Spinning machine with suction apparatus and method for controlling suction apparatus of spinning machine

A suction device, a technology for textile machines, applied in spinning machines, textiles and papermaking, transportation and packaging, etc., can solve problems such as large share, achieve low energy consumption, optimize suction effect, and reliable suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

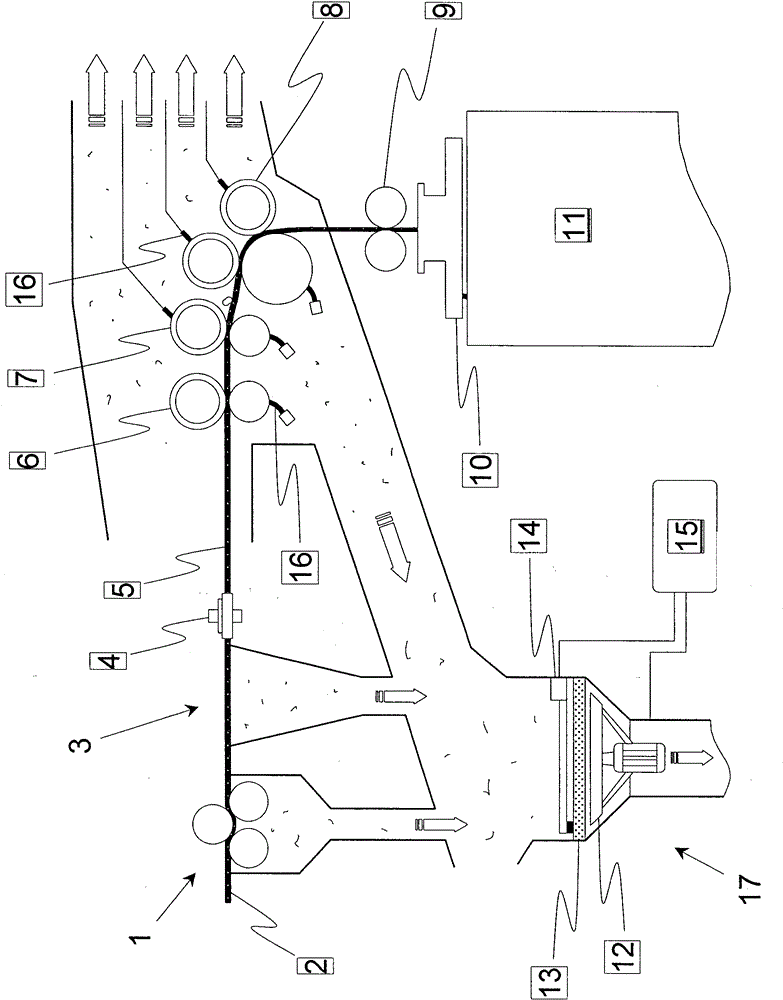

[0049] exist figure 1 The textile machine in the form of a mill according to the invention shown in has in principle an entry area with a corresponding single-stand rolling mill 1 from which a plurality of fibers to be stretched is withdrawn from the (not shown) tank bundle 2. The parallel fiber bundles are then introduced across the corresponding feed table 3 with suction gaps running perpendicularly to the plane of the sheet and finally brought together to form a fiber strand 5 by a first pair of rollers 4, wherein this pair of rollers 4 is also used at the same time. as a measuring device to detect possible thickness fluctuations of the fiber bundle 2 and to take care of the subsequent delay through the roller compactor.

[0050] The calender itself also has an entry roll pair 6 , an intermediate roll pair 7 and an exit or feed roll arrangement 8 , which rotate at successively increasing peripheral speeds in that order. In the calender, the fiber strands 5 are processed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com