Closed-loop-controlled encapsulating piezoelectric ceramic actuator and resistance strain gauge fixing method

A technology of resistance strain gauges and piezoelectric ceramics, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of large number of parts, large volume, flexible hinges and The workbench requires high machining accuracy and other issues, so as to achieve the effect of low drive power, small size, and normal displacement output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

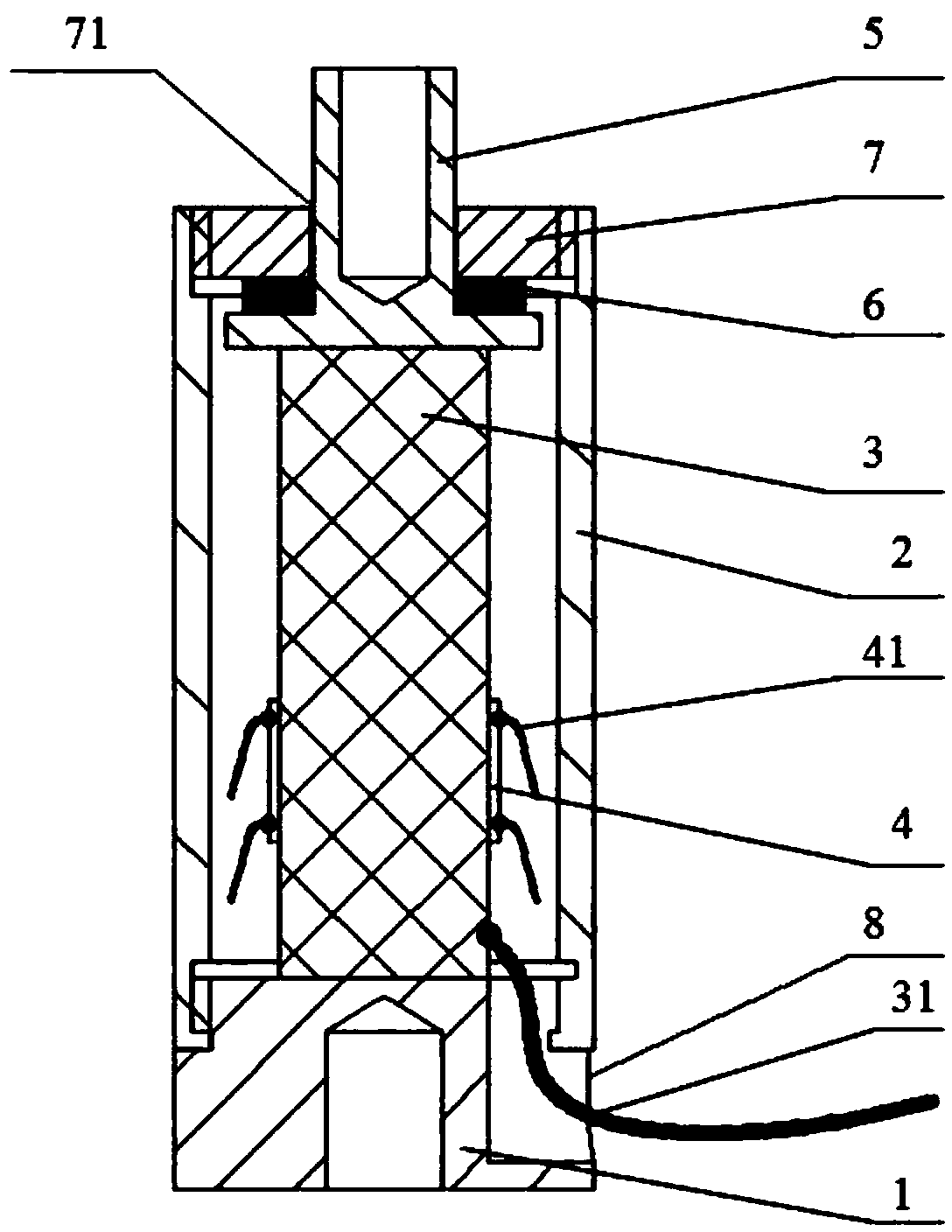

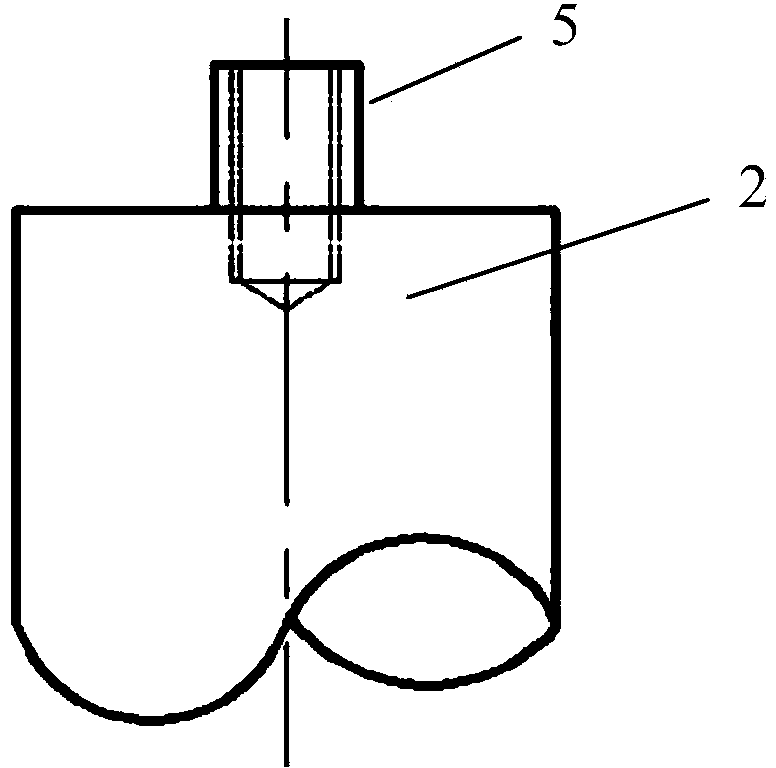

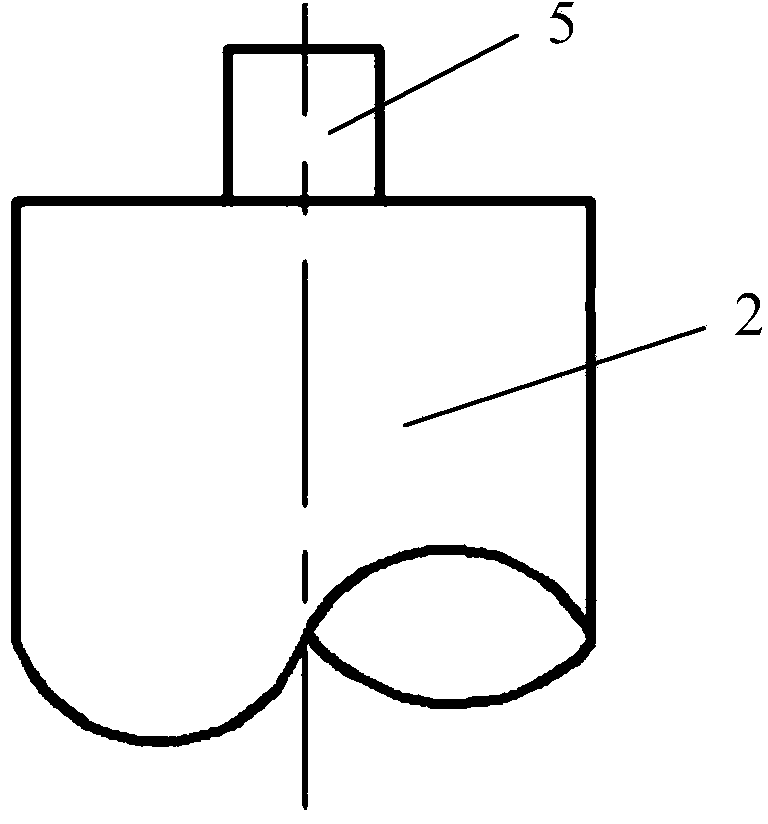

[0035] Piezoelectric ceramic actuators in the prior art all adopt a laminated structure in order to achieve a larger driving range, and are hard and brittle ceramic materials that are easily damaged, so the wear rate is very high during use. On the other hand, due to the hysteresis and creep characteristics of piezoelectric ceramics, the displacement output is nonlinear during the movement process, and the movement accuracy is poor. At present, the method of packaging piezoelectric ceramics is generally used to improve the service life of piezoelectric ceramics. Among them, there is a method of packaging piezoelectric ceramics with flexible hinges "direct drive nanoscale precision positioning platform (patent number: 201220411967.5), but this This kind of structure has a large volume and a large number of parts, and requires high processing accuracy for flexible hinges and workbenches.

[0036] The present invention aims at the deficiencies in the prior art, and the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com