Movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation

A shear deformation and movable plate technology, which is applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of uneven distribution of stress and strain in the sample, concentration, and existing stress, and the distribution is uniform and reduced. The effect of restraint and reduction of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

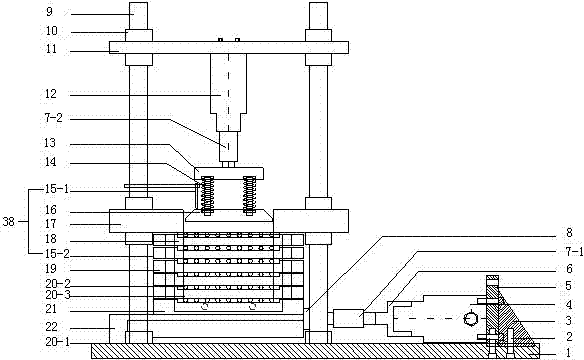

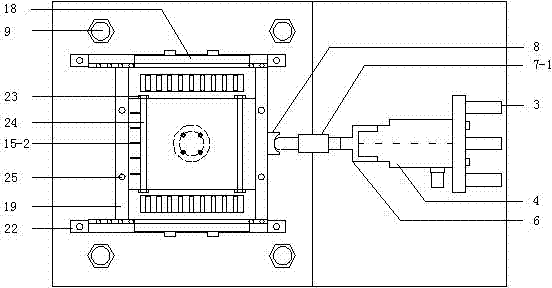

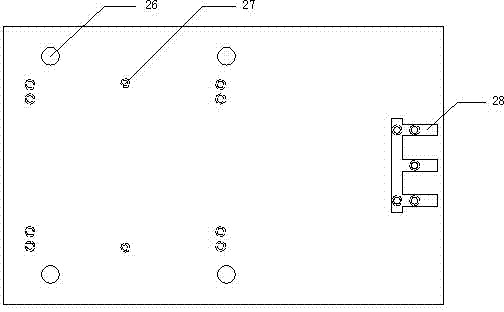

[0040] Embodiment one: simple shear test

[0041] When performing the simple shear test, first assemble the parts of the lower shear box, apply a layer of lubricating oil evenly in the box, pour concrete, and place it on the vibrating plate to vibrate and compact. After the concrete is finally set, stack the ring shearing frames on the lower shear box, fix each ring shearing frame through bolts, and install the guard plate of the movable plate to fix the movable plate. Compact the soil samples layer by layer in the shear box of the stacked ring group, and flatten the top of the sample. Assemble the remaining parts of the device in turn, apply lubricating oil on the bottom surface of the pressure transmission plate, and place it on the soil sample. Adjust the vertical force loading device so that the pressure head of the loading device is against the upper top plate. Install the horizontal reaction force plate, inclined support plate, horizontal force loading device, top cap,...

Embodiment 2

[0044] Embodiment two: direct shear test

[0045] When conducting the direct shear test, it is necessary to remove the movable plate and bearings in the shear frame of the stacked ring, and plug the openings for placing the bearings on the left and right wings of the shear frame of the stacked ring. Fill the lower shear box with concrete materials, and after the concrete has finally set, stack the ring shear frame on the lower shear box and fix it with a bolt. After the sample preparation in the shear box of the stacked ring group is completed, the various components of the test equipment are assembled in sequence as in the simple shear test.

[0046] After the normal pressure is applied by the vertical force loading device, the horizontal force loading device applies the shear force, the normal pressure and shear force are collected by the load sensor, and the displacement of the lower shear box is collected by the displacement sensor.

Embodiment 3

[0047] Embodiment 3: pull-out test

[0048] When carrying out the pull-out test, the concrete material is placed in the lower shear box. After the concrete is finally set, the stacked ring shear frame is stacked on the lower shear box, and the geogrid, geotextile, etc. are sandwiched between the second, Between the third stacked ring shear frame, the second and third shear frames are fixed with bolts. After the sample is prepared, other parts of the test equipment are assembled in sequence. There are special vertical top caps and roof. The geogrid or geotextile is fixed on the horizontal reaction plate with a clamp, the vertical force loading device applies normal pressure to the sample through the top plate, and the horizontal force loading device applies horizontal shear force to the sample through the lower shear box. The normal pressure and shear force are collected by the load sensor, and the displacement of the lower shear box is collected by the displacement sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com