High-temperature flange sealing structure comprising flexible graphite metal omega-shaped tooth composite gasket

A flexible graphite, high-temperature flange technology, used in flange connections, pipes/pipe joints/fittings, through components, etc., can solve the problem of loose pipe flange connection system, leakage failure at flange connections, and bending of flanges. Moment and other issues to achieve the effect of increasing the effective sealing area, enhancing the sealing effect and reducing the pressure energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

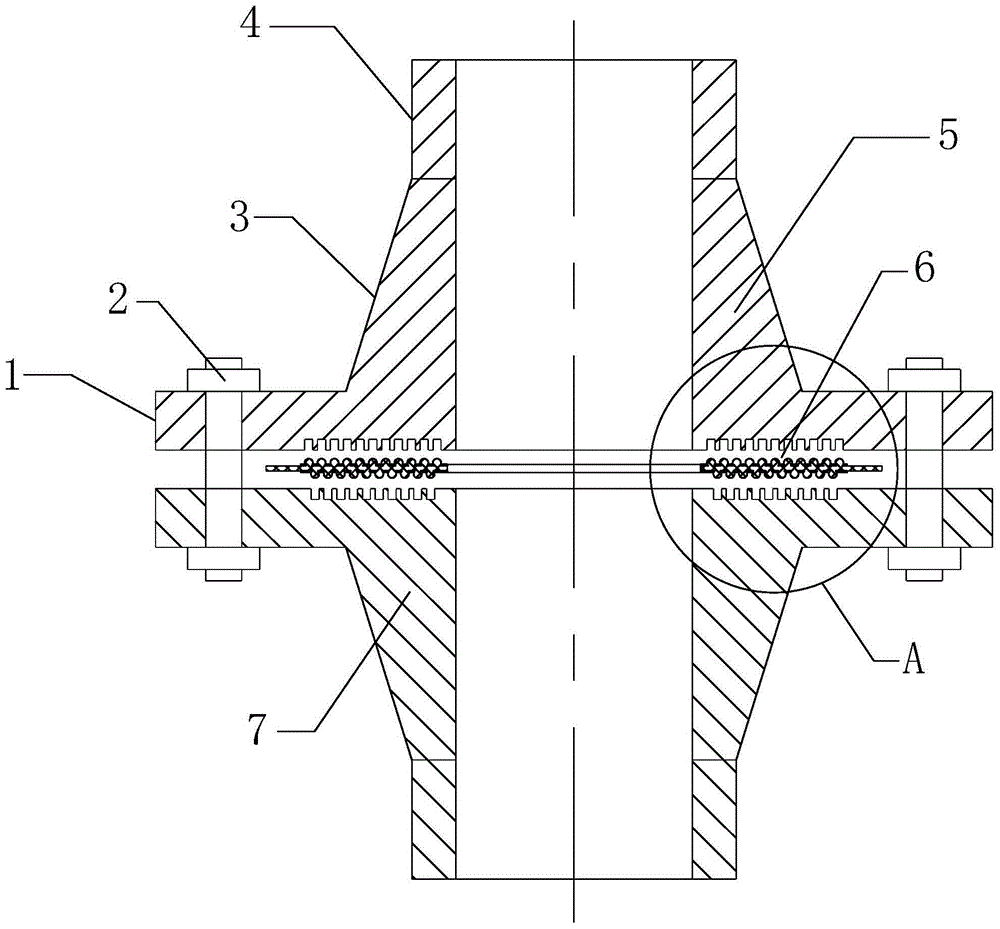

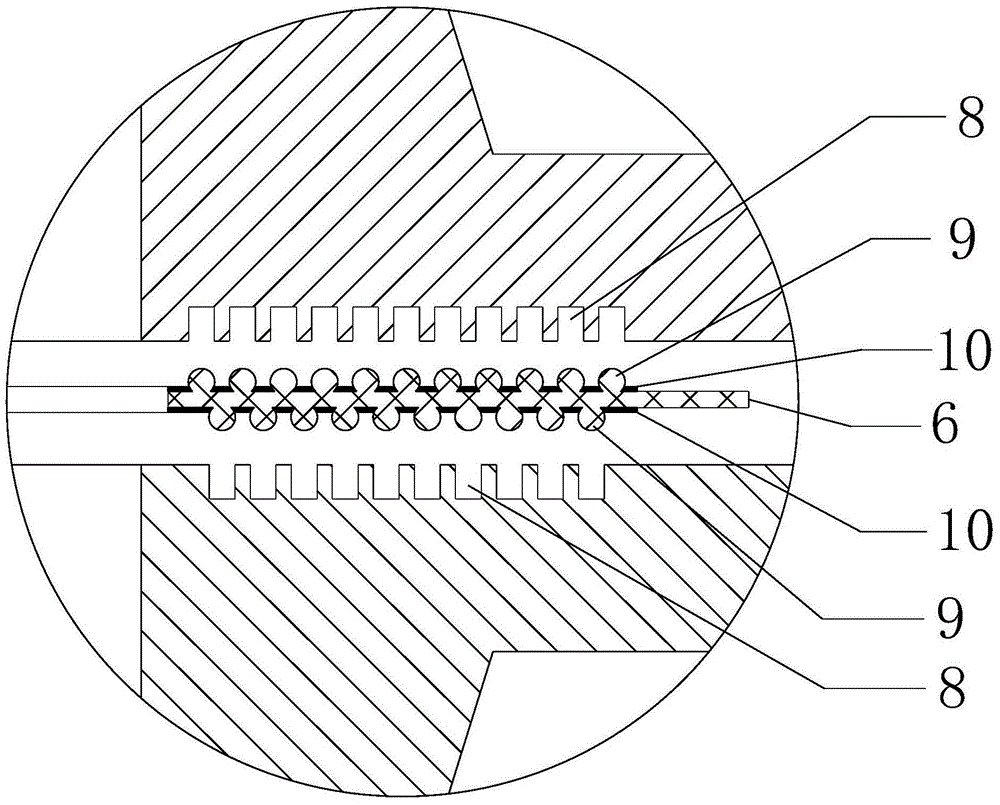

[0018] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described (as figure 1 , 2 , 3).

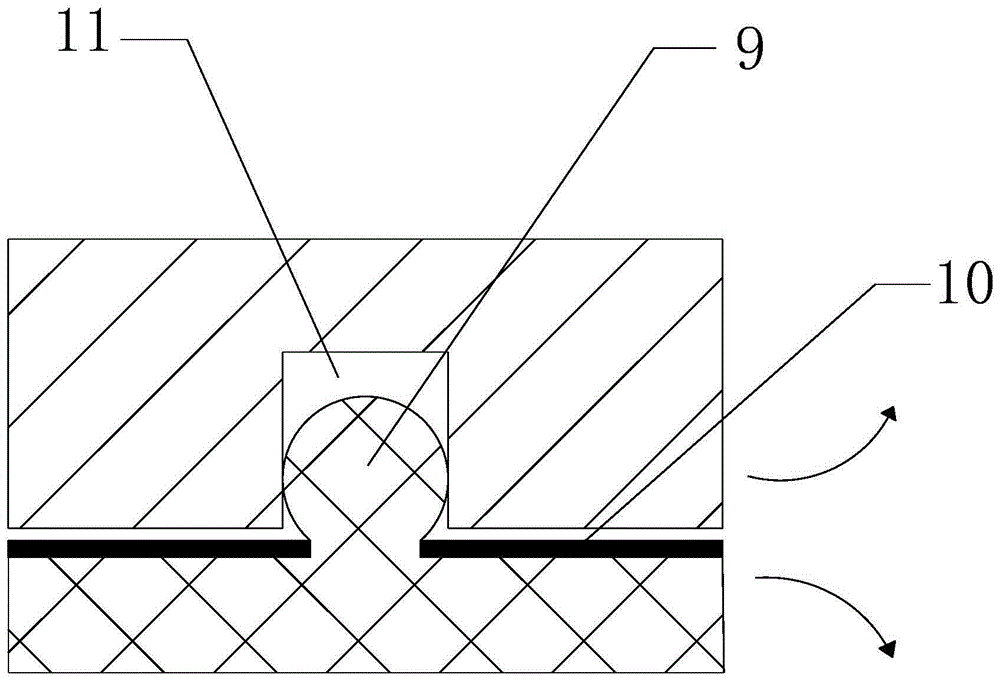

[0019] A high-temperature flange sealing structure containing a flexible graphite metal Ω-shaped tooth composite gasket, which includes an upper flange 5, a lower flange 7, and a flexible graphite metal Ω-shaped tooth composite gasket 6, (the upper flange 5 and the lower flange 7 when they are sealed and connected to each other) the flexible graphite metal Ω-shaped tooth composite gasket 6 is located between the upper flange 5 and the lower flange 7; the metal skeleton of the flexible graphite metal Ω-shaped tooth composite gasket 6 is provided with There are multiple circles of annular bosses 9 with "Ω"-shaped cross-sections, and the multi-circle annular bosses 9 are arranged at equal intervals (that is, there is a certain interval between the annular bosses 9 and the annular bosses 9), and are consistent with the above metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com