Split type pier column anti-impact structure and installation method

An installation method and split-type technology, applied to road safety devices, roads, roads, etc., can solve the problems of occupying too many road resources, inconvenient installation, and high price, so as to reduce traffic jams, improve reliability, and reduce injuries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

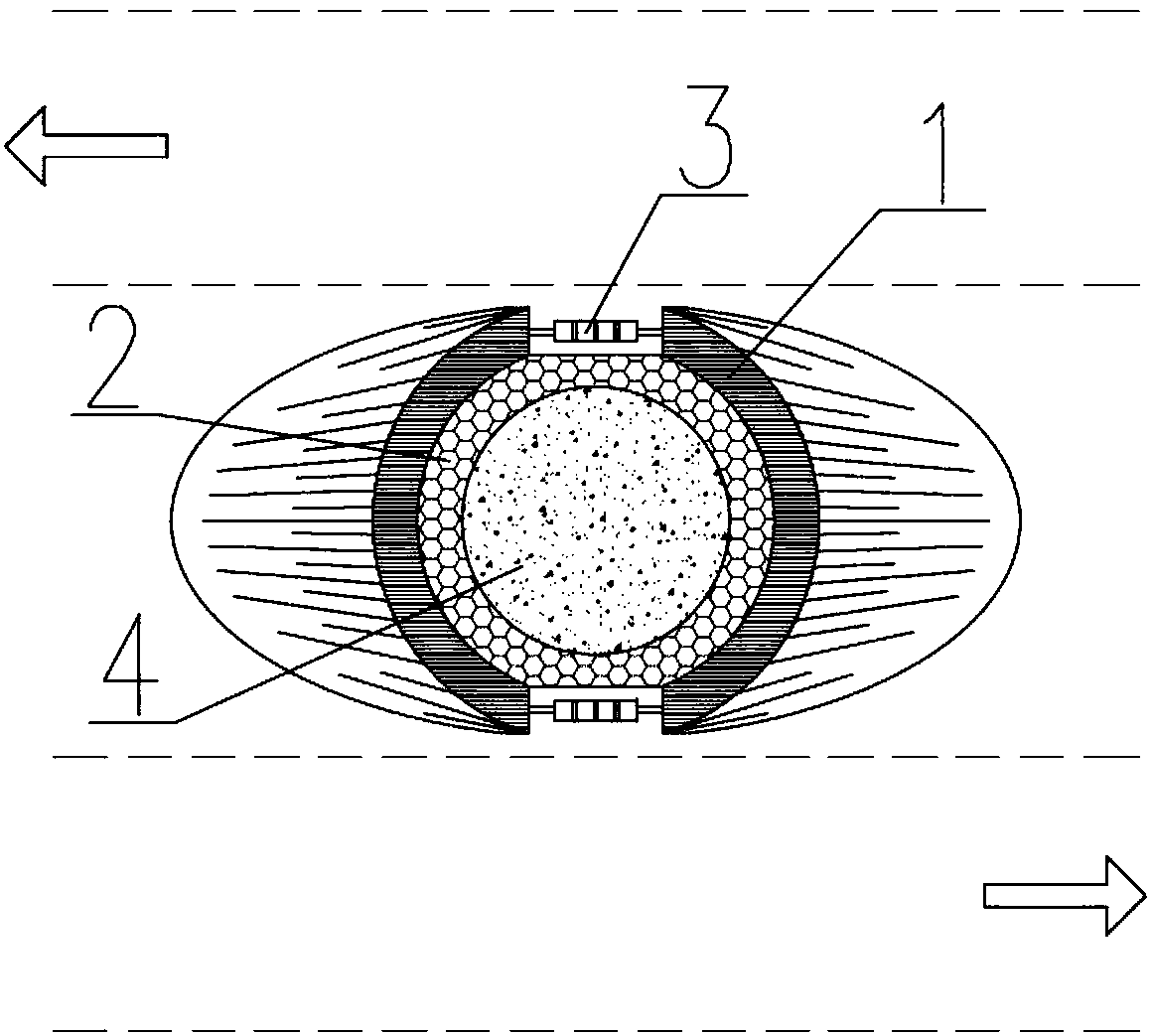

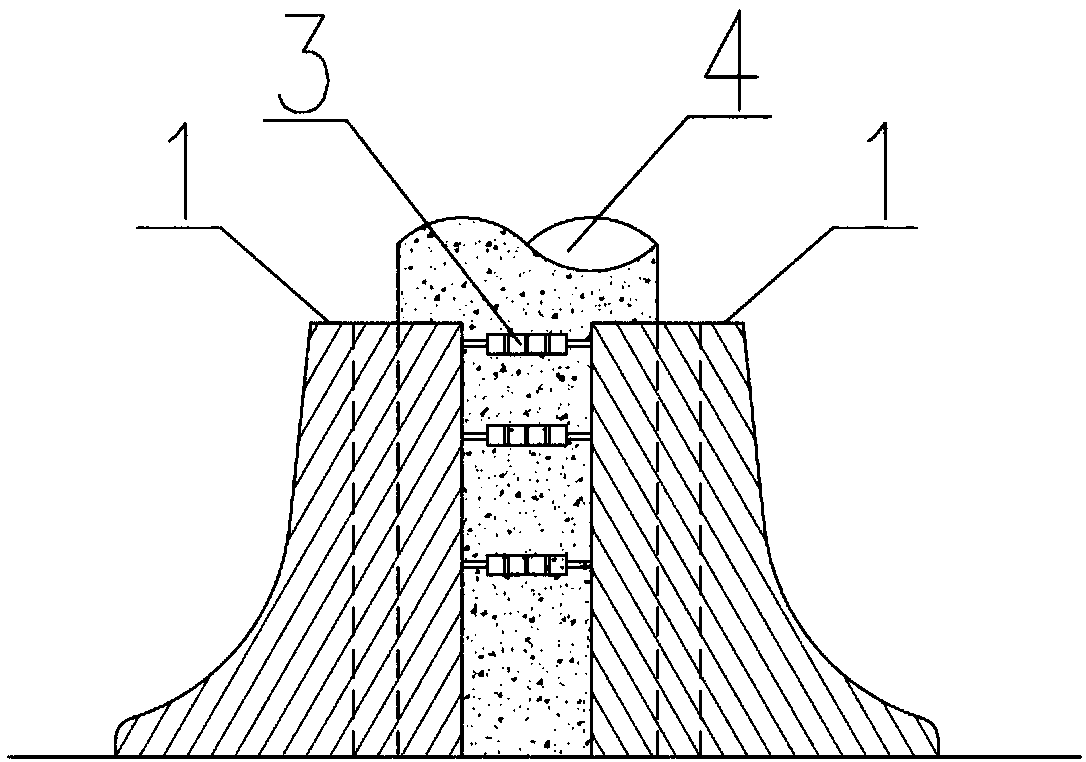

[0027] Such as Figure 1-2 As shown, this embodiment provides a split pier anti-collision structure, including two anti-collision structural boots 1 symmetrically arranged on the outside of the pier column, the two anti-collision structural boots 1 are separately arranged, and the anti-collision structural boots 1 pass through several A speed-locking damper 3 is connected, and a buffer layer 4 is filled between the anti-collision structural boot 1 and the pier column, and the cross-section of the anti-collision structural boot 1 increases sequentially from top to bottom. in, figure 1 The direction of the middle arrow is the driving direction on both sides of the pier.

[0028] In this specific embodiment, the piers are circular piers 4 . The arrangement density of the speed lock dampers 3 decreases sequentially from top to bottom, and the speed lock dampers 3 are arranged symmetrically with respect to the piers.

[0029] The anti-collision structural boots 1 are prefabricat...

Embodiment 2

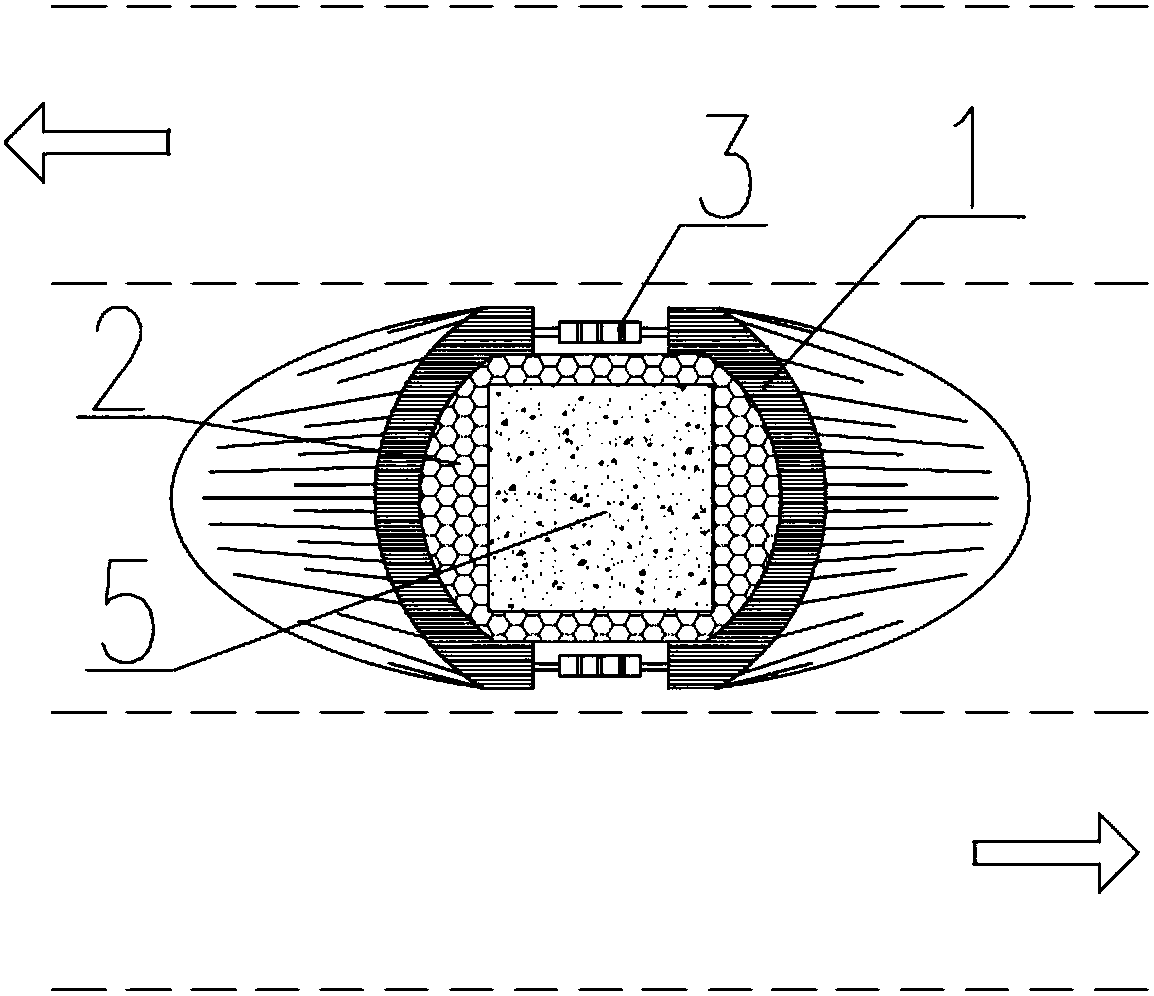

[0036] Such as Figure 3-4 As shown, the pier column in this embodiment is a rectangular pier column 5, and the other parts are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com