Loosening preventing and shaft breaking preventing structure of suspension bush

A technology of anti-loosening and shaft structure, applied in the direction of suspension, cantilever installed on the pivot, transportation and packaging, etc., can solve the problems of broken shaft, suspension bushing loosening, etc., to eliminate moment loosening and ensure axial force The effect of no decline and no decline in handling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

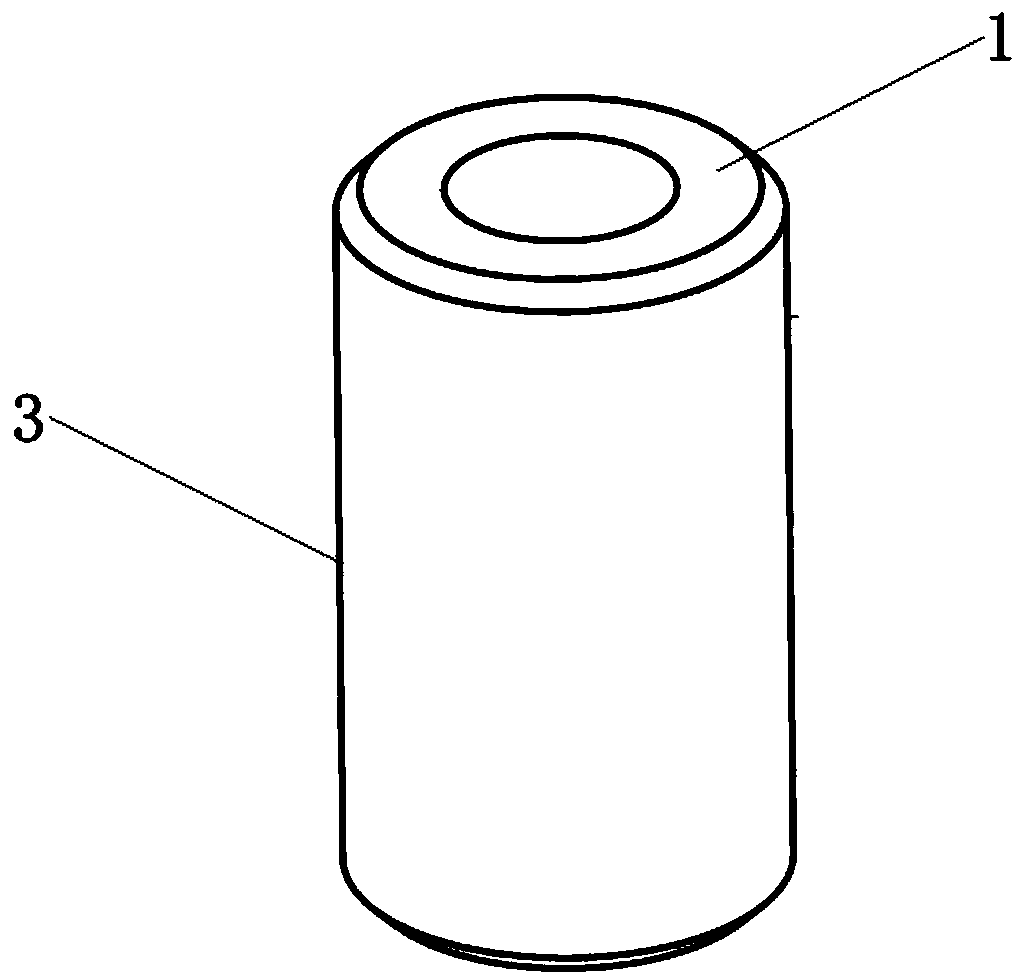

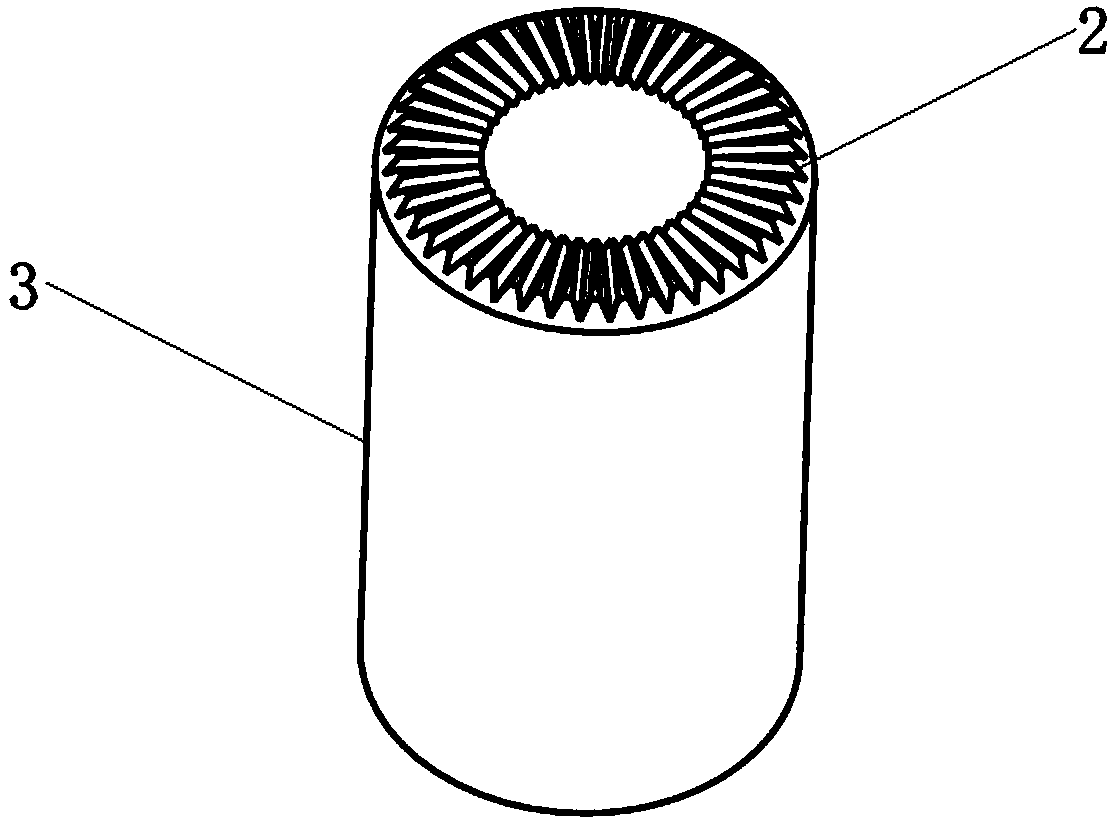

[0038] In the prior art, the contact parts between the suspension bush and the vehicle body or sub-frame are generally connected by two connection methods. One of the connection methods is planar connection, such as figure 1 As shown, the contact part between the suspension bush and the body or sub-frame is connected by plane 1. When this connection is subjected to a large load, it is very easy to loosen. If you continue to drive under this condition, the fastener will Falling off, causing the suspension to separate from the body, causing a broken shaft accident; another connection method is a serrated surface connection, such as figure 2 As shown, the fastening contact parts of the suspension bushing and the body or sub-frame are connected by serrated surface 2. The serrations in this connection method will damage the contact surface and cause corrosion. After long-term use, the material loss of the rusted part will cause the connection The reduction of the moment of the pa...

Embodiment 2

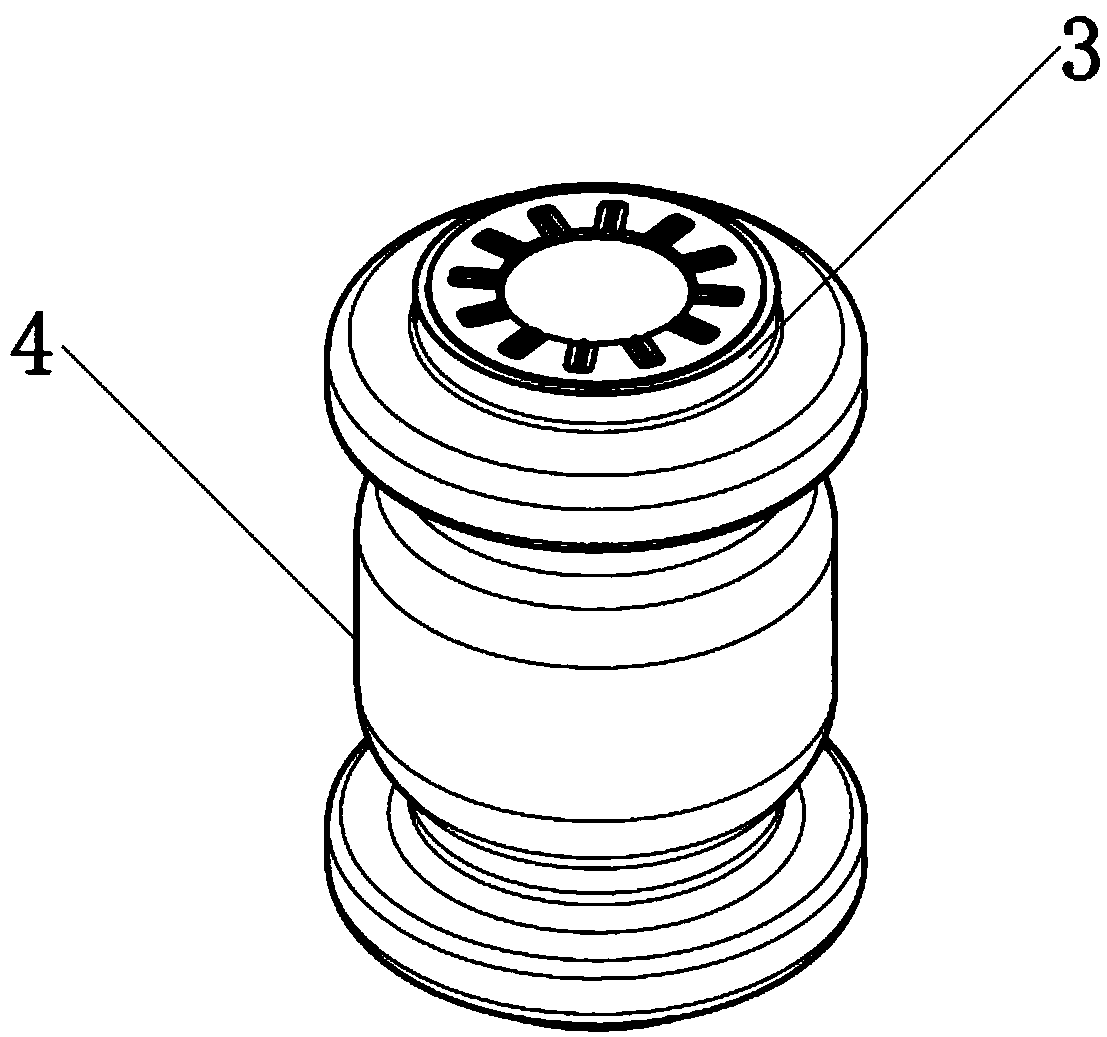

[0054] This embodiment provides a suspension bushing anti-loosening and anti-broken shaft structure, which includes a suspension bushing, and the suspension bushing is connected with a vehicle body or a sub-frame through fasteners. Preferably, the fasteners are bolts and nuts. Such as image 3 As shown, the suspension bushing includes an inner sleeve 3 and an outer sleeve 4 , and the outer sleeve 4 is sleeved on the outside of the inner sleeve 3 . The materials of the inner sleeve 3 and the outer sleeve 4 have a wide range of sources, such as low carbon steel and alloy steel, and the cost is low.

[0055] Such as Figure 4 and Figure 5 As shown, the inner sleeve 3 has a contact surface 31, the contact surface 31 is in contact with the sub-frame or the vehicle body, and a certain amount of anti-loosening is arranged along the circumference of the contact surface 31 by using an upsetting process. Teeth 5, a certain range of grooves 6 are processed around the anti-loosening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com