Device and method for testing normal static characteristics of junction surface of high-strength bolt

A technology of high-strength bolts and static characteristics, which is applied in the field of devices for testing the normal static characteristics of the joint surface of high-strength bolts to achieve the effects of improving accuracy, easy replacement and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

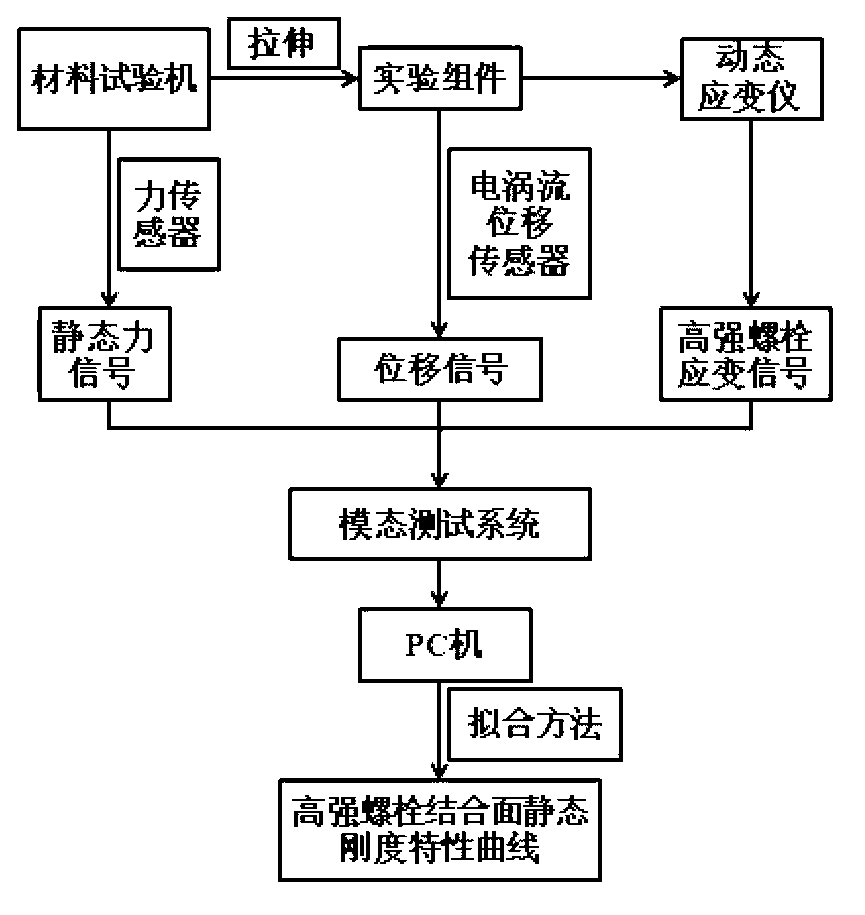

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

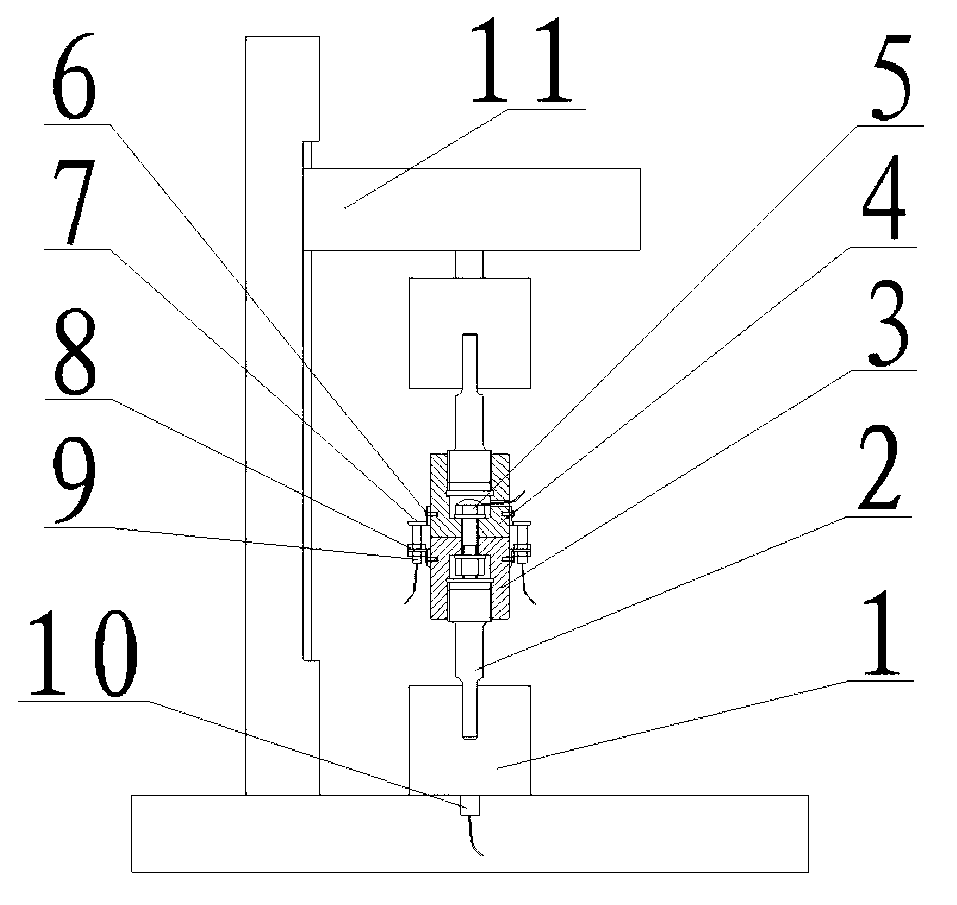

[0055] The device and method for testing the normal static characteristics of the high-strength bolt joint surface of the present invention will be further described in detail below in combination with the working principle and the structural drawings.

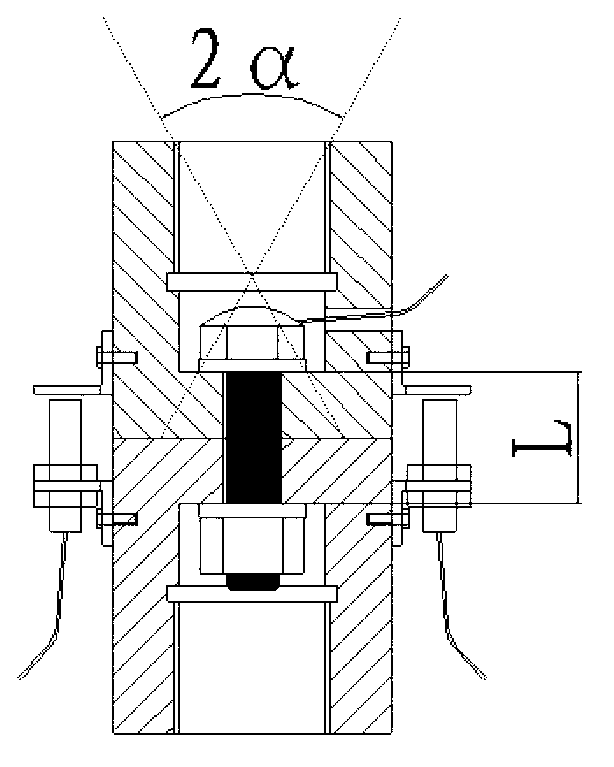

[0056] like Figures 1 to 9 As shown, the two screw rods 2 are threadedly connected with the upper test piece 4 and the lower test piece 3 respectively, and the square end surface of the upper test piece 4 and the square end surface of the lower test piece 3 fit together to form a joint surface. The high-strength bolt 5 passes through the through hole at the center of the upper test piece 4 and the lower test piece 3 and is perpendicular to the joint surface, and exerts force on the high-strength bolt 5 to form a pre-tightening force on the joint surface. As a result, the experimental assembly of the normal static characteristics of the high-strength bolt joint surface was formed. The screw rod 2 is connected with the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com