Control device of a transmission, especially for vehicles

A technology for motor vehicles and gearboxes, applied in the field of gearboxes, can solve problems such as long response time and irreversibility, and achieve the effect of reducing friction and the risk of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

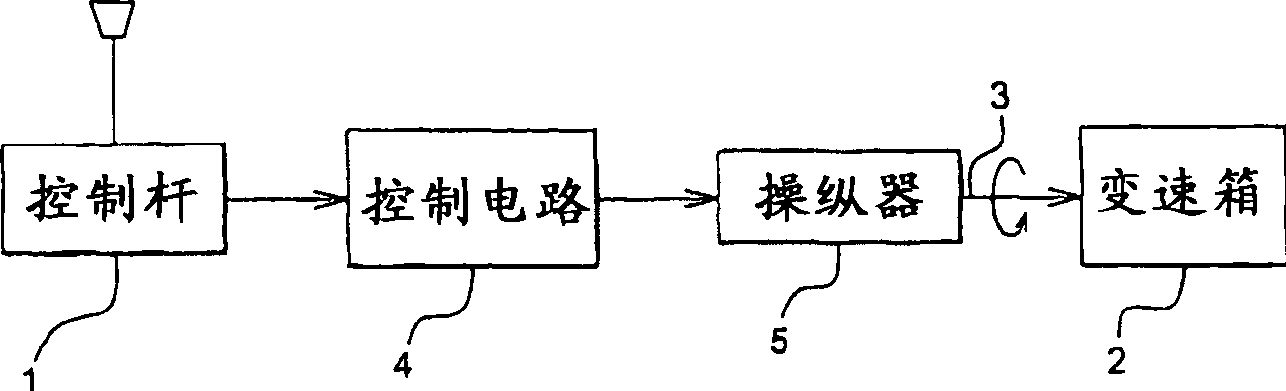

[0030] exist figure 1 In , reference 1 denotes a gear selection device, in particular a lever for turning a shift shaft 3 of an automatic gearbox of a motor vehicle, for example.

[0031] The selector lever 1 is operated by the driver of the vehicle and it moves in a channel having a plurality of predetermined positions, for example of the P-R-N-D type, the selector lever being in any one of those positions for operating the switch to issue an output signal which is transmitted to the control Circuit 4.

[0032] The control circuit 4 generates a control signal for a manipulator 5 which turns the shift shaft 3 in one direction or the other so as to bring it into a predetermined position corresponding to the position of the lever 1 .

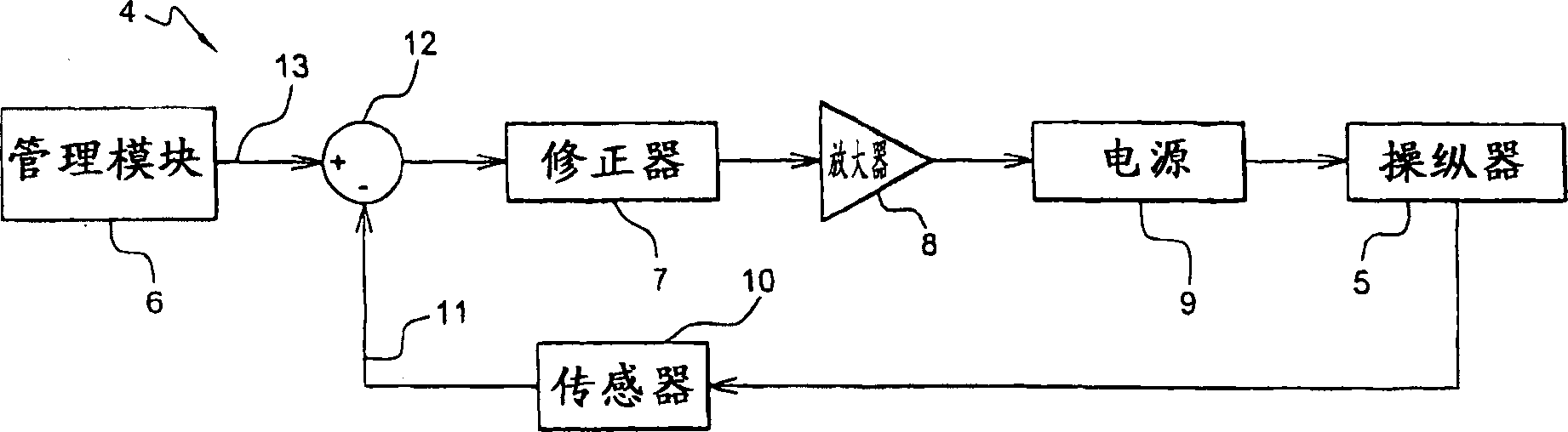

[0033] control circuit 4 in figure 2 As shown in more detail in , the control circuit 4 includes a management module 6 which is controlled by the vehicle computer and generates a reference signal which is applied via a modifier 7 and an amplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com