Warp knitting machine

A warp knitting machine and bar technology, which is applied in the field of warp knitting machines, can solve the problems of high yarn consumption and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

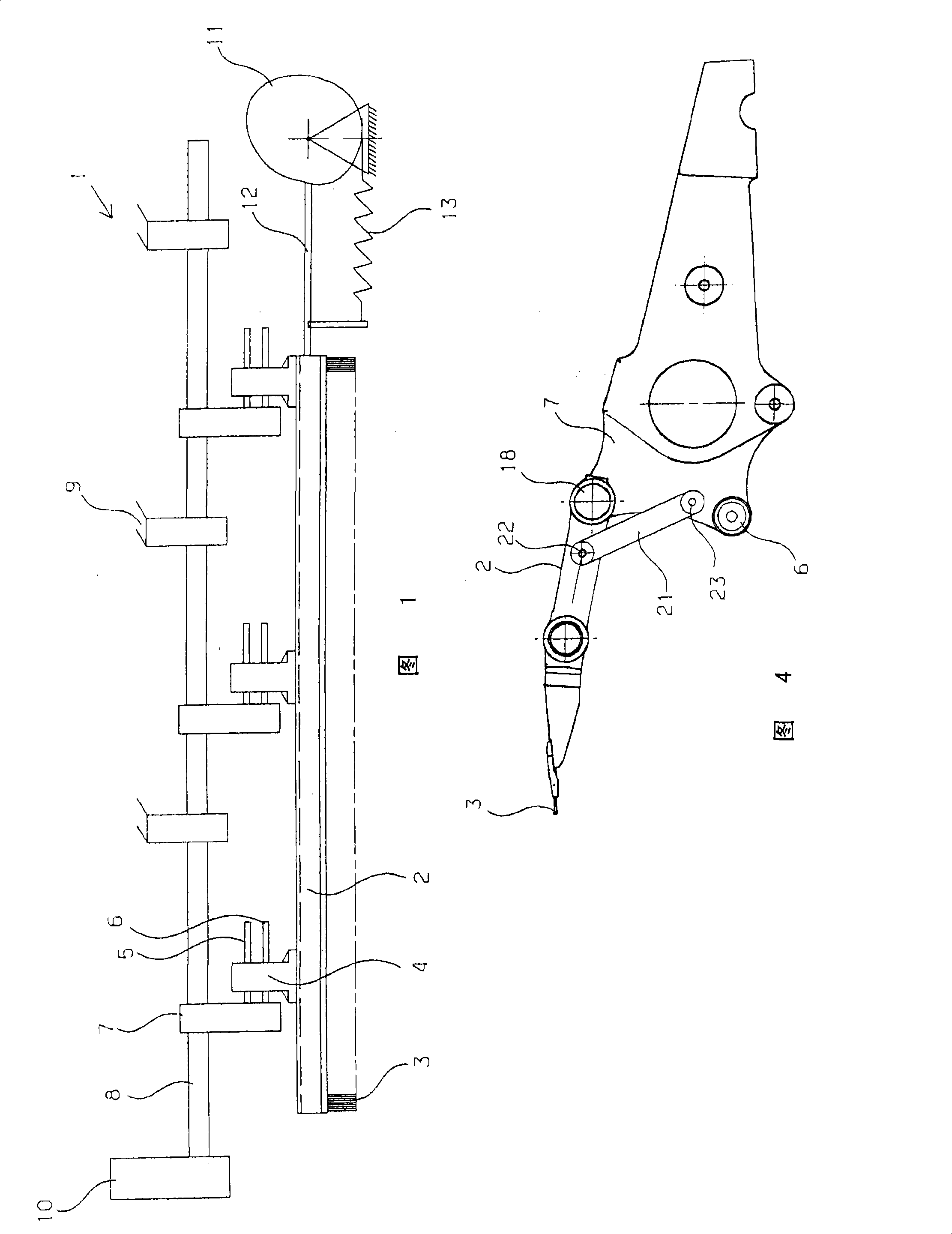

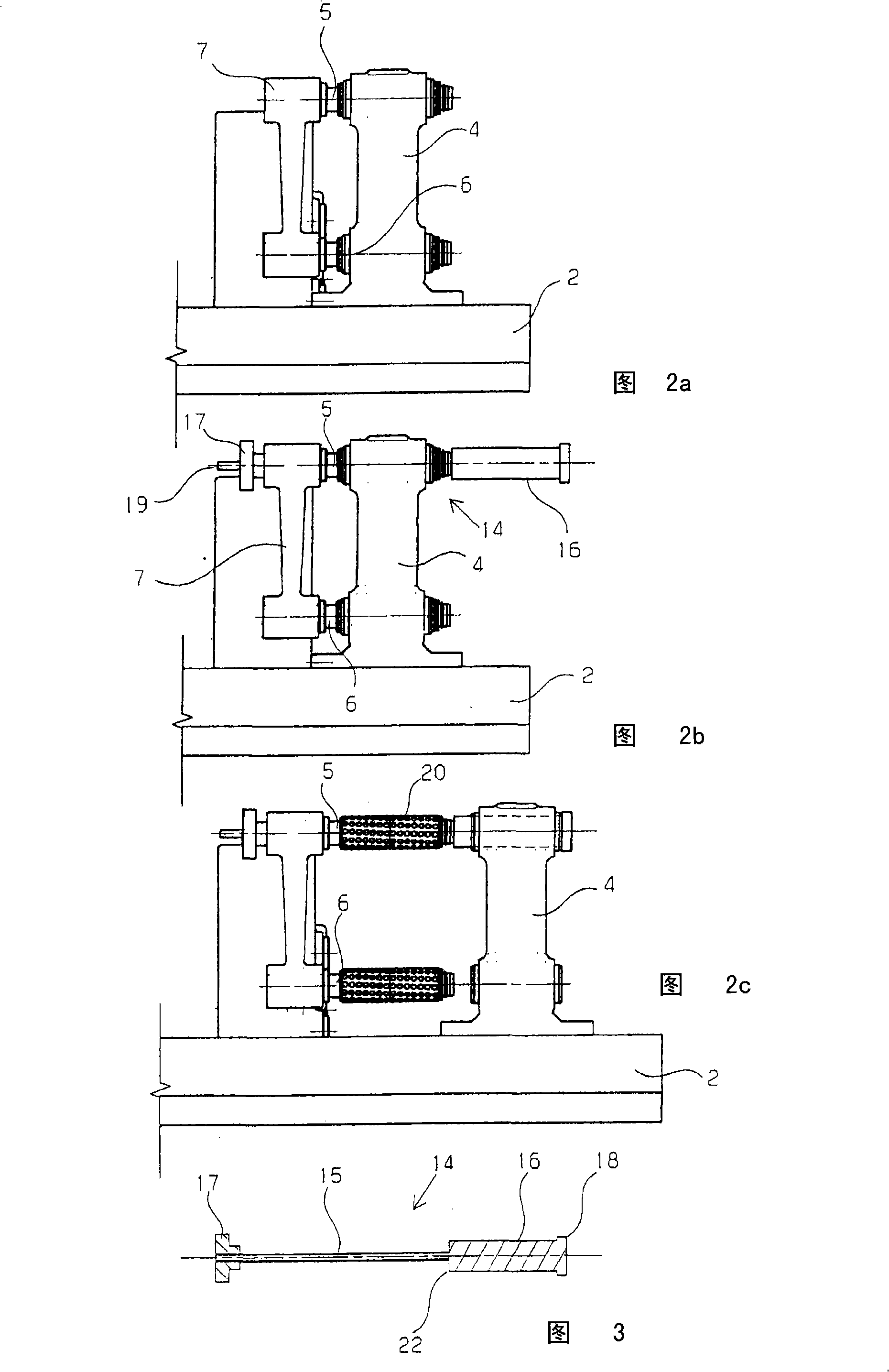

[0029] FIG. 1 shows a section of a warp knitting machine 1 with a bar 2 , which supports a plurality of bar needles 3 , in a significantly simplified schematic view. The comb needle 3 is made of a hole needle.

[0030] The bar has a plurality of bar frames 4 distributed over the length of the bar as guides. Other guides are also possible. Each bar frame is attached to two guide pins 5 , 6 , wherein the guide pins 5 , 6 are shown exaggerated in the illustration in FIG. 1 .

[0031] The guide pins 5 , 6 are each fastened to a comb bar 7 which is connected to a suspension shaft 8 in a torsion-proof manner. The suspension shaft 8 is suspended on bearings 9 and can be rotated back and forth over a small angular range by means of a rotary drive 10 . During rotation, the bar is deflected and the bar 2 is deflected by the bar 7 .

[0032] During operation, the bar 2 is driven parallel to its longitudinal extension by a jacquard wheel 11 , which acts on the bar 2 via a jack 12 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com