Textile machine having a moveable service unit

A technology for service components and textile machines, applied in spinning machines, textiles and papermaking, thin material processing, etc., can solve the problems of inaccurate positioning and ineffectiveness, and achieve the effect of improving reliability, simple and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

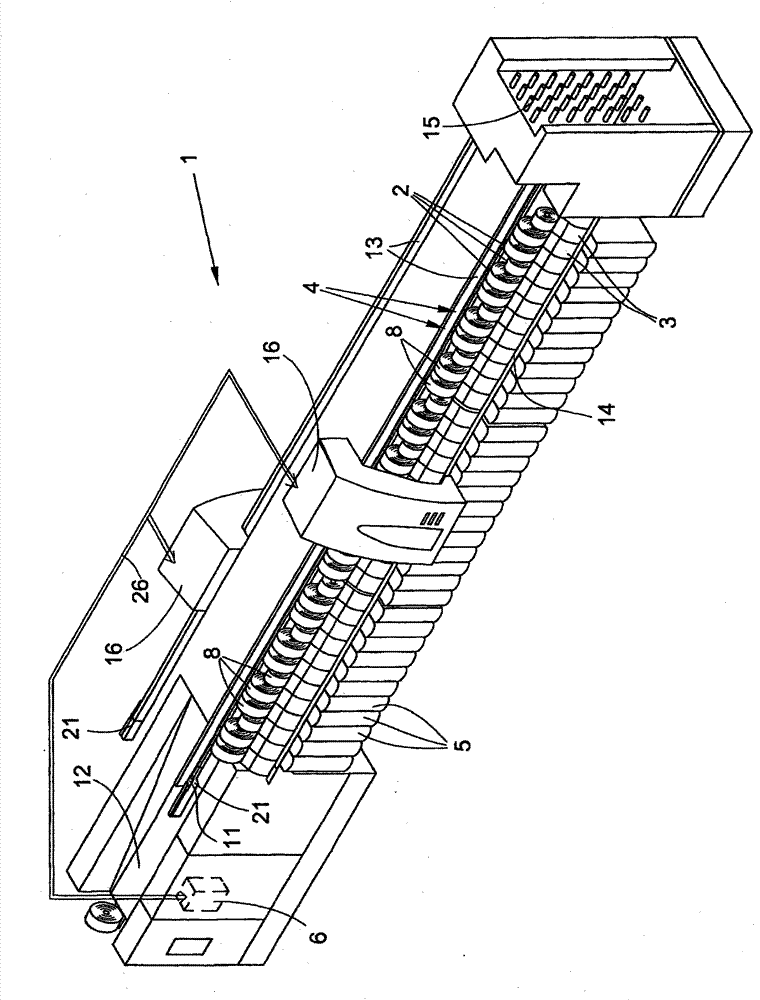

[0035] figure 1 An open-end spinning machine 1 is shown having a plurality of stations 2 each equipped with an open-end spinning device 3 and a winding mechanism 4 . The open-end spinning machine 1 also has two identical service assemblies 16 .

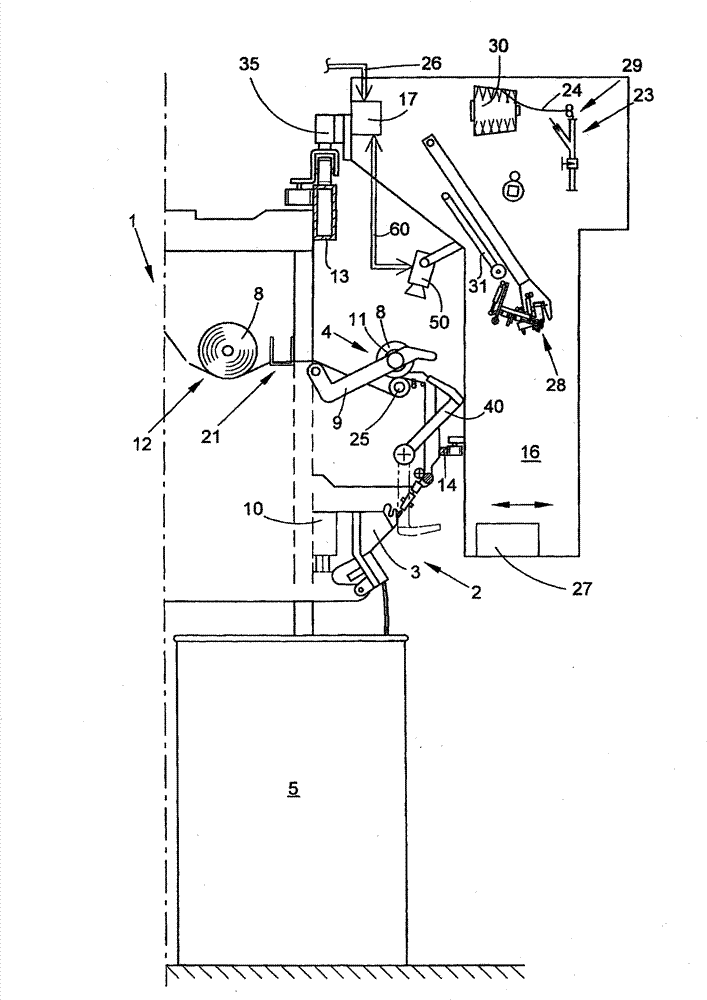

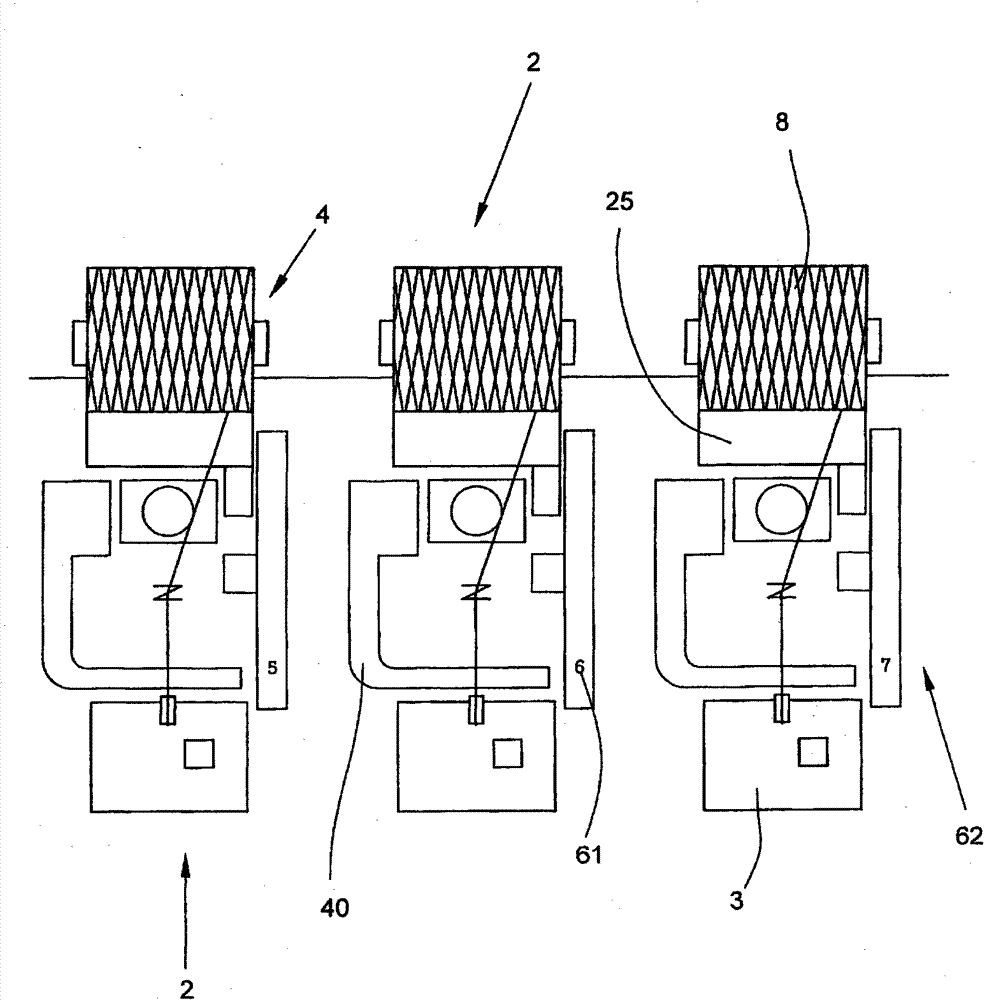

[0036] In the spinning device 3 , the fiber strip fed in the spinning pot 5 is spun into a yarn which is wound up on the winder 4 to form a cross-wound bobbin 8 . like figure 2 As shown, the winding mechanism 4 is equipped with a creel 9 to rotatably hold an empty bobbin 11 or a cross-wound bobbin 8, and a winding drum 25 to rotate these elements. The open-end spinning machine 1 also has a central control unit 6 which is connected via a bus system 26 to a station-specific control mechanism 10 . Furthermore, a textile machine 1 of this type has an empty bobbin feeder, which essentially consists of an empty bobbin cassette 15 and a bobbin transport 12 for the processed cross-wound bobbins 8 . The pipe supply path 21 is composed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com