A high-pressure orifice gas stagnation temperature control device and method

A control device and stagnation temperature technology, which is applied in the direction of temperature control, measurement device, test/calibration device, etc. using electric methods, can solve problems such as short heat exchange time, pipeline blasting accidents, and affecting pipeline pressure resistance , to achieve the effect of improving accuracy and ensuring the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

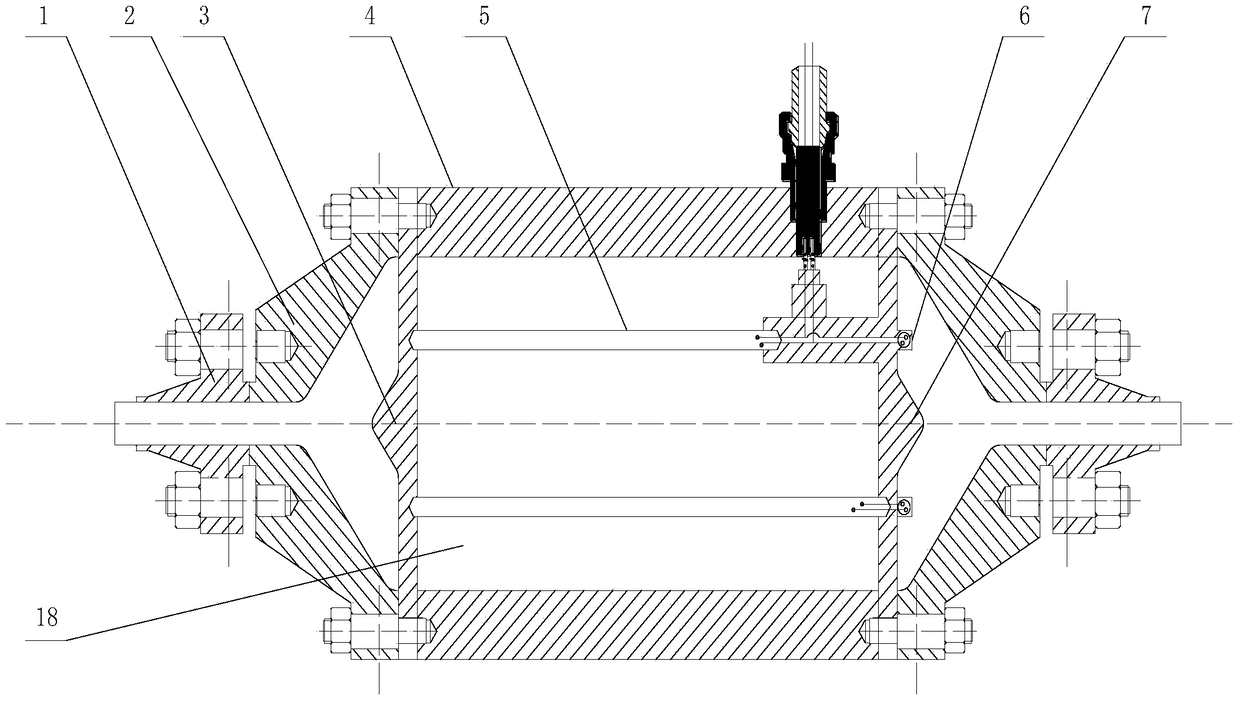

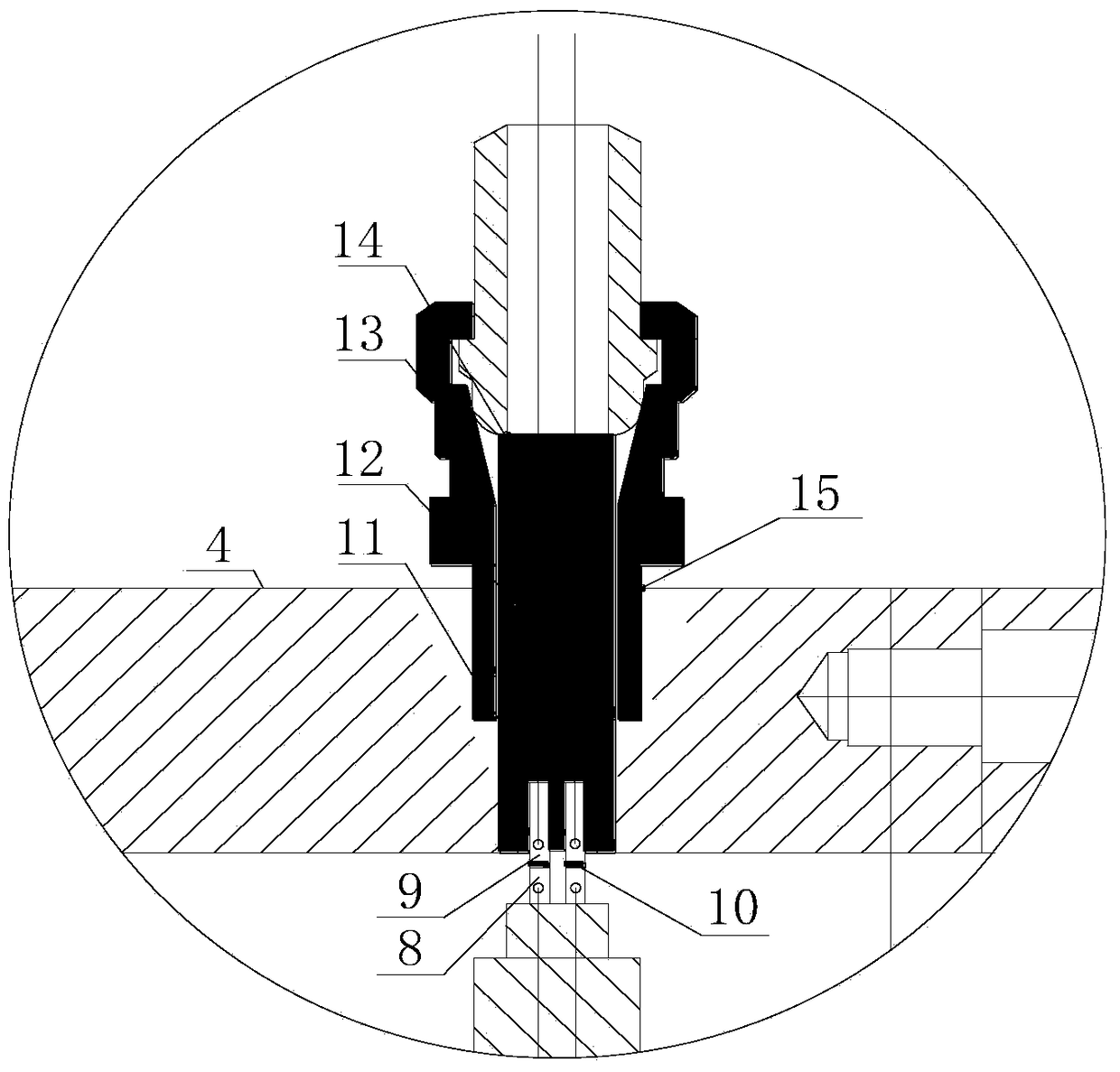

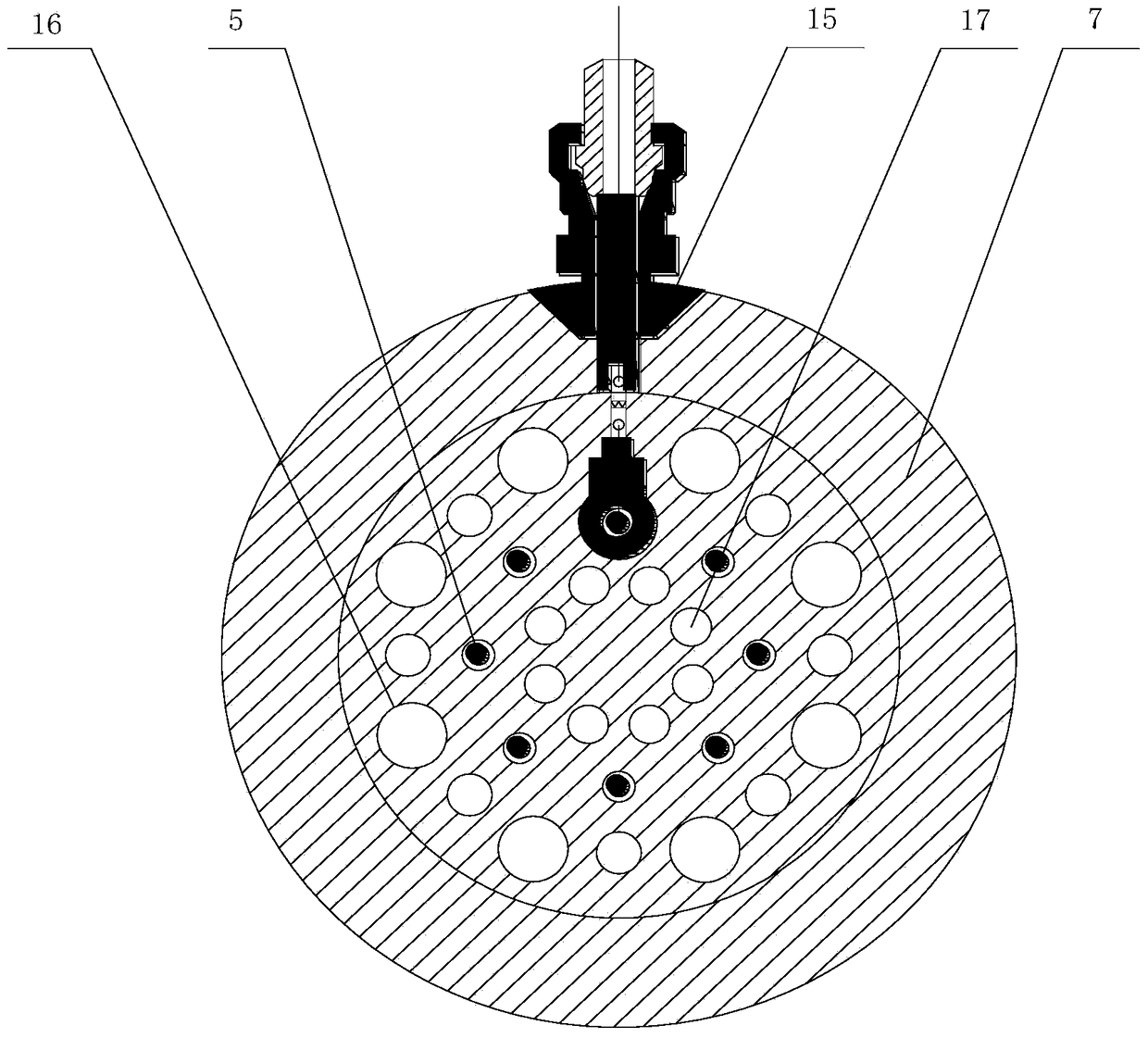

[0037] Such as figure 1 — image 3 As shown, the high-pressure orifice gas stagnation temperature control device of the present invention, that is, the temperature-controlled gas tank 18 includes a temperature-controlled gas tank inlet flange 1, a temperature-controlled gas tank inlet expansion splint flange 2, a front porous rectifying plate 3, Temperature control gas tank wall 4, electric heating rod 5, collector coil 6, rear porous rectifying plate 7, electric heating rod inner electrode 8, outer electrode 9, electrode spring 10, insulating material 11, metal plug 12, ball head-cone sealing structure 13. Welding point A 14, welding point B15, outer ring diversion hole 16, inner ring diversion hole 17;

[0038] The temperature-controlled gas tank inlet flange 1 is externally connected to the gas source outlet, and the front porous rectify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com