Control method of alumina production

A production control method and alumina technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as DCS control systems that have not yet seen alumina, achieve simple and reliable control and maintenance, and achieve centralized Monitoring, improving efficiency and effectiveness of capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

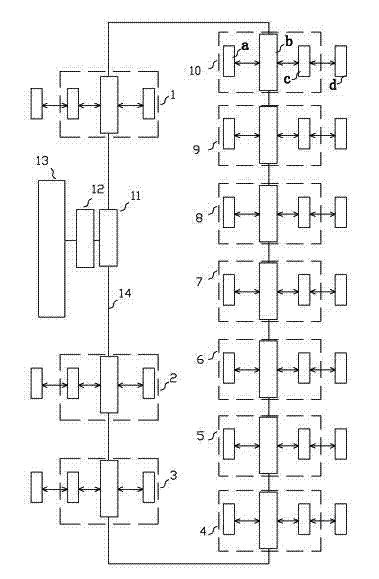

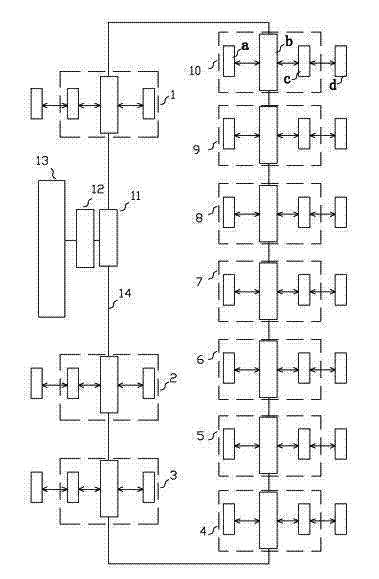

[0012] Such as figure 1 As shown, the method of the present invention adopts a decentralized control system to centrally control the production process of each workshop, and the decentralized control system includes an information control center 13 and a central control room of each workshop, wherein the central control room of each workshop includes a central control room 4 of a raw material crushing workshop, Central control room 5 of raw material grinding workshop, central control room 6 of slurry blending workshop, central control room 7 of clinker firing workshop, central control room 8 of clinker dissolution workshop, central control room 9 of red mud sedimentation desiliconization workshop, central control room 10 of variety decomposition and filtration workshop, Central control room 3 of the evaporation workshop, central control room 2 of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com