Malfunction alarm method based on piston rod vibration dynamic energy index

A fault alarm and dynamic energy technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inability to achieve effective early warning of fracture faults, gas leakage, threats to the safe and stable production of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

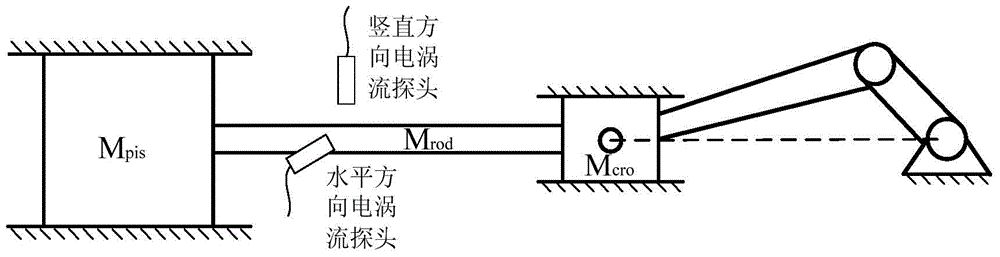

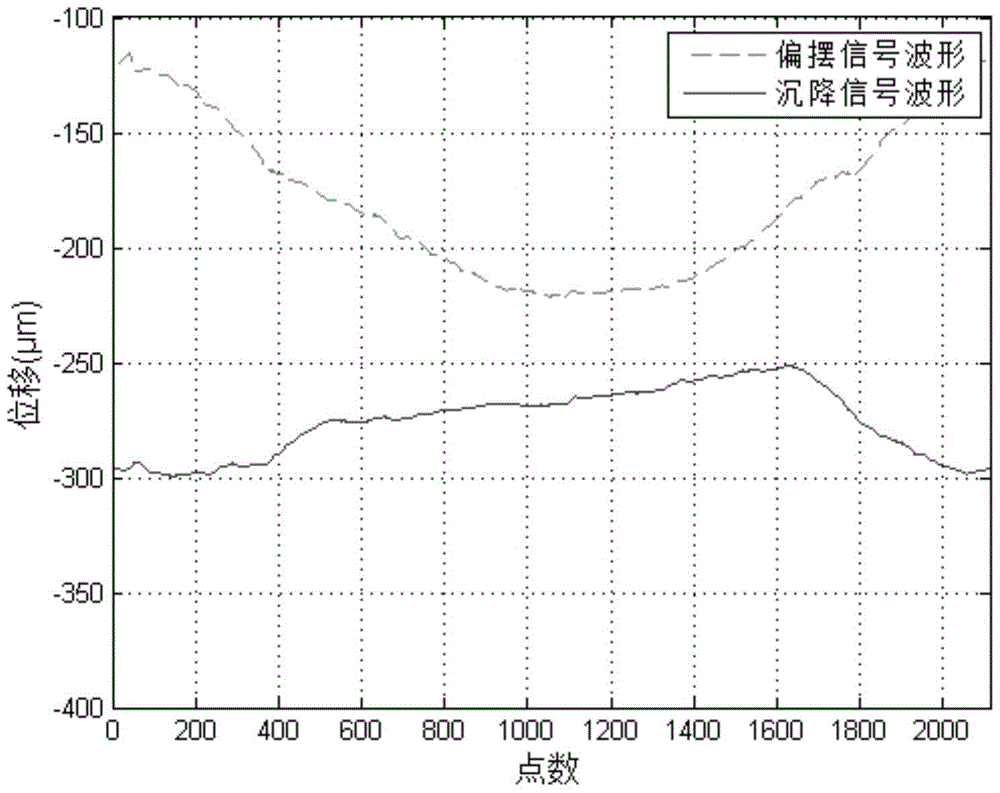

[0054] At present, the on-line fault monitoring and diagnosis systems of reciprocating compressors in service at home and abroad all monitor the displacement of the piston rod. Some monitor the horizontal yaw displacement and vertical settlement displacement signals at the same time, and some monitor the displacement in a single direction; use The sensor is a non-contact eddy current sensor; through the displacement sensor in two directions, the on-line monitoring of the position change signal of the piston rod relative to the sensor during the movement of the piston rod can be realized. The sensor installation schematic diagram is as follows figure 1 As shown, the typical settlement and deflection displacement monitoring signals are as follows figure 2 shown;

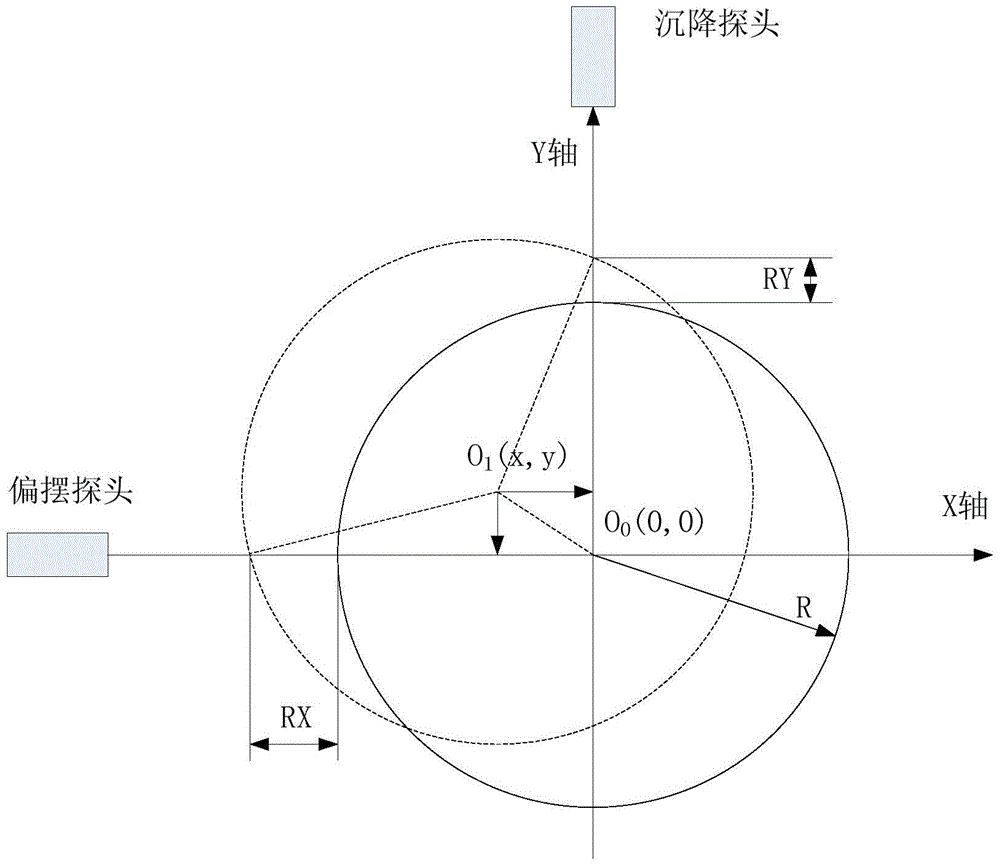

[0055] The conventional displacement monitoring method belongs to relative parameter monitoring, that is, the sensor collects the difference between the signal in real time and the initial installation position, and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com