Horizontal Layout Tape

a horizontal layout and tape technology, applied in the field of measuring devices and methods, can solve the problems of unfavorable creep and stretch if installed improperly, and provide the potential for undesirable stretch during installation, so as to avoid undesired stretching and eliminate creep and installation human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Installation of GAF Grand Timberline Shingles

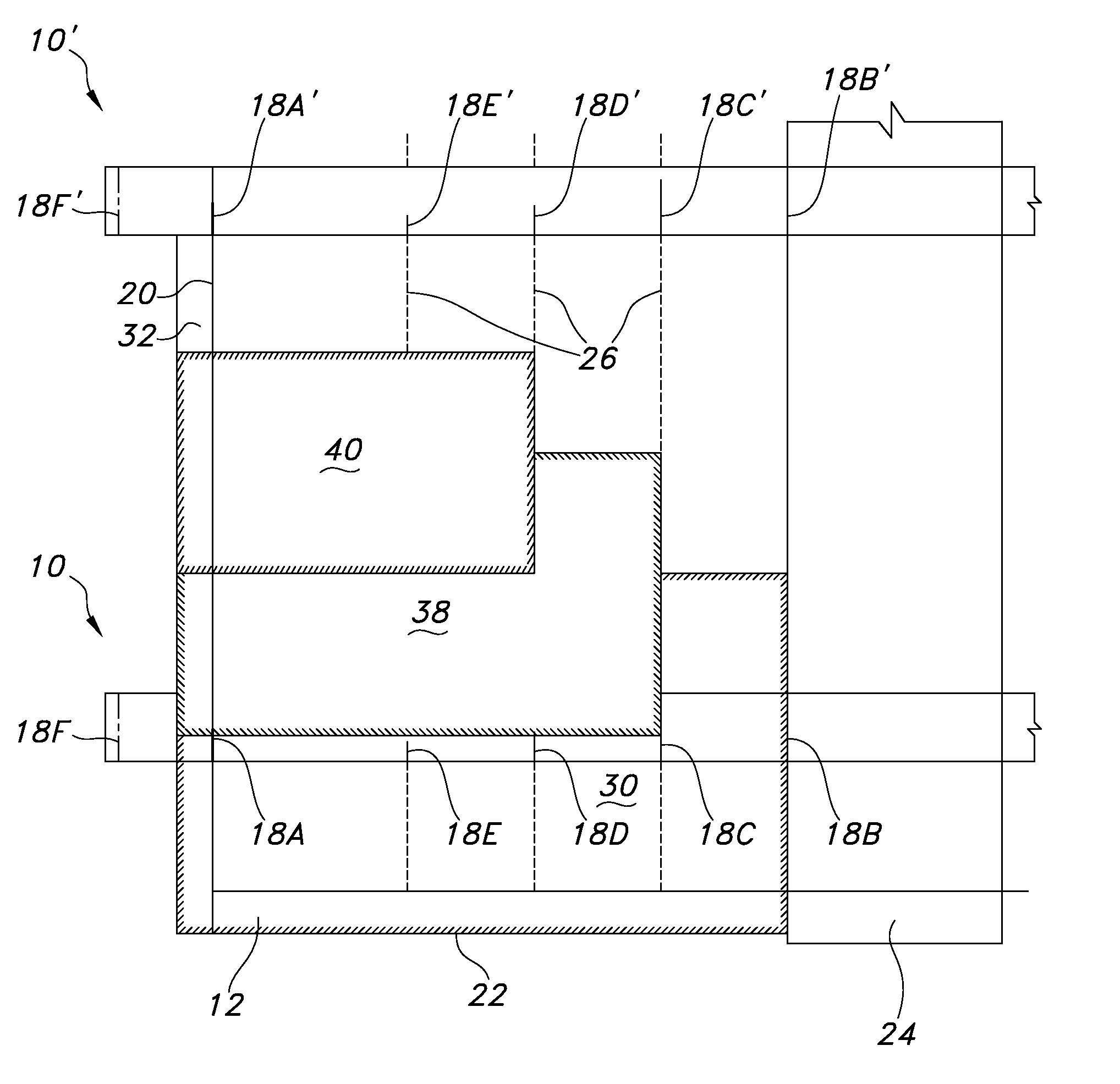

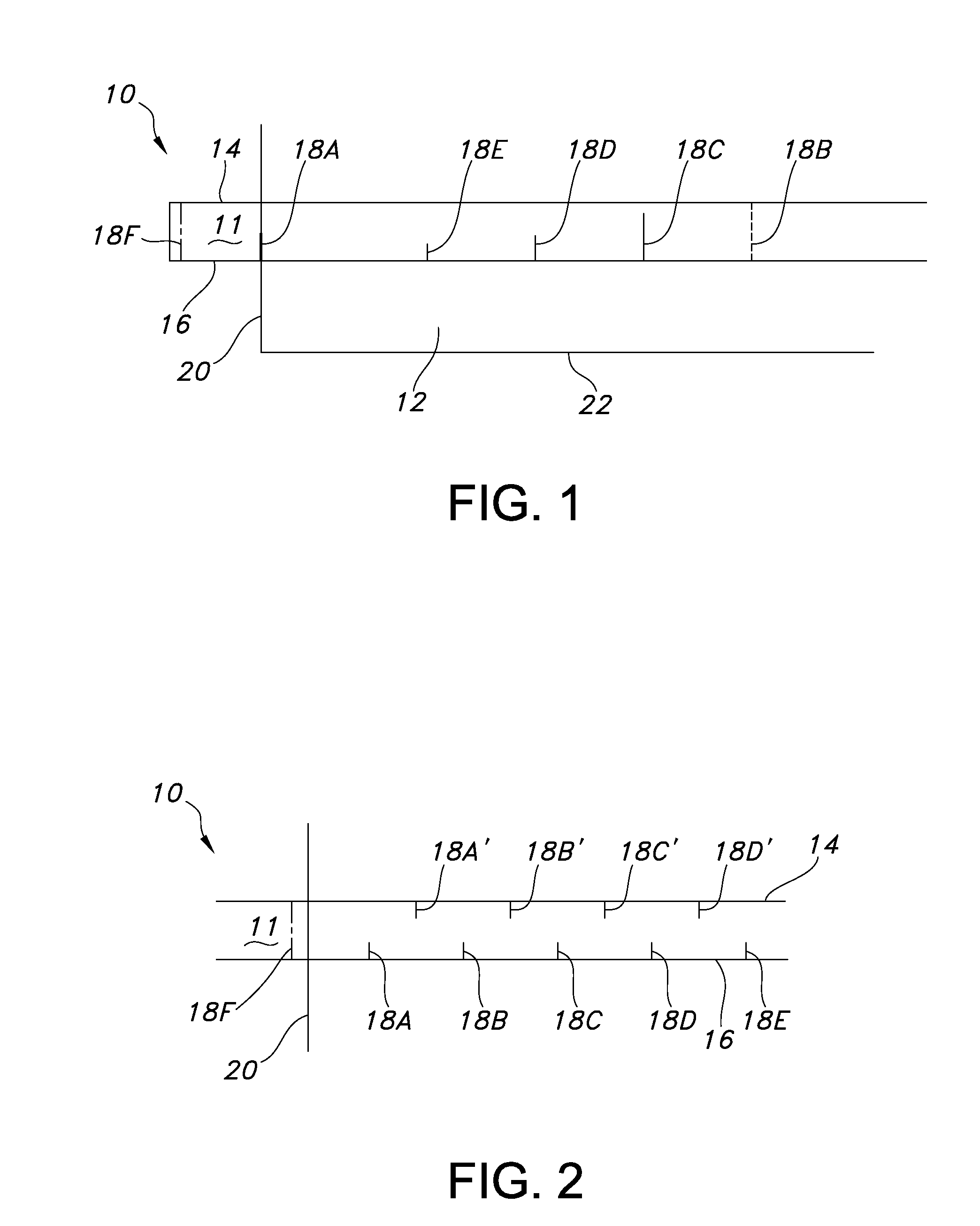

[0052]A roof was installed with a covering of GAF Grand Timberline Shingle. GAF Grand Timberline Shingle is 17″ high by 40″ wide per full, individual piece of shingle. According to the manufacturer's specifications, installation of this shingle requires a full shingle installation with a ⅜″ overlap of the rake drip edge on the side of the house. Following the full shingle installation, the manufacturer's specifications require an offset of 7.5″ for the next shingle course, followed by an offset of 15″ for the next shingle course, and then followed by a 22″ offset for the final shingle course. Once this final course has been installed, the specification calls for installation of a full shingle at the next desired location.

[0053]The roofing tape was prepared with indicia marked thereon indicating proper placement of the shingles pursuant to manufacturer's specifications. The roofing tape was laid on the roof, and vertical layout tape was pl...

example 2

Installation via a Continuous Roll of Roofing Tape

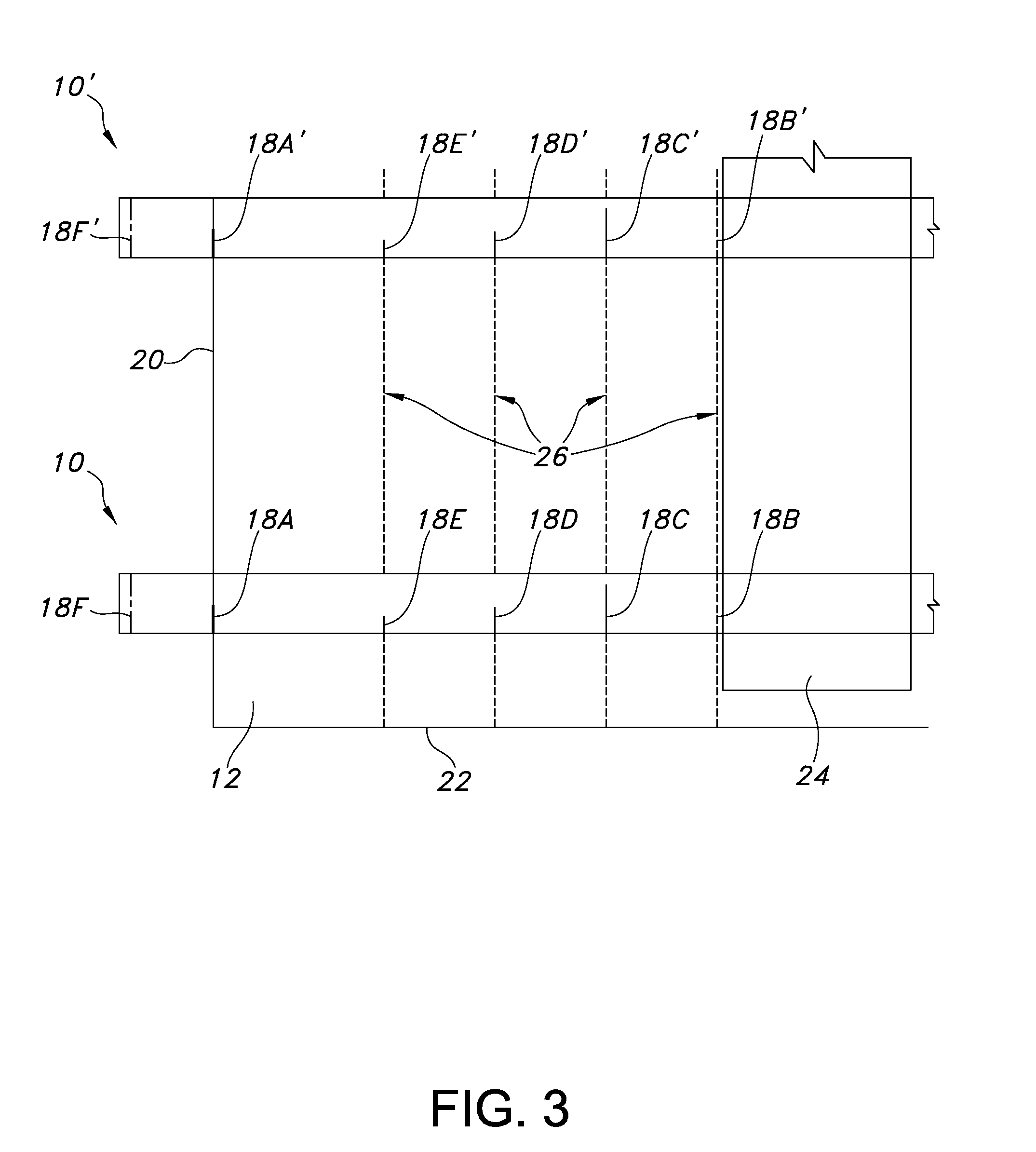

[0054]A continuous roll of roofing tape was provided, manufactured on a 200 food continuous indicia marking roll. The material to be installed was Majestic Slate by Eco-Star. Each individual slate was 12″ wide, and required a 6″ off-set between courses. Further, each course required a ⅜″ gap between each piece. The roofing tape had a 12⅜″ mark on one side of the front of the roofing tape, and a corresponding mark with a 6″ offset on the opposite side of the front of the roofing tape. Thus, these indicia created the strike line locations for all vertical installation lines of both the full shingle courses and the 6″ step shingle courses, complete with the ⅜″ gap between each shingle.

[0055]No individual measurement and human calculation was needed for this installation. The roofing tape was accurate to one pel in 25′.

example 3

Installation via a Continuous Roll of Roofing Tape with an End Wall

[0056]Similar to the process described in Example 2, a roofing of Majestic Slate material is installed on a building with an end wall present. In this Example, the roofing tape includes indicia #6 on the side of the roofing tape proximal to Indicia #1 with a ⅜″ gap between indicia #6 and indicia #1. The roofing tape is placed on the roof to align indicia #6 along the end wall. Thus, the resultant roof includes a ⅜″ gap between the end wall and the installed roofing.

[0057]No individual measurement and human calculation is needed for this installation. The roofing tape is accurate to one pel in 25′.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com