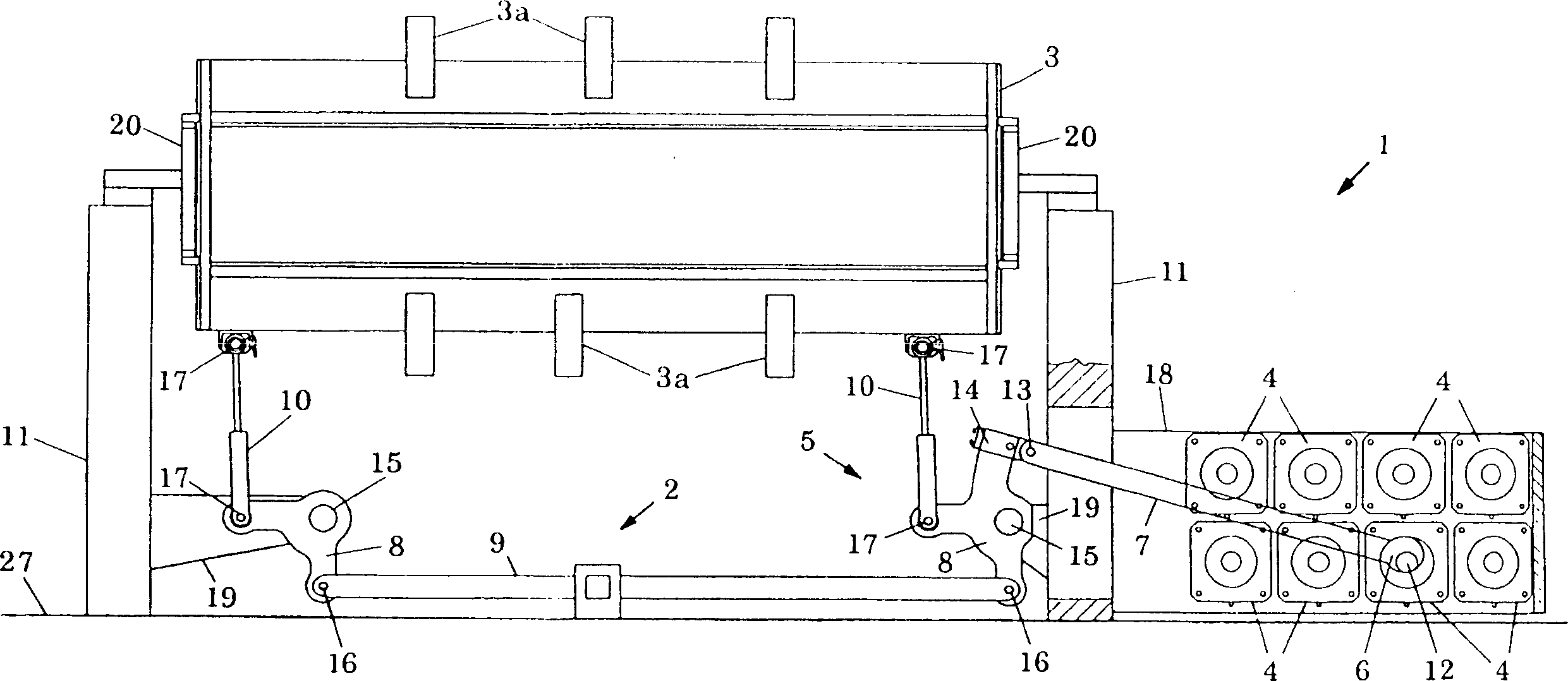

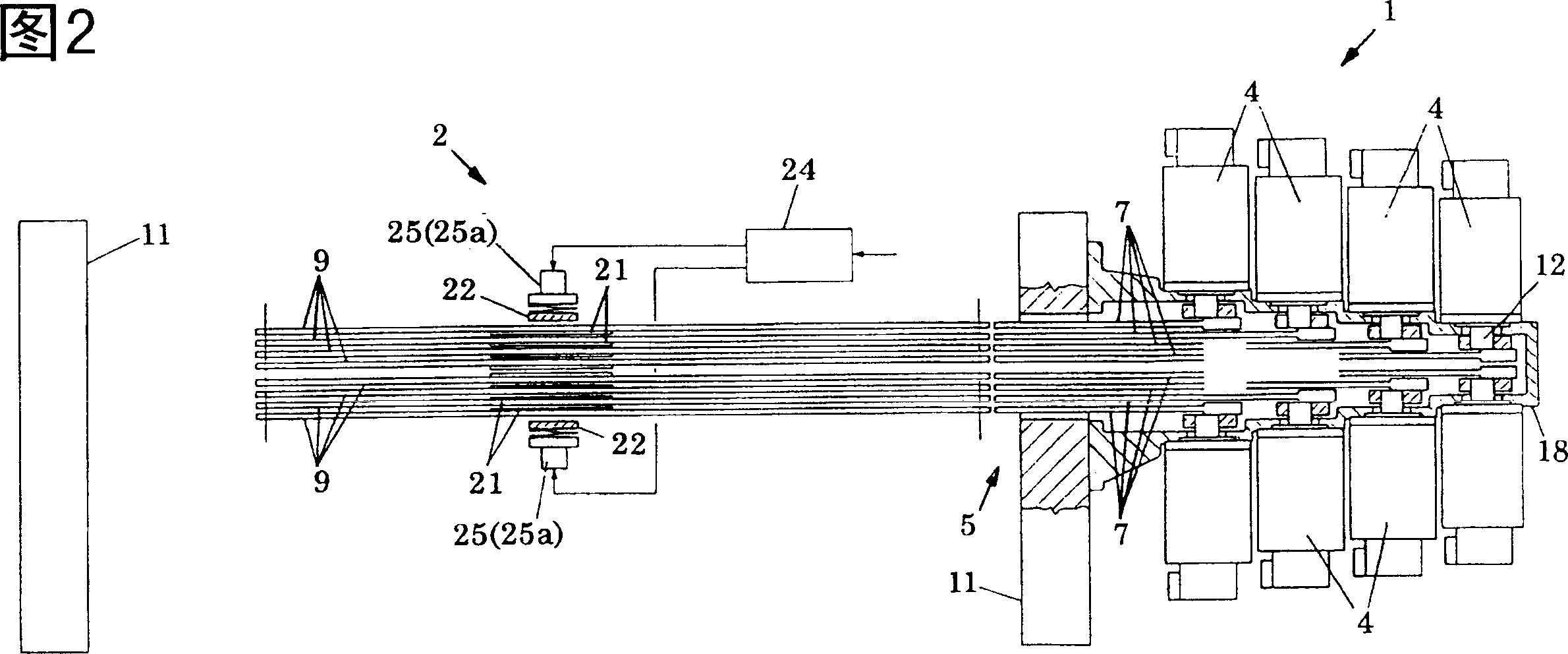

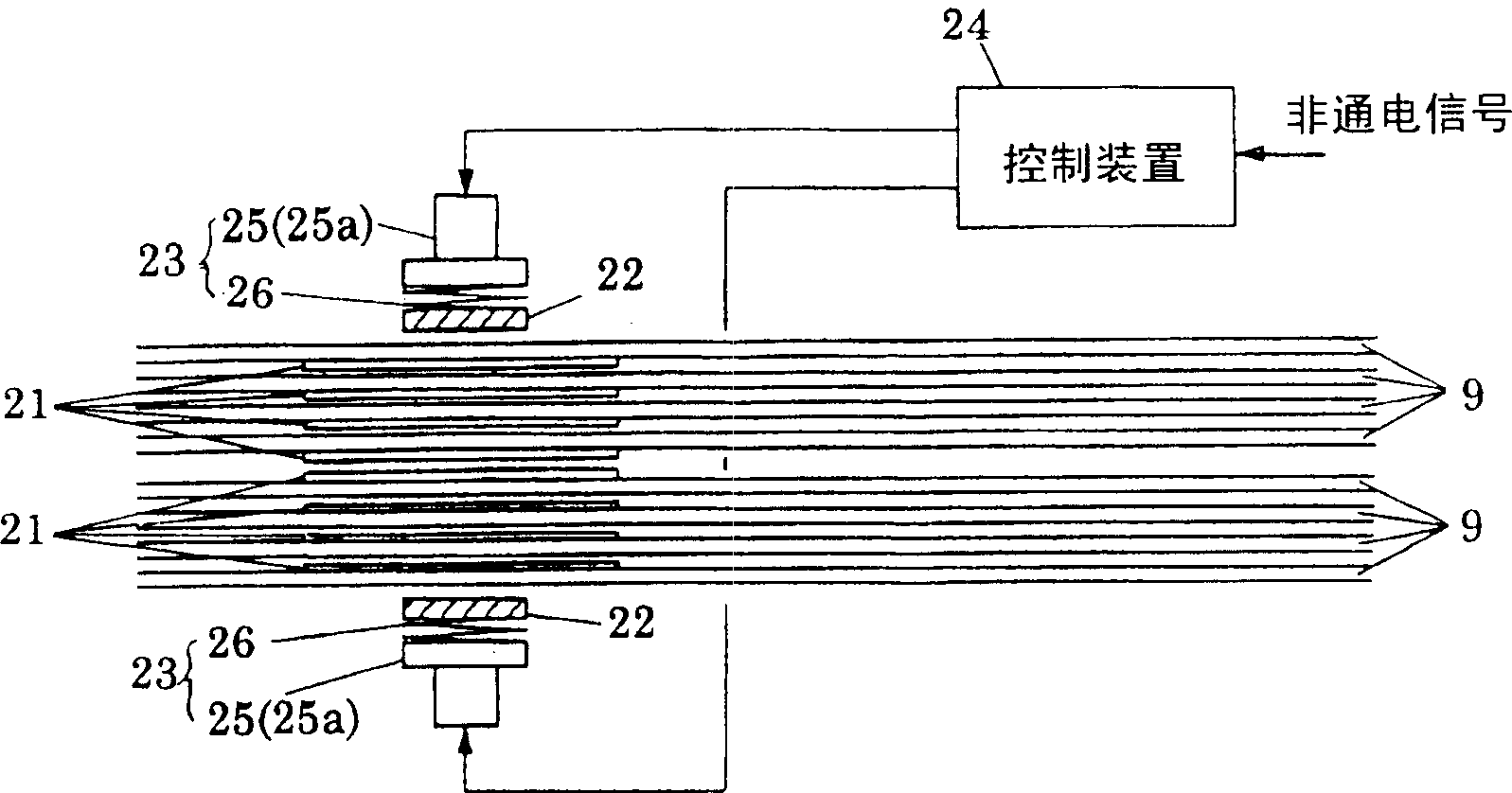

[0036] Figure 1 to Figure 3 It shows the state where the brake device 2 of the electric opening device according to the present invention is assembled to the electric opening device 1 . In the electric shedding device 1 , a plurality of, for example, 16 heald frames 3 are driven by respective drive motors 4 and shedding motion systems 5 to perform shedding motion. The shedding motion system 5 converts the rotary motion of the driving motor 4 into a reciprocating linear motion along the shedding direction, so as to transmit it to the corresponding heald frame 3, which consists of an eccentric shaft 6, a swing rod 7, a pair of driving levers 8, a connecting member 9, The driving rod 10 and the like are constituted.

[0037] 8 drive motors 4 are arranged on the outside of one of the loom frames 11 in a pair of loom frames 11 in a group of 8 by means of brackets 18, and the eccentric shafts 6 of each output shaft 12 , swing bar 7, connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com