Organosilicone-epoxy-polyimide adhesive and preparation method thereof

A technology of polyimide and polyimide resin, which is applied in the field of silicone-epoxy-polyimide adhesive and its preparation, can solve problems such as energy consumption and copper foil oxidation reaction, and achieve environmental protection and source The effect of convenience and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

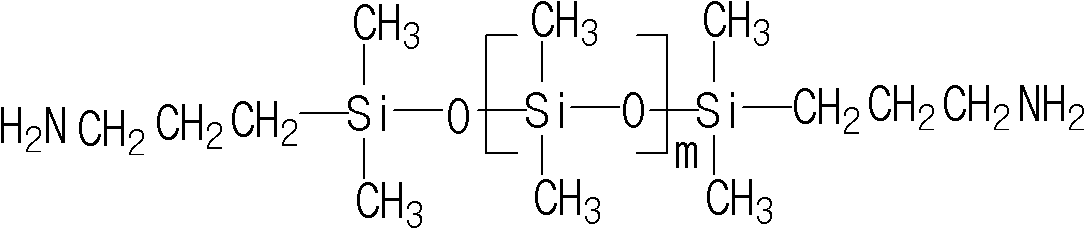

Method used

Image

Examples

Embodiment 1

[0026] 0.1 moles (15.2 grams) of 3,5-diaminobenzoic acid and 0.1 moles (41.0 grams) of 2,2-bis[4-(4-aminophenoxy)phenyl]propane were added to the reactor, and 800 N, N-dimethylacetamide solvent in milliliters, stirred at room temperature to dissolve into a homogeneous solution, added 0.22 moles (114.4 g) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl] Propane dianhydride, after stirring and reacting at room temperature, add 800 ml of toluene and 10.7 g of p-toluenesulfonic acid, heat and reflux for water separation for 10-15 hours, separate 800 ml of toluene, add 16000 ml of ethanol solvent, and precipitate a solid powder, filtered, and dried to obtain 159.2 grams of carboxyl-containing polyimide resin, designated as CPI-11.

Embodiment 2

[0028] 0.1 moles (15.2 grams) of 3,5-diaminobenzoic acid and 0.6 moles (246.0 grams) of 2,2-bis[4-(4-aminophenoxy)phenyl]propane were added to the reactor, and 10460 One milliliter of N, N-dimethylacetamide solvent, stirred and dissolved at room temperature to form a homogeneous solution, added 0.84 moles (436.8 grams) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl] Propane dianhydride, after the stirring reaction at room temperature is complete, add 10460 ml of toluene and 51.2 g of p-toluenesulfonic acid, heat and reflux for water separation for 10-15 hours, separate 10460 ml of toluene, add 209200 ml of ethanol solvent, and precipitate a solid powder, filtered, and dried to obtain 659.2 grams of carboxyl-containing polyimide resin, designated as CPI-16.

Embodiment 3

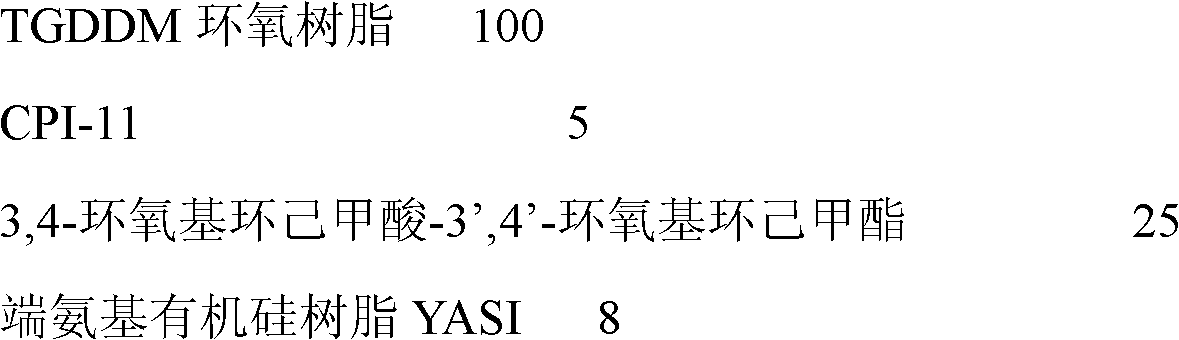

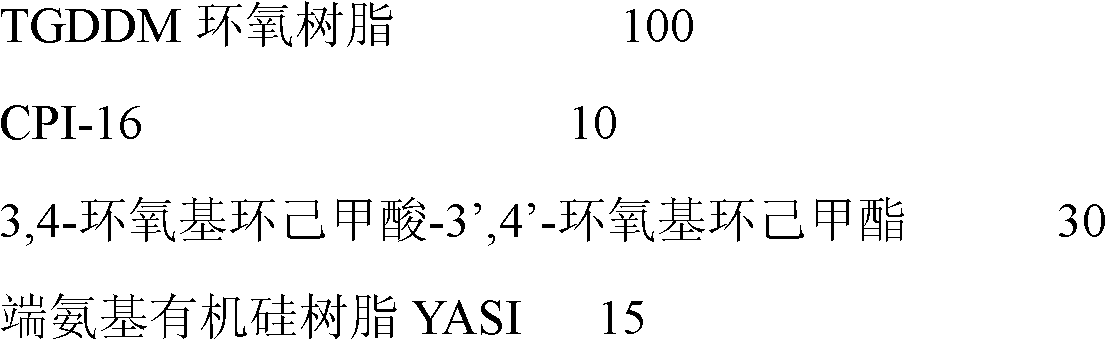

[0030] According to the mass 100 of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy resin (TGDDM):

[0031] A component:

[0032]

[0033] B component:

[0034] 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane 15

[0035] When ready to use, just mix the two components evenly. The curing process is as follows: start to heat up from room temperature to 100°C, keep for 1 hour, continue to heat up to 160°C, keep for 2 hours, and naturally cool to room temperature. The performance test is shown in Table 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com