Bi-component acrylic ester adhesive

An acrylic and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of easy flow, unsuitable for bonding, low viscosity, etc., and achieve convenient sizing, good thixotropic performance, and comprehensive The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the selected components and contents of component A in Table 1, put methyl methacrylate, methacrylic acid and organoboron moisturizing soil into the reaction kettle, stir at room temperature for 1-10 hours to make it evenly dispersed, and then add chlorine Sulfonated polyethylene, ABS and hydroquinone, stir for 24 to 48 hours to dissolve completely, and finally put in cumene hydrogen peroxide, stir for 1 to 10 hours to make it evenly dispersed, then the A component can be prepared , The prepared component A is sealed and packaged separately.

[0026] According to the selected components and content of component B in Table 1, put methyl methacrylate, methacrylic acid and organoboron moisturizing soil into the reaction kettle, fully stir for 1-10 hours to make it evenly dispersed, and then add chlorine Sulfonated polyethylene, ABS and substituted thiourea are stirred for 24 to 48 hours to dissolve completely. Then the B component can be prepared, and the prepared...

Embodiment 2

[0032] Repeat the preparation method of Example 1 to prepare the required A and B components according to the selected components and contents of the A and B components in Table 2 below. However, the selection of elastomers, thixotropic agents, accelerators and stabilizers is different. Nitrile rubber is used instead of chlorosulfonated polyethylene, gas-phase white carbon black is used instead of organic boron soil, and aldehyde amine condensate is used instead of thiourea. The stabilizer is a mixture of 2,6-di-tert-butyl-4-methylphenol and hydroquinone.

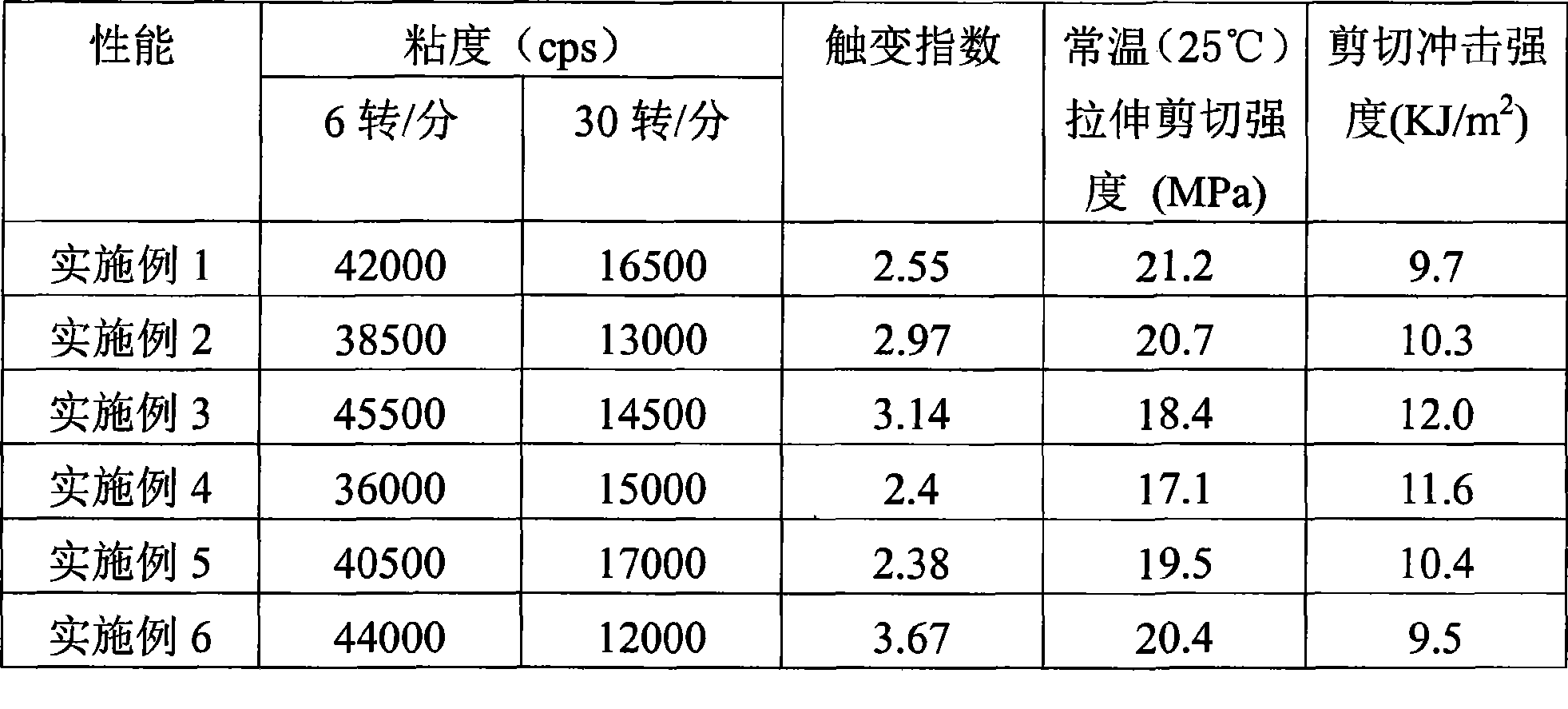

[0033] The performance test data of the prepared two-component acrylate adhesive is shown in Table 7

[0034] Table 2

[0035] Ratio A component %wt B component %wt Methyl methacrylate 58.9 55.4 Methacrylate 12.5 9.2 ABS 5 10 Nitrile rubber 15 18.4 Fumed white carbon black 3 2 Aldamine Condensate 5 2,6-Di-tert-butyl-4-methylphenol 1.5 Quinol 0.1 Cumene...

Embodiment 3

[0037] Repeat the preparation method of Example 1 to prepare the required A and B components according to the selected components and contents of the A and B components in Table 3 below. However, the selection of monomers, elastomers, thixotropic agents, stabilizers and peroxides are different. The monomer uses a mixture of methyl methacrylate and hydroxypropyl methacrylate, and nitrile rubber is used instead of chlorosulfonated polycarbonate. Ethylene, hydrogenated castor oil instead of organoboronite, the stabilizer is a mixture of 2,6-di-tert-butyl-4-methylphenol and hydroquinone, and tert-butyl hydroperoxide is used instead of cumene hydroperoxide.

[0038] The performance test data of the prepared two-component acrylate adhesive is shown in Table 7

[0039] table 3

[0040] Ratio A component %wt B component %wt Methyl methacrylate 48.4 51.3 Hydroxypropyl methacrylate 12.1 17.1 Methacrylate 6 4 ABS 12 8.1 Nitrile rubber 13.8 15....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com