A Cableway Hydraulic Driving System Using Accumulator to Regulate Pressure

A drive system and accumulator technology, applied to fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve problems such as many fault points and maintenance points, increased equipment maintenance difficulty, and increased costs. Achieve the effect of stable and reliable system control, complete safety protection and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

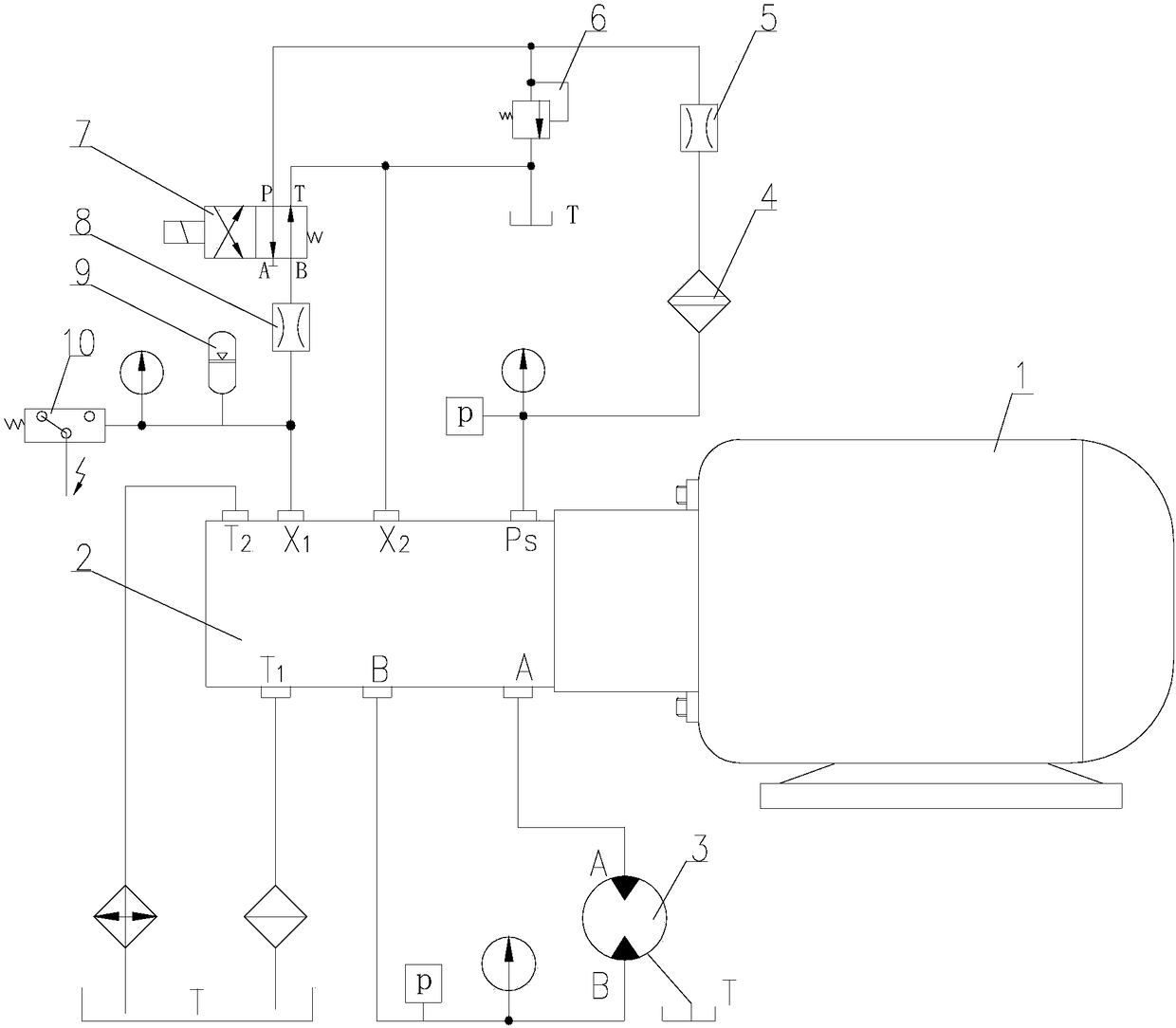

[0010] like figure 1 As shown, a cableway hydraulic drive system adopting accumulator speed regulation is composed of motor 1, variable oil pump 2, motor 3 and hydraulic drive system. It is connected with oil ports A and B of the motor 3, and it is characterized in that: the hydraulic drive system includes a variable oil pump 2, and the supplementary pump port PS in the variable oil pump 2 is connected with the filter 4, and the filter 4 is connected with the orifice of the pressure limiting valve group 5 connected, the orifice 5 of the pressure limiting valve group is respectively connected with the P port of the pressure limiting valve group 6 and the electromagnetic reversing valve 7, the outlet of the pressure limiting valve group 6, the T port of the electromagnetic reversing valve 7, and the pilot of the variable oil pump 2 The control port X2 is connected with the oil tank T, and the B port of the electromagnetic reversing valve 7 is respectively connected with the accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com