Normal displacement and angle sensing optical measuring head and measuring method thereof

An angle sensing and displacement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increasing system complexity, troublesome installation and combination debugging, expensive price, etc., and achieves compact structure, reduced development cost, and high integration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

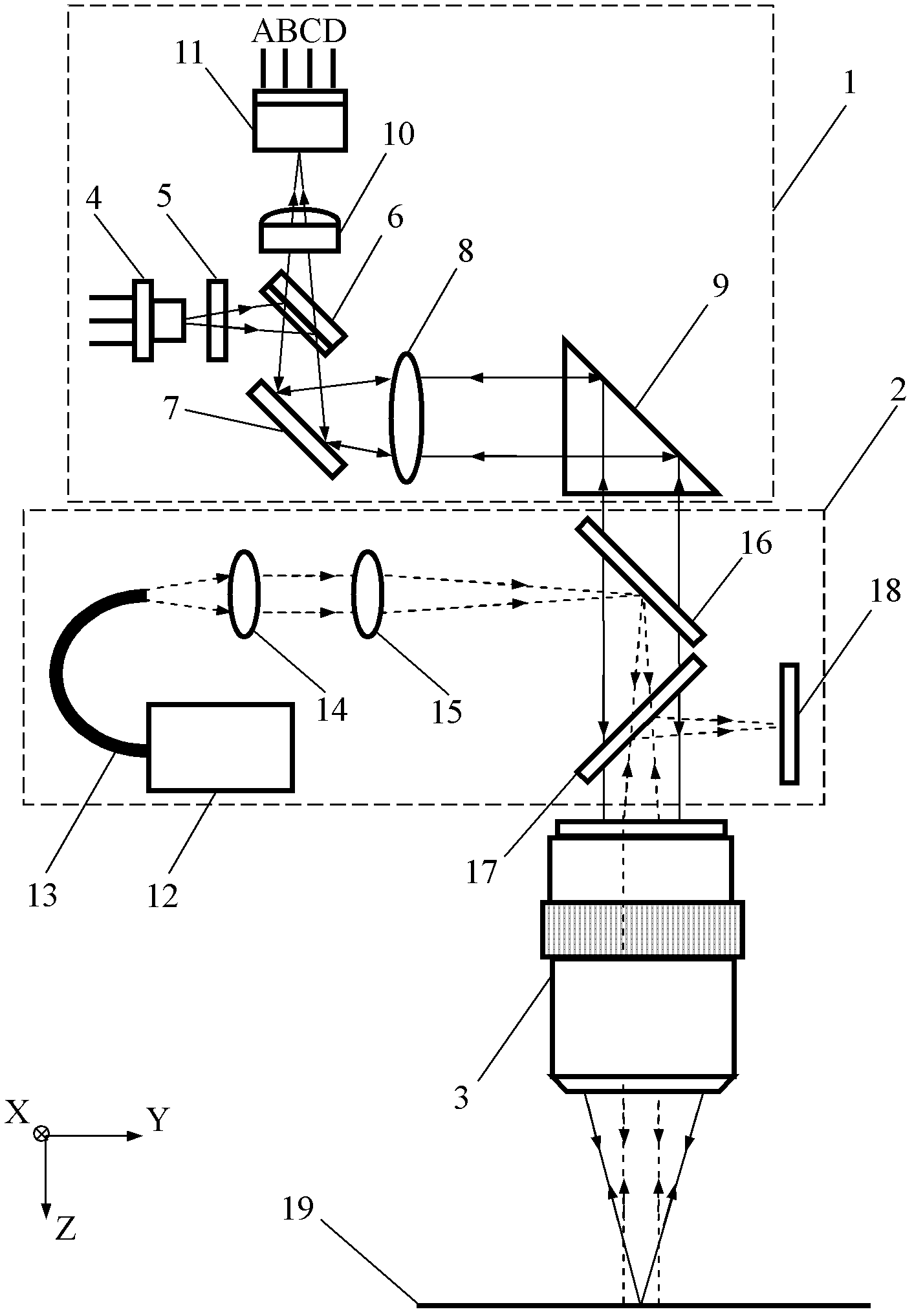

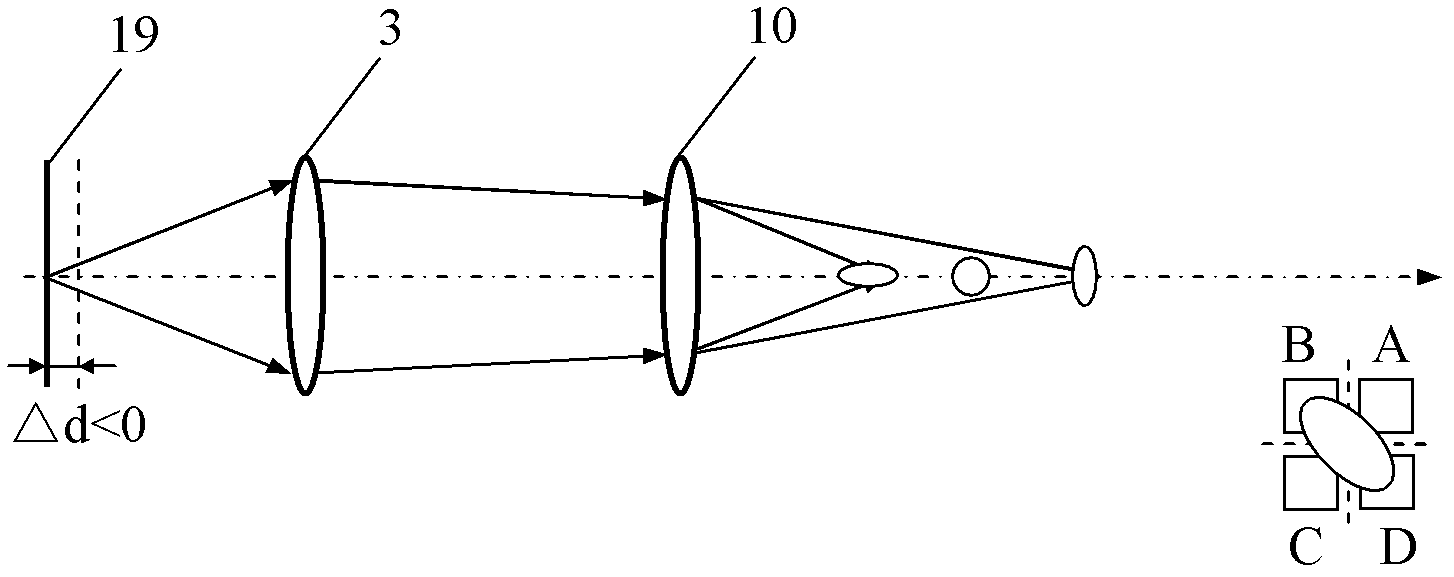

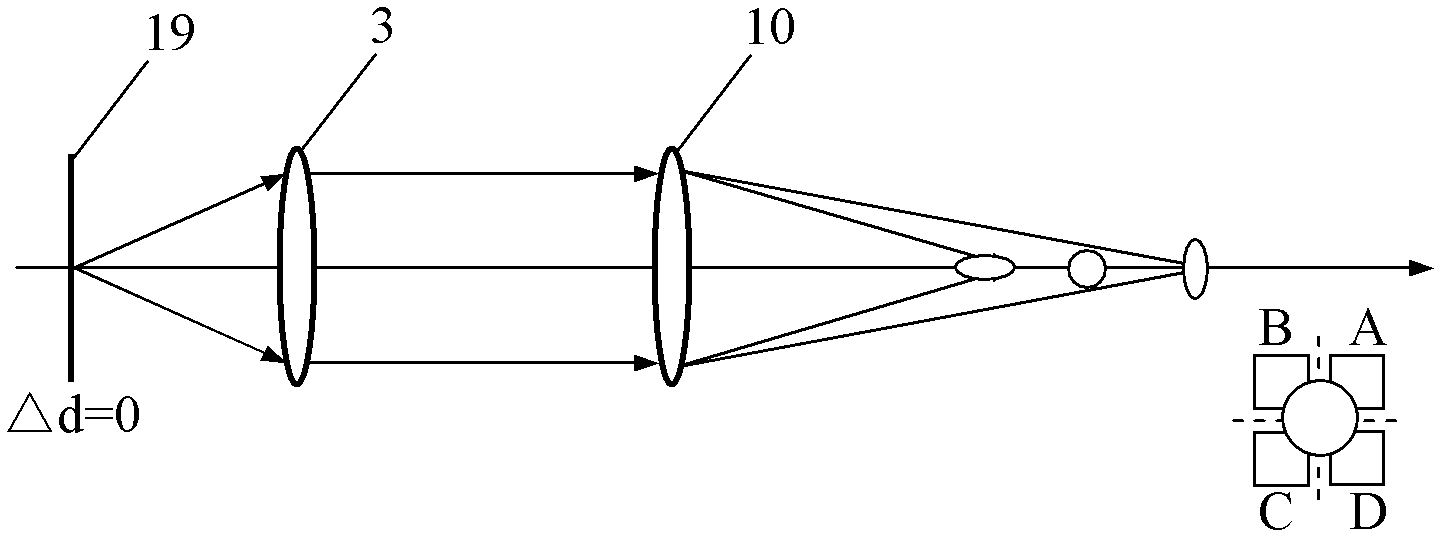

[0026] Such as figure 1 As shown, the normal displacement and angle sensing optical probe of this embodiment is composed of an autofocus unit 1, an inclination detection unit 2 and a microscopic objective lens 3; the autofocus unit 1 includes a semiconductor laser 4, a spectroscopic grating 5, a spectroscope 6, Mirror 7, collimating mirror 8, rectangular prism 9, astigmatic lens 10 and four-quadrant detector 11; Inclination angle detection part 2 comprises infrared laser light source 12, light guide fiber 13, collimating mirror 14, focusing mirror 15, infrared reflection Mirror 16, infrared beam splitter 17 and two-dimensional DSP18; Microscopic objective lens 3 is a microscopic objective lens corrected for finite far-infrared apochromatic aberration.

[0027] Such as figure 1 , the autofocus function is realized by the astigmatism method. The laser light with a central wavelength of 650nm emitted by the semiconductor laser 4 is divided into three beams by the beam splitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com