Intermediate frequency spot welding method for aluminum alloy and zinc-plated high-strength steel dissimilar material

A technology of dissimilar materials and aluminum alloys, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problem of high cost, achieve the effects of low cost, control growth behavior, prevent adhesion and alloying reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

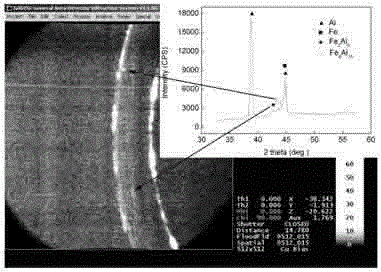

Embodiment 1

[0049] The chemical composition of the galvanized high-strength steel plate to be welded is (wt.%): C0.01%, Si0.09%, Mn0.51%, S0.01%, P0.05%, Nb0.02%, Ti0.01% , Fe balance; the galvanizing process adopts double-sided hot-dip galvanizing, and the thickness of the galvanized layer is 8 μm; the main phase structure is α-Fe, the yield strength is 260MPa, the tensile strength is 410MPa, and the elongation is 32%; galvanized high-strength The steel plate is processed into 100mm×25mm×1mm by wire cutting. The chemical composition of the aluminum alloy plate to be welded is (wt.%): Mg0.45%, Si0.56%, Cu0.15%, Mn0.45%, Zn0.01%, Fe0.19%, V0.08%, Ti0.02%, Al balance; the initial supply state is T6 state; the main phase structure is α-Al, the yield strength is 270MPa, the tensile strength is 310MPa, and the elongation is 15%; the aluminum alloy plate is processed by wire cutting 100mm×25mm×1.5mm. The intermediate frequency spot welding method of the present invention is used for welding, ...

Embodiment 2

[0052] The material and workpiece size of the galvanized high-strength steel plate and the aluminum alloy plate to be welded are the same as those in Example 1. The intermediate frequency spot welding method of the present invention is used for welding, wherein the spot welding electrode material is CuCr alloy, the aluminum alloy side electrode is a spherical electrode with a diameter of 70 mm, and the galvanized high-strength steel side electrode is a flat end electrode with a diameter of 12 mm. The roughness Ra values are all 0.8 μm. The medium frequency spot welding process parameters are selected as follows: the spot welding current is 24kA, the welding time is 0.35s, the electrode pressure is 3.5kN, the preloading time is 0.4s, and the holding time is 0.4s.

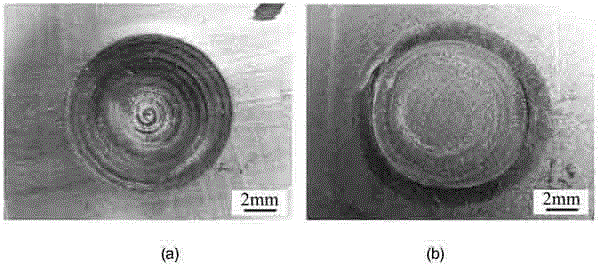

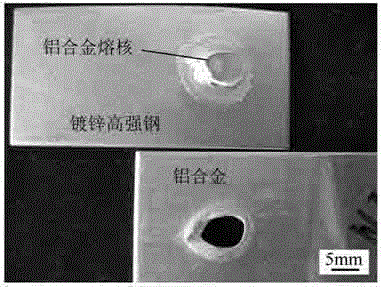

[0053] The test results show that the surface of the intermediate frequency spot welding joint of aluminum alloy / galvanized high-strength steel dissimilar materials is well formed (such as Figure 8 As shown), the...

Embodiment 3

[0055] The material and workpiece size of the galvanized high-strength steel plate and the aluminum alloy plate to be welded are the same as those in Example 1. The intermediate frequency spot welding method of the present invention is used for welding, wherein the spot welding electrode material is CuCr alloy, the aluminum alloy side electrode is a spherical electrode with a diameter of 100 mm, and the galvanized high-strength steel side electrode is a flat end electrode with a diameter of 10 mm. The roughness Ra values are all 0.8 μm. The medium frequency spot welding process parameters are selected as follows: the spot welding current is 25kA, the welding time is 0.4s, the electrode pressure is 4kN, the preloading time is 0.4s, and the holding time is 0.4s.

[0056] The test results show that the surface of the intermediate frequency spot welding joint of aluminum alloy / galvanized high-strength steel dissimilar materials is well formed (such as Figure 11 As shown), the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com