Rock tensile-shearing test system

A technology of tensile shear and test system, applied in the field of test system, can solve the problems of tensile shear damage, complex equipment, lack of experimental data, etc., and achieve the effect of perfecting and improving the strength criterion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

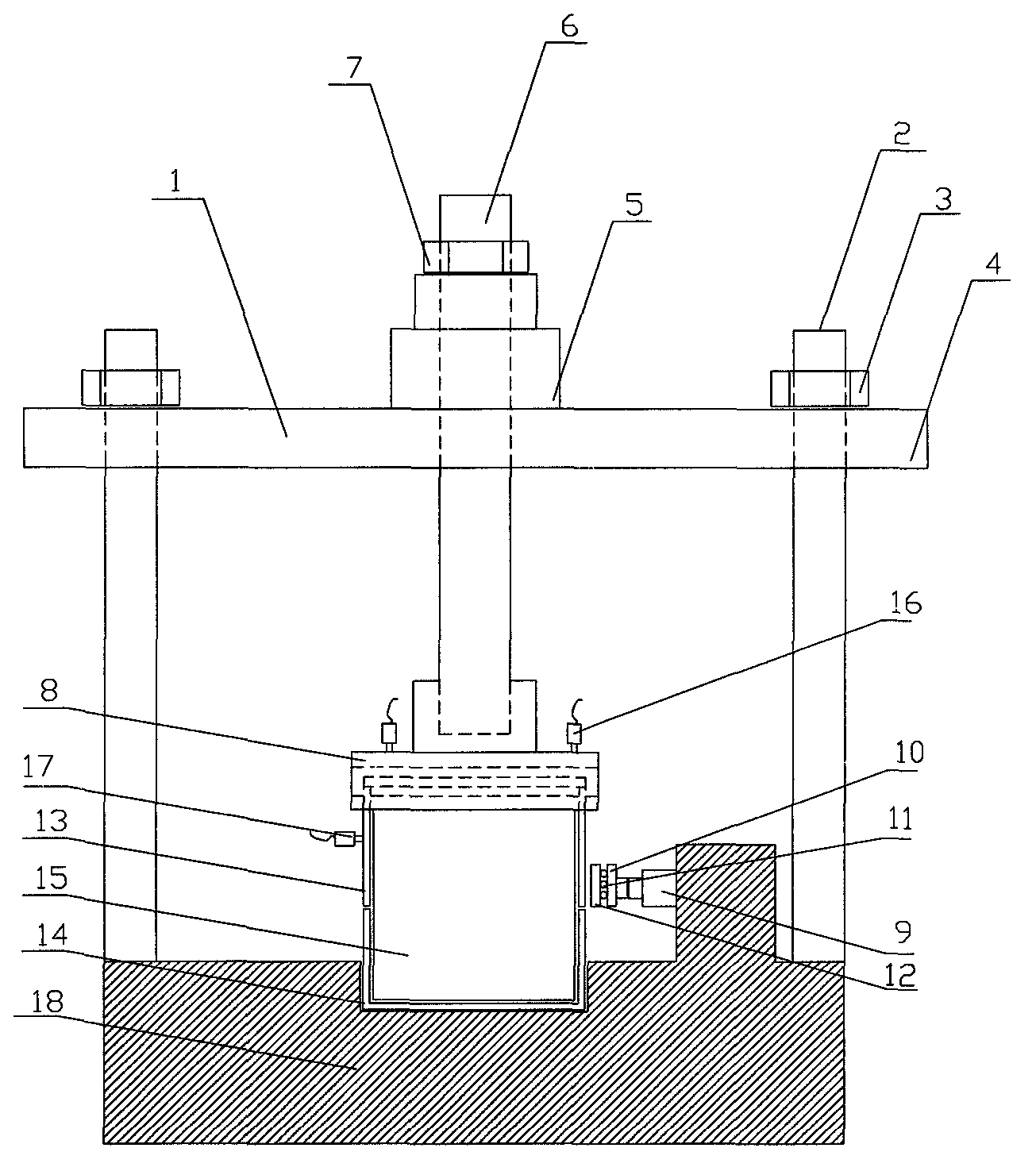

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] see Attachment

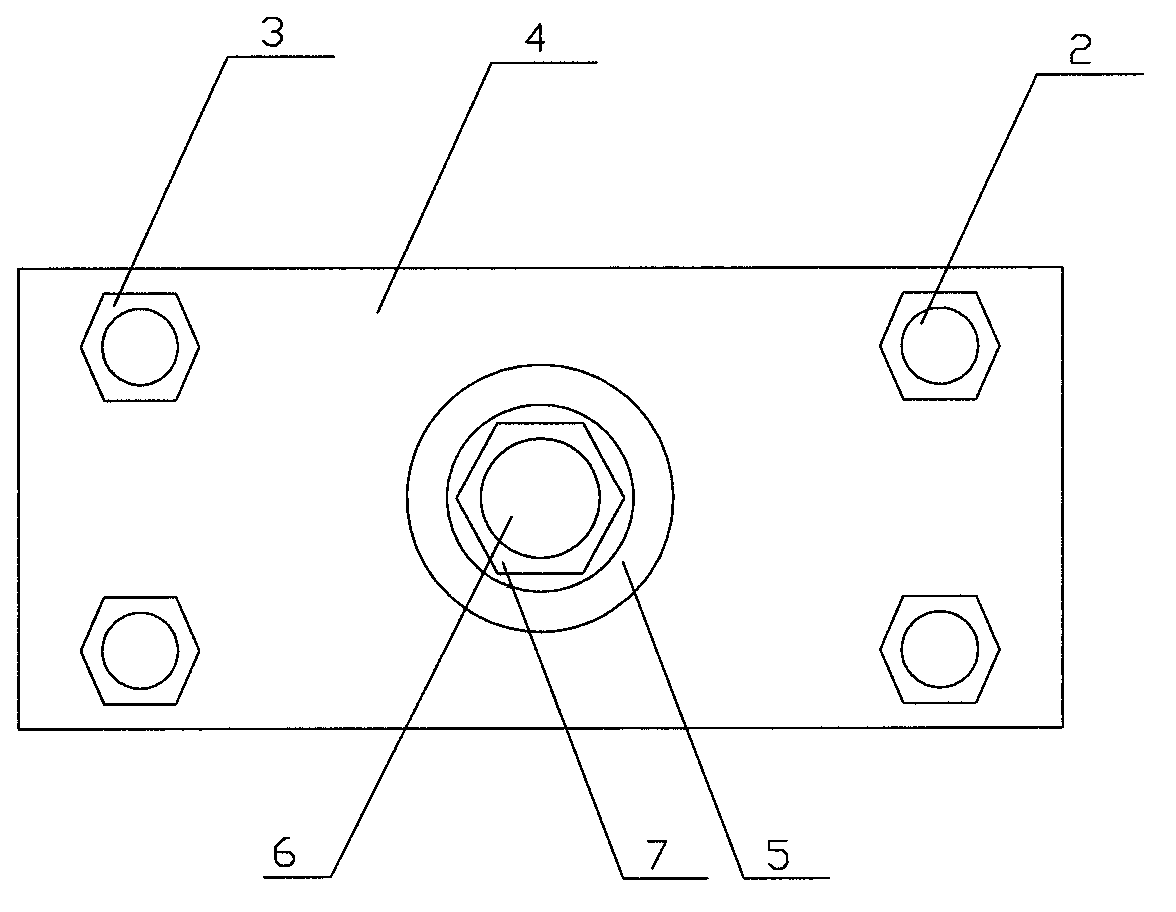

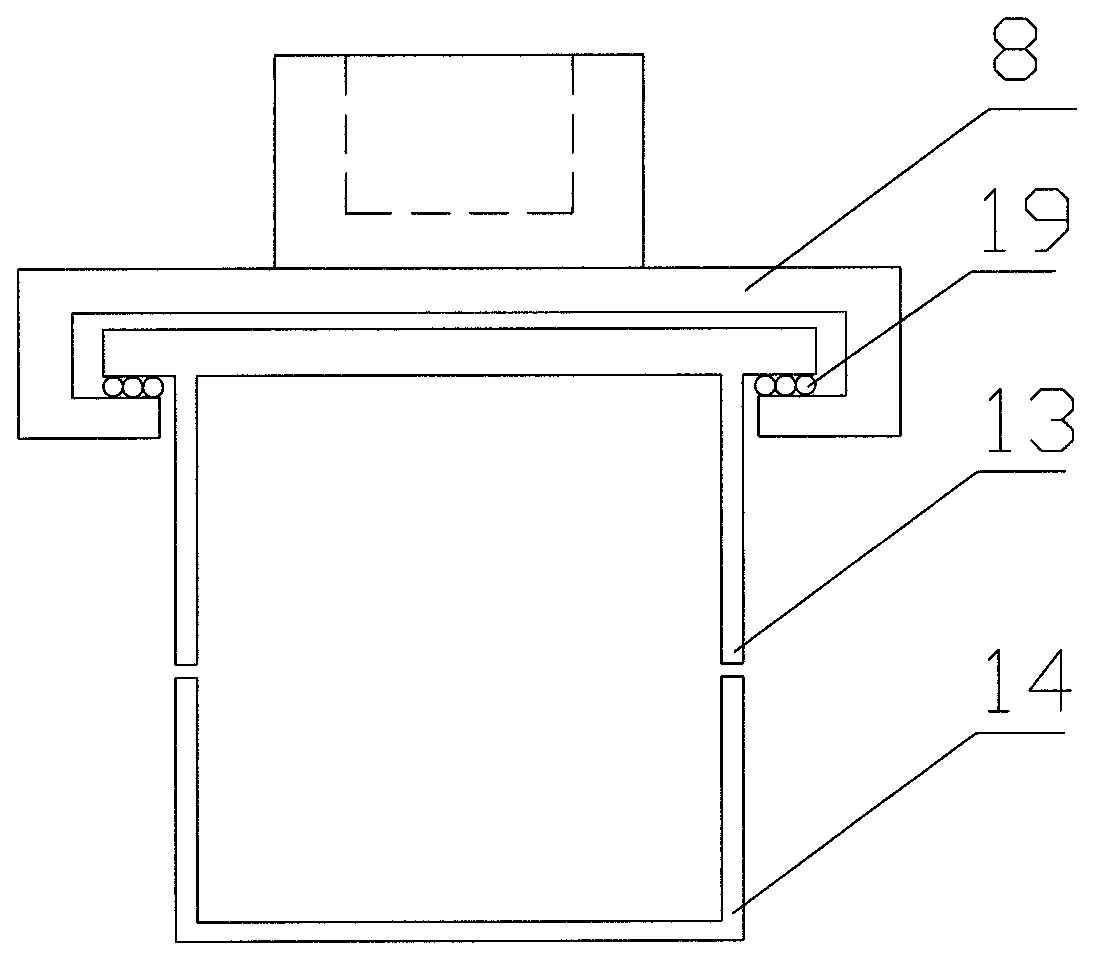

[0017] Rock tensile-shear test system, the test system is composed of a reaction force device 1, a vertical loading system, a horizontal loading system, an upper shear box 13, a lower shear box 14, a measurement system, a hydraulic control system and a base 18. The reaction device 1 described above is composed of four steel beams 2, nuts 3 and bearing plates 4, the bearing plate 4 is fixedly connected to the upper ends of the four steel beams 2 through the nuts 3, and the lower ends of the four steel beams 2 are fixedly connected to each other. in the base 18;

[0018] The vertical loading system is composed of a hollow hydraulic jack 5, a tension column 6, a locking nut 7, and a tension plate 8. The hollow hydraulic jack 5 is located above the bearing plate 4, and the tension column 6 moves through the bearing plate 4. The upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com