Tensile-shear compressive-shear complex loading tester

A test device and composite loading technology, applied in the direction of measuring device, machine/structural component testing, instruments, etc., can solve the problems of high manufacturing cost, high equipment price, and high test cost, and achieve low manufacturing cost, compact structure, and easy use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

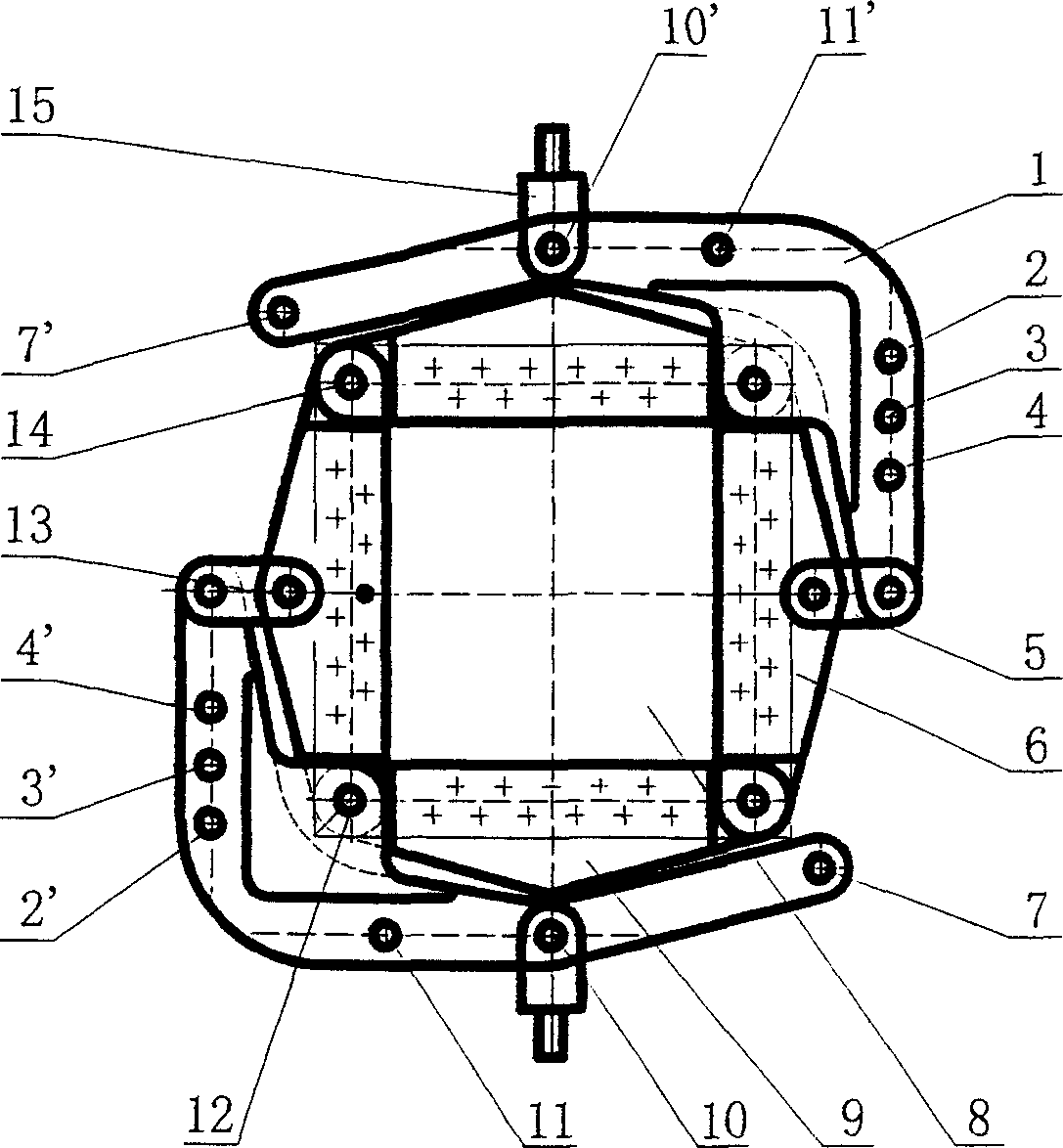

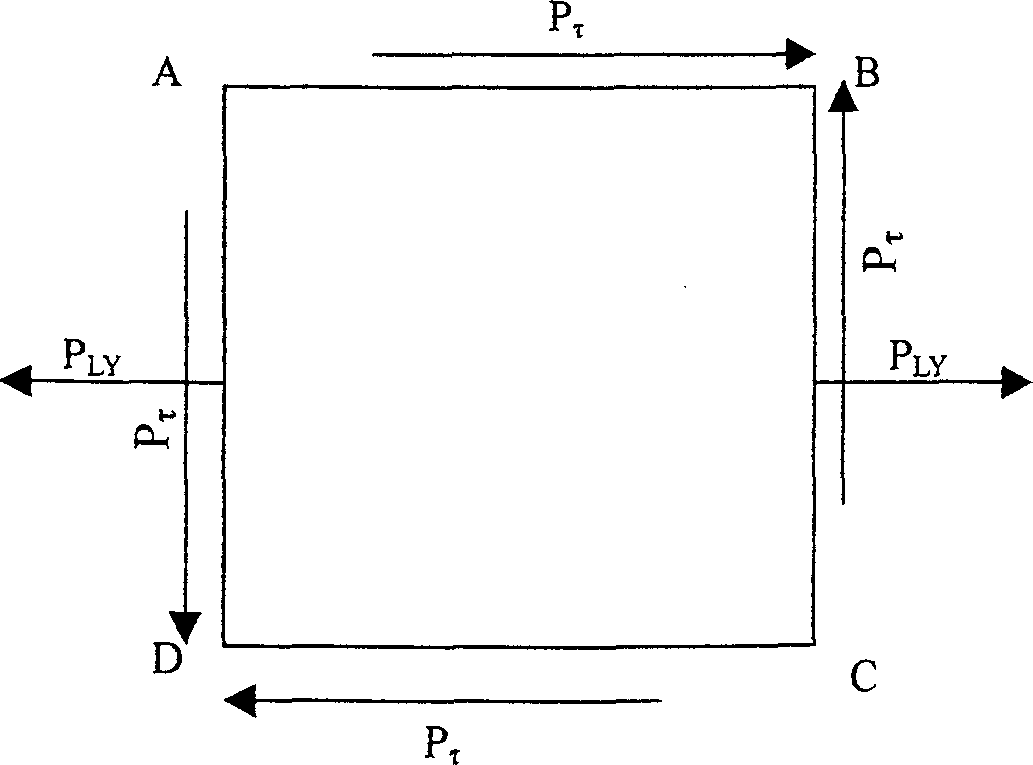

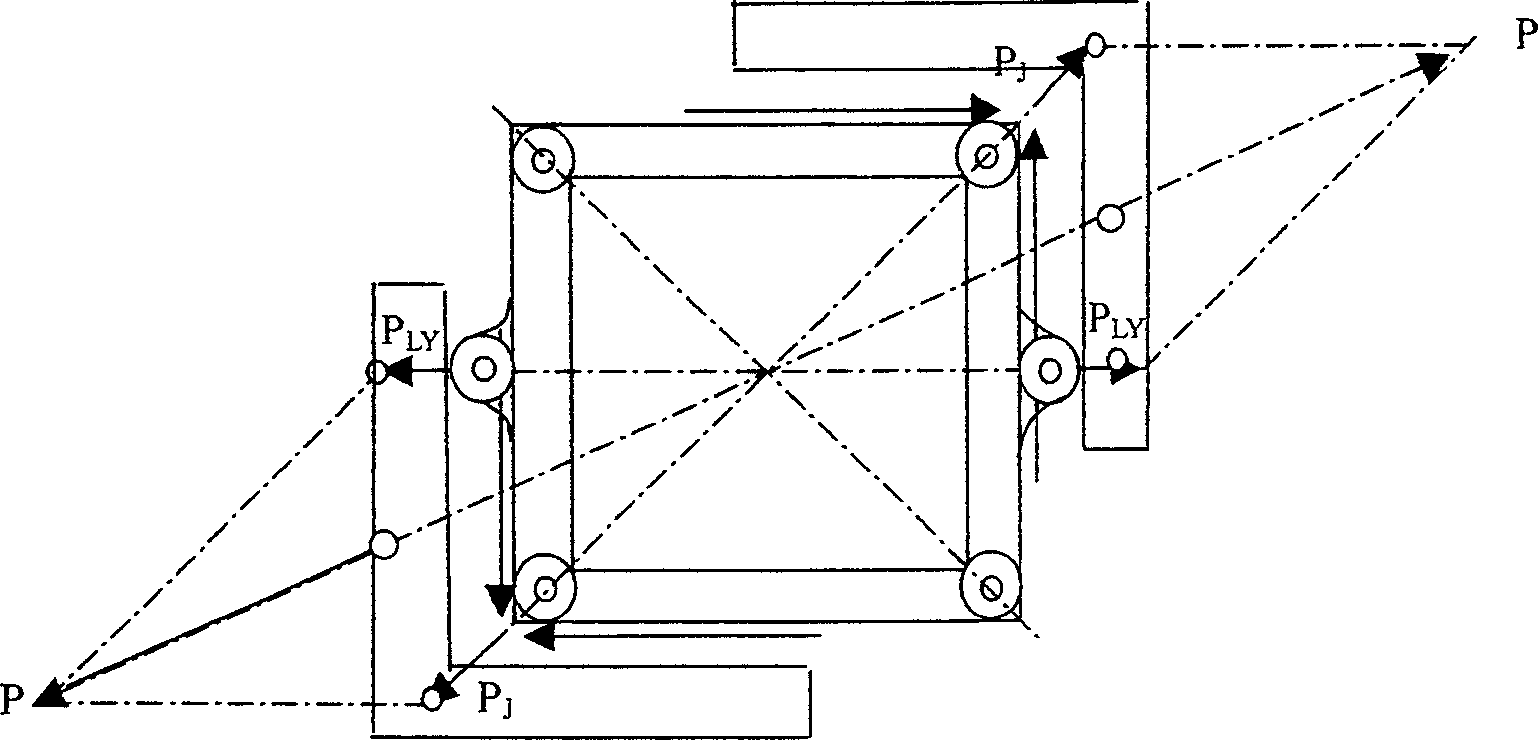

[0025] It can be seen from the figure that the tensile-shear-compression-shear multiple loading test device is composed of four shear and tension-compression loading splints 6 and 9 connected to form a rectangular loading frame, and two L-shaped levers 1 are symmetrically placed on one outside of the rectangular loading frame. On the diagonal, that is, the ends of the short longitudinal rods of the L-shaped lever 1 are respectively connected to the midpoints of the two shearing and tension-compression loading splints 6 on the two opposite sides through hinged connecting pieces 5, and the horizontal long rods of the L-shaped lever 1 The midpoint of the middle point is connected to the midpoints of the other two shearing and tension-compression loading splints 9 of the other two opposite sides by hinged lugs 15 respectively. When a single axial tensile force is applied to the pair of hinged lugs 15, the test device can be automatically centered under load. The two longitudinal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com