A lead frame feeding and conveying device

A technology of lead frame and conveying device, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve the problem of inability to ensure that the lead frame can be accurately moved to the next station, poor stability and accuracy of lead frame transportation, and inconvenience Problems such as installation and commissioning of the device, to prevent deviating from the track, improve adsorption stability, and prevent slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

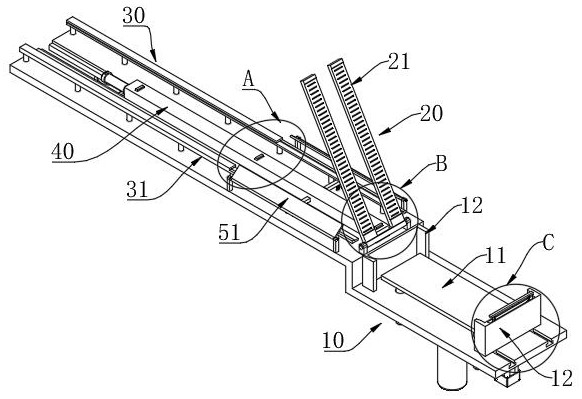

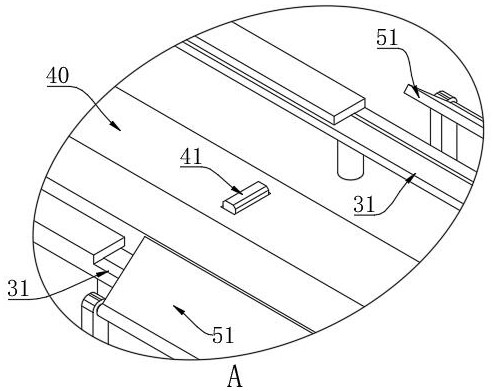

[0047] Such as figure 1 As shown, a lead frame feeding and conveying device includes: a storage mechanism 10 , a turning suction cup 20 and a conveying mechanism 30 arranged in sequence.

[0048] Specifically, the storage mechanism 10 is provided with a lifting plate 11, and the top surface of the lifting plate 11 is used for stacking and storing lead frames, and the pins of the lead frames face downward when stacked. The lifting plate 11 is moved vertically, and the lifting plate is driven by a linear servo motor, so that the lifting distance can be controlled more accurately.

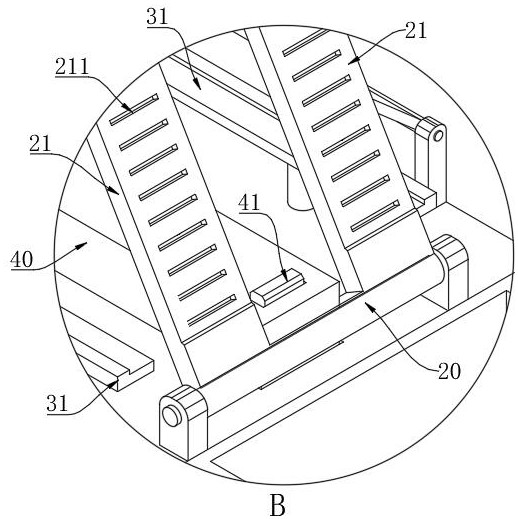

[0049] Specifically, the rear end of the flip suction cup 20 is provided with a rotating shaft, the rotating shaft is located between the storage mechanism 10 and the conveying mechanism 30, the rotating shaft is perpendicular to the line between the storing mechanism 10 and the conveying mechanism 30, and is parallel to the lifting plate 11, Turn over suction cup 20 and turn its rotating shaft to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com