Full-automatic direct shear apparatus for densely-compacted bentonite unsaturated shear property study

A technology of bentonite and high-pressure compaction, which is applied in the direction of applying stable shear force to test the strength of materials, etc. It can solve the problem that the shear strength parameters cannot be measured, the direct shear instrument cannot meet the requirements of unsaturated shear tests, and the environment is sensitive to humidity. and other issues, to achieve important engineering significance and practical value, and the overall reliable and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with examples of implementation.

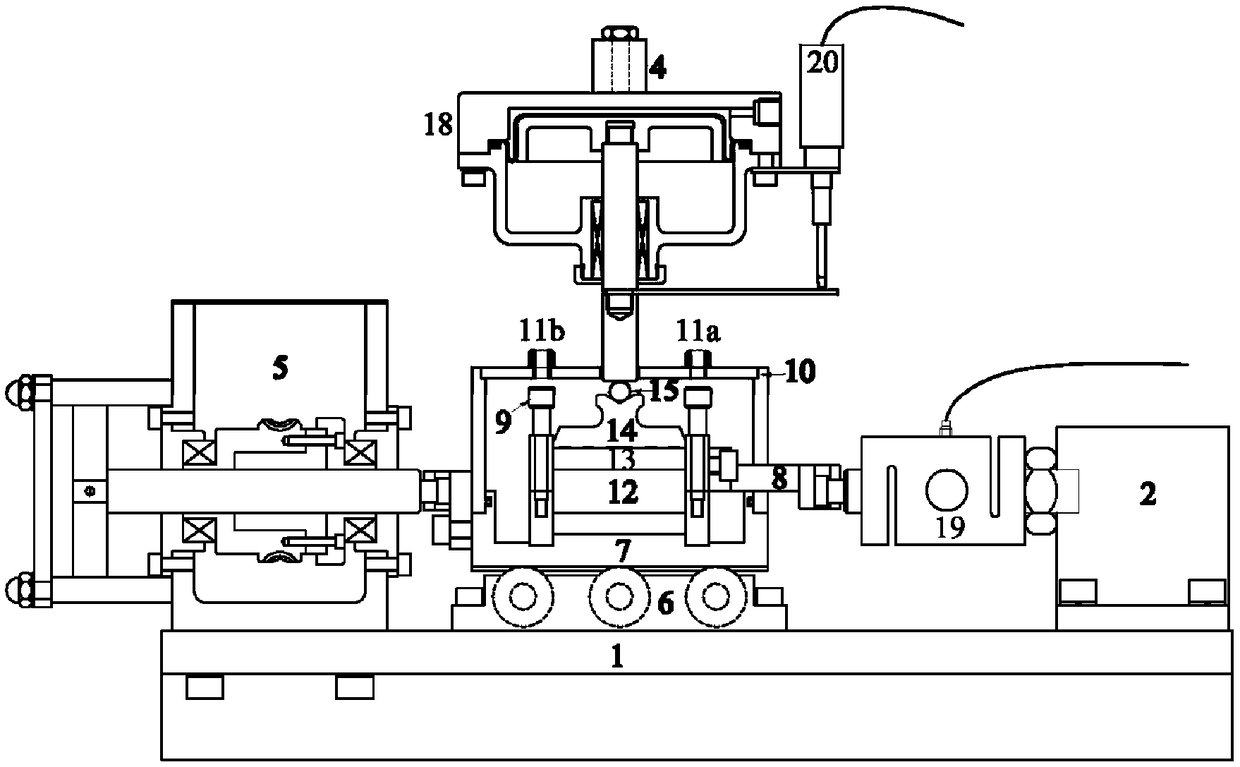

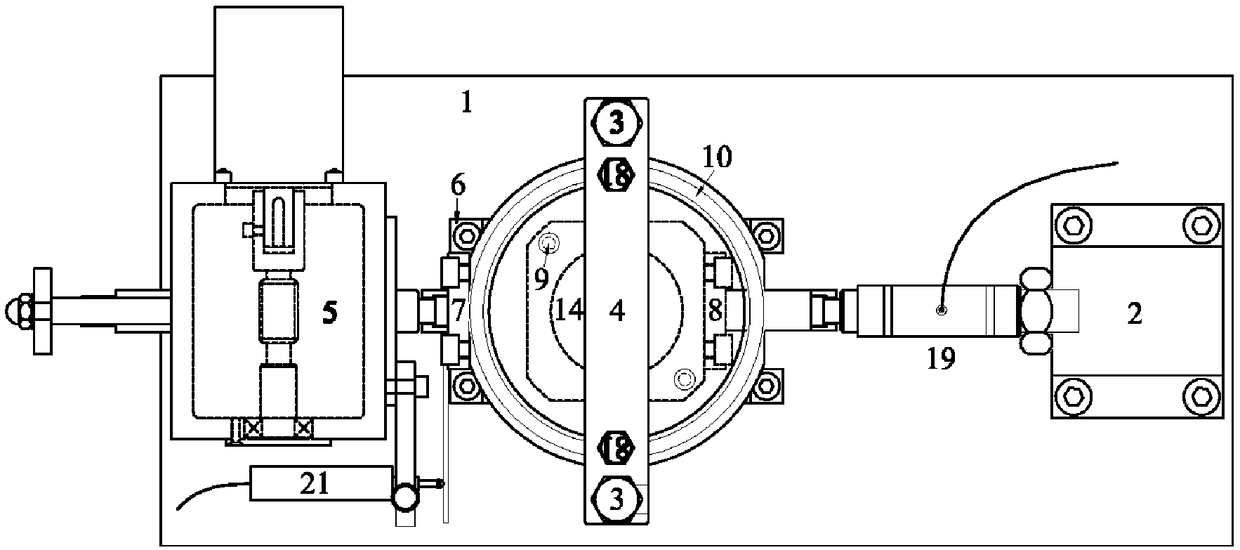

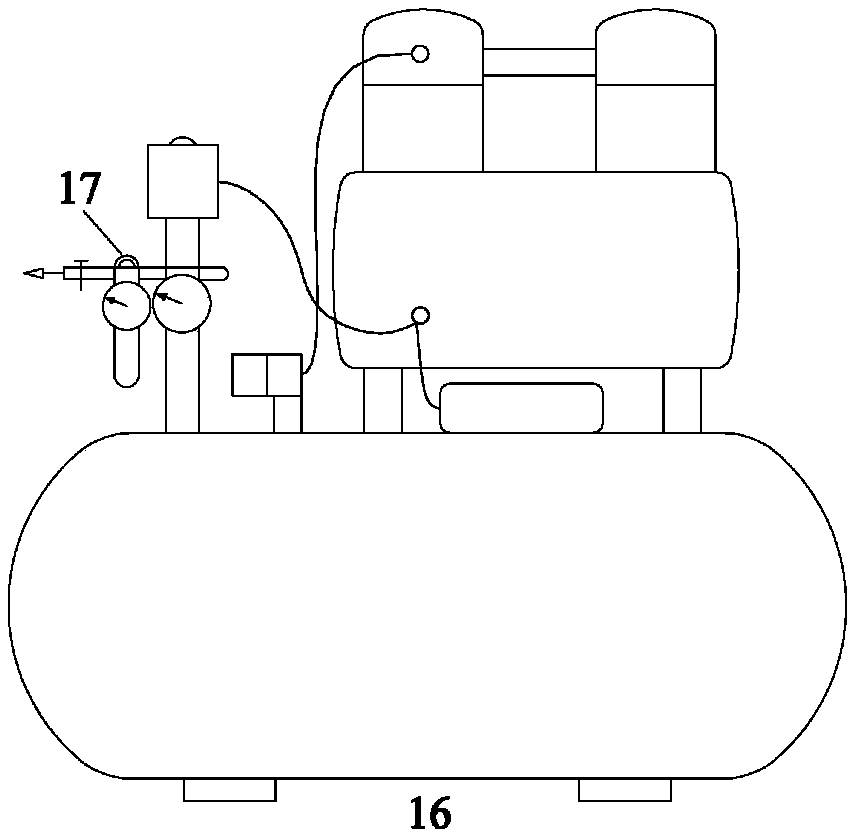

[0033] Such as Figure 1 to Figure 5 As shown, the present invention provides a fully automatic direct shear instrument for the research of unsaturated shear properties of high compacted bentonite, including a shear system, a normal pressure loading system, a measurement system, an automatic control and data acquisition system, a gas phase French suction control system.

[0034] The shearing system includes a base, a propulsion mechanism 5, a rolling guide 6, and a shearing box. The base includes a bottom plate 1, a fixed end 2, two columns 3, and a beam 4. The fixed end 2 and the two columns 3 are respectively fixed on the base plate 1 with bolts, and the fixed end 2 is located at the right end of the base plate 1, and the two columns 3 are respectively located at the front and rear ends of the base plate 1; one end of the beam 4 is the fixed end of the beam, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com