Novel optical fiber temperature and pressure sensor

A pressure sensor, optical fiber temperature technology, applied in thermometers, fluid pressure measurement using optical methods, thermometers with physical/chemical changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

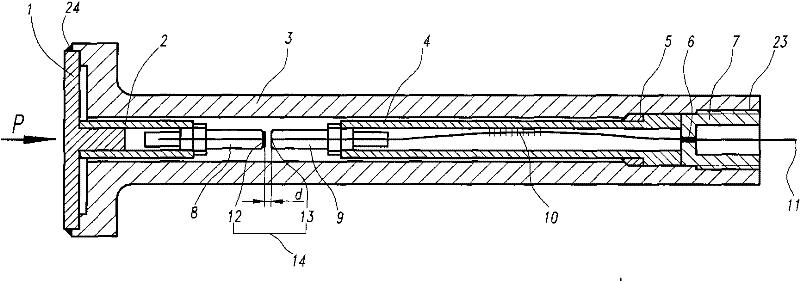

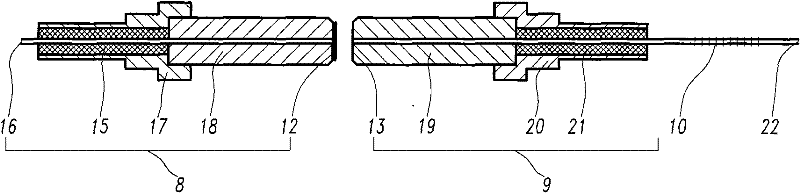

[0023] The second ceramic ferrule assembly 9 includes a cylindrical second metal connector 20 and a second ceramic rod 19 with a central hole, one end of the second metal connector 20 is inserted into the long connecting pipe 4 and fixedly connected thereto, The other end of the second metal connector 20 is fixed with a second ceramic rod 19 , and a second optical fiber 22 is fixed between the second metal connector 20 and the second ceramic rod 19 by high temperature resistant glue.

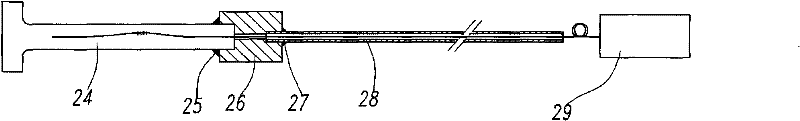

[0024] A regulating pipe 5 is sleeved on the outside of the long connecting pipe 4 . The FAP cavity 14 is used to detect pressure, and the fiber Bragg grating 10 is used to detect temperature and perform temperature compensation on the FAP cavity 14 . The FA-P cavity 14 is composed of a first ceramic ferrule assembly 8 and a second ceramic ferrule assembly 9 .

[0025] like figure 2 As shown, the first optical fiber 16 is bonded to the first ceramic rod 18 and the first metal connector 17 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com