A control tool that carries the operating carrier to move axially and circumferentially relative to the operating base

A circumferential motion and matrix technology, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problems of low construction efficiency, single motion function of machines and high installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

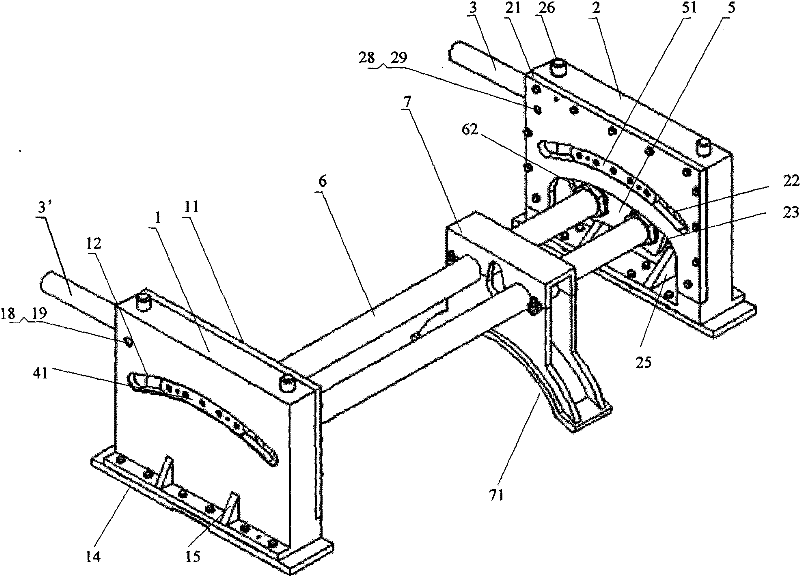

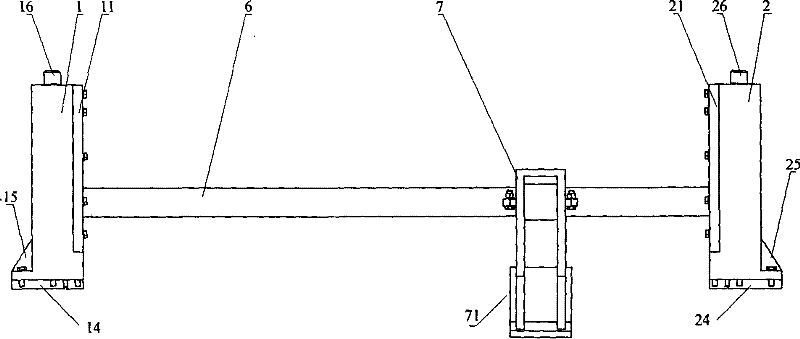

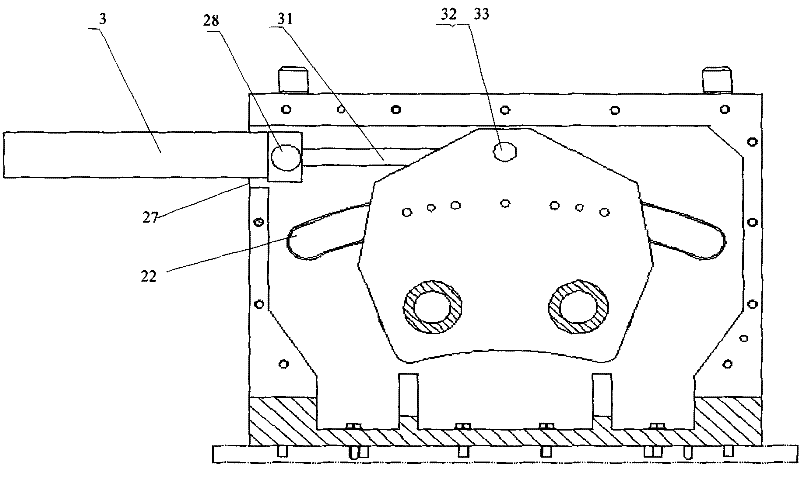

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 5A As shown, the present invention carries the control tool for the axial and circumferential movement of the working carrier relative to the working base, which includes an outer frame and an inner frame; the outer frame is connected to the outer receiving base, which includes a left box 1 and a right box 2 ; The left box 1 is provided with a convex keyway 12 and is screwed to the box cover 11, the box cover 11 is provided with a convex keyway and a guide rail opening, and the right box 2 is provided with a convex keyway and is screwed to the box cover 21. The box cover 21 is provided with a convex keyway 22 and a guide rail opening 23, and the side wall of the left box 1 is provided with a hydraulic cylinder, and the side wall of the right box 2 is also provided with a hydraulic cylinder 3; the inner frame includes a left-handed Rotating body, right rotating body 5 and guide rail 6 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com