Vertical force control method of magnetic flux reverse permanent-magnet linear motor

A permanent magnet linear motor, magnetic flux reversal technology, applied in electronic commutation motor control, motor generator control, AC motor control and other directions, can solve problems such as reducing work efficiency and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

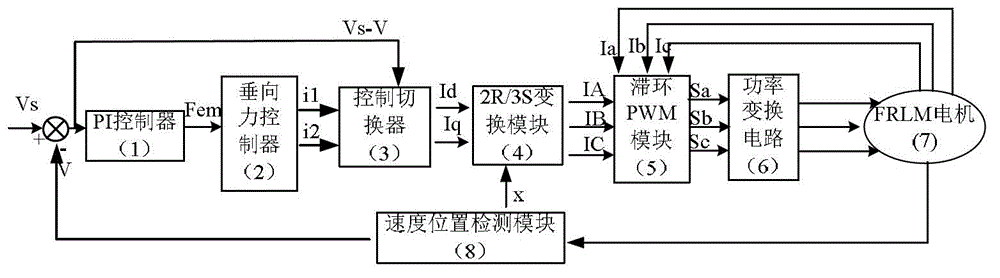

[0030] The present invention will be further explained below according to the accompanying drawings and specific embodiments of the specification.

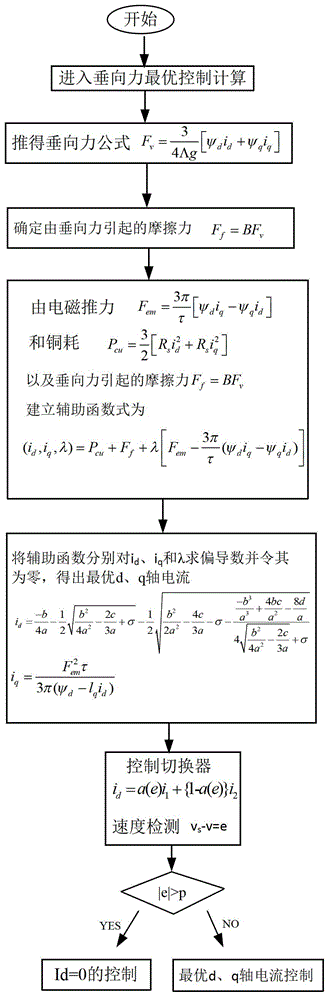

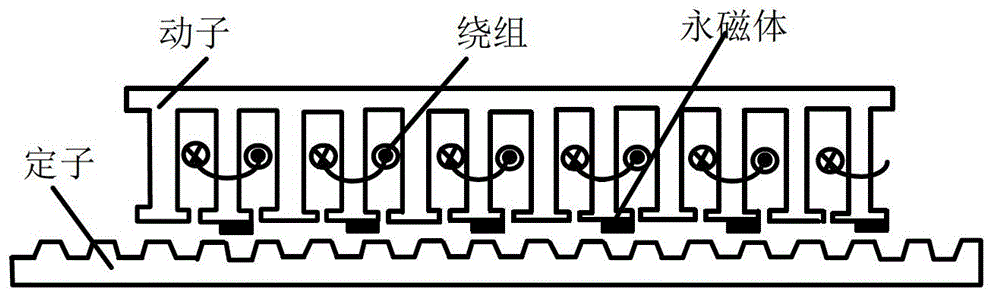

[0031] Such as figure 1 As shown, a vertical force control method of a magnetic flux reversal permanent magnet linear motor, the steps include:

[0032] 1) Use the method of integrating the surface of Maxwell's electromagnetic force tensor to obtain the electromagnetic force in the Z direction of the linear motor, that is, the vertical force

[0033] F zi = L i μ 0 4 ∫ 0 D Re [ H z H z * - H x H z * ] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com