Device and method for testing normal static stiffness characteristics of joint surfaces of shim plate, foundation and foundation bolt of heavy-duty machine tool

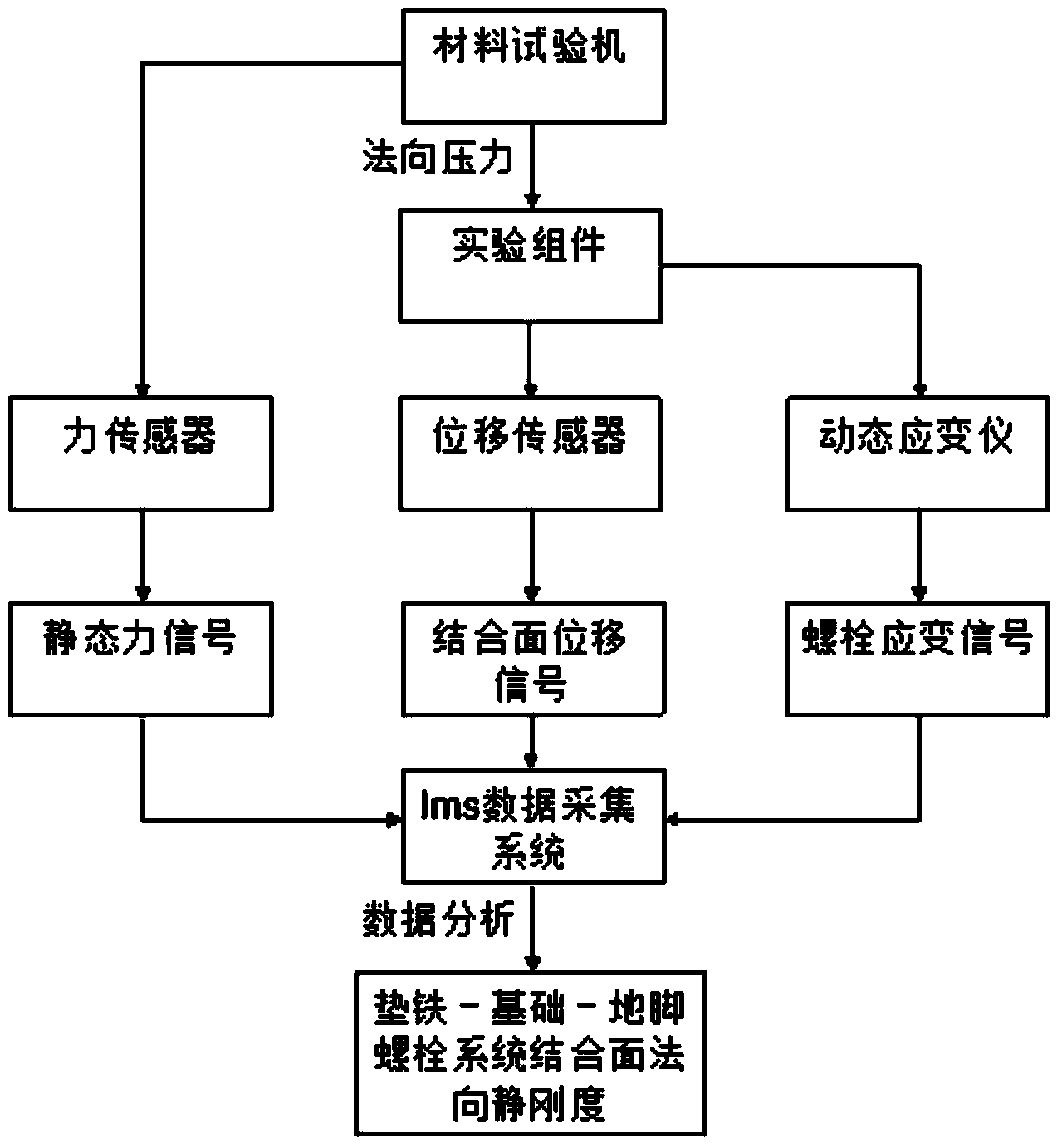

A technology of anchor bolts and joint surfaces, applied in the direction of measuring devices, strength characteristics, and testing of mechanical components, can solve the problem of insufficient attention to the contact stiffness of the bed-shield iron-foundation system, which affects the manufacturing accuracy and service life of the machine tool, and the bed The increase in the workload of body leveling and other issues, to achieve the effect of reducing the number of physical quantities, simple and reliable data processing methods, and simplifying the process of data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

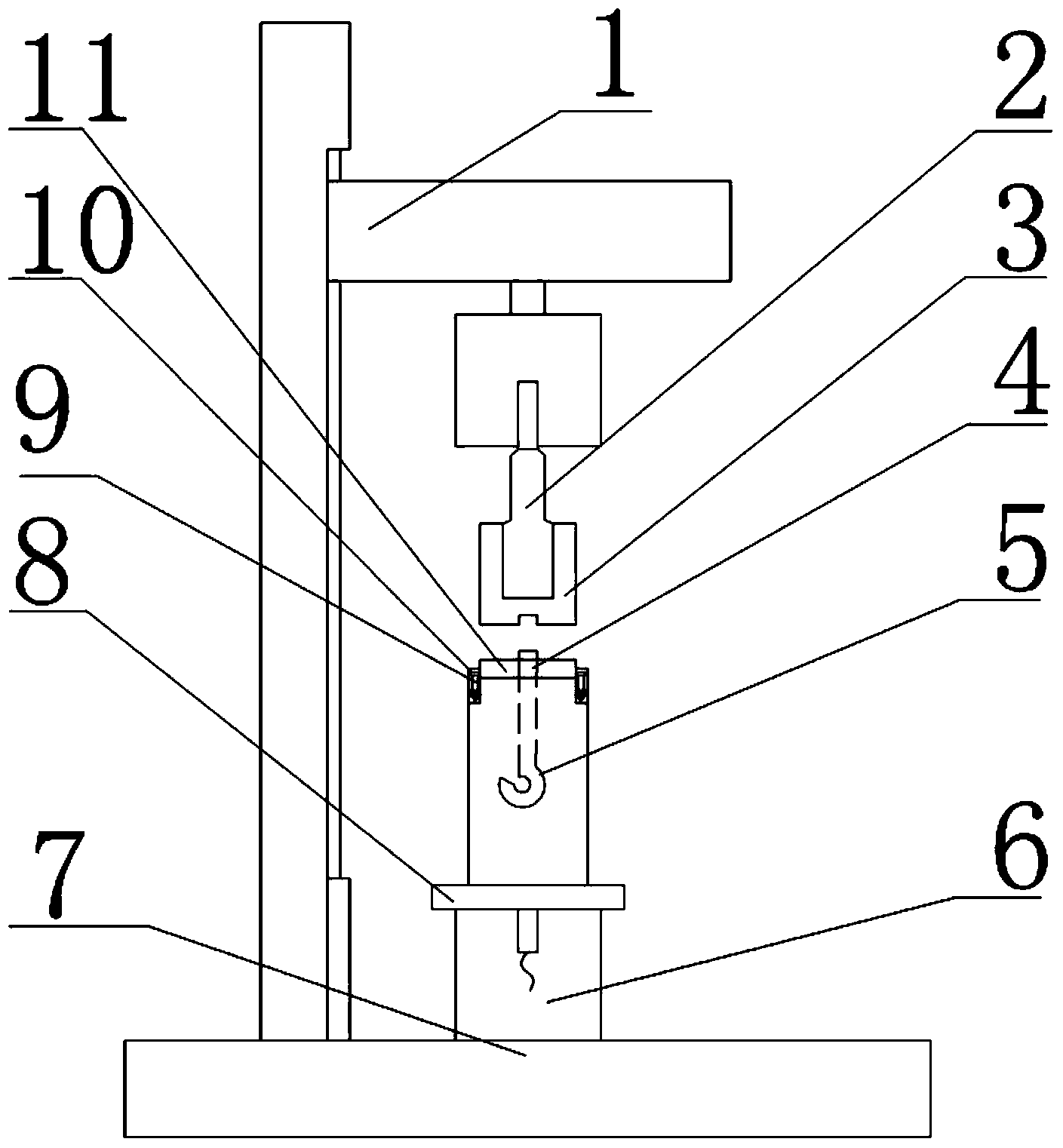

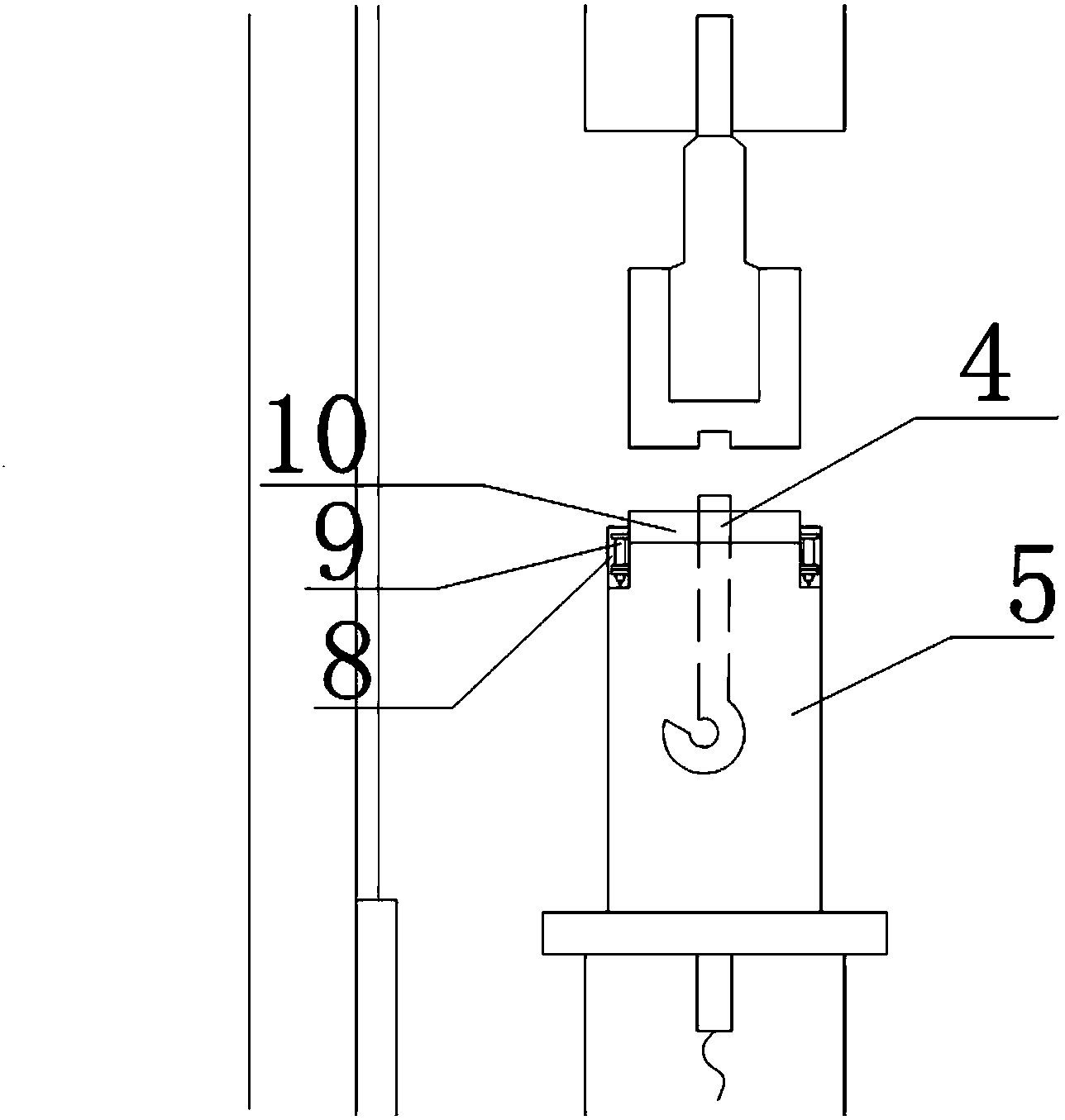

[0033] The test system for the normal static stiffness characteristics of the pad iron-foundation-anchor bolt joint surface of the present invention will be further described in detail below in combination with the working principle and the structural drawings.

[0034] As shown in the figure, the iron test piece (10) and the concrete foundation (5) are connected by the method of secondary grouting through the anchor bolts (4), and the test piece (10) and the concrete foundation (5) are bonded to form a bond On the surface, apply force to the anchor bolt (4) to form a pre-tightening force on the joint surface.

[0035] The specification of the anchor bolts in the experiment is M12, considering the national standard: 1. The relationship between the diameter of the anchor bolts and the size of the reserved holes is as follows:

[0036]

[0037] 2. The distance between the edge of the reserved hole of the anchor bolt and the edge of the equipment foundation is ≥100mm

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com