Superlarge double-opening steel door

A technology for extra-large steel doors, which is applied to door leaves, windows/doors, and door/window accessories. Compensate the relative displacement of the axis, eliminate creep, and work stably and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

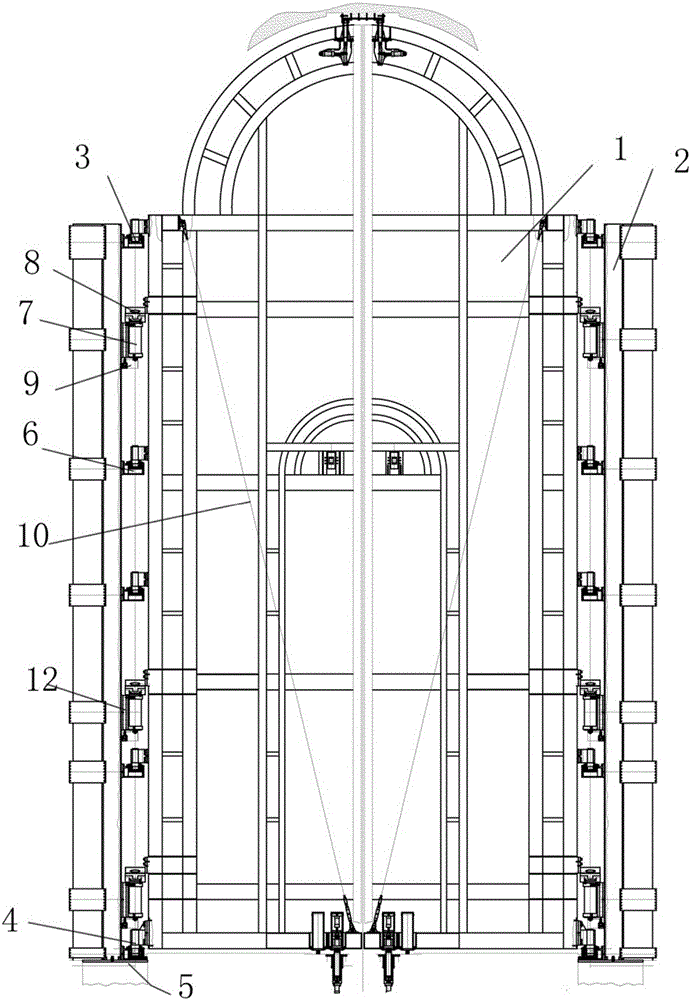

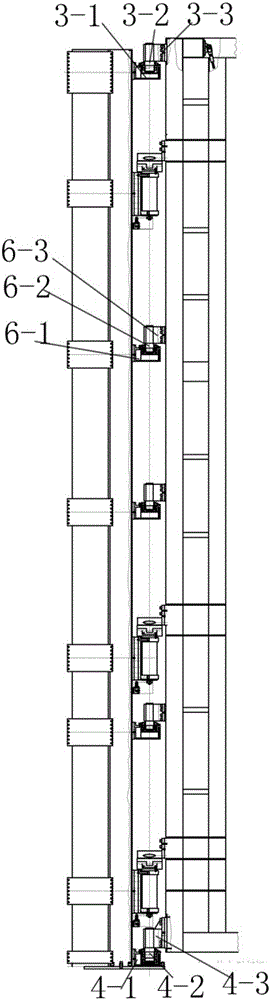

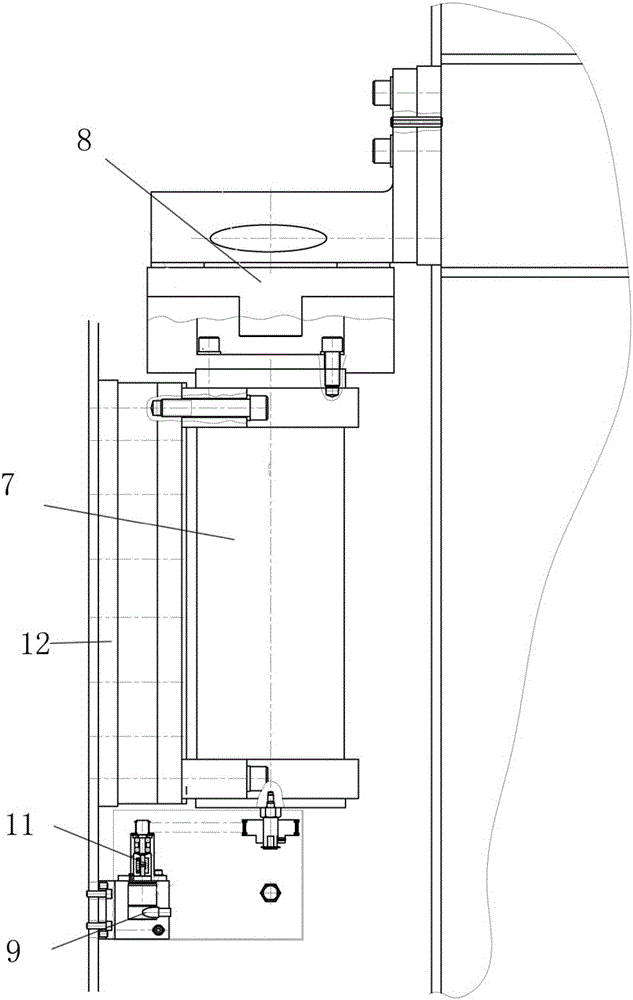

[0022] The technical solution will be described in detail below in conjunction with specific embodiments.

[0023] Such as Figure 1-Figure 3 As shown, the present invention is a kind of extra-large double-leaf steel door, comprising a door leaf 1 and a door frame 2, and the door leaf 1 is welded by stainless steel profiles and plates. The single door is 23m high, 5.4m wide, 0.6m thick, and weighs 50t. The opening and closing rotation range of the single door is 157.5°. The working condition of the door is that it can withstand the blow of a 13-level hurricane during opening, closing and turning.

[0024] Between the door leaf 1 and the door frame 2, there are upper and lower main hinge shaft assemblies 3, 4 and a multi-point linkage synchronous drive mechanism for driving the door leaf to rotate. load, the upper main hinge shaft assembly 3 bears the radial force of the single door, and the connection line between the hinge shaft of the upper main hinge shaft assembly 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com