Patents

Literature

37results about How to "Eliminate creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

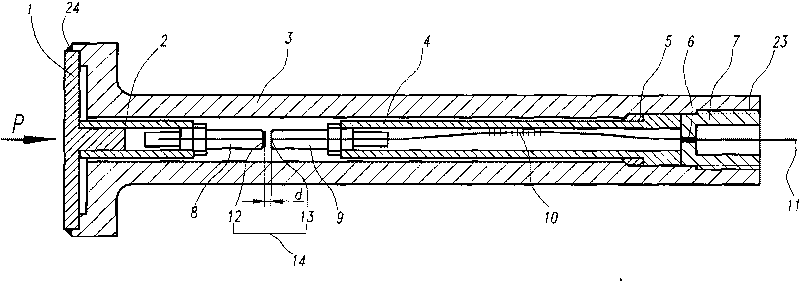

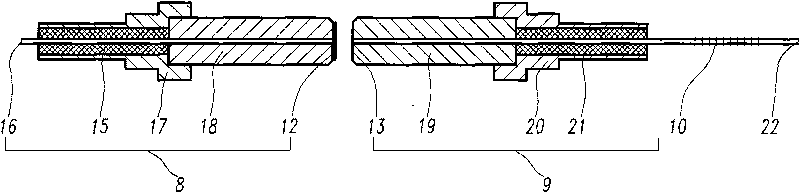

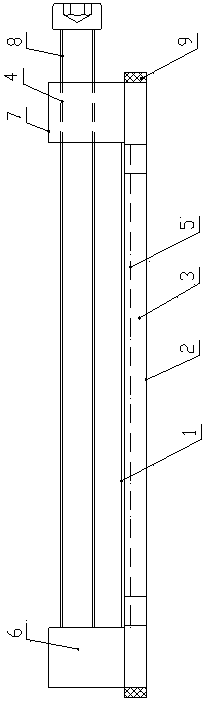

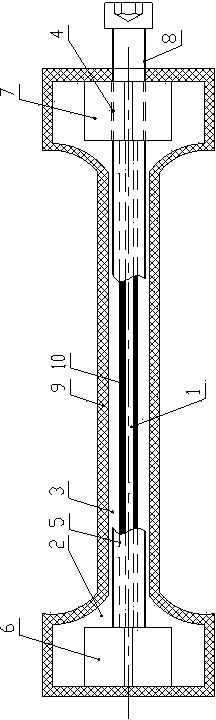

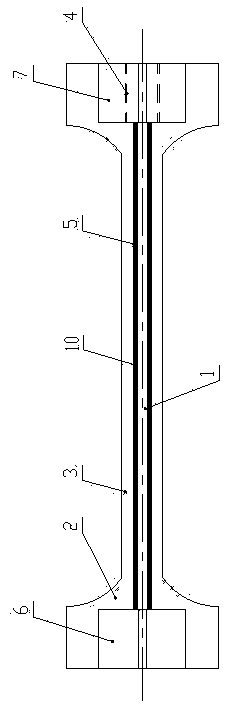

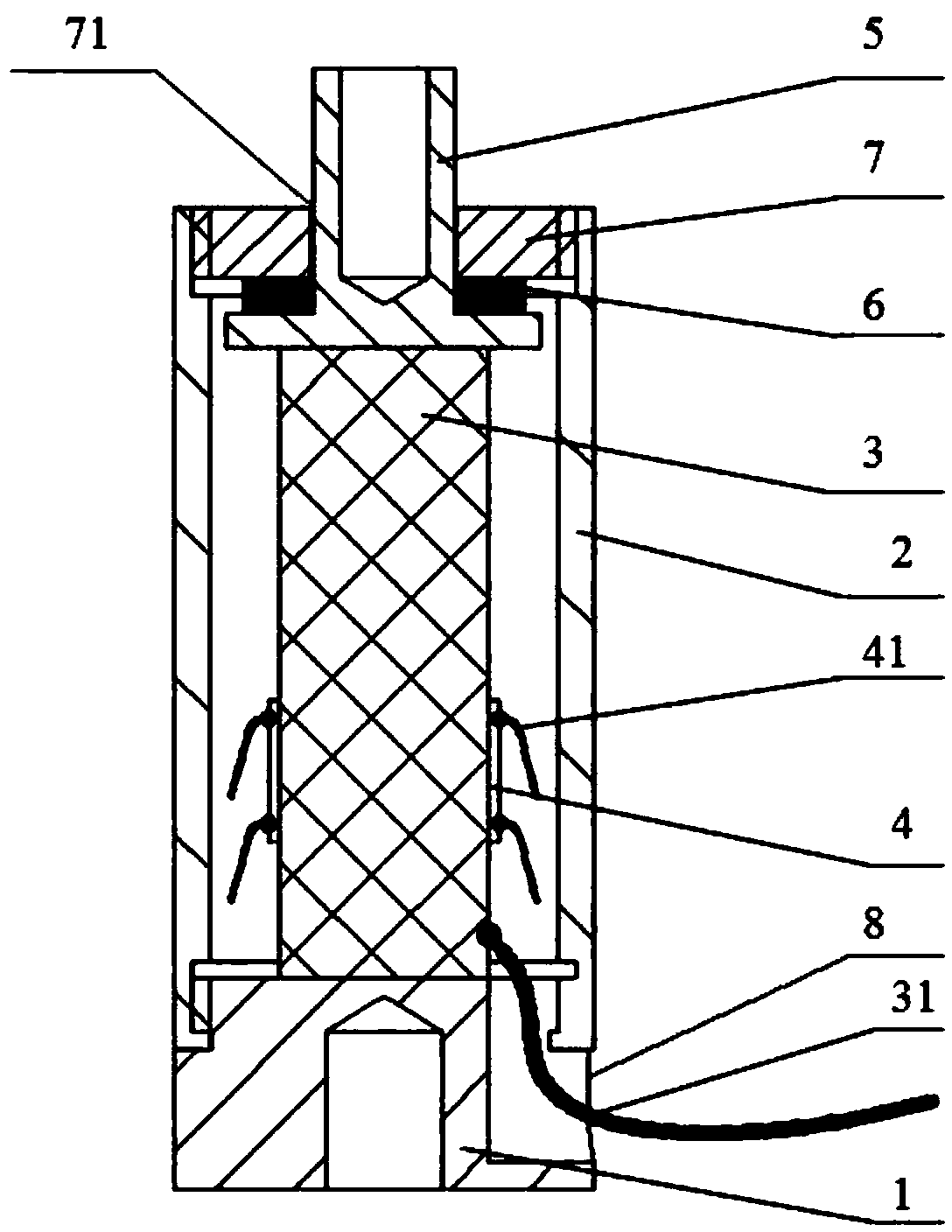

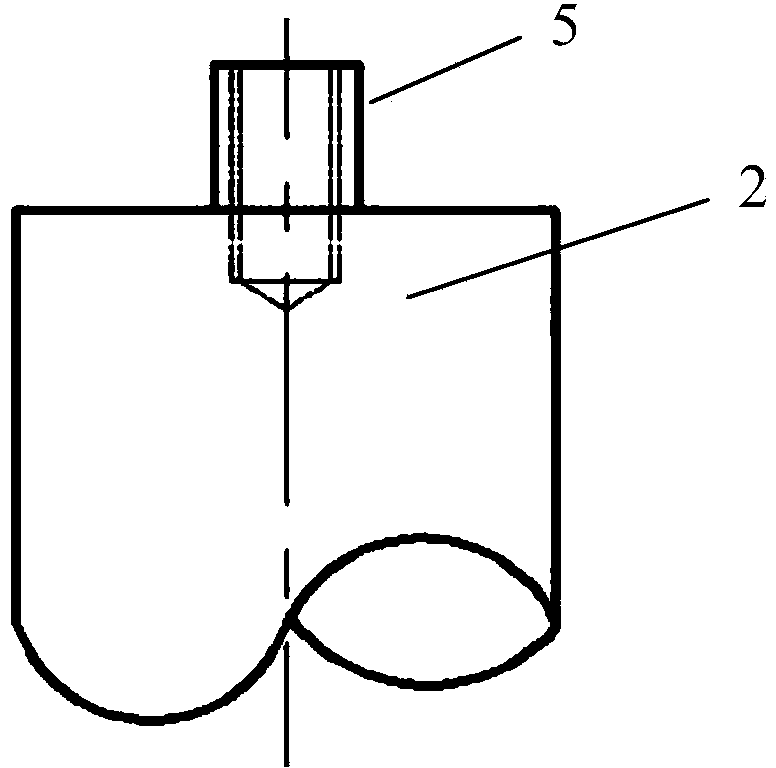

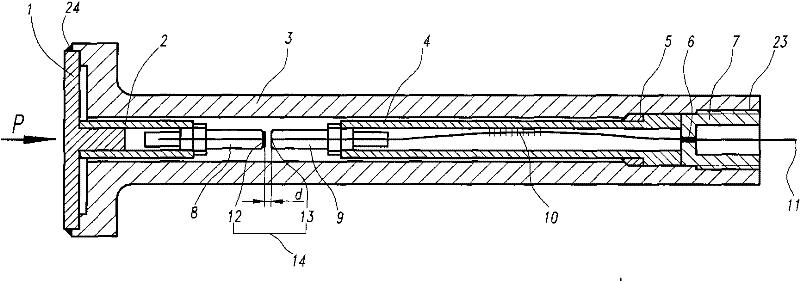

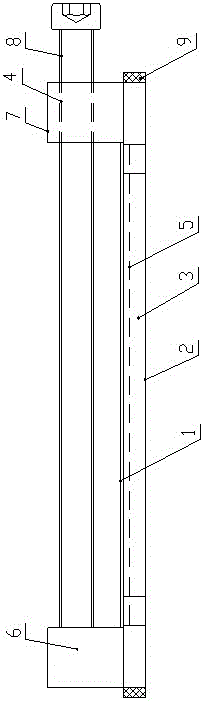

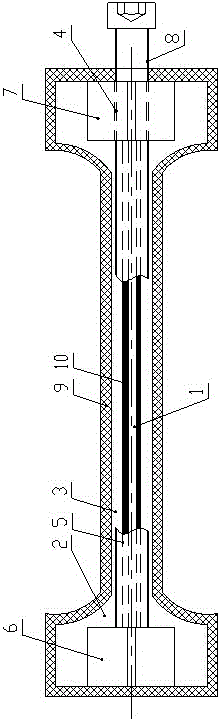

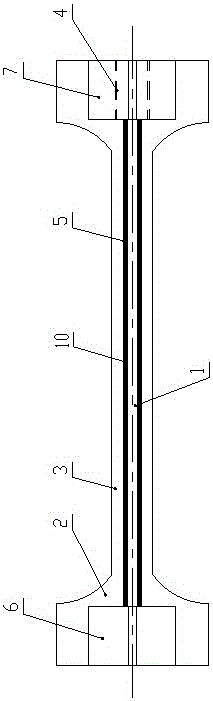

Novel optical fiber temperature and pressure sensor

ActiveCN101709638AGood for accurate demodulationEliminate creepSurveyConstructionsEngineeringOptical fiber cable

The invention relates to a novel optical fiber temperature and pressure sensor, which comprises an elastic diaphragm, an optical fiber Bragg grating and a demodulator connected with the optical fiber Bragg grating, wherein a short connecting pipe is sleeved on a raised column of the elastic diaphragm; the other end of the short connecting pipe is fixedly provided with a hollow rod; the hollow rod and the end face of a first optical fiber in the center thereof form a first reflecting surface through polishing; a reflecting film is plated on the first reflecting surface; the other end of an outer protection tube is inserted into a long connecting pipe with a second ceramic ferrule component; the bending part of a second optical fiber is provided with the optical fiber Bragg grating; a second ceramic rod and the end face of the second optical fiber in the center thereof form a second reflecting surface through polishing; and the first reflecting surface of the hollow rod and the second reflecting surface of the second ceramic ferrule component are centered and are provided with a space therebetween to form a Fabry-Perot cavity. The optical fiber temperature and pressure sensor is used for manufacturing optical fiber sensors.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

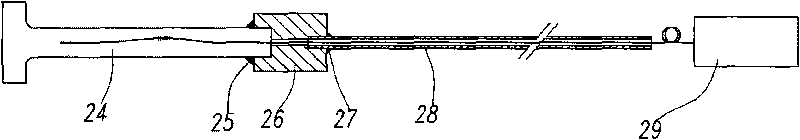

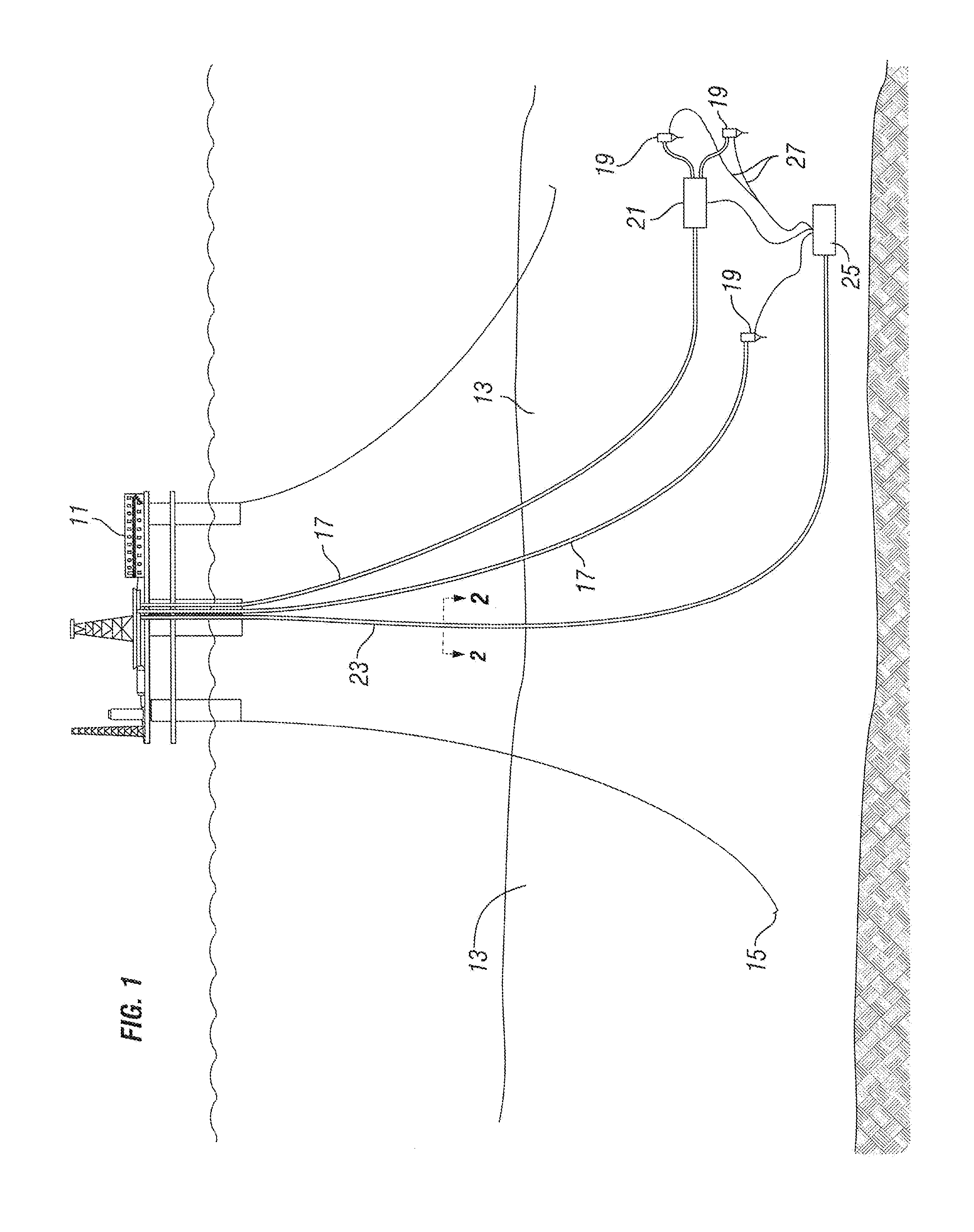

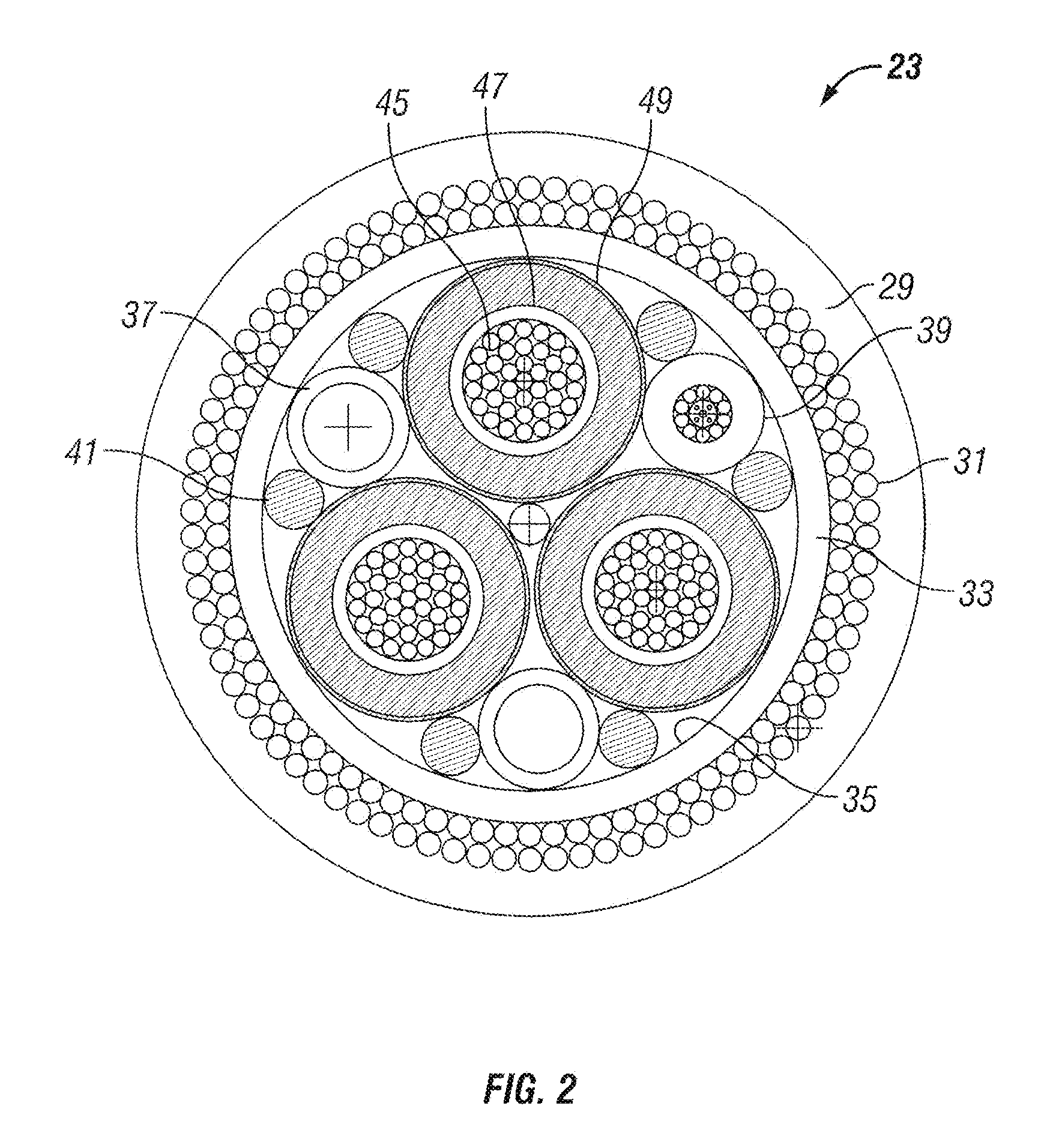

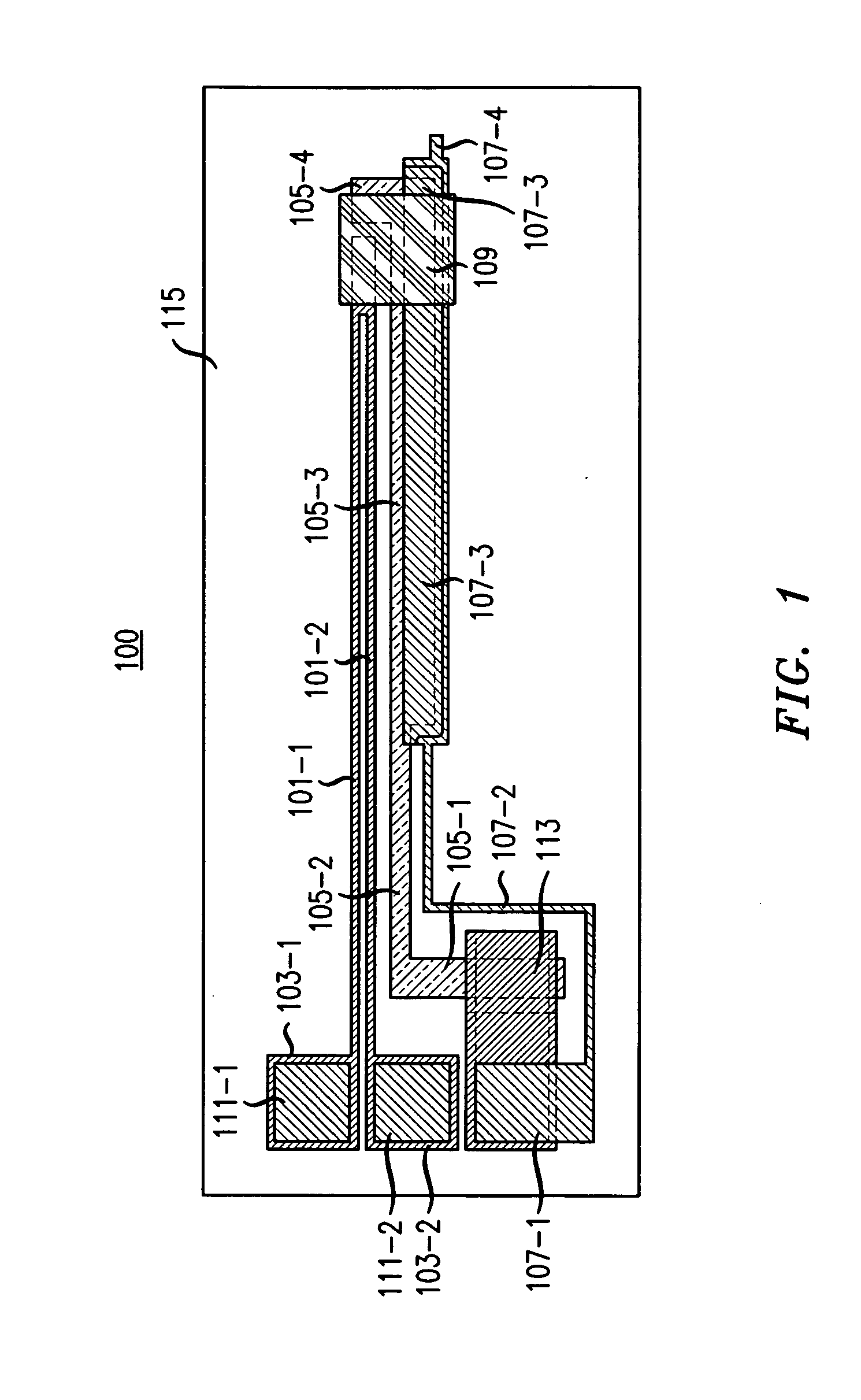

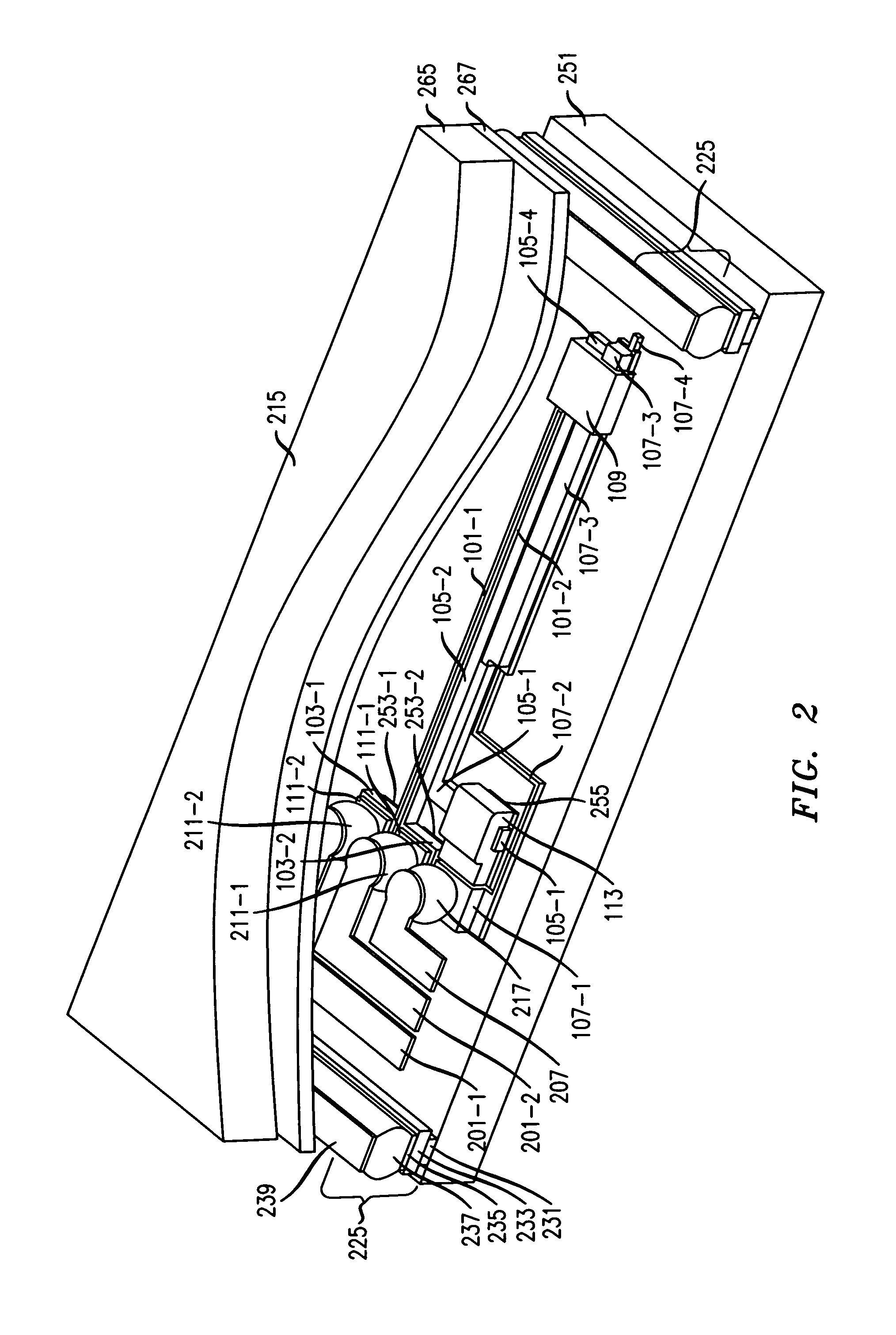

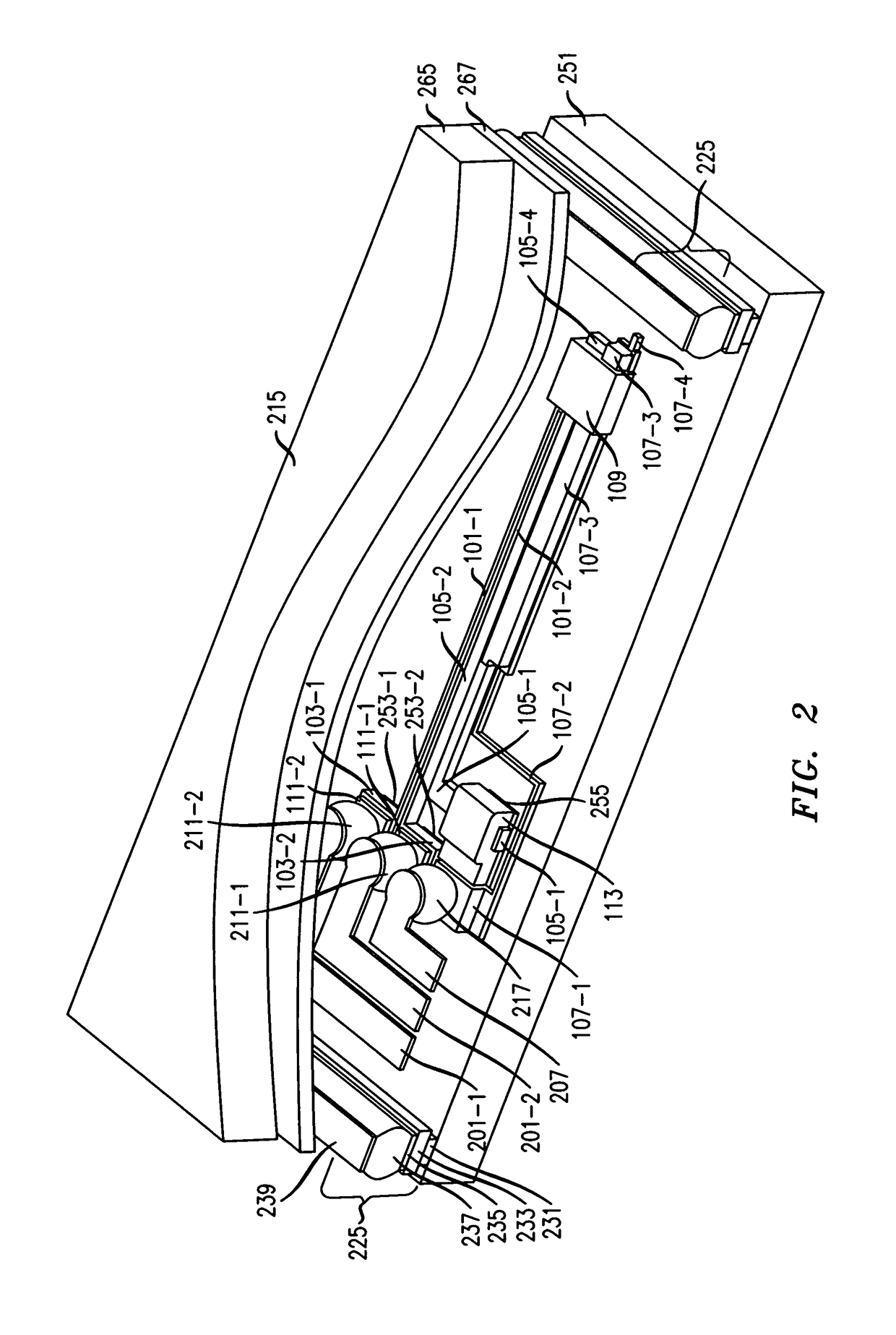

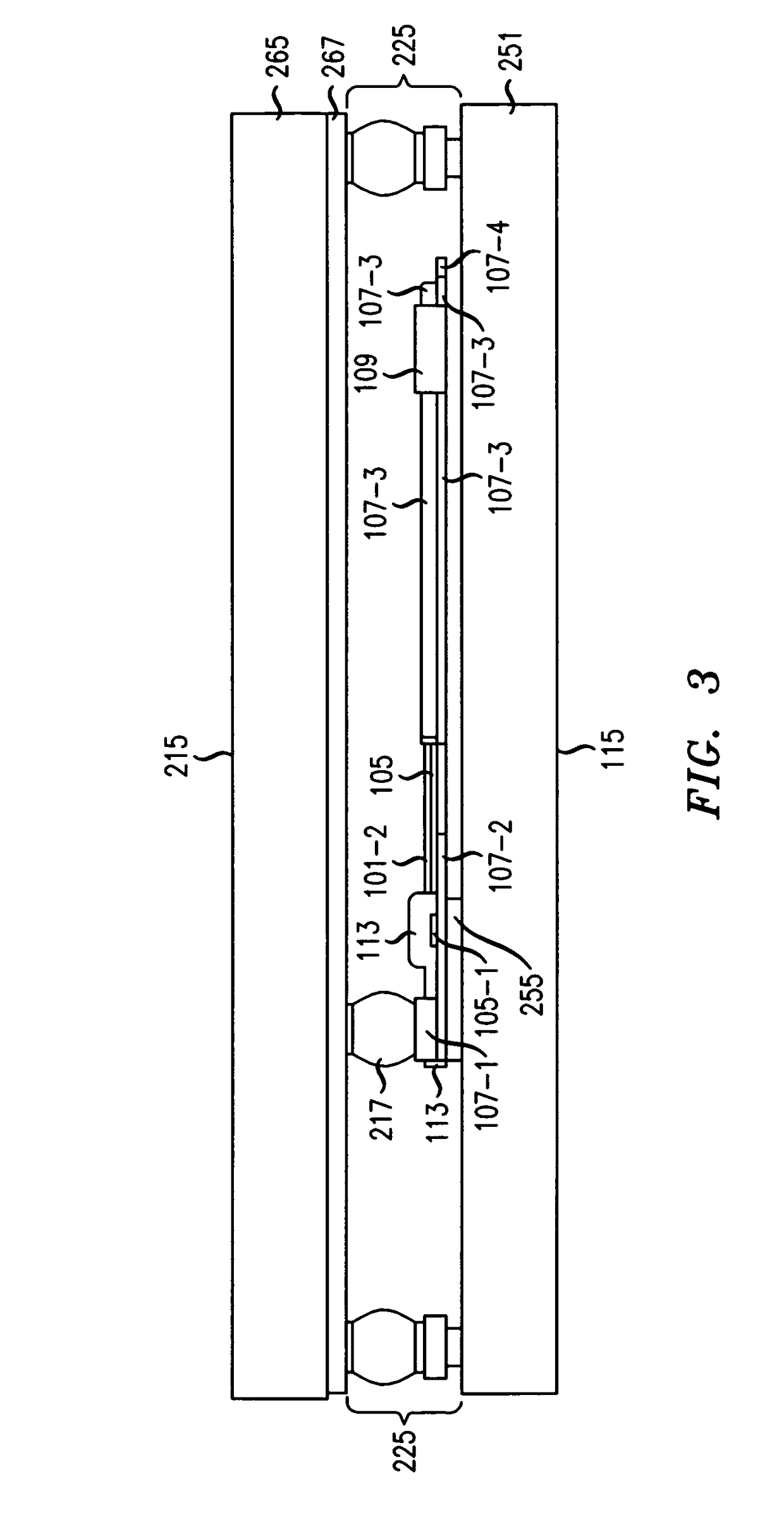

Subsea power umbilical

InactiveUS20090120632A1Increase frictionEliminate creepDerricks/mastsFluid removalElectrical conductorHydrogen

An umbilical assembly for supplying power to subsea equipment includes an electrical conductor to convey an electrical current to the subsea equipment. An insulator surrounds the conductor. A support member is positioned between the insulator and the conductor. The support member has either non-magnetic properties or low-magnetic properties because of its material composition. The support member is adapted to connect to a structure at the surface of the sea. The support member supports the weight of the conductor. The supporting of the weight of the conductor by the support member can be to reduce creep typically associated with the conductor supporting its own weight. The support member can be used to hermetically seal the conductor and prevent hydrogen migration along the conductor.

Owner:CHEVROU USA INC

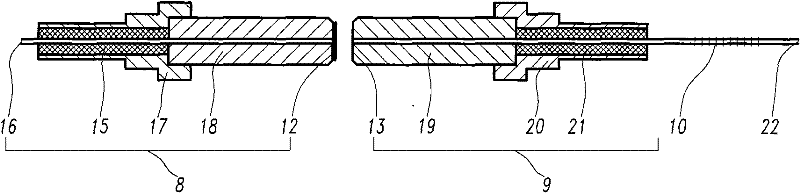

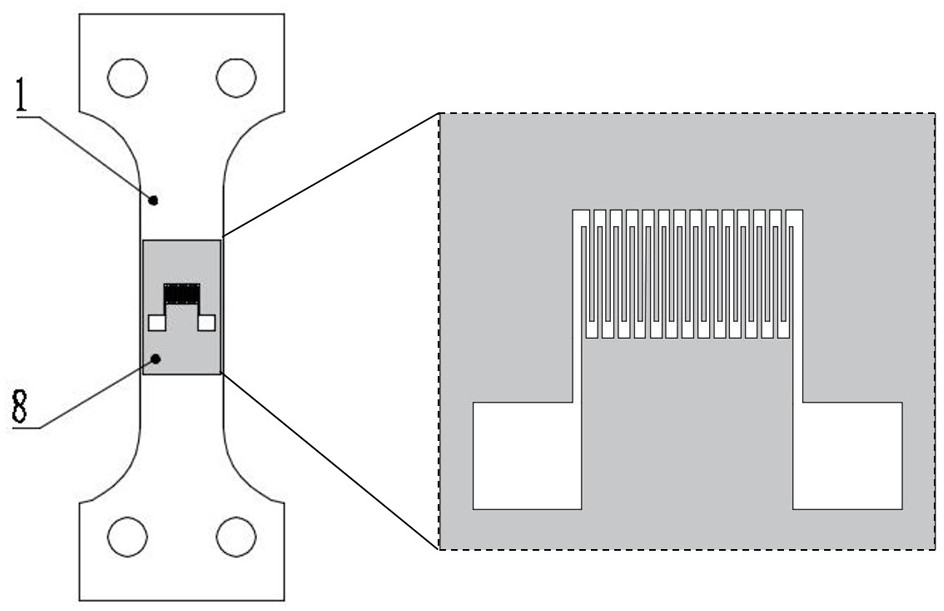

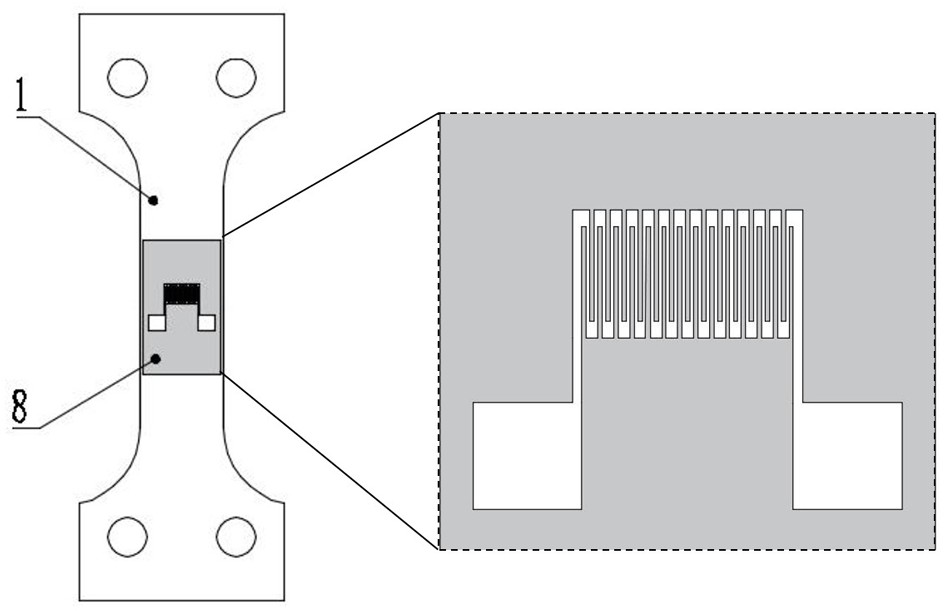

Spot welding fiber bragg grating strain sensor and installation method thereof

ActiveCN104048615AHigh sensitivityQuick responseUsing optical meansFiberElectrical resistance and conductance

The invention discloses a spot welding fiber bragg grating strain sensor. The spot welding fiber bragg grating strain sensor comprises a fiber bragg grating strain sensor body and a base body made of high-elasticity alloy materials, wherein the base body comprises a substrate, a left regulating block and a right regulating block, the left regulating block and the right regulating block are connected with the left end and the right end of the base body respectively in an integrated mode, a base body groove is formed in the middle of the position, between the two regulating blocks, of the base body, the outer side of the fiber bragg grating strain sensor body is provided with a packaging layer made of low-melting-point glass powder, and the lower half portion of the packaging layer is connected with the base body groove; the right regulating block is transversely provided with a regulating hole, a regulating bolt penetrates through the regulating hole, and the left end of the regulating bolt abuts against the right side face of the left regulating block; the periphery of the substrate is provided with a rubber layer used for sealing. As the spot welding fiber bragg grating strain sensor is obviously superior to a traditional resistance strain gage, the purpose that the real-time state of strain of an iron tower electric transmission line is known comprehensively for a long time is achieved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

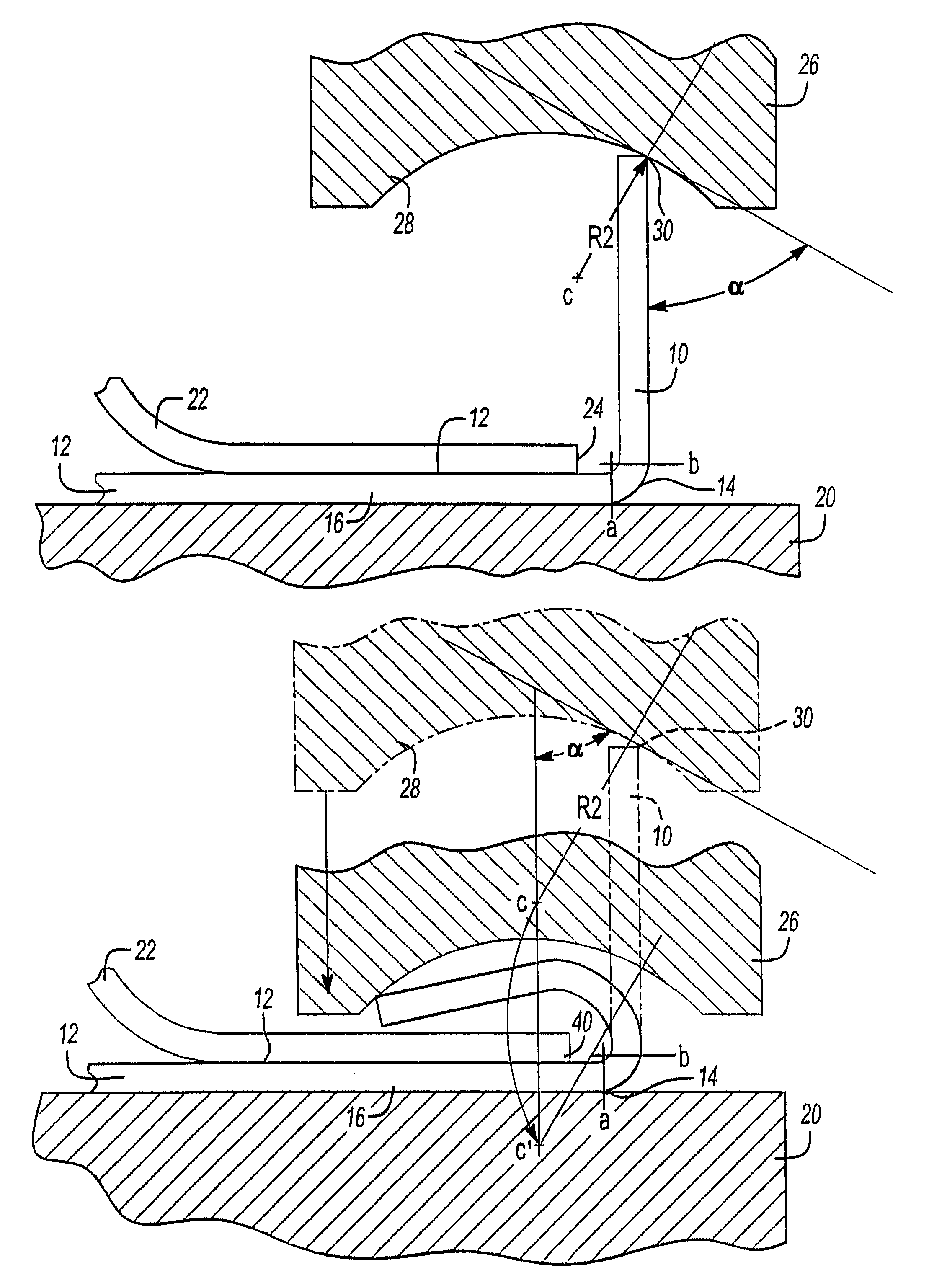

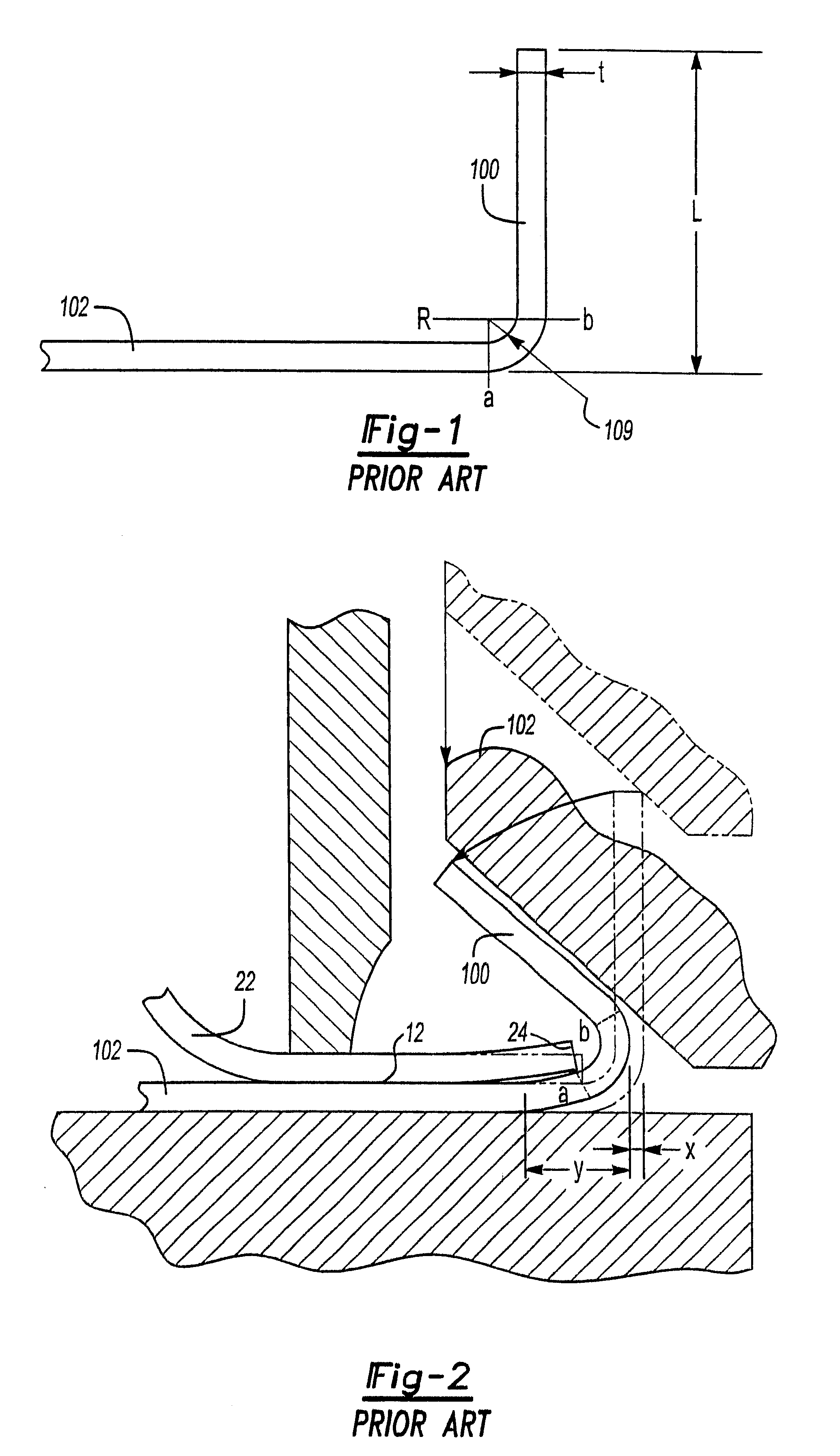

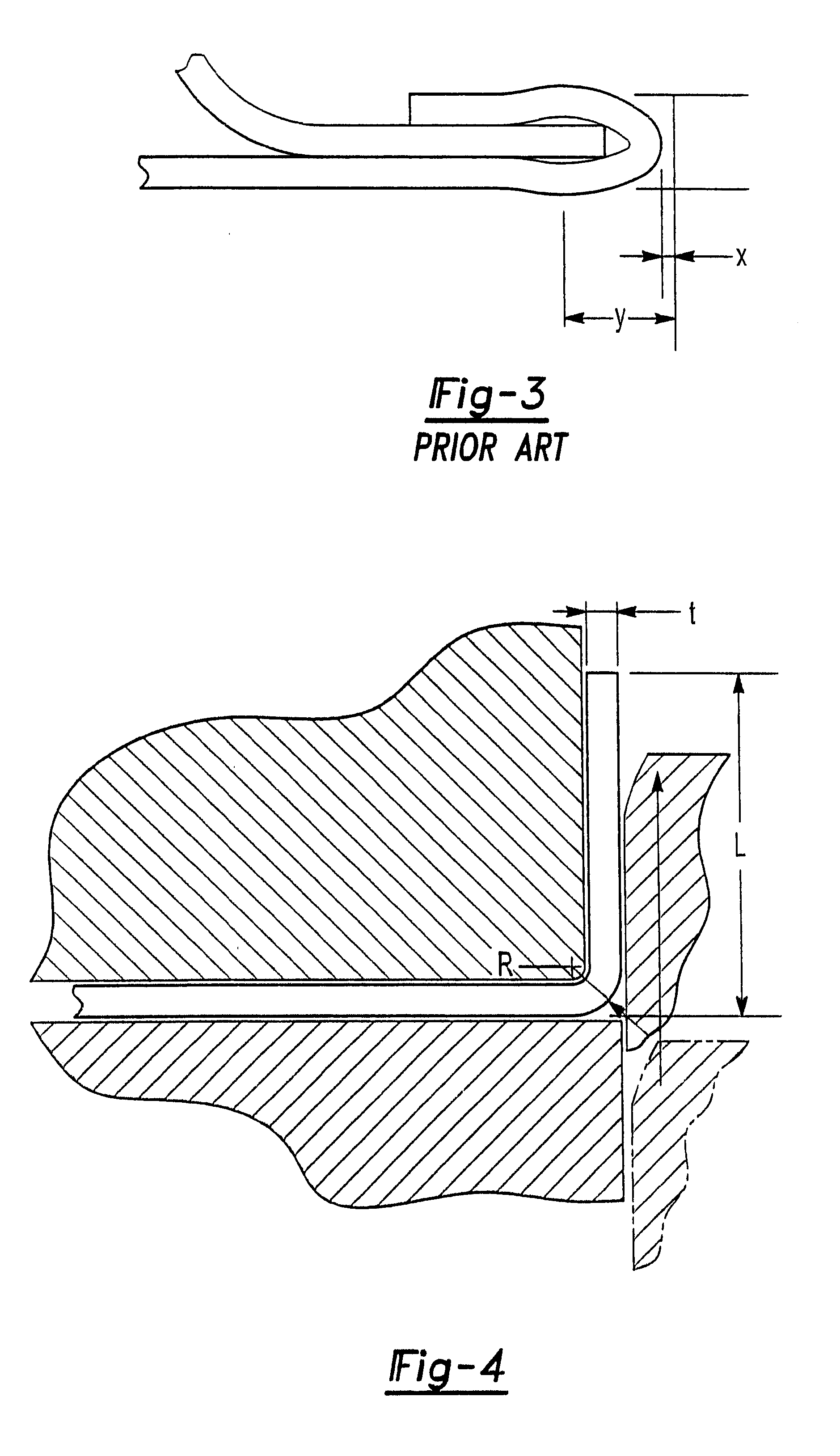

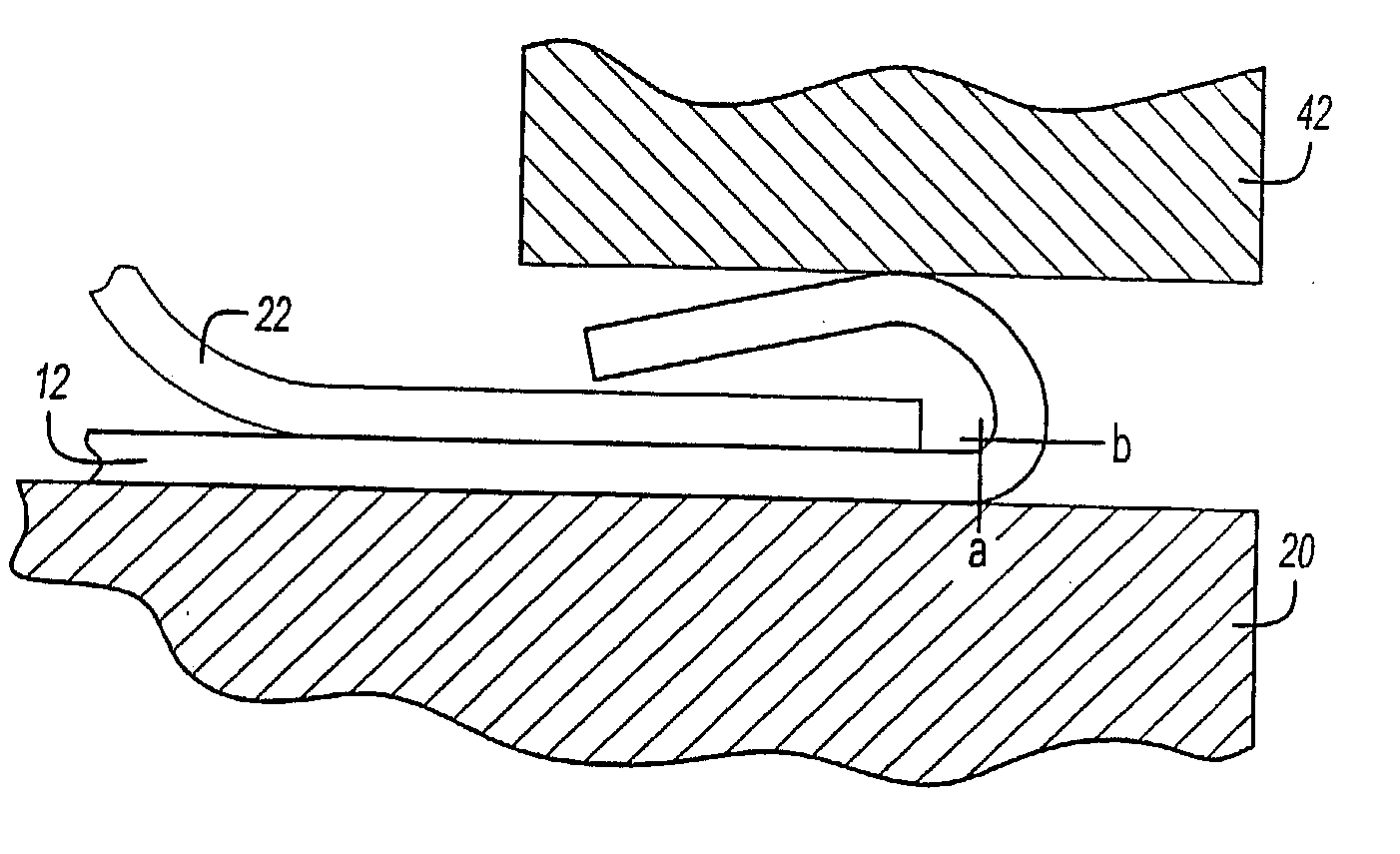

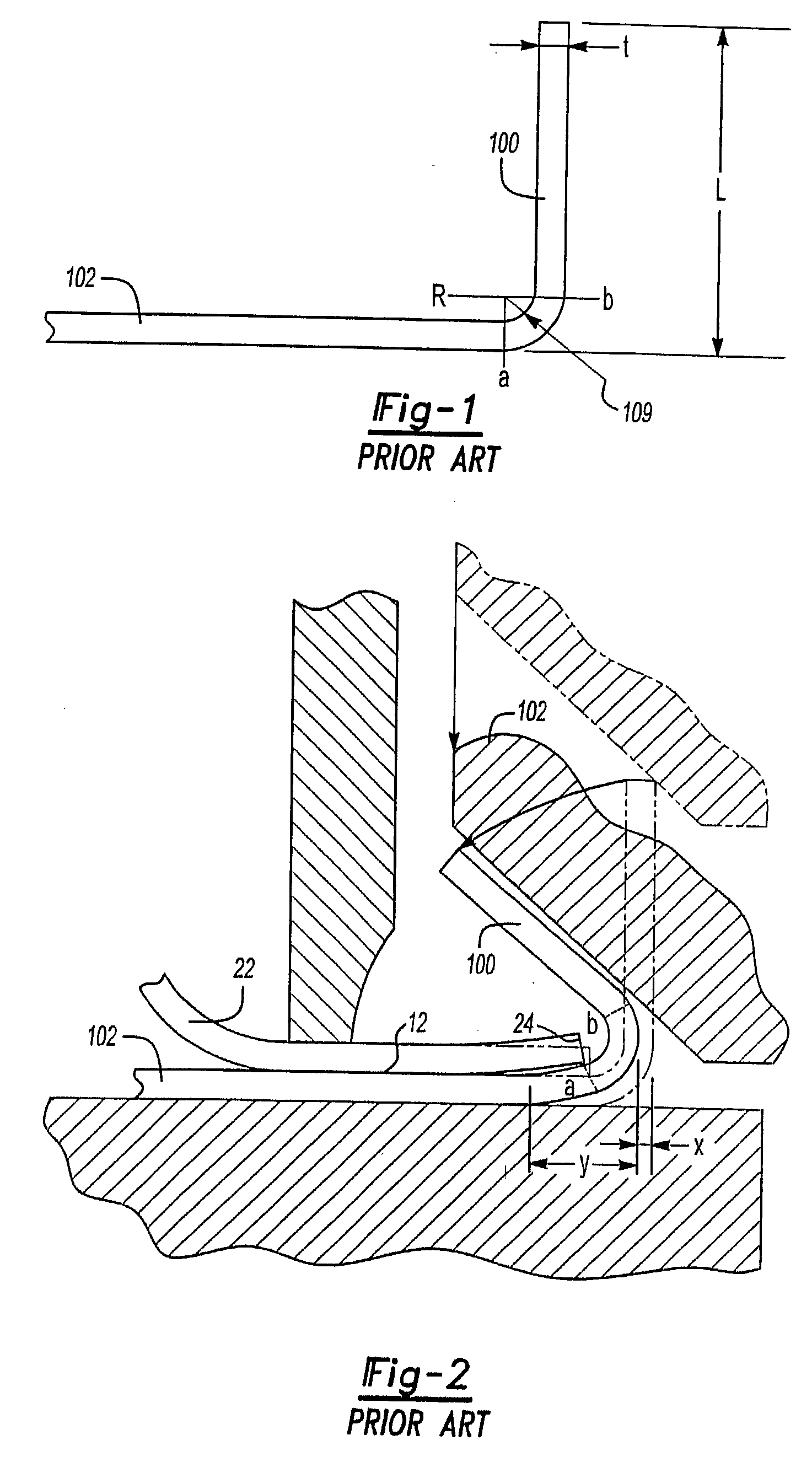

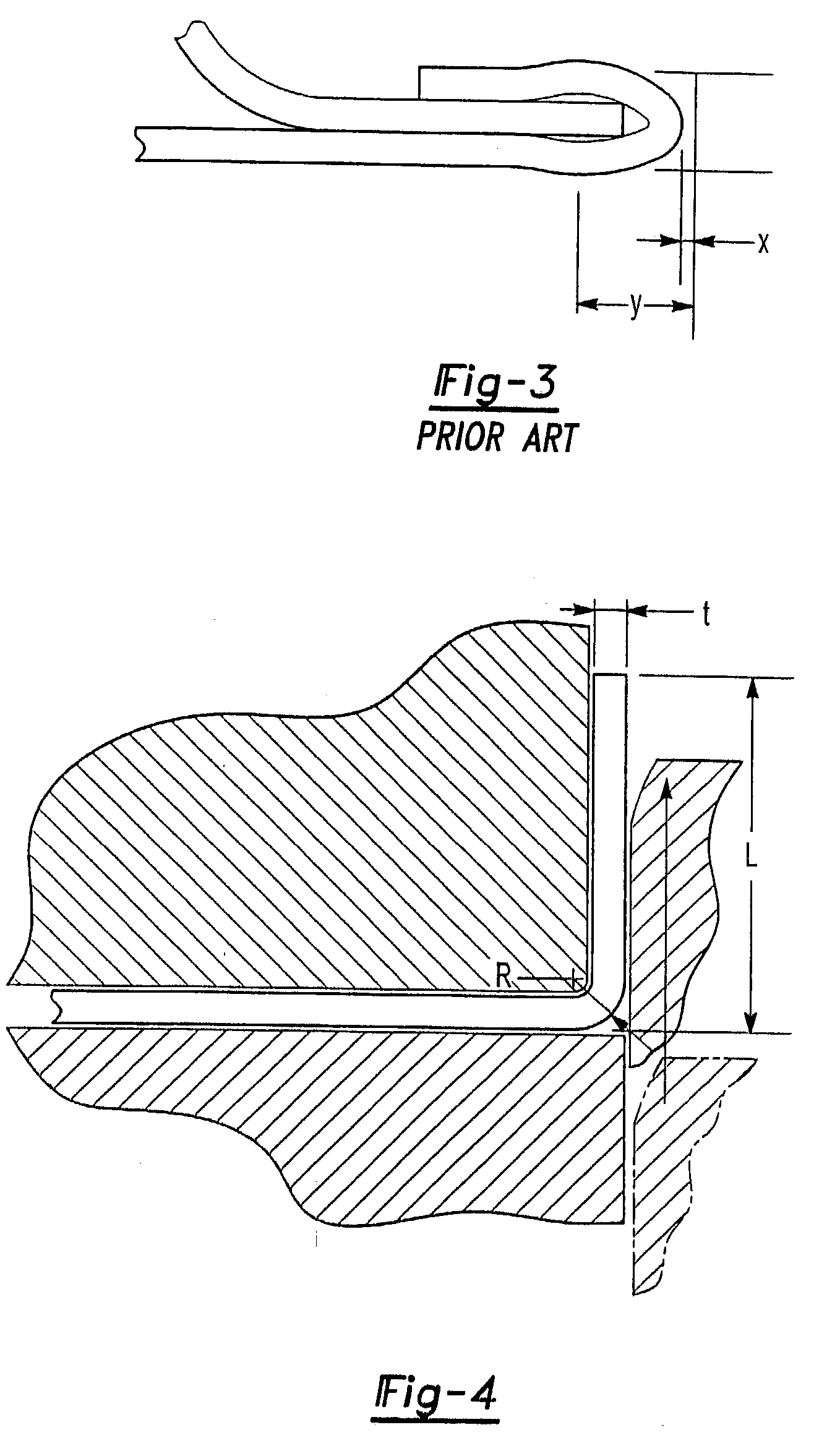

Method for hemming

A method for sharp, crisp hemming inner and outer aluminum sheet metal panels in which a flange is formed along an outer edge so that the flange extends from a bend line and lies in a plane generally perpendicular to the plane of the outer panel. This bend line, furthermore, has an outer radius in the range of (1.0 mm+t)>R>(0.2 mm+t) where t=the thickness of the outer panel. The inner panel is then positioned on the outer panel so that an outer edge of the inner panel is adjacent the bend line. The flange is then bent so that the flange overlies the outer edge of the inner panel while simultaneously compressing the flange in the direction towards the bend line. Thereafter, the flange is compressed against the outer peripheral portion of the inner panel thus completing the hem. The present invention thus achieves a sharp radius bend on the outer edge of the panel with a layer radius bend on the inner panel as well as a class "A" surface on the outer panel adjacent the hem which is free of recoil or other distortion.

Owner:VALIANT CO LTD

Closed-loop-controlled encapsulating piezoelectric ceramic actuator and resistance strain gauge fixing method

ActiveCN103595292AEliminate hysteresisEliminate creepPiezoelectric/electrostriction/magnetostriction machinesClosed loopActuator

The invention discloses a closed-loop-controlled encapsulating piezoelectric ceramic actuator and a resistance strain gauge fixing method. Resistance strain gauges are arranged on the planes of the two opposite sides of piezoelectric ceramic so that nonlinear characteristics such as lag and creepage of the piezoelectric ceramic in the process of displacement output can be effectively eliminated. Consequently, the normal displacement output of the piezoelectric ceramic is guaranteed, and output accuracy is improved. Meanwhile, the displacement output amount can be fed back through the resistance strain gauges, so that closed loop control is achieved, and the actuator is simple and compact in overall structure and small in size. Due to the fact that the piezoelectric ceramic is arranged inside a stainless steel sleeve, the stainless steel sleeve is capable of effectively protecting the piezoelectric ceramic against external vibration, impact, inertia force and the like so as to improve reliability, stability and installability of the piezoelectric ceramic and ensure the service life of the piezoelectric ceramic.

Owner:苏州迈客荣自动化技术有限公司

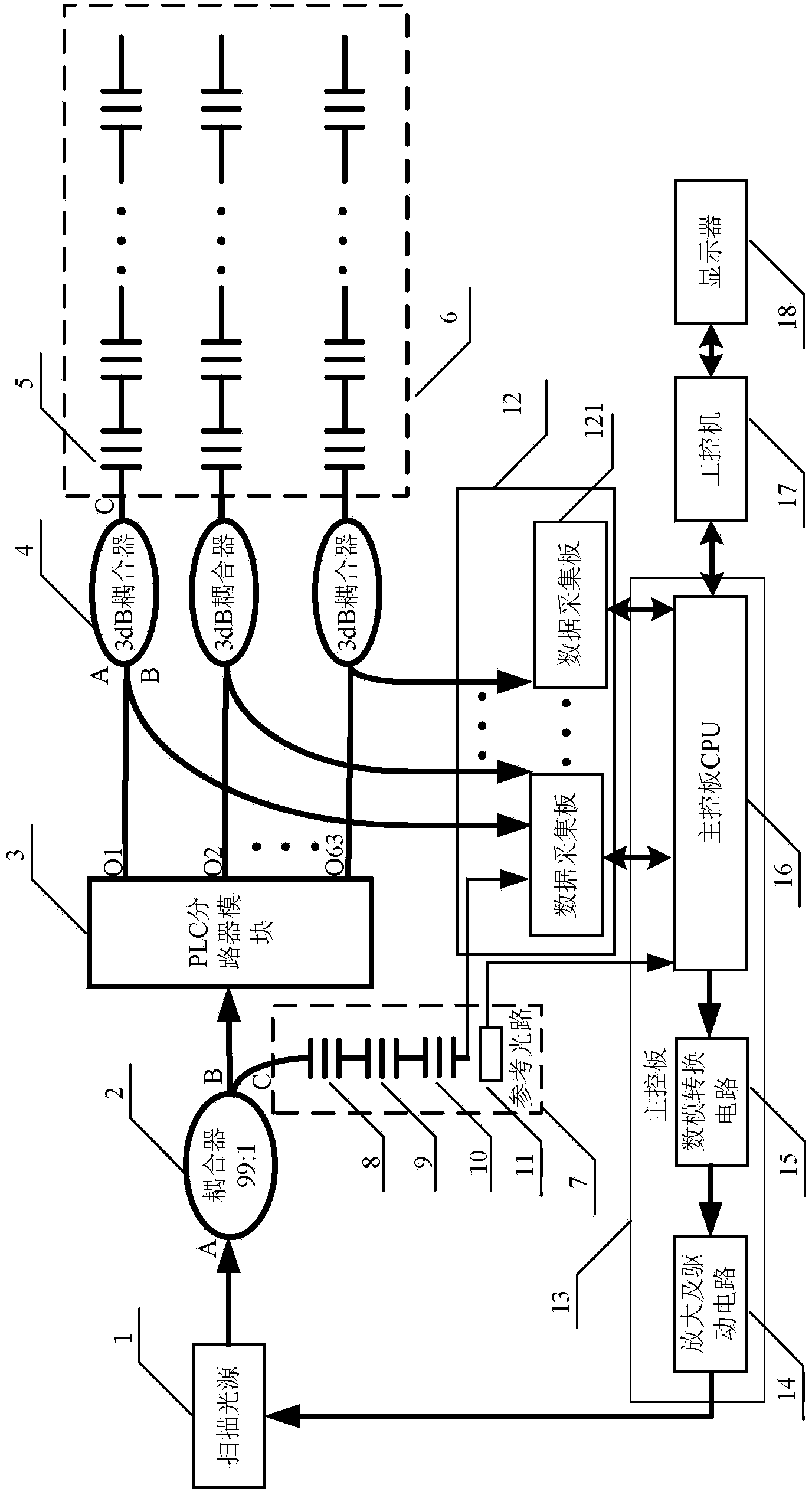

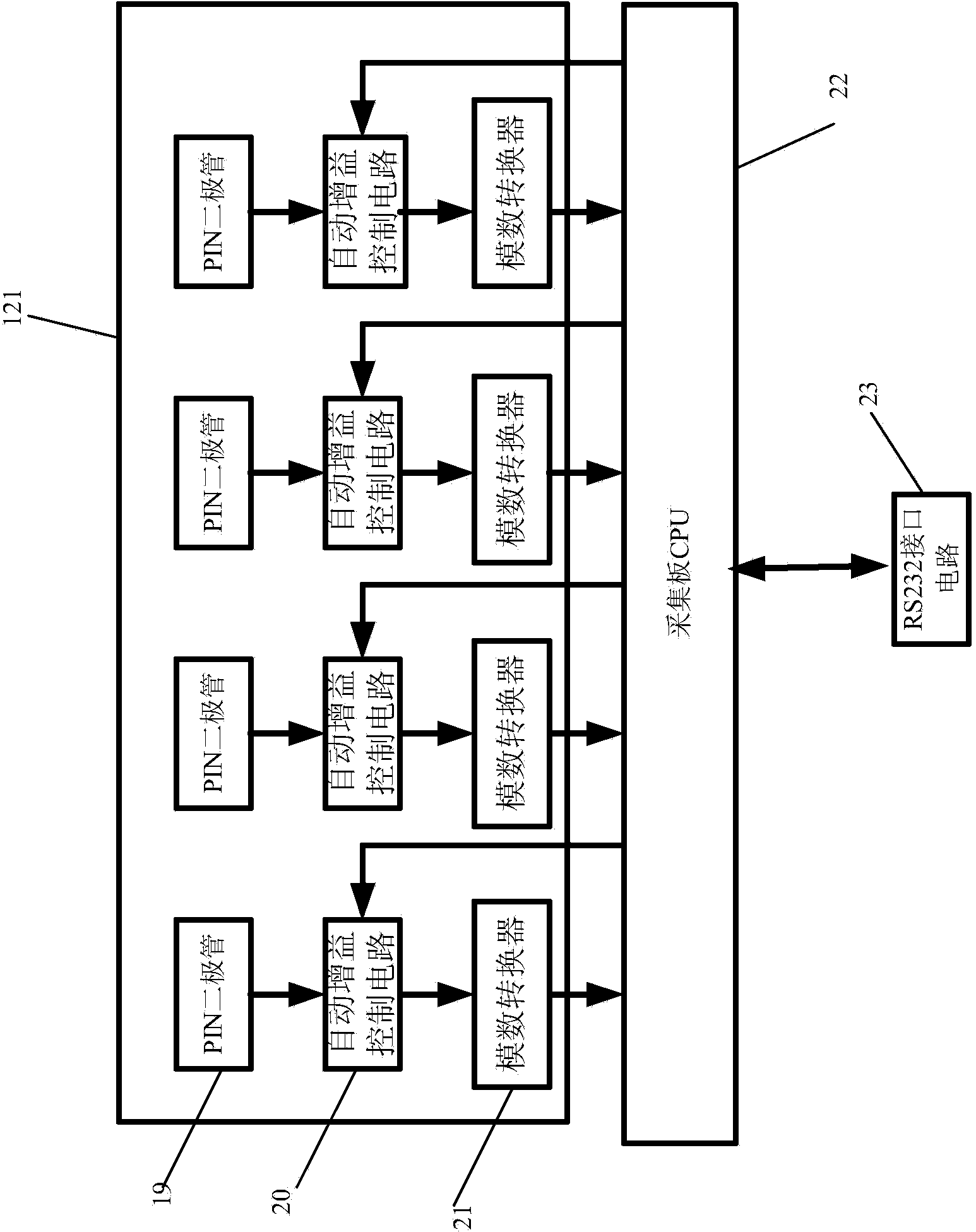

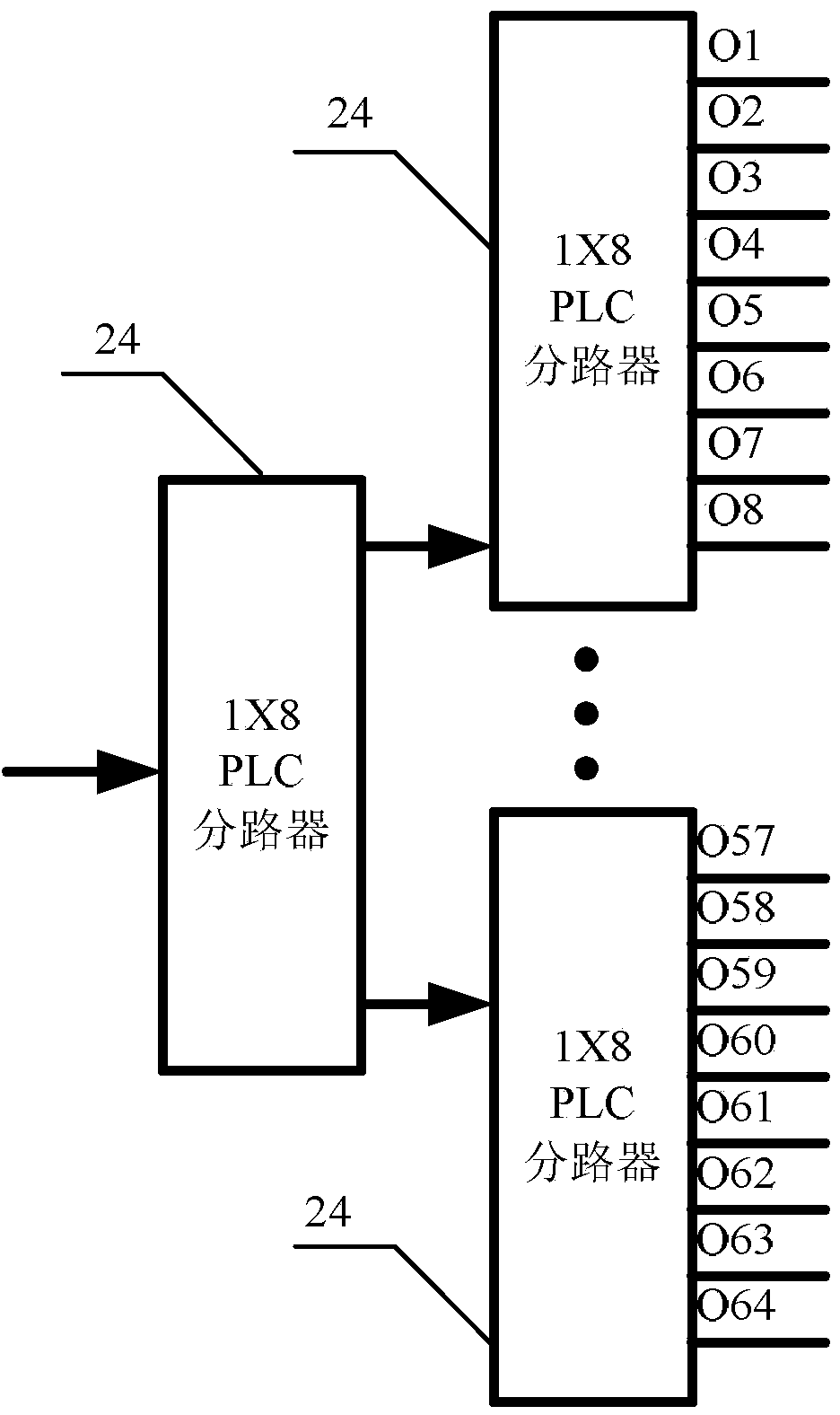

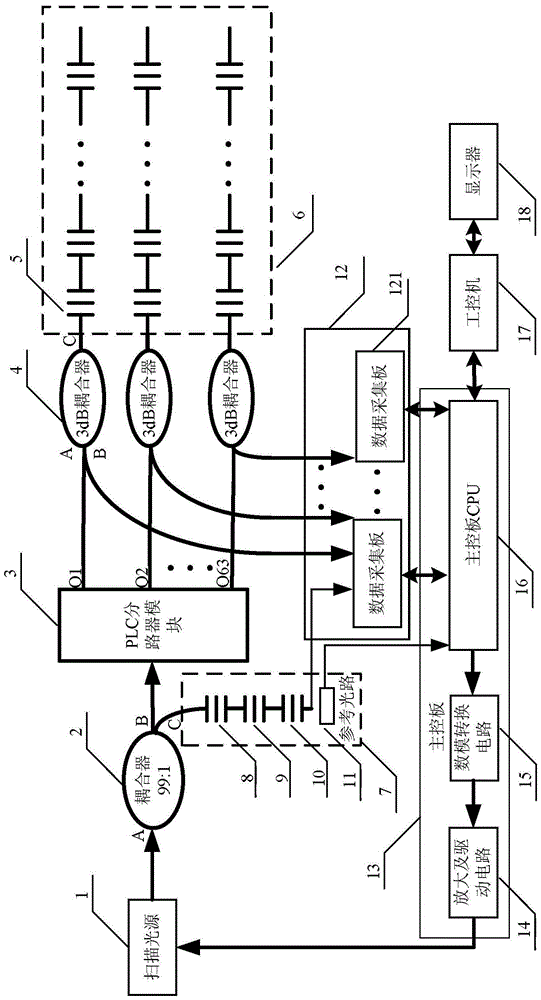

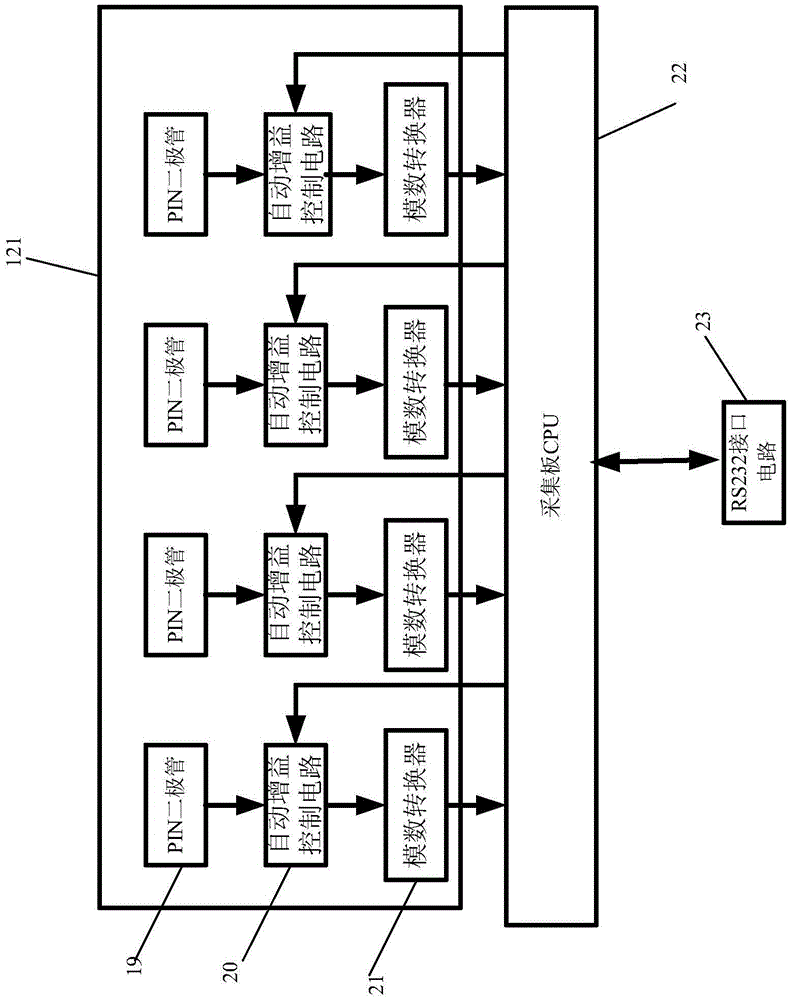

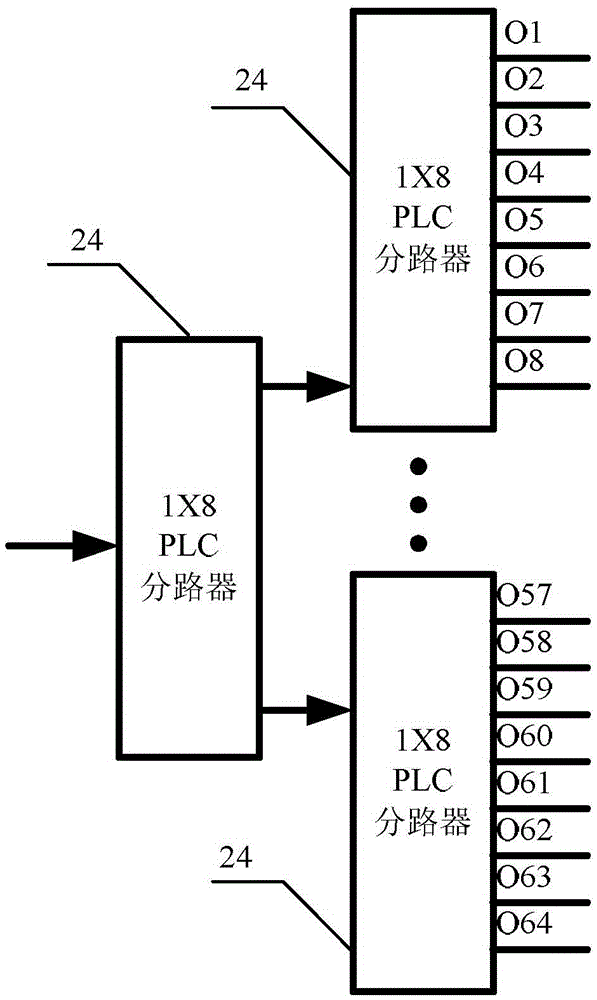

FBG (fiber bragg grating) interrogator

ActiveCN103528607AEliminate creepSolve the real problemConverting sensor output opticallyHysteresisGrating

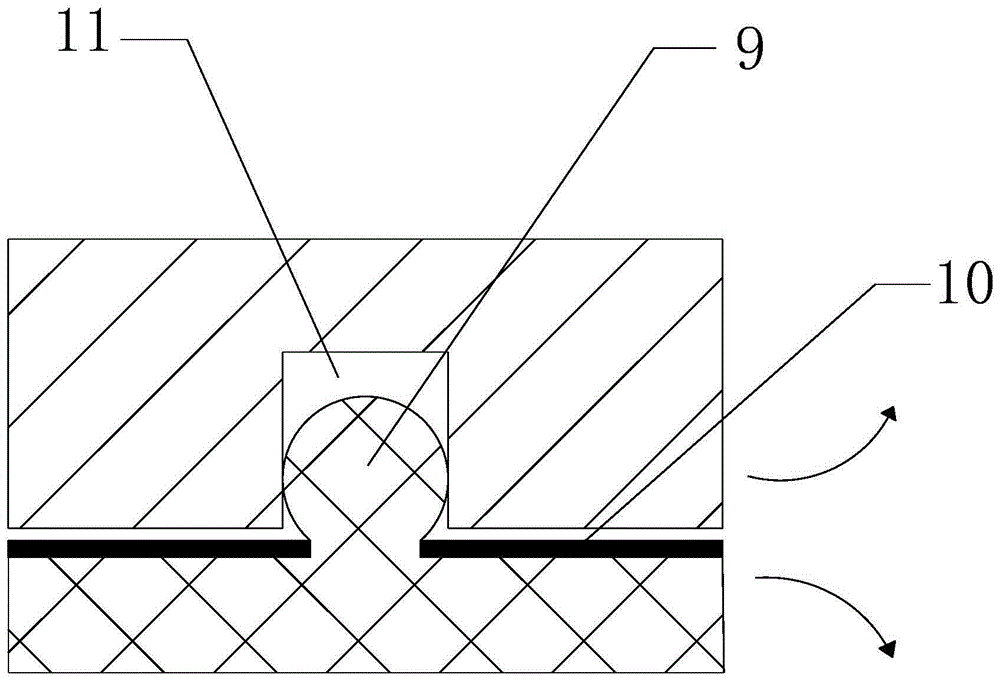

The invention relates to an FBG interrogator which is characterized by comprising a scanning light source (1), a coupler (2) with a splitting ratio of 99 :1, a PLC (programmable logic controller) shunt module (3), a plurality of 3dB couplers (4), a FBG array (6), a reference light path (7), a data collection module (12), a main control panel (13), an industrial personal computer (17) and a display (18), wherein the reference light path (7) comprises a first reference optical grating (8), a second reference optical grating (9), a third reference optical grating (10) and a temperature sensor; the temperature sensor is connected with the main control panel; the wave length lambada 2 of the first reference optical grating (8) and the wave length lambada 3 of the second reference optical grating (9) are close to one end of the wave length of a system; the wave length lambada 4 of the third reference optical grating (10) is close to the other end of the wave length of the system; and the proportion of the difference between the lambada 4 and the lambada 3 and the difference between the lambada 3 and the lambada 2 ranges between 4 : 1 and 7 :1. Compared with the prior art, a costly FP etalon is replaced with three simple reference gratings and one temperature sensor, and the gratings and the temperature sensor form the reference light path, so that creep deformation of the scanning light source and influence on the demodulation accuracy which is caused by the change of the output wave length of the light source due to hysteresis and drift are eliminated very effectively.

Owner:浙江振东光电科技有限公司

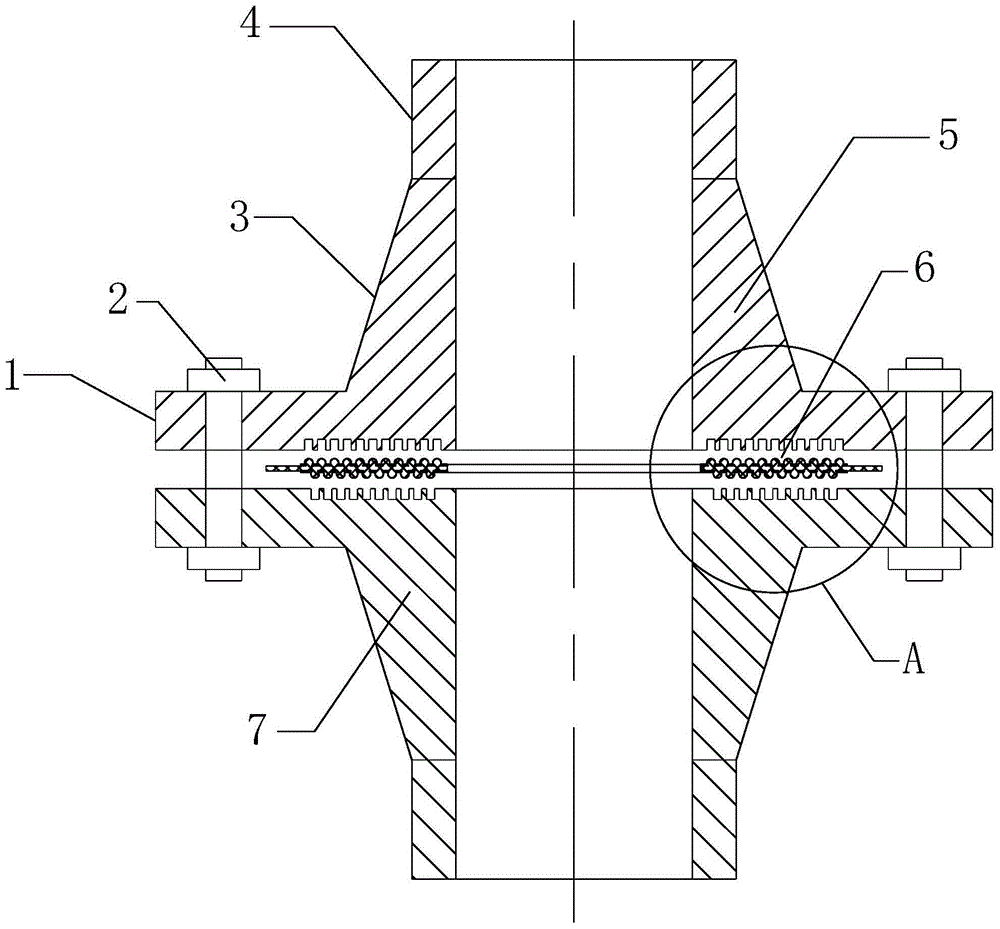

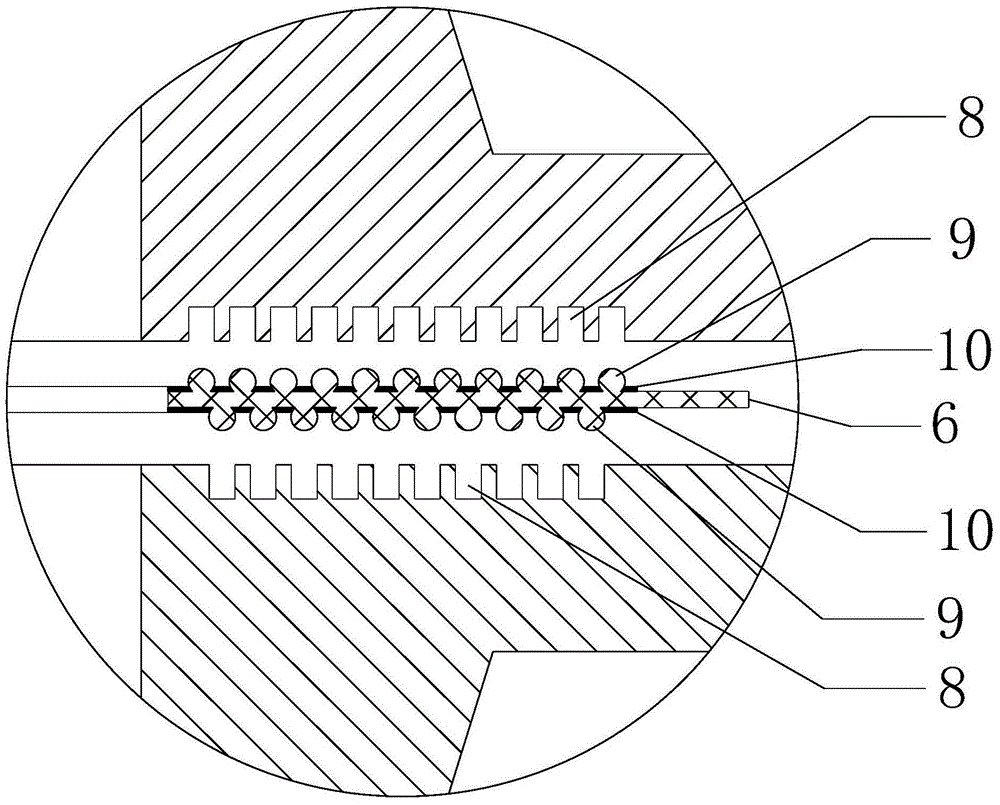

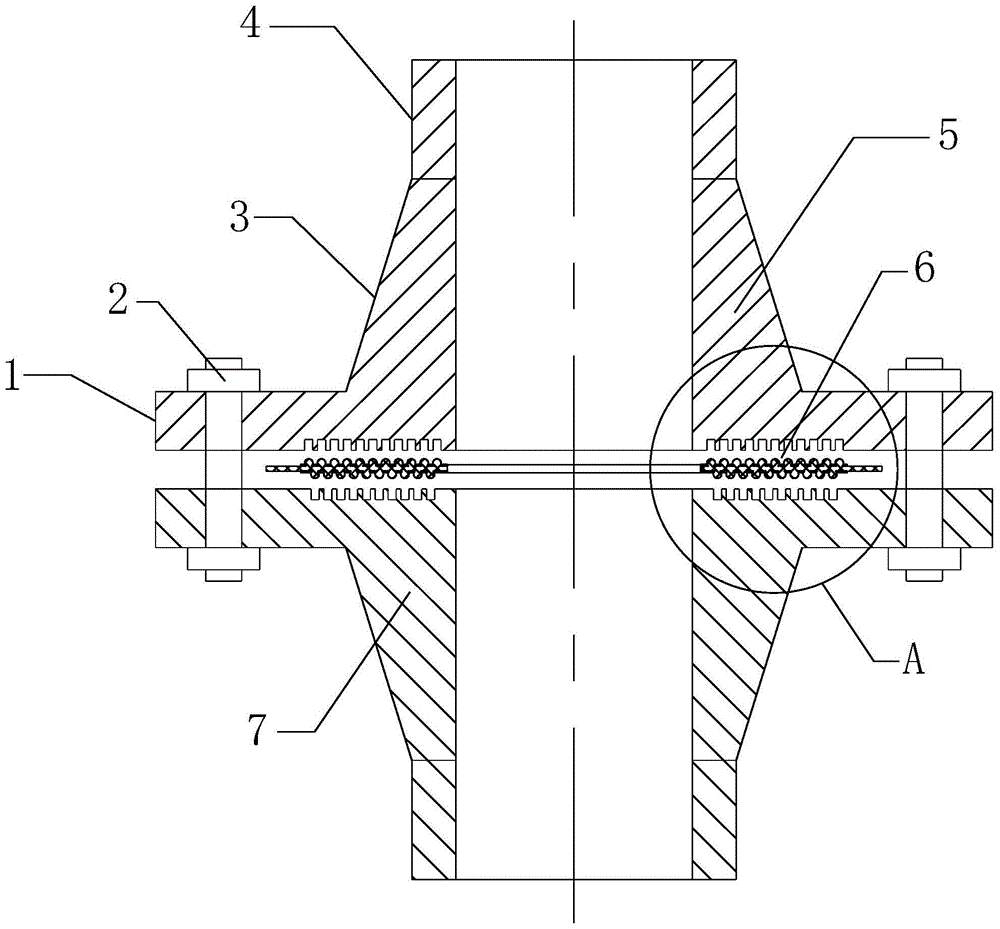

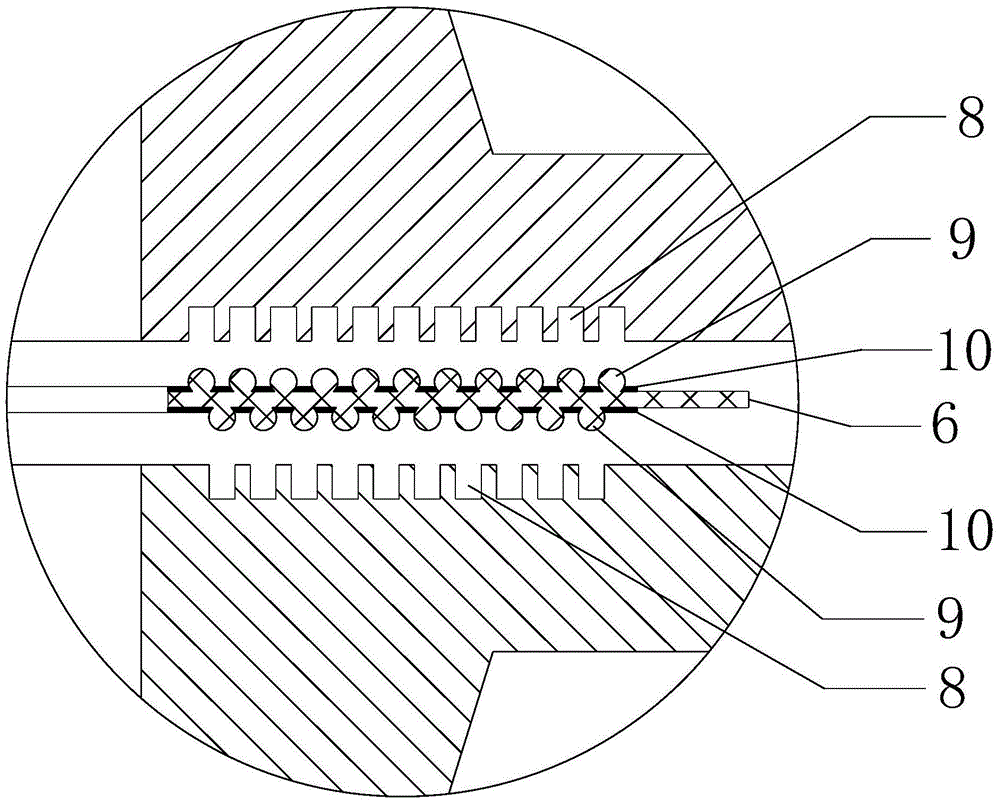

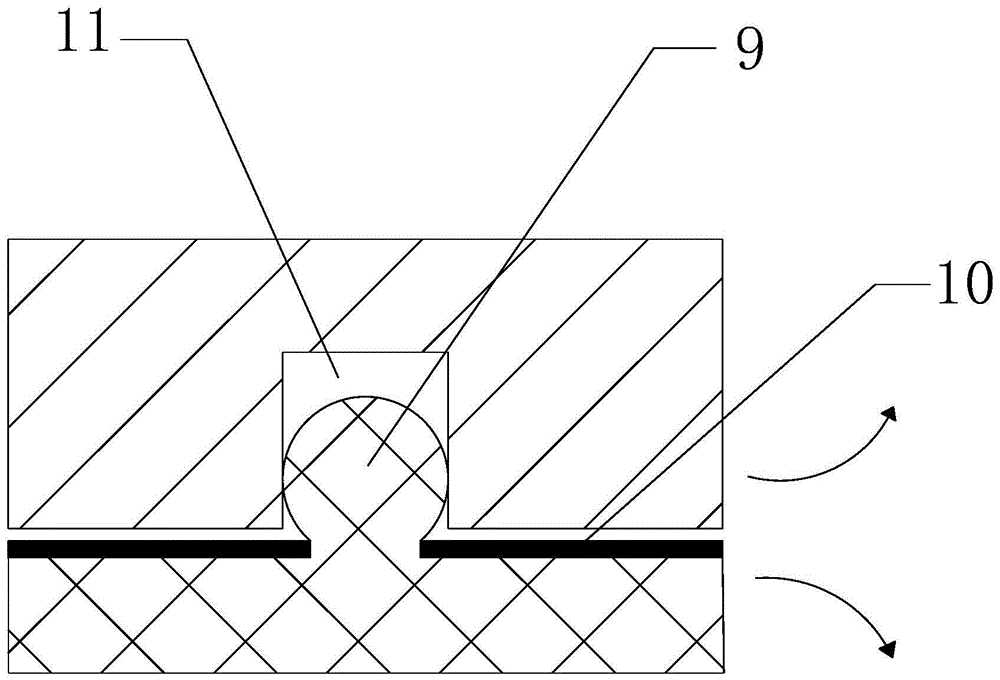

High-temperature flange sealing structure comprising flexible graphite metal omega-shaped tooth composite gasket

InactiveCN104565618APrevent leakageLeakage slowed or even eliminatedFlanged jointsInterference fitGraphite

The invention relates to the field of a pipeline flange sealing structure, in particular to a high-temperature flange sealing structure comprising a flexible graphite metal omega-shaped tooth composite gasket. The high-temperature flange sealing structure is characterized by comprising an upper flange, a lower flange and the flexible graphite metal omega-shaped tooth composite gasket. The upper surface and the lower surface of a metal frame of the flexible graphite metal omega-shaped tooth composite gasket are provided with annular boss in multiple circles respectively, the annular bosses are provided with omega-shaped sections and arranged at equal distance, the planar parts of the upper and lower surfaces of the flexible graphite metal omega-shaped tooth composite gasket are provided with flexible graphite layers, annular grooves matched with the annular bosses are arranged on the contact surfaces of the upper flange, the lower flange and the flexible graphite metal omega-shaped tooth composite gasket and provided with rectangular sections, the annular bosses are inserted into the annular grooves correspondingly and are in interference fit with the same. The high-temperature flange sealing structure can be applied to high-temperature and -pressure working conditions, excellent tightness can be kept for a long time, and leak of the flanges can be effectively prevented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

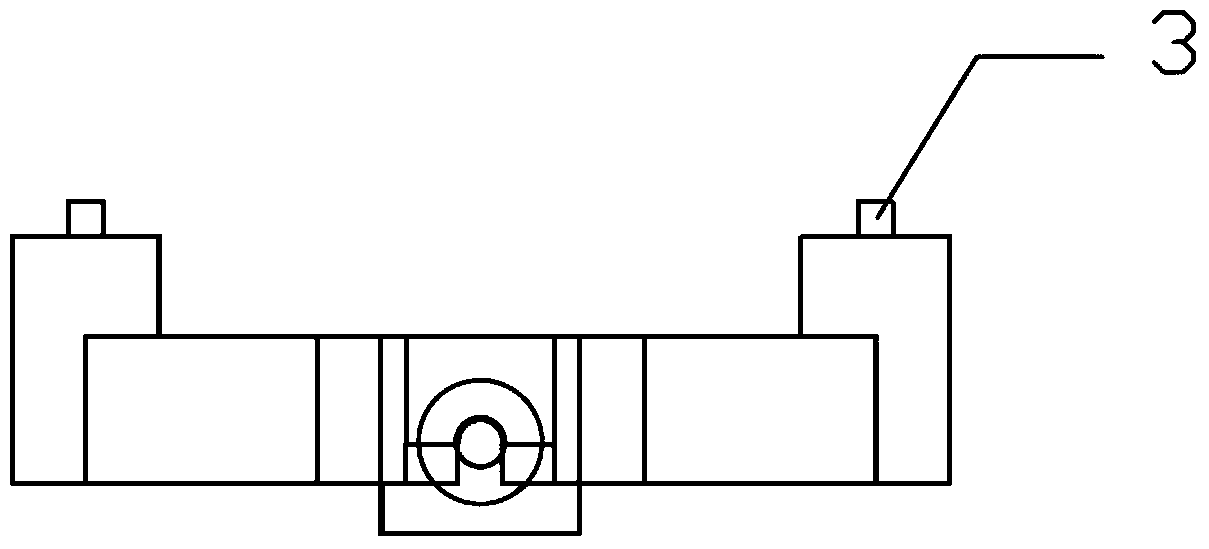

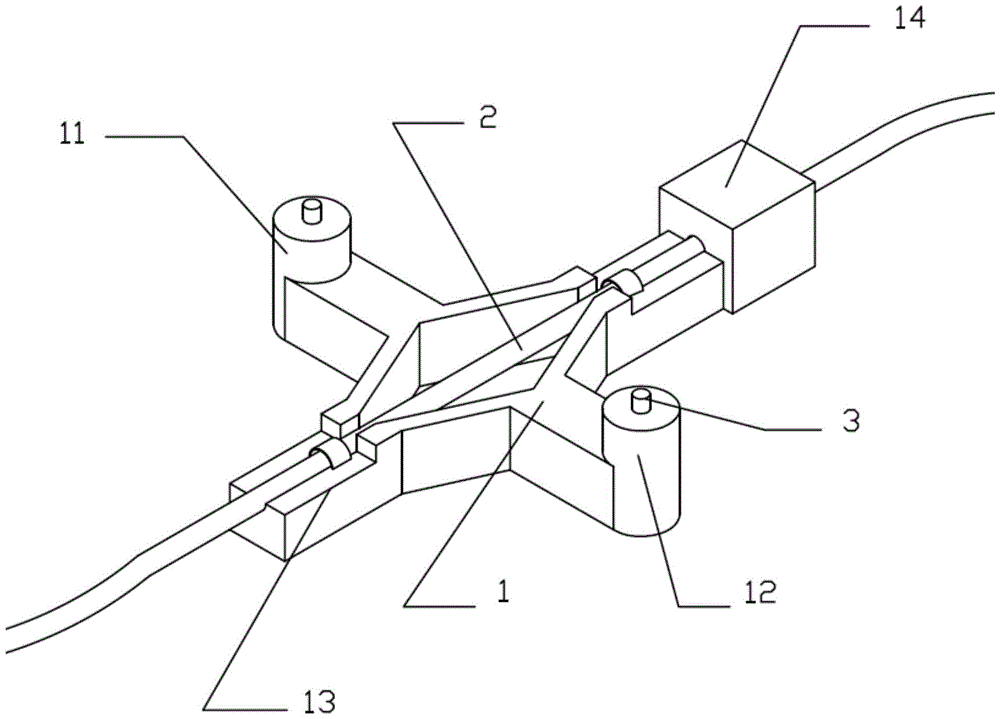

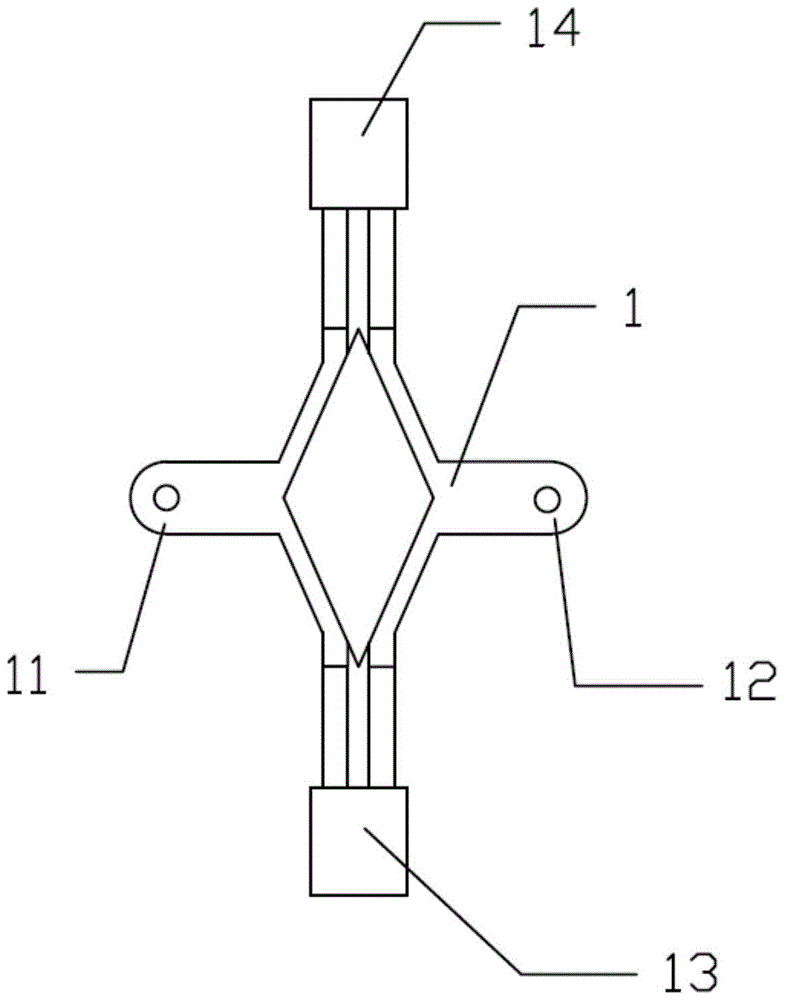

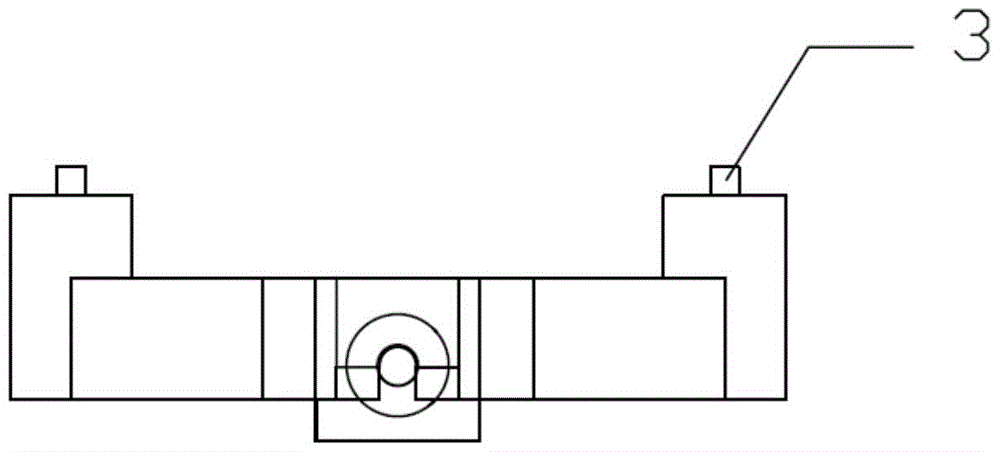

Optical fiber sensor capable of measuring stress-strain of metal accurately

ActiveCN103438817AImprove long-term stabilityHigh precisionUsing optical meansNonlinear deformationOptical fiber cable

The invention relates to an optical fiber sensor capable of measuring stress-strain of metal accurately. The optical fiber sensor comprises a strain elastic beam provided with a first measuring fixing end and a second measuring fixing end. The connecting line of the first measuring fixing end and the second measuring fixing end is perpendicular to an axis of an optical fiber. Due to the fact that the optical fiber sensor capable of measuring the stress-strain of metal accurately adopts the structure, creep deformation caused by a traditional gluing method is changed, and long-term stability of a zero point is improved. The output of the optical fiber installed on a tested metal structural body is hardly affected by the changes of the environment temperature, and secondary compensation does not need to be carried out by utilizing an additional temperature measuring sensor. The transverse sensitivity of the optical fiber is reduced, the optical fiber is sensitive only about the stain of the strain elastic beam in the measuring direction, and the optical fiber can have good strain measurement single-direction performance. The rigidity of a strain transmission interface is guaranteed through the technology that the strain elastic beam is directly welded to the tested metal structural body, and creep deformation and non-linear deformation of the strain transmission interface are removed.

Owner:SHANGHAI BAIANTEK SENSING TECH CO LTD

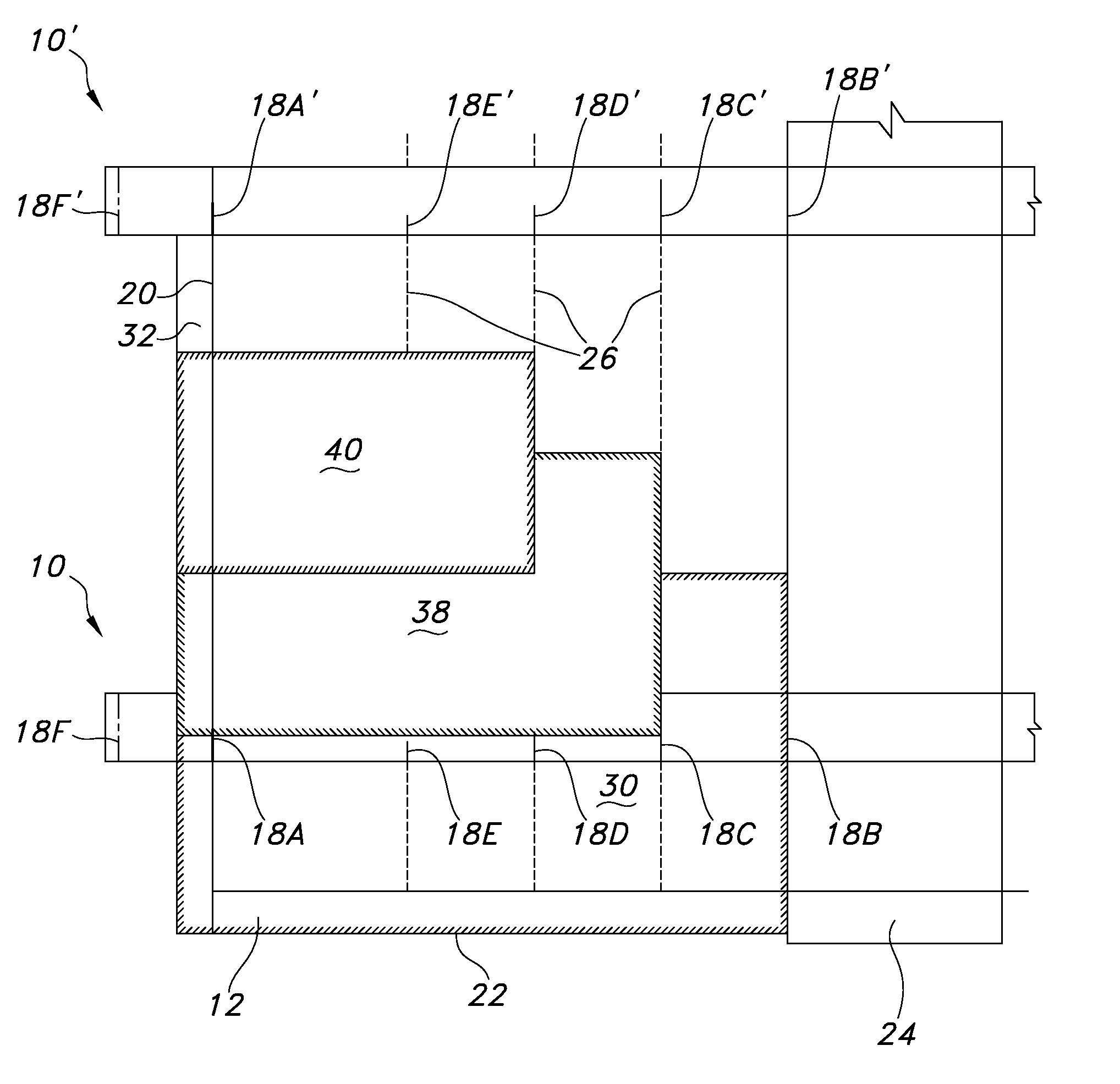

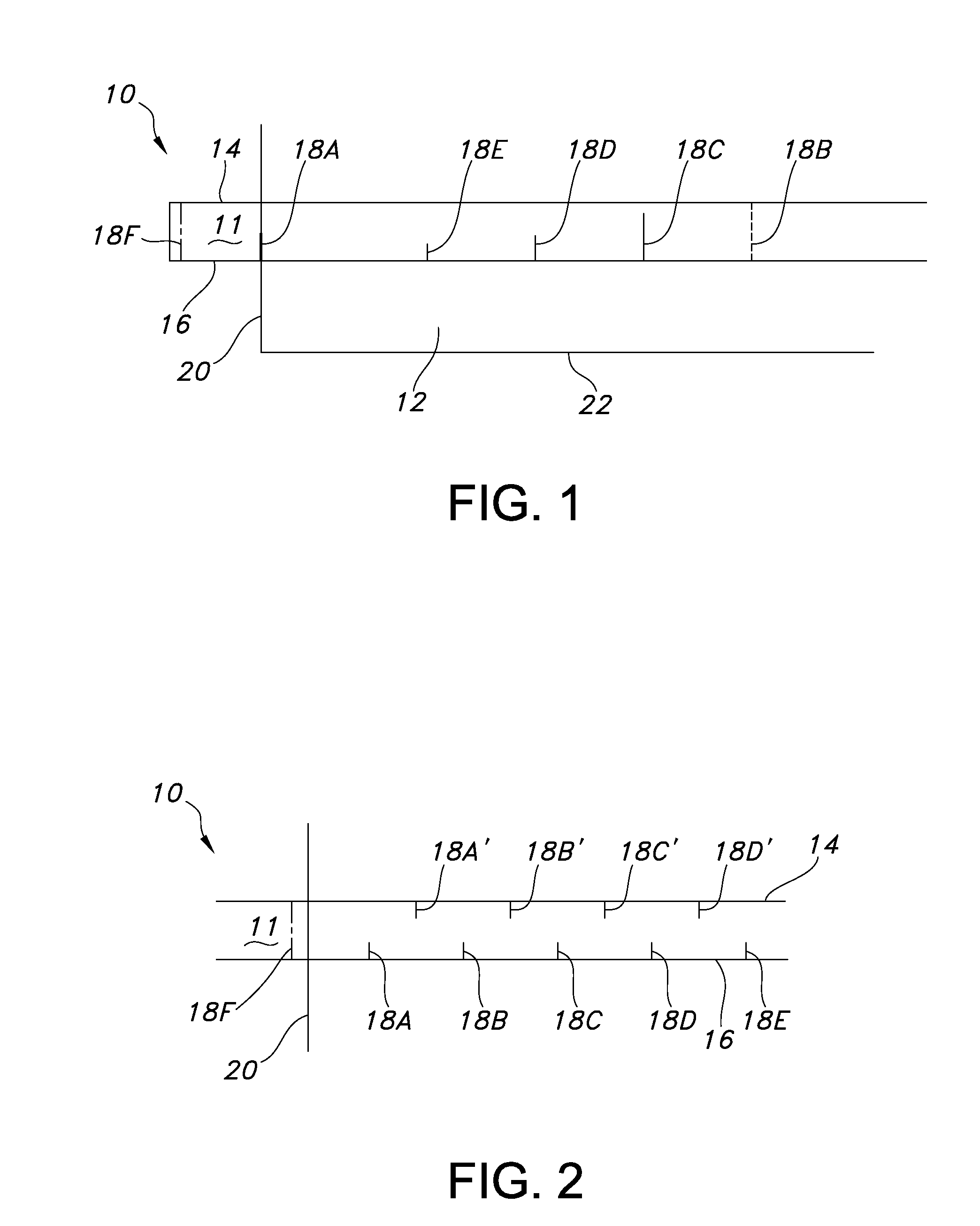

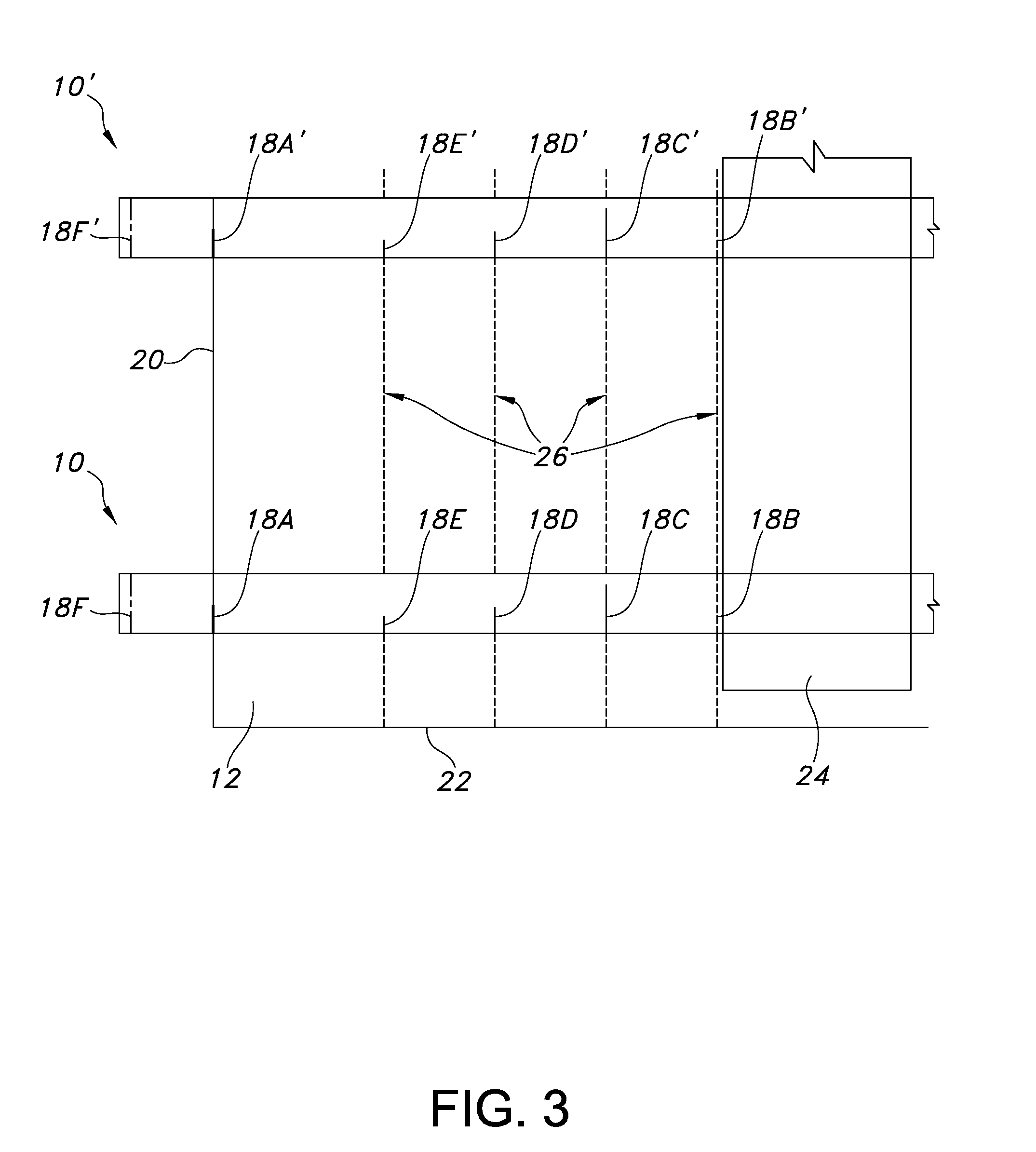

Horizontal Layout Tape

InactiveUS20090217602A1Eliminate creepEliminate installation human errorRoof covering using slabs/sheetsRoof covering using tiles/slatesCivil engineering

Owner:HUNGARTER RONALD CHARLES

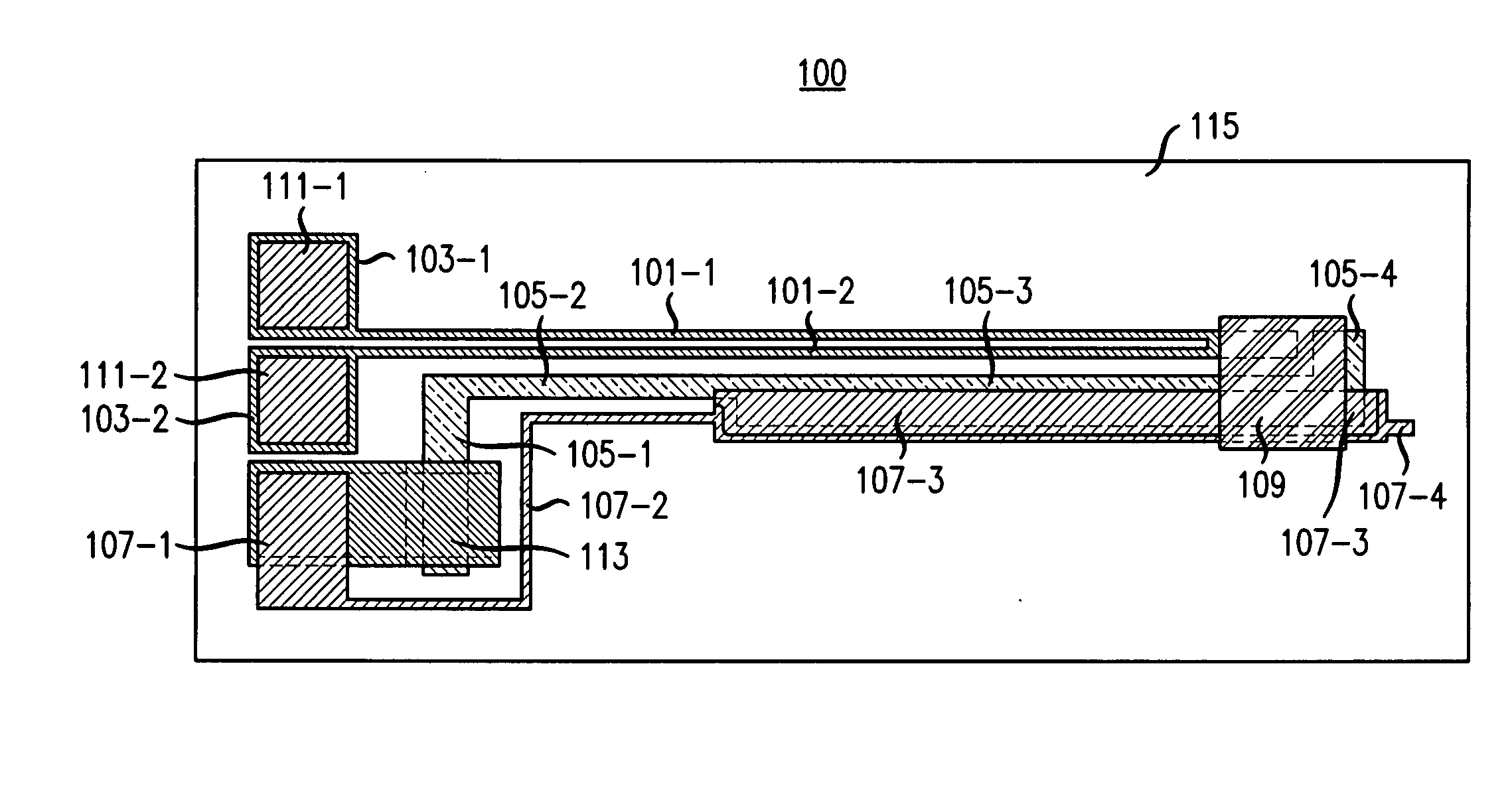

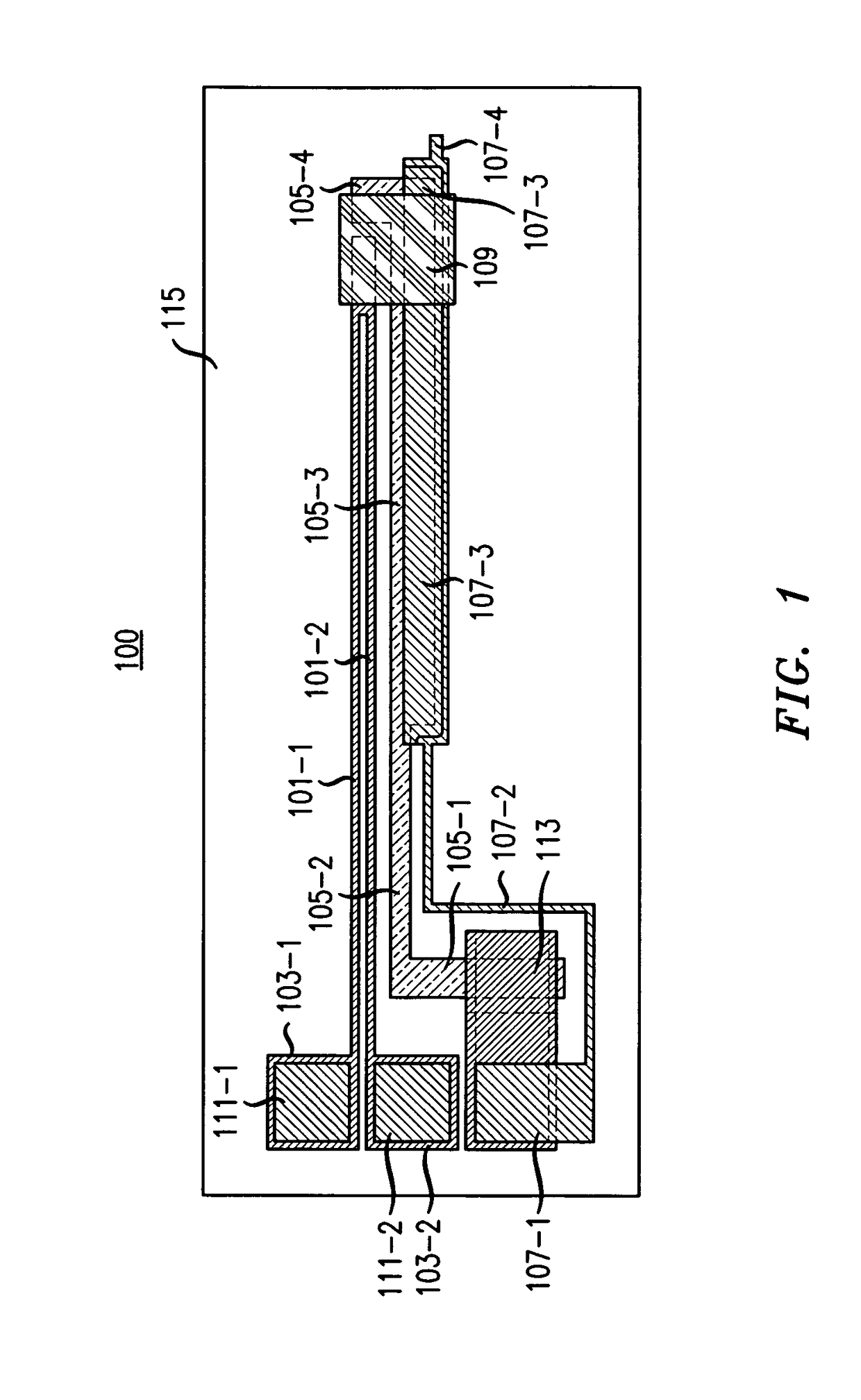

Micro-actuator and locking switch

ActiveUS20080061387A1Eliminate creepLower impedanceElectrothermal relaysSolid-state devicesMicro actuatorElectrical control

A micro-electromechanical actuator employs metal for the hot arm and silicon for at least the flexible portion of the cold arm. The cold arm made of silicon is coupled to a metal wire that moves with it and is used to carry the signal to be switched when at least two of such actuators are formed into a switch. Arrays of such switches on a first chip may be cooperatively arranged with a second chip that is flip-chip bonded to the first chip, the second chip having thereon wires routing the electrical control currents to the various hot arms for heating them as well as the signals to be switched by the various switches.

Owner:WSOU INVESTMENTS LLC

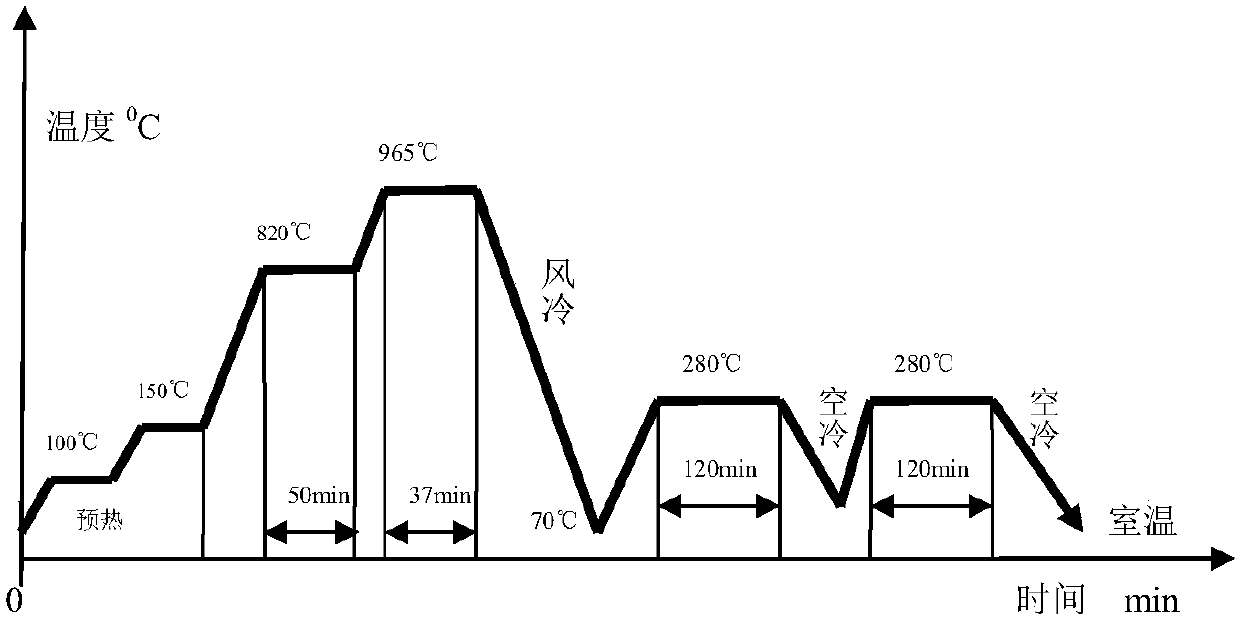

Heat treatment and quenching process for high-carbon high-chromium tool steel

InactiveCN107739783AExtended service lifeImprove mechanical propertiesHigh carbonMechanical property

The invention discloses a heat treatment and quenching process for high-carbon high-chromium tool steel. The material is high-carbon high-chromium ledeburite cold-worked tool steel with the steel number of ASSAB XW-5 imported from Sweden, and the tool steel mainly comprises, by weight percentage, 2.05% of carbon, 12.5% of chromium, 1.3% of wolfram, 0.8% of molybdenum and 0.3% of silicon. The heattreatment and quenching process comprises the following steps that (1), workpieces are put into a quenching furnace to be preheated to 150 DEG C; (2), the workpieces are put into the quenching furnacefor two-stage heating until the quenching temperature is 965 DEG C, and then heat preservation is carried out; (3), the workpieces are taken out from the quenching furnace for air-blast quenching until the temperature is 70 DEG C; and (4) the workpieces are placed into a tempering furnace, the workpieces are heated to 280 DEG C, heat preservation and tempering are carried out on the workpieces, the workpieces are taken out from the tempering furnace for air cooling, and then the above procedures in the step (4) is repeated. According to the heat treatment and quenching process, staged heatingand twice tempering are adopted, and therefore the heating is more uniform, the hardenability of the workpieces is improved, the crystal grains can be refined, uniform, stable and reliable, the service life and the mechanical property of the parts are obviously improved, the toughness and the impact resistance of the workpieces are improved, and the use requirements of the precise parts are met.

Owner:HUBEI ENG INST

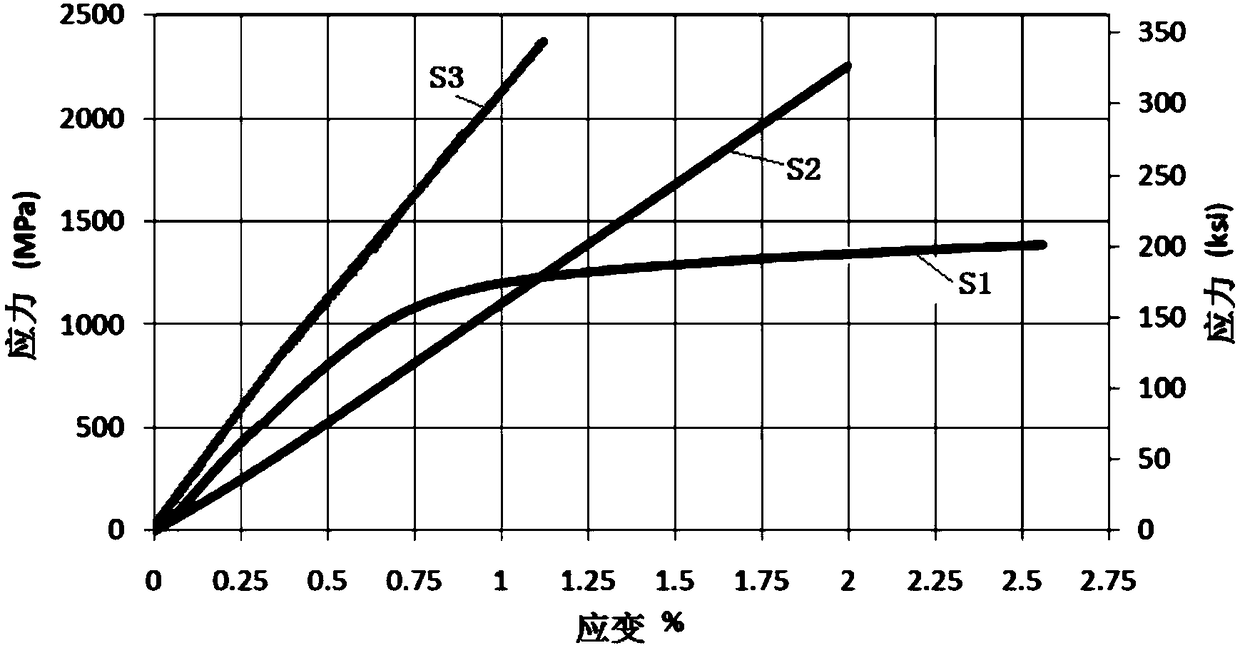

Creep-resistish long glass fiber, creep-resistish long glass fiber enhanced propene polymer (PP) composite material and preparation method thereof

The invention discloses a creep-resistish long glass fiber, a creep-resistish long glass fiber enhanced propene polymer (PP) composite material and a preparation method thereof. The creep-resistish long glass fiber enhanced PP composite material has excellent impact resistance property and creep-resistish performance by adopting a special assistant and a compatilizer to reduce creeping problems and floating fibre problems, has smooth surface without floating fibers, is particularly suitable to prepare products such as vehicle parts, electronics components, instrument parts and aviation equipment parts and the like.

Owner:HUIZHOU CHANGYI TECH

Method for hemming

A method for sharp, crisp hemming inner and outer aluminum sheet metal panels in which a flange is formed along an outer edge so that the flange extends from a bend line and lies in a plane generally perpendicular to the plane of the outer panel. This bend line, furthermore, has an outer radius in the range of (1.0 mm+t)>R>(0.2 mm+t) where t=the thickness of the outer panel. The inner panel is then positioned on the outer panel so that an outer edge of the inner panel is adjacent the bend line. The flange is then bent so that the flange overlies the outer edge of the inner panel while simultaneously compressing the flange in the direction towards the bend line. Thereafter, the flange is compressed against the outer peripheral portion of the inner panel thus completing the hem. The present invention thus achieves a sharp radius bend on the outer edge of the panel with a layer radius bend on the inner panel as well as a class "A" surface on the outer panel adjacent the hem which is free of recoil or other distortion.

Owner:VALIANT CO LTD

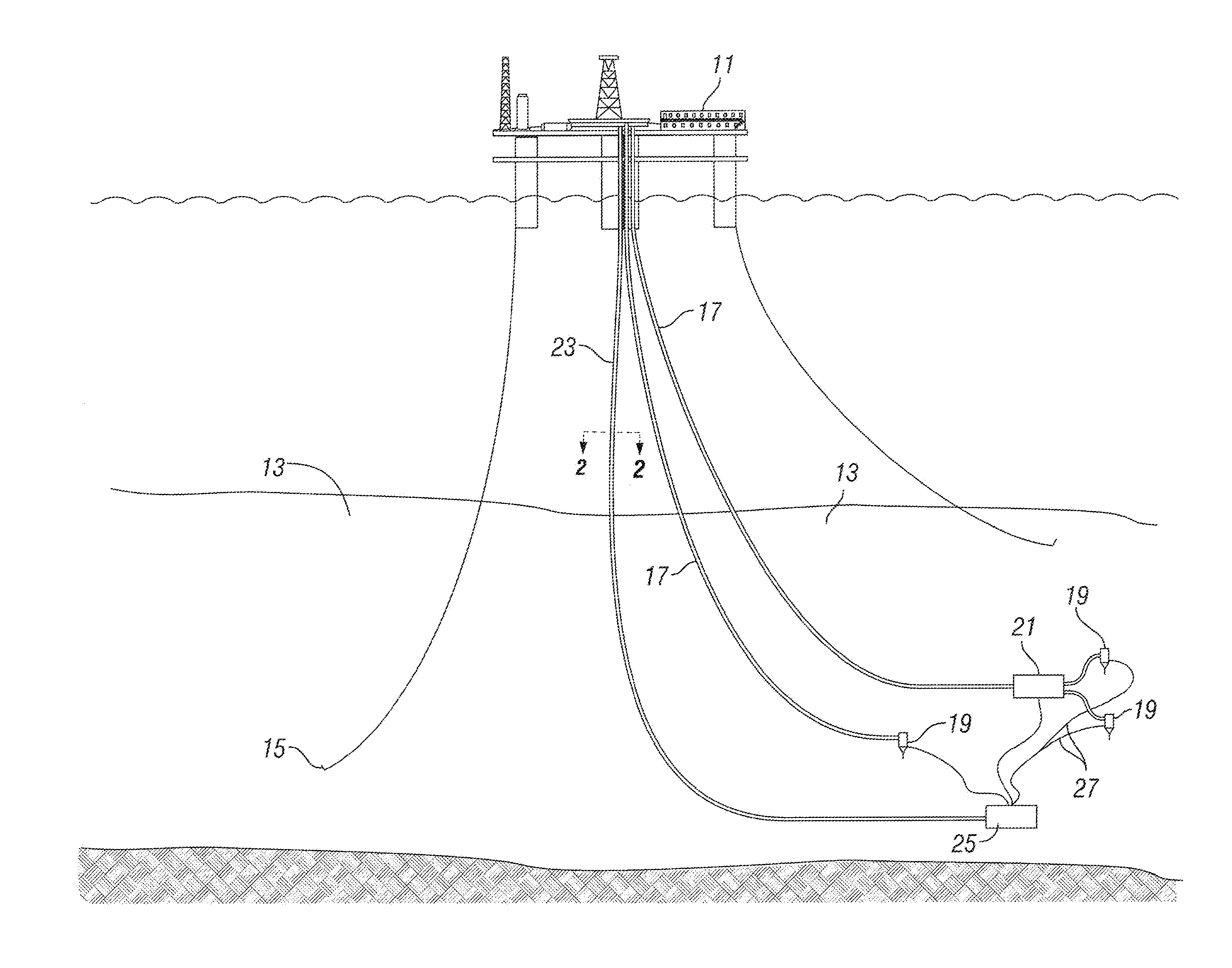

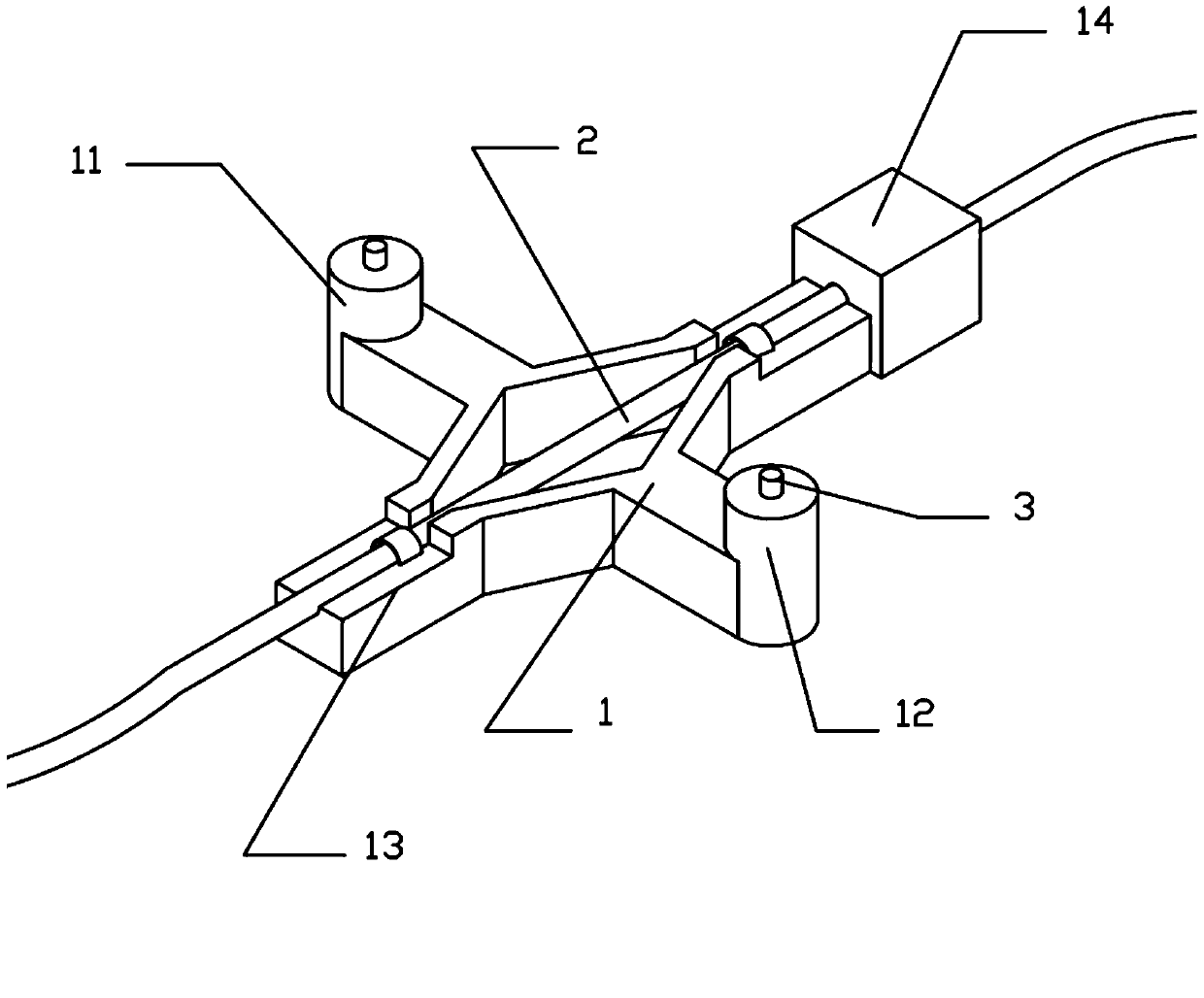

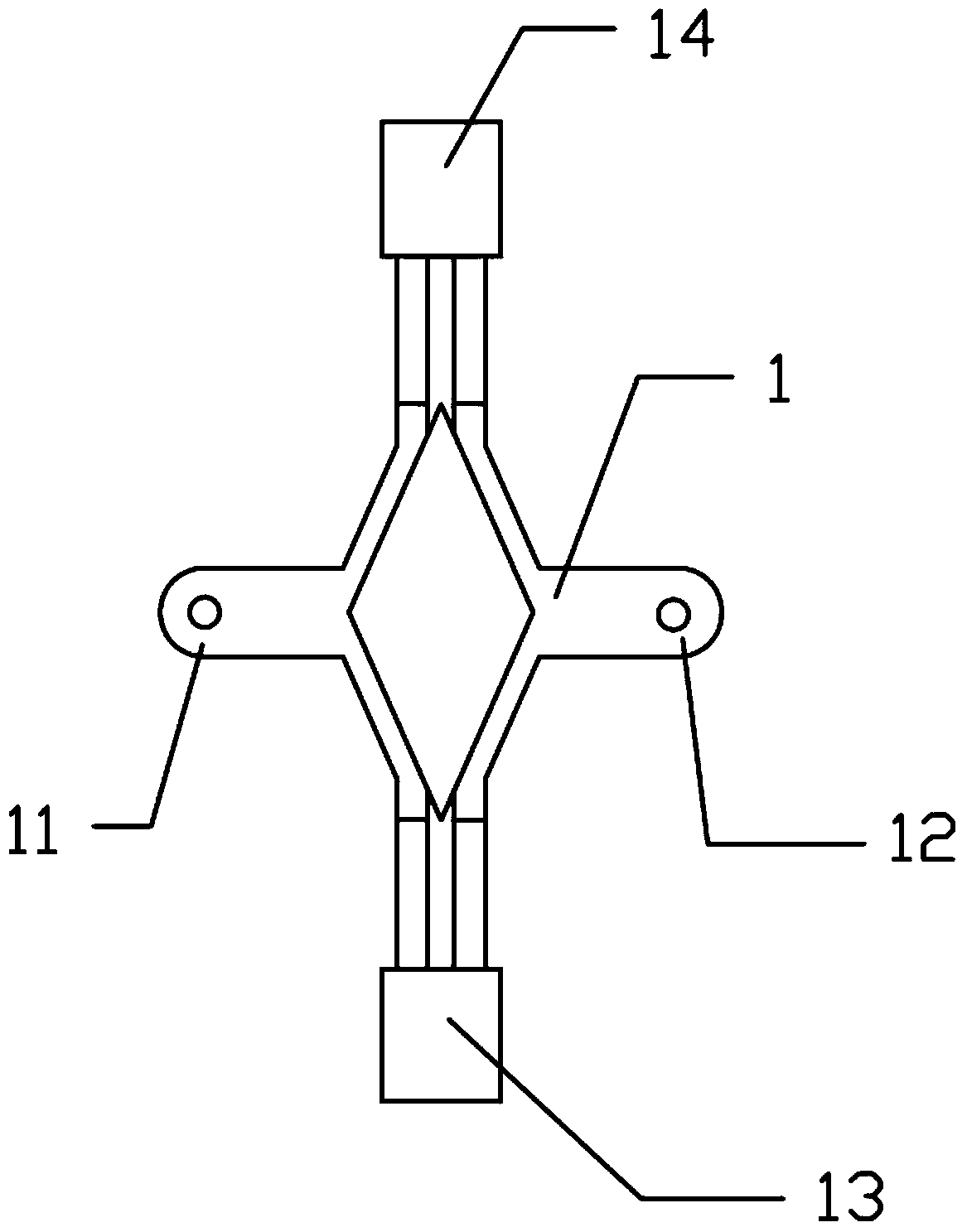

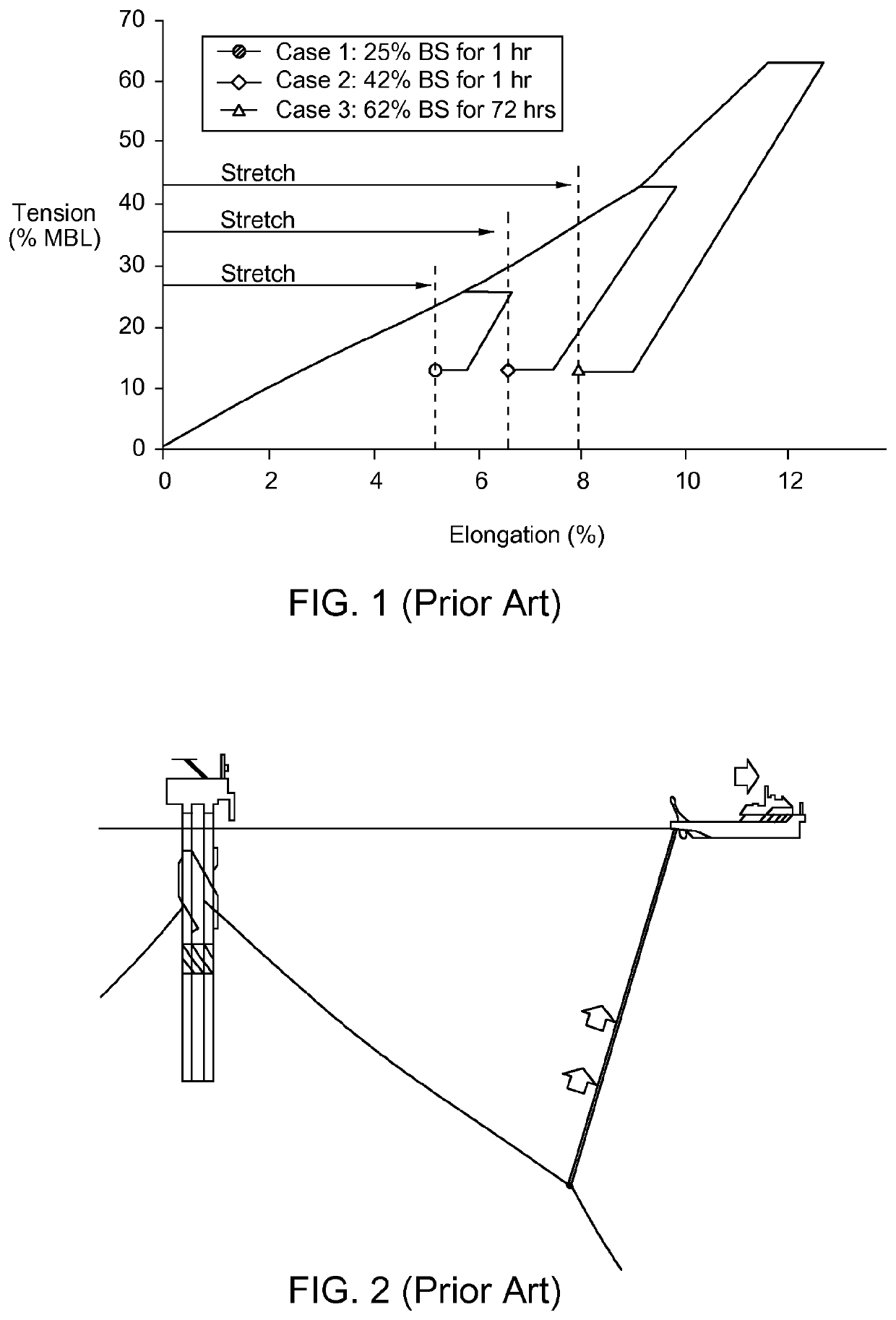

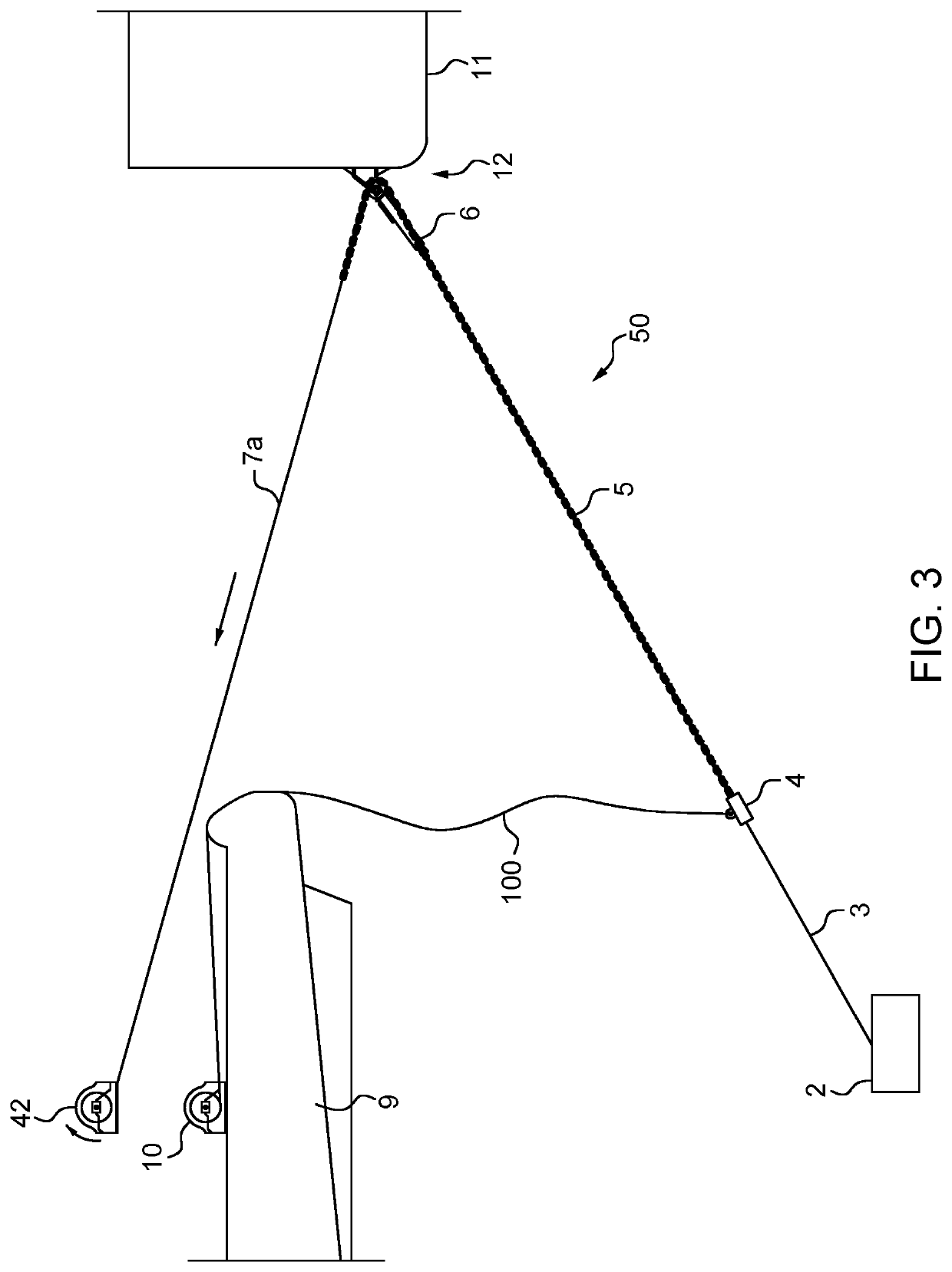

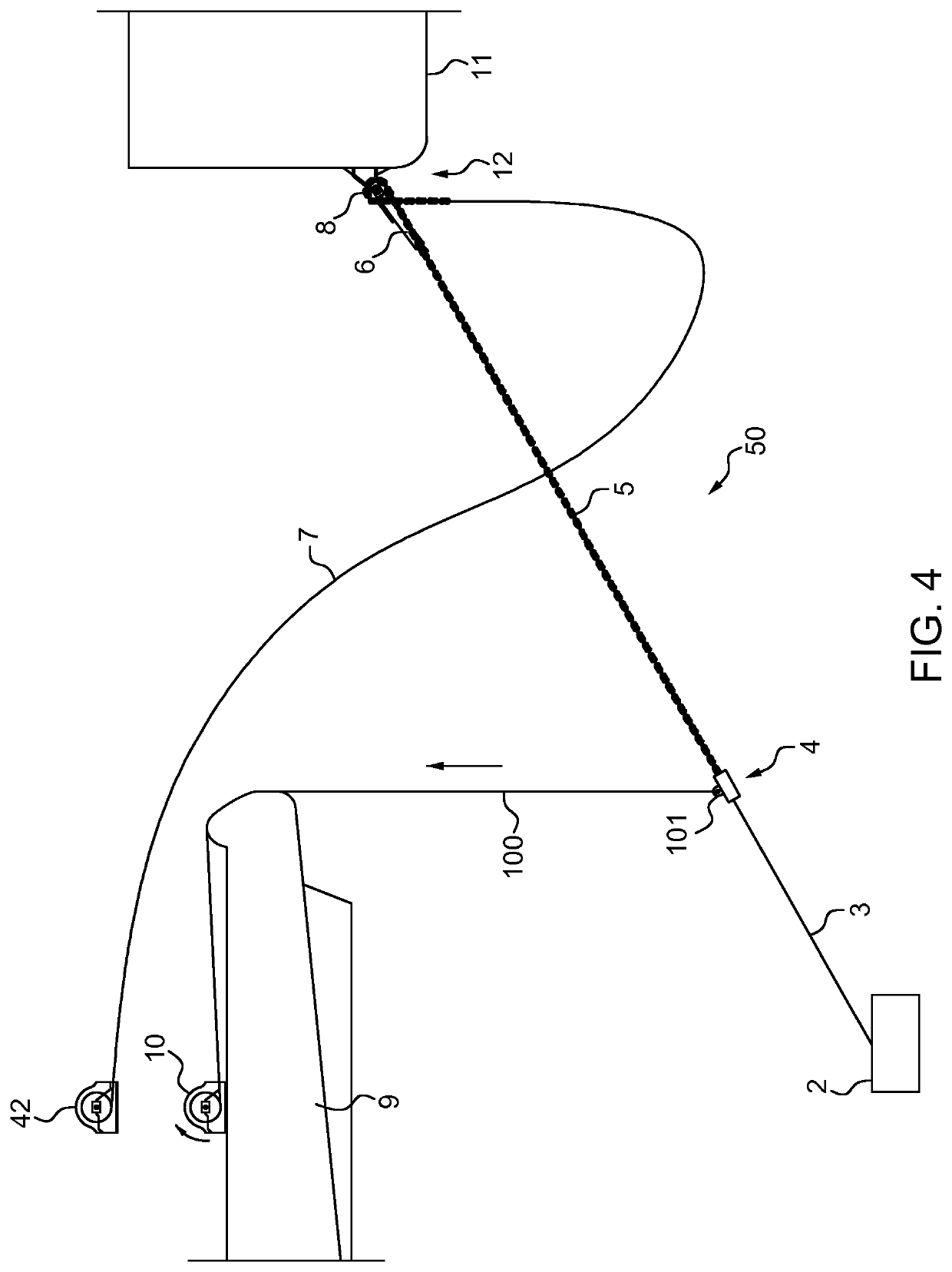

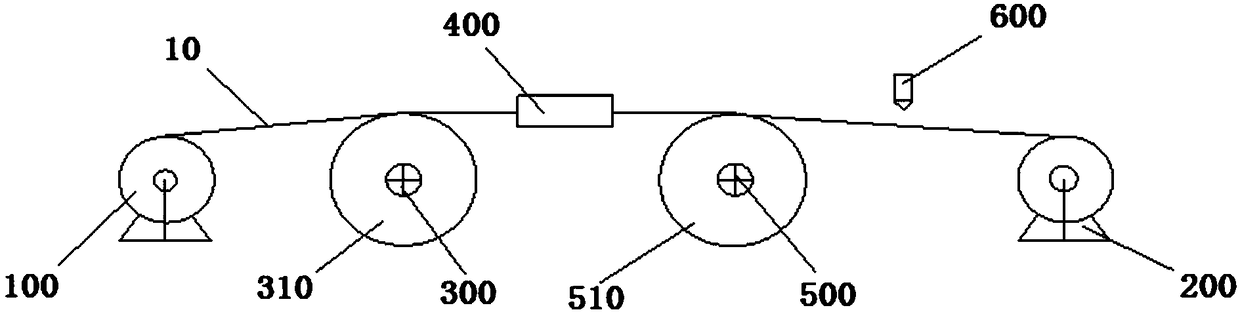

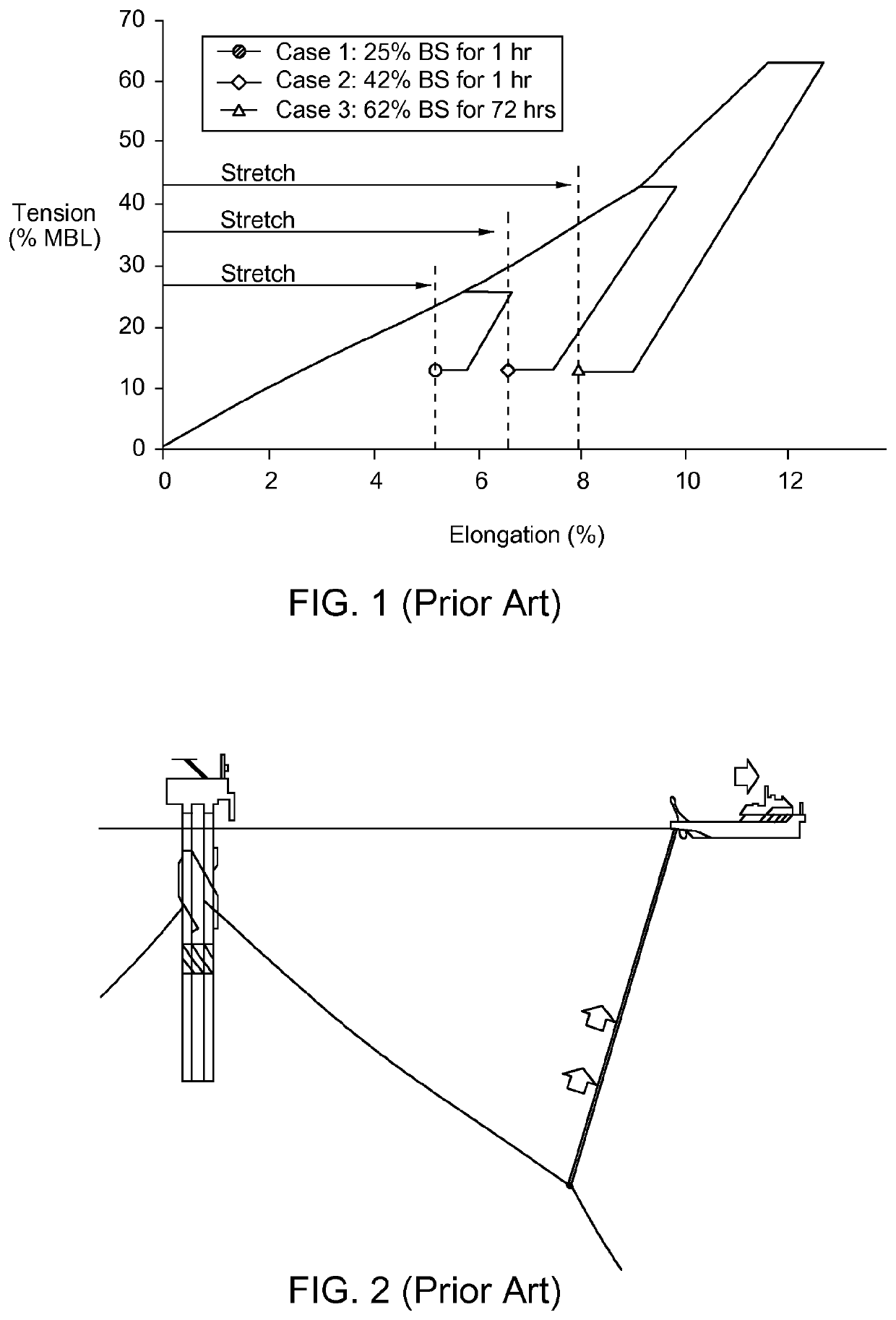

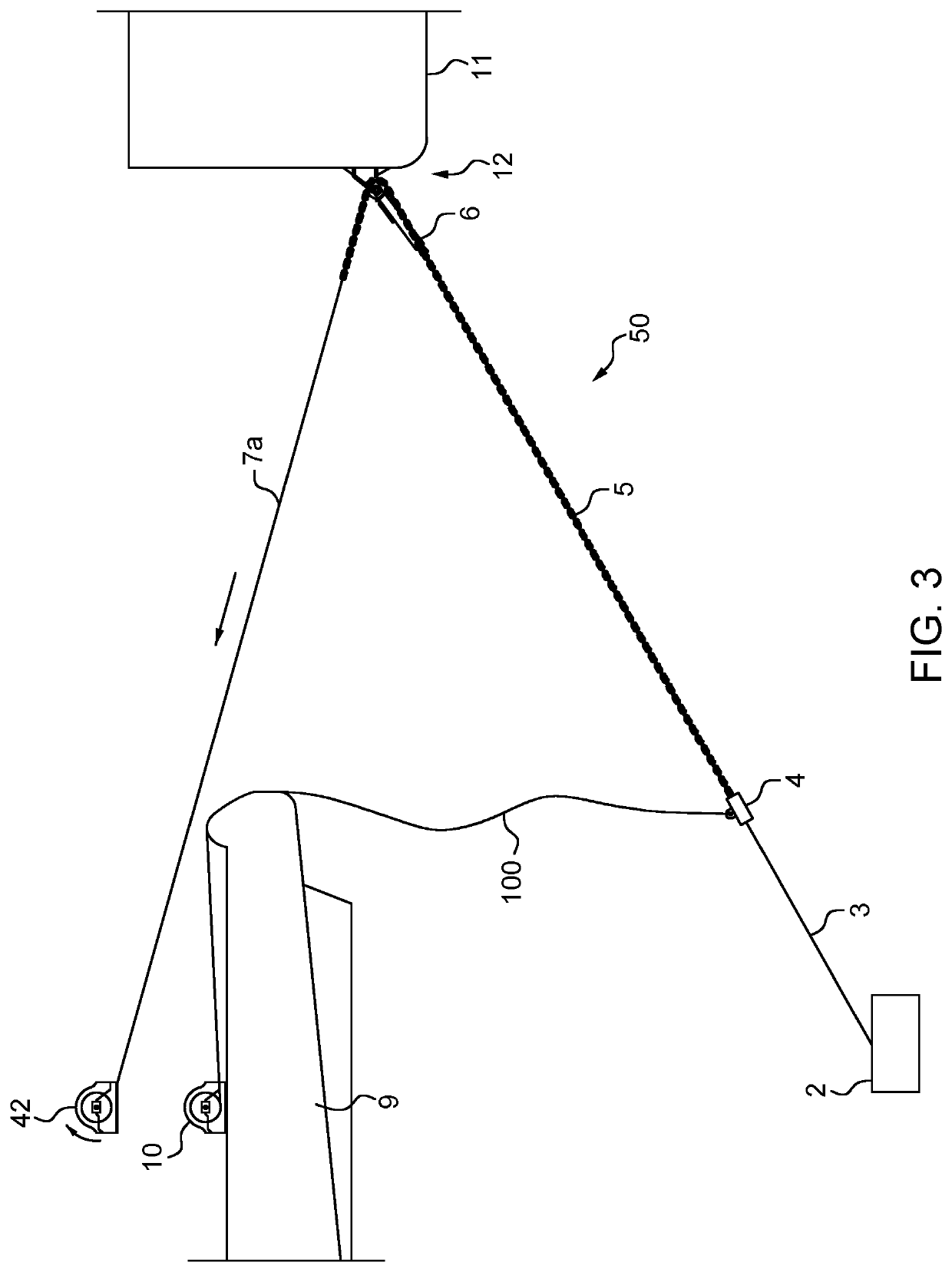

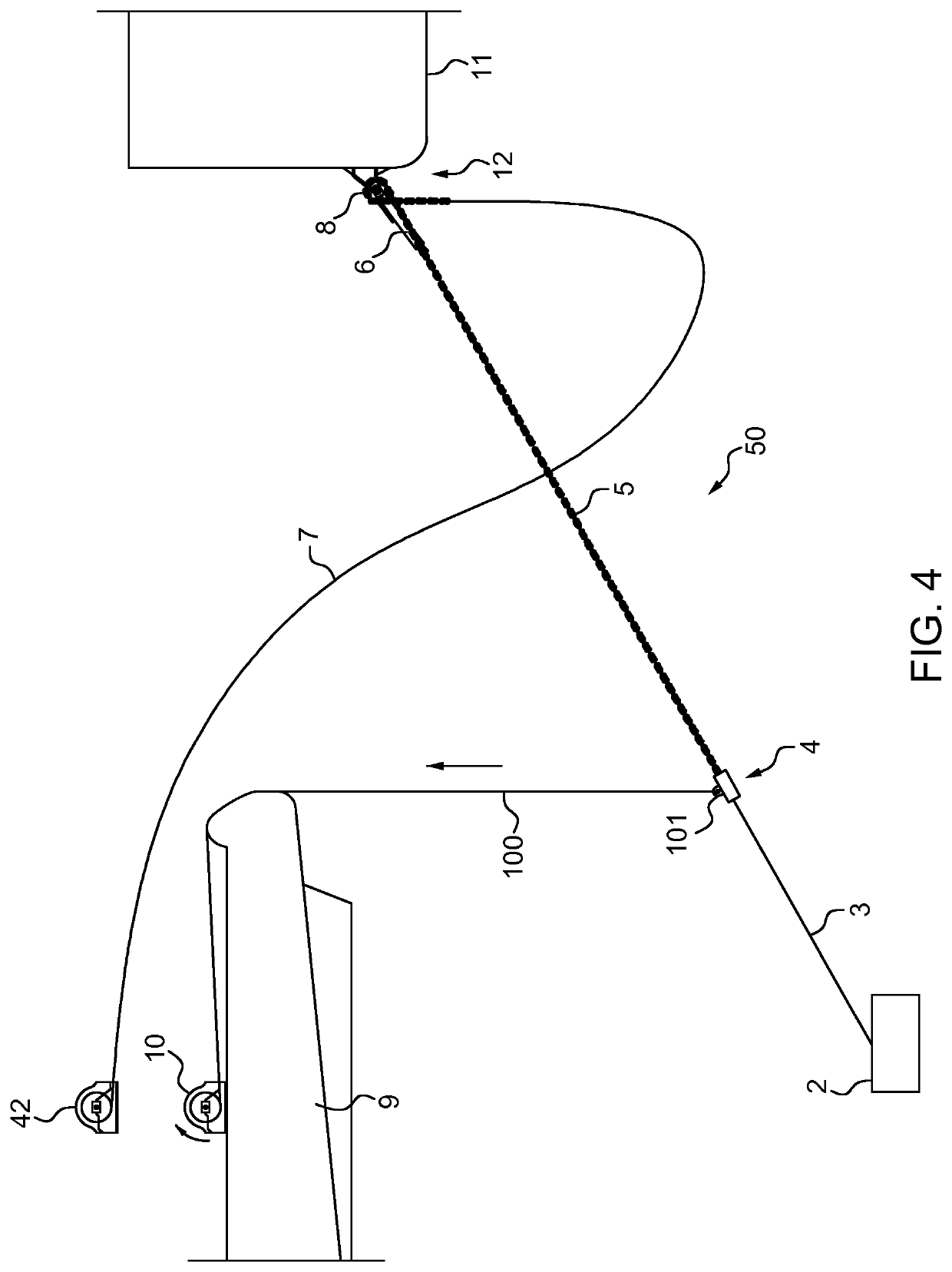

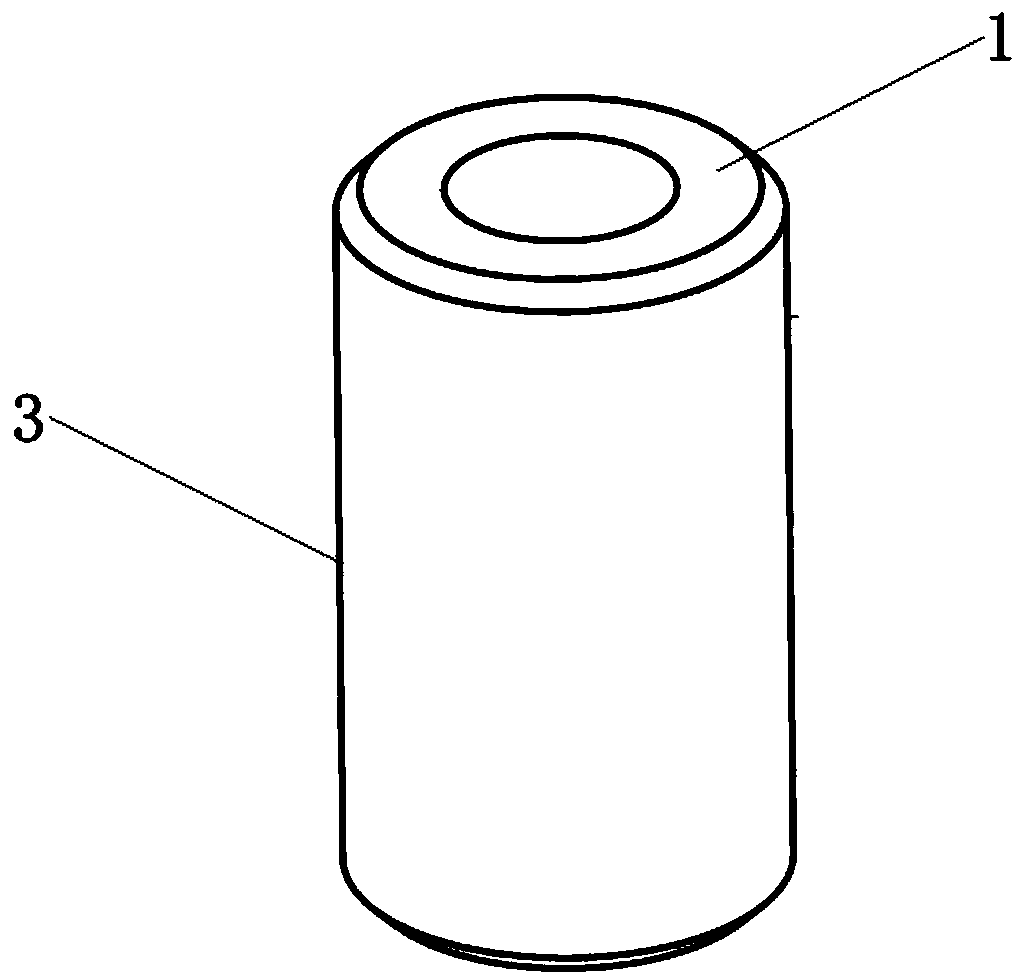

Method and an arrangement for removing stretch in polyester mooring lines with an inline tensioner

The invention relates to a mooring tensioning arrangement for a floating structure or a vessel (11), comprising -a mooring line (3, 5, 7) having a first mooring part (3) and a second mooring part (5, 7), divided by a midwater coupling (4, 40, 400, 111), said at least a portion of the mooring line (3, 5, 7) is made of synthetic material, -said mooring line (3, 5, 7) is extending between an anchor (2) arranged on the seabed and a pulling unit (9, 10, 42) arranged separate from the floating structure or vessel (11), said mooring line (3, 5, 7) is extending at least via a fairlead pulley or a chain wheel (8, 80) arranged on the floating structure (11) between the anchor and the pulling unit (9, 10, 42) when the mooring line (3, 5, 7) being pre-tensioned, -a chain stopper (6, 60) being arranged in connection with the mooring line (3, 5, 7) between the anchor (2) and the floating vessel or structure (11) for tensioning the part of the mooring line (3, 5, 7) situated between the floating structure (11) and the anchor (2) at a pretension level. The mooring tensioning arrangement further comprising a second tensioning line (100) configured to be attached in one end to the midwater coupling (4, 40, 400) and in the other end coupled to the pulling unit (9,10, 42) when said mooring line (3, 5, 7) being re-tensioned, said midwater coupling (4, 40, 400) and the pulling unit (9, 10, 42) being arranged relative each other such that the tensioning line (100) is configured to impose a lateral force on the part of the mooring line (3, 5, 7) arranged between the anchor (2) and the floating structure (11) for removing stretch in the mooring line (3, 5, 7). The invention also relates to a method tor tensioning the mooring tensioning arrangement.

Owner:SEASYSTEMS AS

Novel optical fiber temperature and pressure sensor

ActiveCN101709638BGood for accurate demodulationEliminate creepSurveyConstructionsGratingFiber Bragg grating

The invention relates to a novel optical fiber temperature and pressure sensor, which comprises an elastic diaphragm, an optical fiber Bragg grating and a demodulator connected with the optical fiber Bragg grating, wherein a short connecting pipe is sleeved on a raised column of the elastic diaphragm; the other end of the short connecting pipe is fixedly provided with a hollow rod; the hollow rodand the end face of a first optical fiber in the center thereof form a first reflecting surface through polishing; a reflecting film is plated on the first reflecting surface; the other end of an outer protection tube is inserted into a long connecting pipe with a second ceramic ferrule component; the bending part of a second optical fiber is provided with the optical fiber Bragg grating; a second ceramic rod and the end face of the second optical fiber in the center thereof form a second reflecting surface through polishing; and the first reflecting surface of the hollow rod and the second reflecting surface of the second ceramic ferrule component are centered and are provided with a space therebetween to form a Fabry-Perot cavity. The optical fiber temperature and pressure sensor is used for manufacturing optical fiber sensors.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

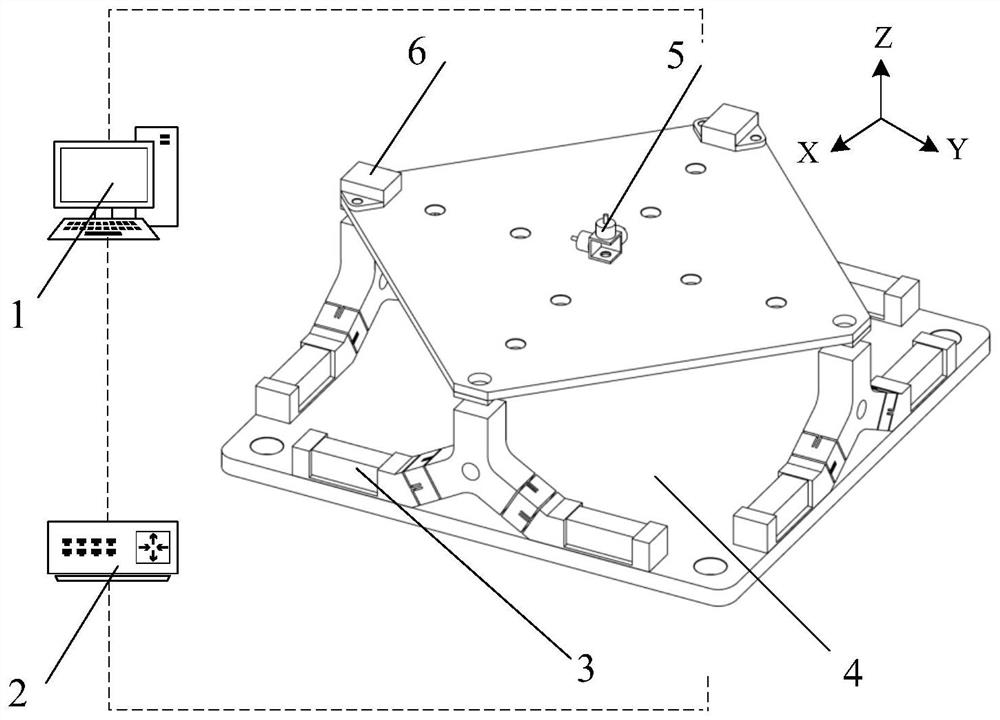

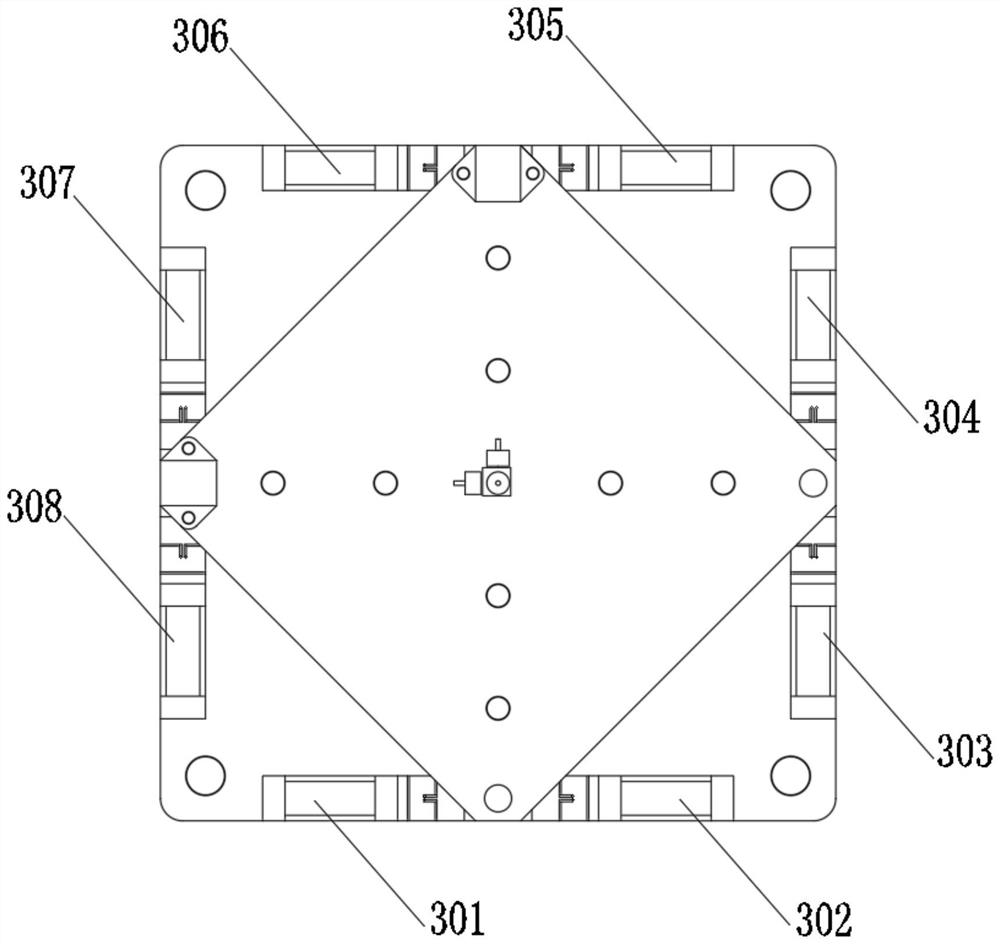

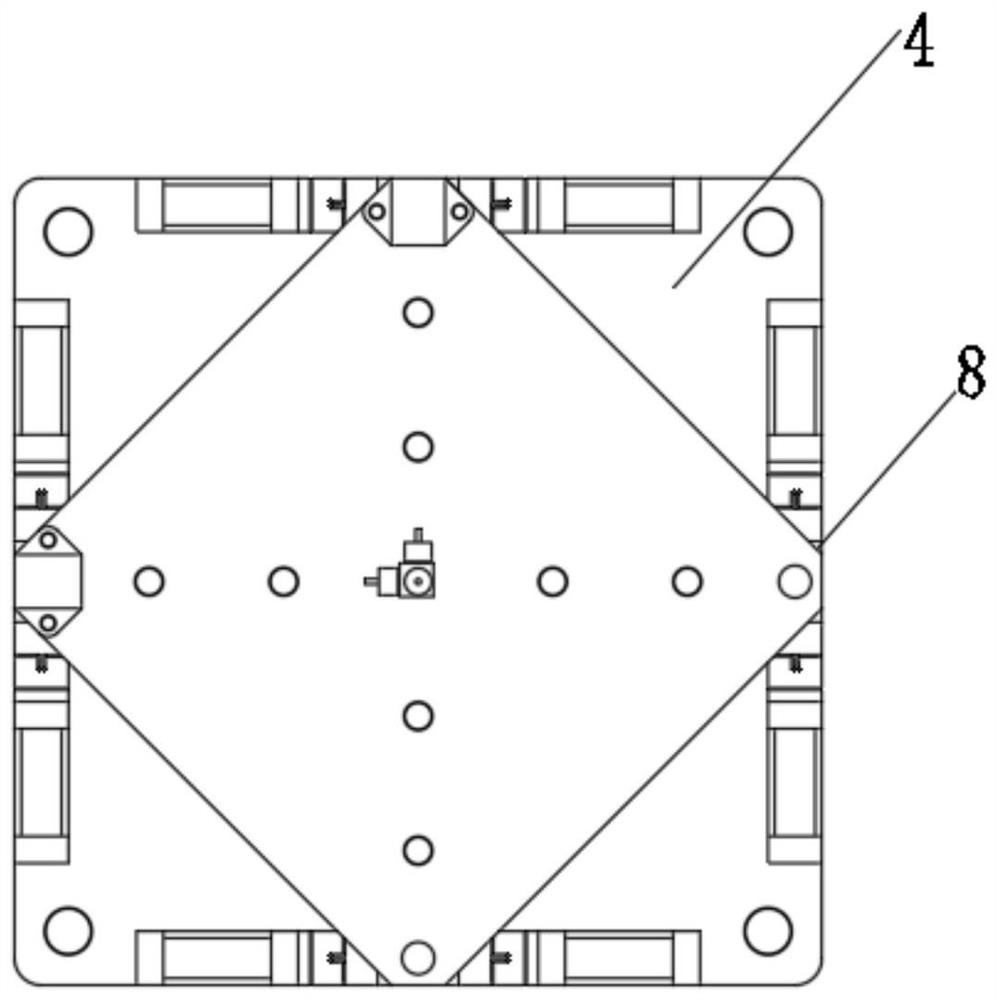

Piezoelectric driving six-degree-of-freedom compliant positioning system and control method thereof

PendingCN114649976AEliminate hysteresisEliminate creepPiezoelectric/electrostriction/magnetostriction machinesLoop controlControl engineering

The invention discloses a piezoelectric driving six-degree-of-freedom compliant positioning system which comprises an industrial personal computer, the industrial personal computer is electrically connected with a piezoelectric ceramic controller, the piezoelectric ceramic controller is electrically connected with a plurality of piezoelectric ceramic actuators, and the piezoelectric ceramic actuators are arranged at the bottom of a six-degree-of-freedom compliant positioning platform. Driving branch chains are arranged on the four sides of the six-degree-of-freedom flexible positioning platform, the displacement detection stop block is fixed to the centroid position of the upper surface of the flexible positioning platform, the multiple capacitance displacement sensors are arranged on the surface of the displacement detection stop block at equal intervals, and gaps are reserved in parallel. According to the scheme, the compliant positioning platform adopts modular and symmetrical design, the mechanism is simple and compact, feedback is simple and easy to use by adopting the capacitance sensor and the tilt angle sensor, closed-loop control positioning is accurate, and the platform is suitable for different application occasions.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +2

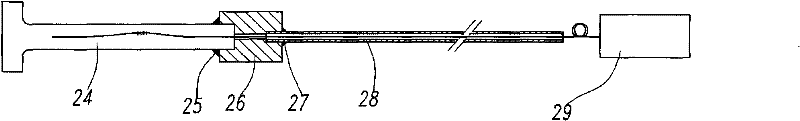

Steel core prestress processing system and prestress processing method of steel-cored aluminium strand

The invention provides a steel core prestress processing system and prestress processing method of a steel-cored aluminium strand. A wire feeding tension device, a heating device and a wire outgoing tension device are sequentially arranged between a guide wire pay-off rack and a guide wire take-off rack, wherein the wire feeding tension device comprises a wire feeding tension wheel and a wire feeding driving part for driving the wire feeding tension wheel to be rotated; the wire outgoing tension device comprises a wire outgoing tension wheel and a wire outgoing driving part for driving the wire outgoing tension wheel to be rotated; rotation speed of the wire feeding tension wheel is smaller than that of the wire outgoing tension wheel; and a steel core which is coated with the steel-coredaluminium strand and is paid off from the guide wire pay-off rack is arranged on the wire feeding tension wheel in a winding manner, penetrates through the heating device, and is arranged on the wireoutgoing tension wheel in a winding manner. According to the steel core prestress processing system and prestress processing method of the steel-cored aluminium strand disclosed by the invention, theproblem that a conventional steel-cored aluminium strand is adopted, and the stress property of the steel-cored aluminium strand is changed due to produced deformation and creepage under a temperatureand stress effect so as to affect operation safety of the steel-cored aluminium strand is solved.

Owner:SHANGHAI ELECTRIC CABLE RES INST

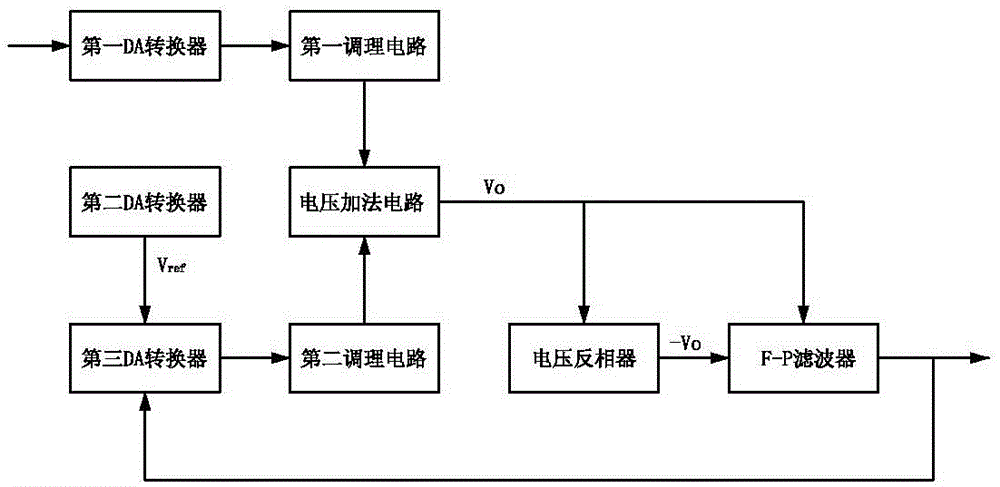

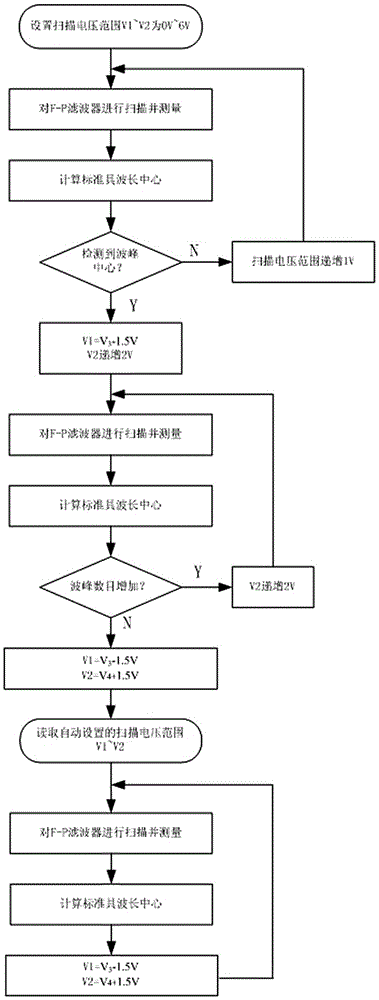

Automatic calibration circuit and calibration method for fiber grating demodulator F-P filter

The invention discloses an automatic calibration circuit for a fiber grating demodulator F-P filter. A CPU controls the output voltage of a first DA converter to reach a starting voltage; the output voltage of a second DA converter serves as a reference voltage of a third DA converter; adjustable range of the output voltage of the third DA converter is realized by adjusting the output voltage of the second DA converter; and a voltage adder enables the starting voltage and a scanning voltage to be superposed, and then, through phase inversion of a voltage phase inverter, the voltage drives the F-P filter. The invention further discloses an automatic calibration method for the fiber grating demodulator F-P filter. The method is characterized by, in the operation process, calculating a center voltage V3 of the first peak and a center voltage V4 of the last peak of an etalon after each scanning measurement; and controlling the range V1-V2 of the output voltage Vo of the voltage adder to be from V3-1.5 V to V4+1.5 V. The method can determine the voltage scanning range of the F-P filter automatically, thereby saving time and labor.

Owner:NANJING NARI GROUP CORP +1

Spot welded fiber grating strain sensor and its installation method

ActiveCN104048615BHigh sensitivityQuick responseUsing optical meansFiberElectrical resistance and conductance

The invention discloses a spot welding fiber bragg grating strain sensor. The spot welding fiber bragg grating strain sensor comprises a fiber bragg grating strain sensor body and a base body made of high-elasticity alloy materials, wherein the base body comprises a substrate, a left regulating block and a right regulating block, the left regulating block and the right regulating block are connected with the left end and the right end of the base body respectively in an integrated mode, a base body groove is formed in the middle of the position, between the two regulating blocks, of the base body, the outer side of the fiber bragg grating strain sensor body is provided with a packaging layer made of low-melting-point glass powder, and the lower half portion of the packaging layer is connected with the base body groove; the right regulating block is transversely provided with a regulating hole, a regulating bolt penetrates through the regulating hole, and the left end of the regulating bolt abuts against the right side face of the left regulating block; the periphery of the substrate is provided with a rubber layer used for sealing. As the spot welding fiber bragg grating strain sensor is obviously superior to a traditional resistance strain gage, the purpose that the real-time state of strain of an iron tower electric transmission line is known comprehensively for a long time is achieved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

A fiber grating demodulator

ActiveCN103528607BEliminate creepSolve the real problemConverting sensor output opticallyFiberHysteresis

Owner:浙江振东光电科技有限公司

Fiber optic sensor realizes precise measurement of metal stress and strain

ActiveCN103438817BImprove long-term stabilityHigh precisionUsing optical meansNonlinear deformationStrain measurement

The invention relates to an optical fiber sensor capable of measuring stress-strain of metal accurately. The optical fiber sensor comprises a strain elastic beam provided with a first measuring fixing end and a second measuring fixing end. The connecting line of the first measuring fixing end and the second measuring fixing end is perpendicular to an axis of an optical fiber. Due to the fact that the optical fiber sensor capable of measuring the stress-strain of metal accurately adopts the structure, creep deformation caused by a traditional gluing method is changed, and long-term stability of a zero point is improved. The output of the optical fiber installed on a tested metal structural body is hardly affected by the changes of the environment temperature, and secondary compensation does not need to be carried out by utilizing an additional temperature measuring sensor. The transverse sensitivity of the optical fiber is reduced, the optical fiber is sensitive only about the stain of the strain elastic beam in the measuring direction, and the optical fiber can have good strain measurement single-direction performance. The rigidity of a strain transmission interface is guaranteed through the technology that the strain elastic beam is directly welded to the tested metal structural body, and creep deformation and non-linear deformation of the strain transmission interface are removed.

Owner:SHANGHAI BAIANTEK SENSING TECH CO LTD

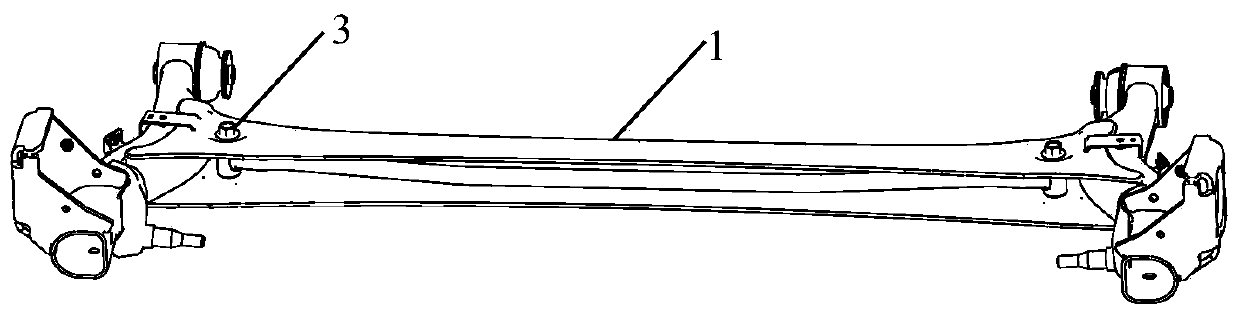

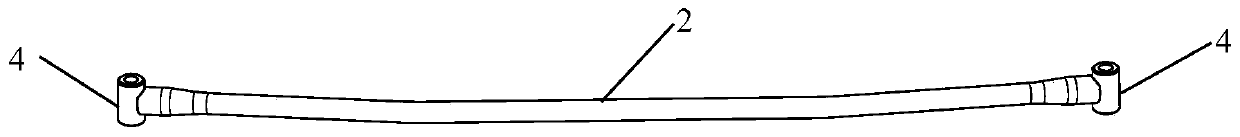

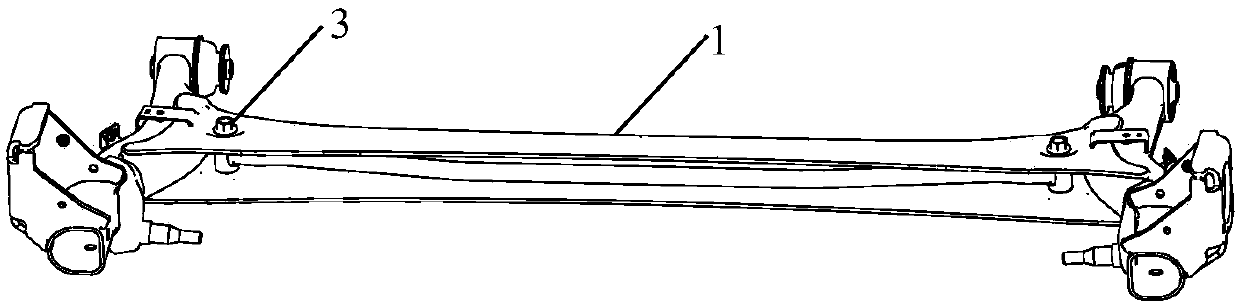

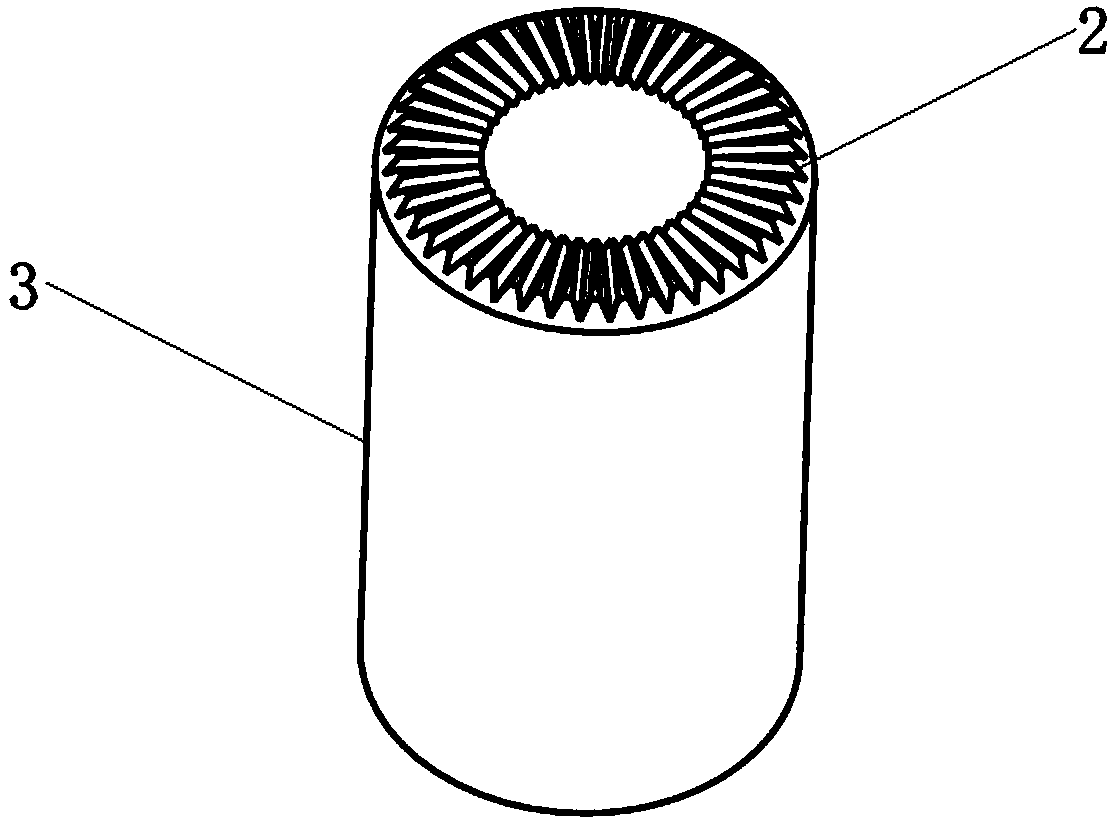

Anti-loosening and anti-abnormal noise structure for rear axle stabilizer bar

ActiveCN107901723BSimple structureIncrease coefficient of frictionInterconnection systemsEngineeringTooth root

The invention discloses a structure for preventing a rear axle stabilizer rod from loosening and having abnormal sound. The structure comprises a rear axle stabilizer rod, wherein stabilizer rod sleeve barrels are respectively and fixedly connected to two ends of the rear axle stabilizer rod; each stabilizer rod sleeve barrel is provided with a barrel top surface and a barrel bottom surface; eachbarrel top surface comprises a first annular plane and a second annular plane; the height between each second annular plane and the corresponding barrel bottom surface is greater than that between thecorresponding first annular plane and the corresponding barrel bottom surface; loosening preventing teeth are arranged on each first annular plane, and each loosening preventing tooth is provided with a tooth top and a tooth root; and the height between each tooth top and the corresponding tooth root is greater than that between each first annular plane and the corresponding second annular plane.The structure disclosed by the invention is simple in structure, low in cost, and high in reliability; the problems that the torque of a relevant part is loosened, and a chassis at the relevant parthas abnormal sound can be solved; and the driving quality and the appearance quality can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Micro-actuator and locking switch

ActiveUS8120133B2Eliminate creepLower impedanceElectrothermal relaysSolid-state devicesElectricityPower flow

A micro-electromechanical actuator employs metal for the hot arm and silicon for at least the flexible portion of the cold arm. The cold arm made of silicon is coupled to a metal wire that moves with it and is used to carry the signal to be switched when at least two of such actuators are formed into a switch. Arrays of such switches on a first chip may be cooperatively arranged with a second chip that is flip-chip bonded to the first chip, the second chip having thereon wires routing the electrical control currents to the various hot arms for heating them as well as the signals to be switched by the various switches.

Owner:WSOU INVESTMENTS LLC

A High Temperature Flange Sealing Structure Containing Flexible Graphite Metal ω-shaped Teeth Composite Gasket

InactiveCN104565618BPrevent leakageLeakage slowed or even eliminatedFlanged jointsInterference fitGraphite

The invention relates to the field of a pipeline flange sealing structure, in particular to a high-temperature flange sealing structure comprising a flexible graphite metal omega-shaped tooth composite gasket. The high-temperature flange sealing structure is characterized by comprising an upper flange, a lower flange and the flexible graphite metal omega-shaped tooth composite gasket. The upper surface and the lower surface of a metal frame of the flexible graphite metal omega-shaped tooth composite gasket are provided with annular boss in multiple circles respectively, the annular bosses are provided with omega-shaped sections and arranged at equal distance, the planar parts of the upper and lower surfaces of the flexible graphite metal omega-shaped tooth composite gasket are provided with flexible graphite layers, annular grooves matched with the annular bosses are arranged on the contact surfaces of the upper flange, the lower flange and the flexible graphite metal omega-shaped tooth composite gasket and provided with rectangular sections, the annular bosses are inserted into the annular grooves correspondingly and are in interference fit with the same. The high-temperature flange sealing structure can be applied to high-temperature and -pressure working conditions, excellent tightness can be kept for a long time, and leak of the flanges can be effectively prevented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Structure for preventing rear axle stabilizer rod from loosening and having abnormal sound

ActiveCN107901723ASimple structureIncrease coefficient of frictionInterconnection systemsEngineeringTooth root

The invention discloses a structure for preventing a rear axle stabilizer rod from loosening and having abnormal sound. The structure comprises a rear axle stabilizer rod, wherein stabilizer rod sleeve barrels are respectively and fixedly connected to two ends of the rear axle stabilizer rod; each stabilizer rod sleeve barrel is provided with a barrel top surface and a barrel bottom surface; eachbarrel top surface comprises a first annular plane and a second annular plane; the height between each second annular plane and the corresponding barrel bottom surface is greater than that between thecorresponding first annular plane and the corresponding barrel bottom surface; loosening preventing teeth are arranged on each first annular plane, and each loosening preventing tooth is provided with a tooth top and a tooth root; and the height between each tooth top and the corresponding tooth root is greater than that between each first annular plane and the corresponding second annular plane.The structure disclosed by the invention is simple in structure, low in cost, and high in reliability; the problems that the torque of a relevant part is loosened, and a chassis at the relevant parthas abnormal sound can be solved; and the driving quality and the appearance quality can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Method and an arrangement for removing stretch in polyester mooring lines with an inline tensioner

The invention relates to a mooring tensioning arrangement for a floating structure or a vessel (11), comprising -a mooring line (3, 5, 7) having a first mooring part (3) and a second mooring part (5, 7), divided by a midwater coupling (4, 40, 400, 111), said at least a portion of the mooring line (3, 5, 7) is made of synthetic material, -said mooring line (3, 5, 7) is extending between an anchor (2) arranged on the seabed and a pulling unit (9, 10, 42) arranged separate from the floating structure or vessel (11), said mooring line (3, 5, 7) is extending at least via a fairlead pulley or a chain wheel (8, 80) arranged on the floating structure (11) between the anchor and the pulling unit (9, 10, 42) when the mooring line (3, 5, 7) being pre-tensioned, -a chain stopper (6, 60) being arranged in connection with the mooring line (3, 5, 7) between the anchor (2) and the floating vessel or structure (11) for tensioning the part of the mooring line (3, 5, 7) situated between the floating structure (11) and the anchor (2) at a pretension level. The mooring tensioning arrangement further comprising a second tensioning line (100) configured to be attached in one end to the midwater coupling (4, 40, 400) and in the other end coupled to the pulling unit (9,10, 42) when said mooring line (3, 5, 7) being re-tensioned, said midwater coupling (4, 40, 400) and the pulling unit (9, 10, 42) being arranged relative each other such that the tensioning line (100) is configured to impose a lateral force on the part of the mooring line (3, 5, 7) arranged between the anchor (2) and the floating structure (11) for removing stretch in the mooring line (3, 5, 7). The invention also relates to a method tor tensioning the mooring tensioning arrangement.

Owner:SEASYSTEMS AS

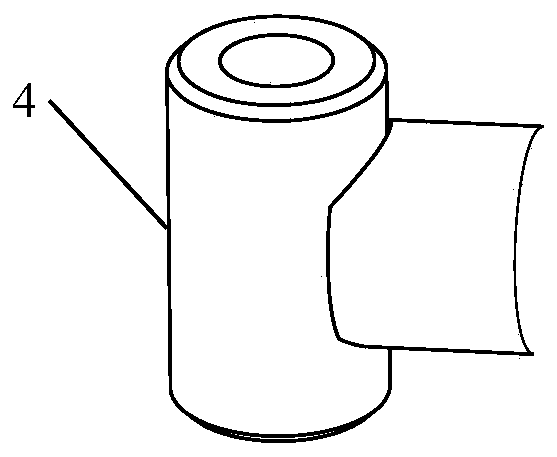

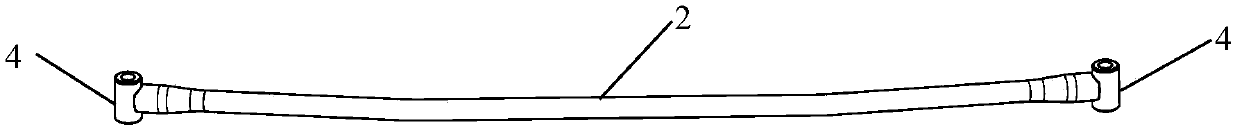

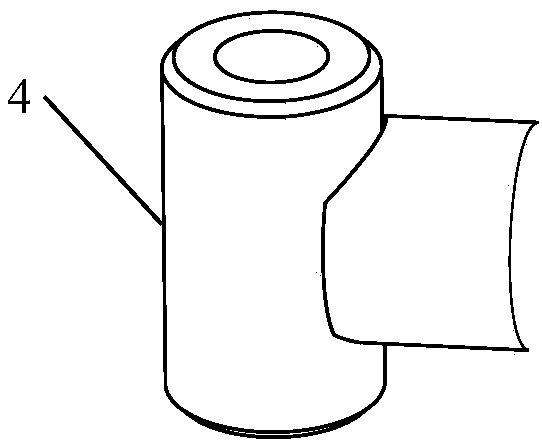

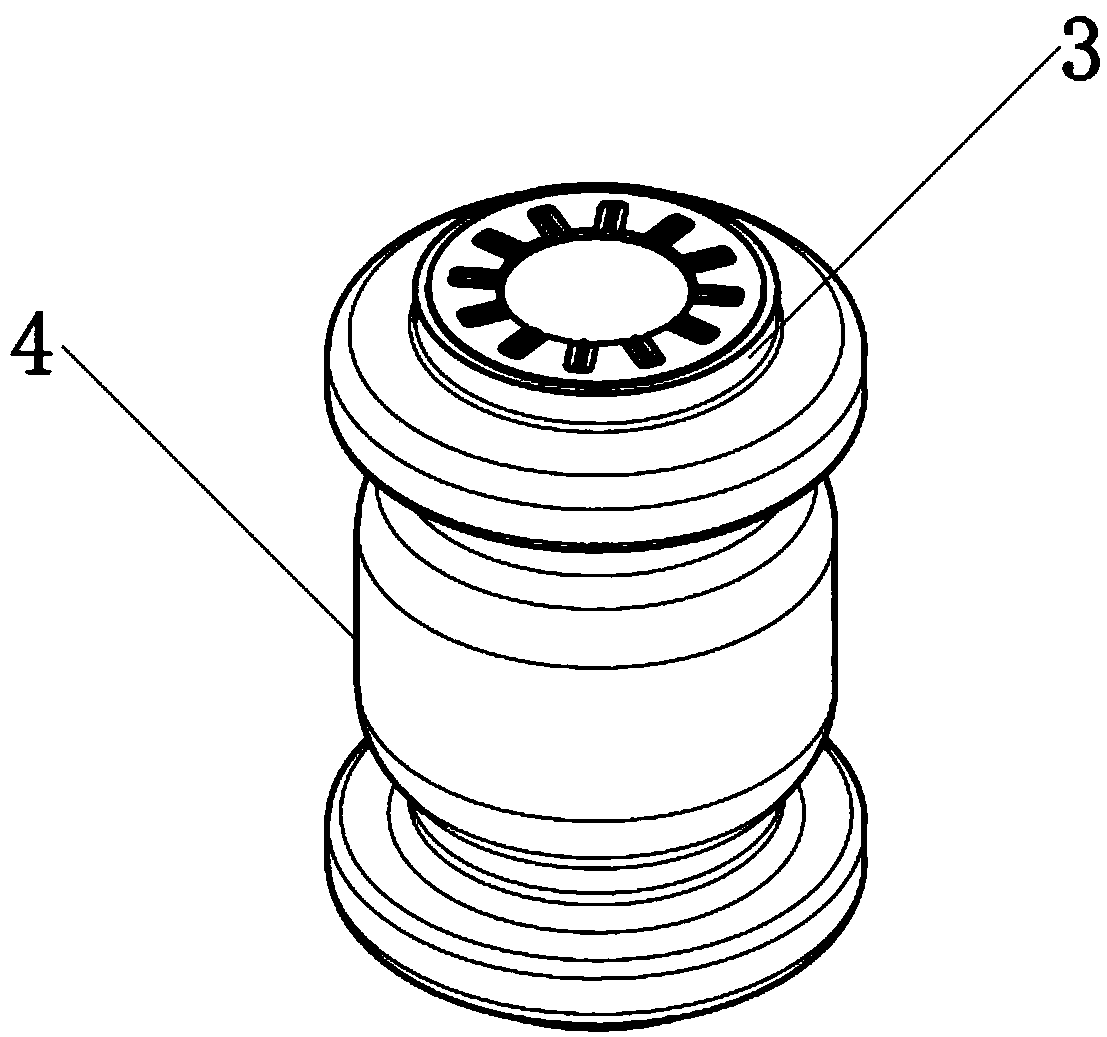

Loosening preventing and shaft breaking preventing structure of suspension bush

InactiveCN108327472ASimple structureHigh forming precisionPivoted suspension armsAutomotive engineeringChassis

The invention discloses a loosening preventing and shaft breaking preventing structure of a suspension bush. The structure comprises the suspension bush, wherein the suspension bush is used for beingconnected with a subframe or a vehicle body and comprises an inner sleeve which is provided with a contact surface, the contact surface is in contact with the subframe or the vehicle body, a pluralityof anti-loosening teeth are arranged in the circumferential direction of the contact surface, and grooves are formed in peripheries of the anti-loosening teeth. The suspension bush is tightly connected with the subframe or the vehicle body, so that the problems of looseness and shaft breakage of the suspension bush commonly existing in the prior art can be effectively solved, the operation stability of a chassis is prevented from being reduced, the driving quality is improved, looseness of a vehicle after a certain service life is avoided, and potential after-sale complaints and recall risksare eliminated.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

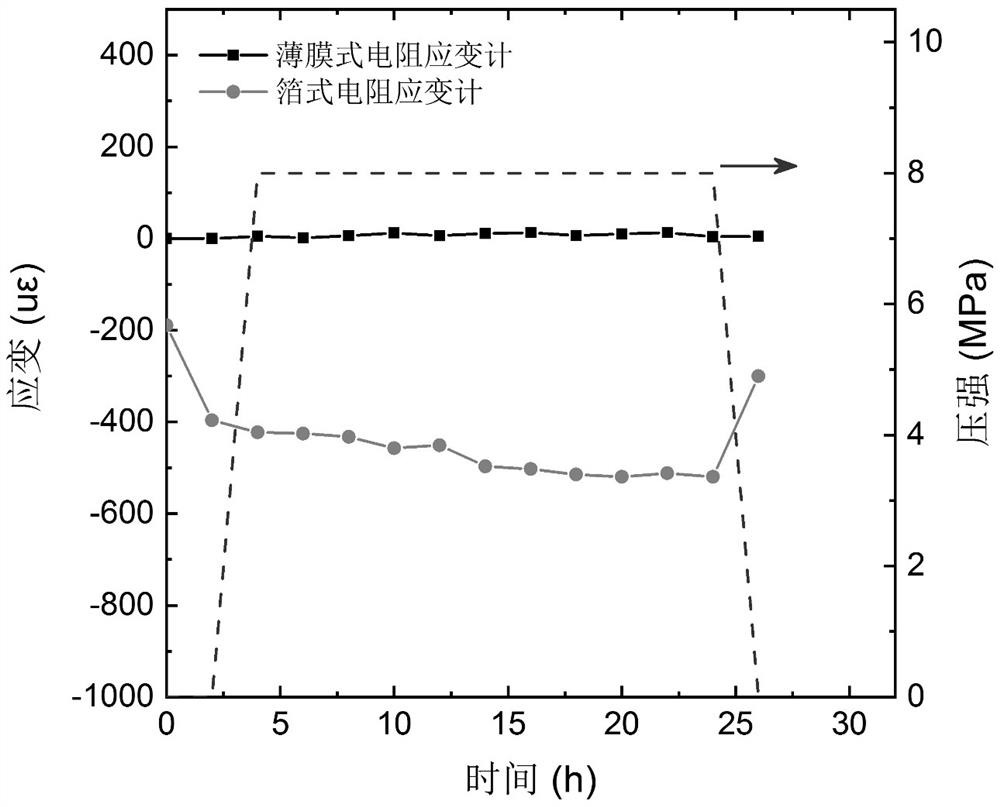

Load Cell Elements for Use in Wet Water Environments

ActiveCN112432720BAvoid errorsRelieve stressVacuum evaporation coatingForce measurementSS - Stainless steelAlloy

Owner:ZHEJIANG UNIV OF TECH

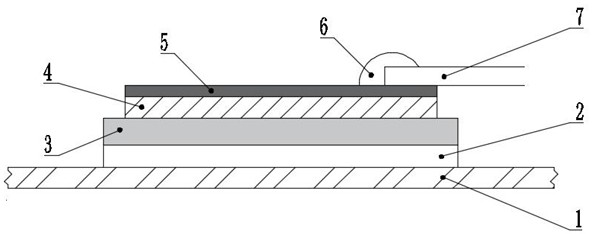

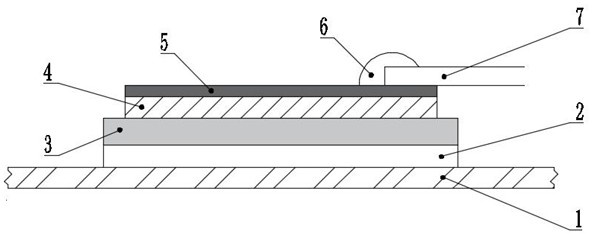

Film type resistance strain gauge used in high-pressure hydrogen sulfide environment

PendingCN112525062AAvoid errorsRelieve stressForce measurementVacuum evaporation coatingTest sampleThin membrane

The invention discloses a film type resistance strain gauge used in a high-pressure hydrogen sulfide environment. The film type resistance strain gauge comprises a substrate, a transition buffer layerarranged on the upper surface of the substrate, an insulating layer arranged on the upper surface of the transition buffer layer, a functional layer arranged on the upper surface of the insulating layer, and a protective layer arranged on the upper surface of the functional layer, wherein the substrate is made of a 316L stainless steel material, the transition buffer layer is a Cr film, the insulating layer is an AlN film, the functional layer is a FeNi alloy film, and the protective layer is a CrOx film. In a high-pressure hydrogen sulfide environment, the film type resistance strain gauge can be firmly fixed on a test sample, and the connection between the film type resistance strain gauge and the test sample is inorganic so that zero drift and creep deformation are eliminated, temperature self-compensation is realized, and the sensitivity of the film type resistance strain gauge and the accuracy of a measurement result are improved.

Owner:ZHEJIANG UNIV OF TECH

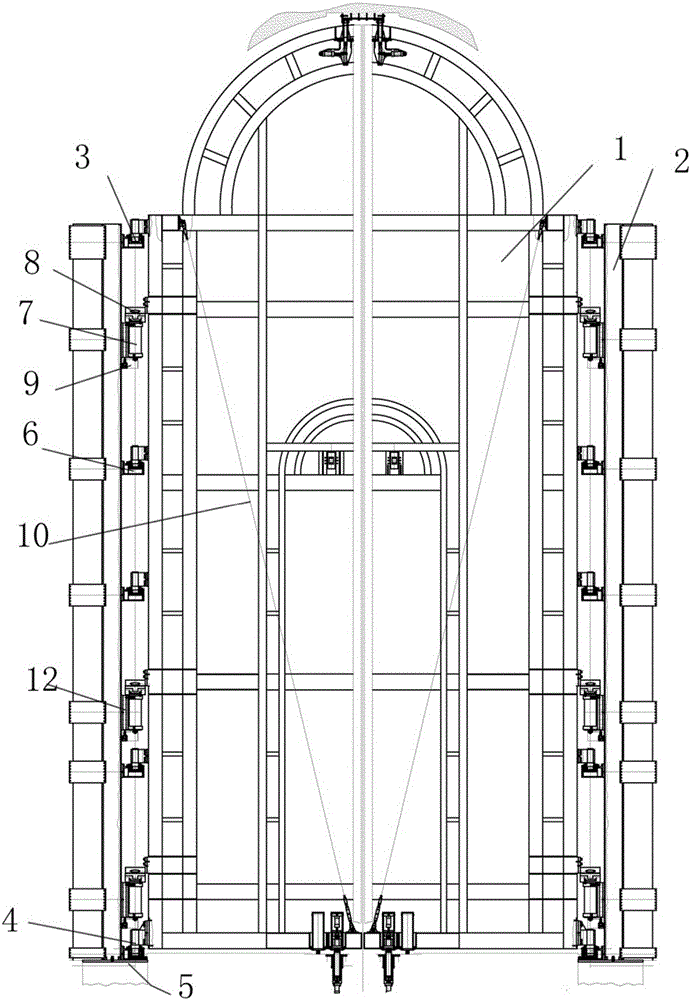

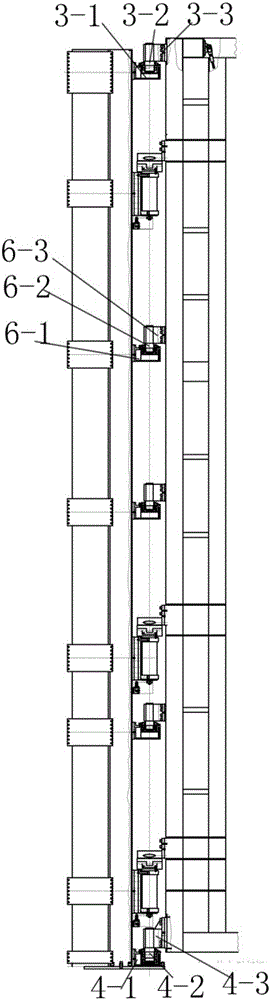

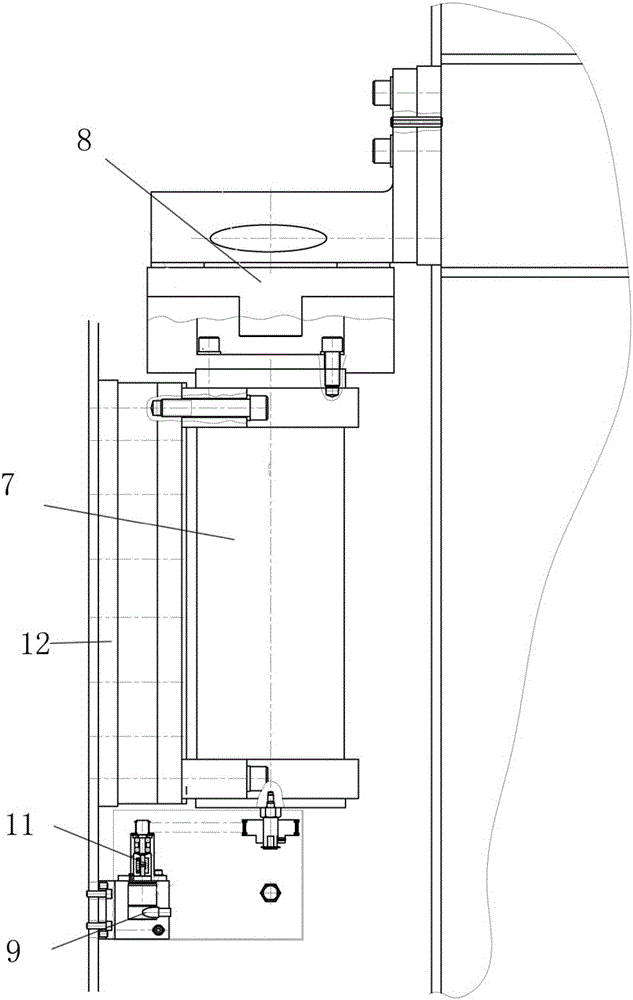

Superlarge double-opening steel door

ActiveCN105822187ARun freelyWork reliablyWindow/door framesPower-operated mechanismSynchronous controlCoupling

The invention discloses a superlarge double-opening steel door. The superlarge double-opening steel door comprises door leaves and a door frame. The superlarge double-opening steel door is characterized in that an upper main hinge shaft assembly, a lower main hinge shaft assembly and a multi-point linkage synchronous driving mechanism are arranged between the door leaves and the door frame, and the multi-point linkage synchronous driving mechanism is used for driving the door leaves to rotate; the lower main hinge shaft assembly is used for centering in the radial direction, and bearing the whole load of the single door, and the upper main hinge shaft assembly is used for bearing the radial action force of the single door; the lower part of each door leaf is provided with a support pier, and each support pier is connected with the lower main hinge shaft assembly and is used for supporting the lower main hinge shaft assembly; at least three groups of auxiliary hinge shaft assemblies are arranged between the upper main hinge shaft assembly and the lower main hinge shaft assembly; the multi-point linkage synchronous driving mechanism comprises at least three groups of spiral hydraulic rotary driving cylinders and a synchronous control device, the spiral hydraulic rotary driving cylinders synchronously work, a cross slide block coupling is connected between each spiral hydraulic rotary driving cylinder and the corresponding door leaf, each spiral hydraulic rotary driving cylinder is connected with a rotary encoder for sampling, and the output end of the rotary encoder is connected with the synchronous control device. The superlarge double-opening steel door has the advantages that the structure is simple, the appearance is attractive and elegant, the single door can flexibly rotate, and the working is stable and reliable.

Owner:FOSHAN YEPENG MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com