Three-dimensional force sensor decoupling calibration and filtering method and device for constant force grinding

A sensor, three-dimensional force technology, applied in the direction of measuring devices, instruments, force/torque/work measuring instrument calibration/testing, etc. Simple and effective decoupling calibration and precise filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

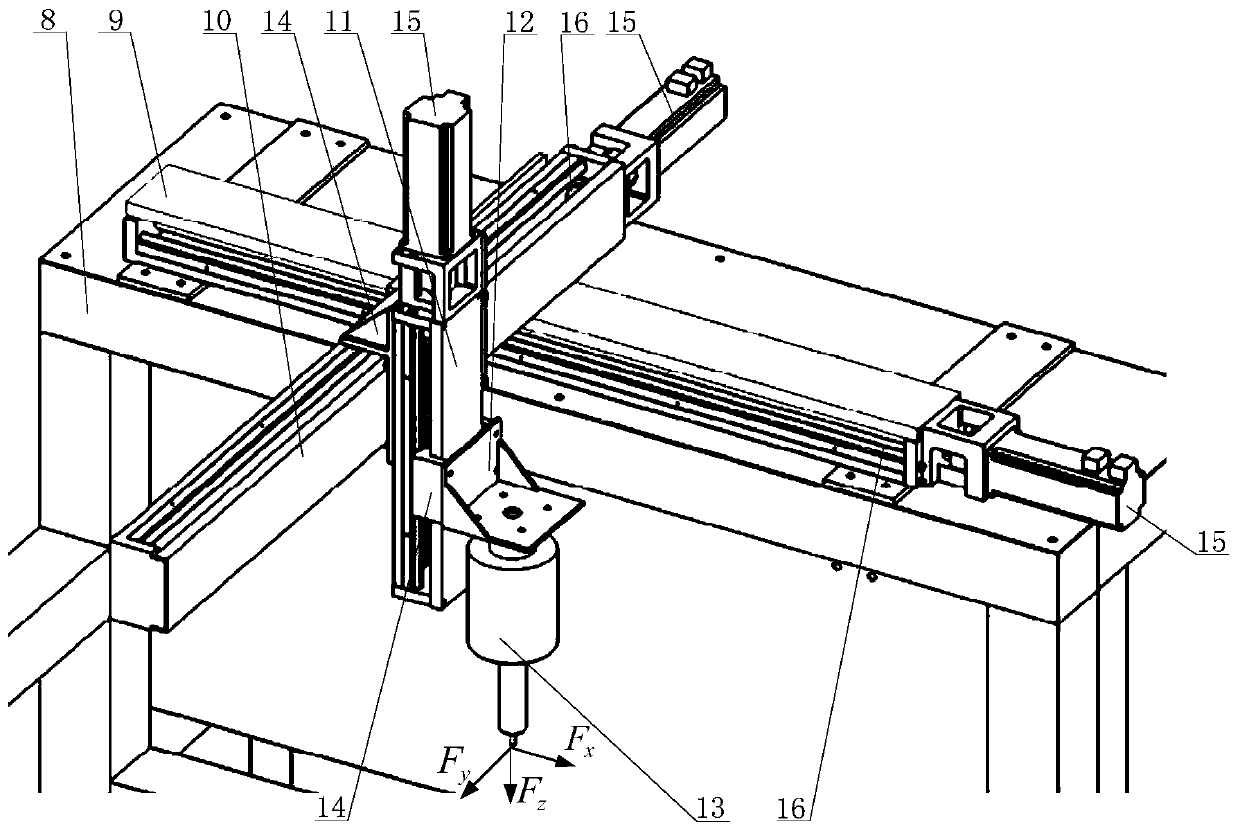

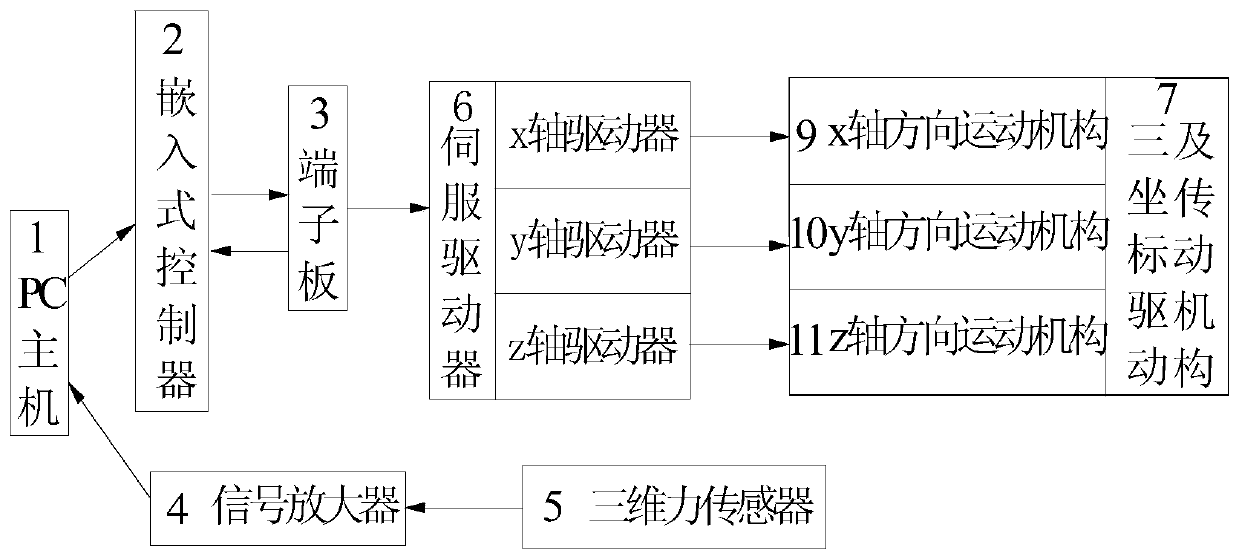

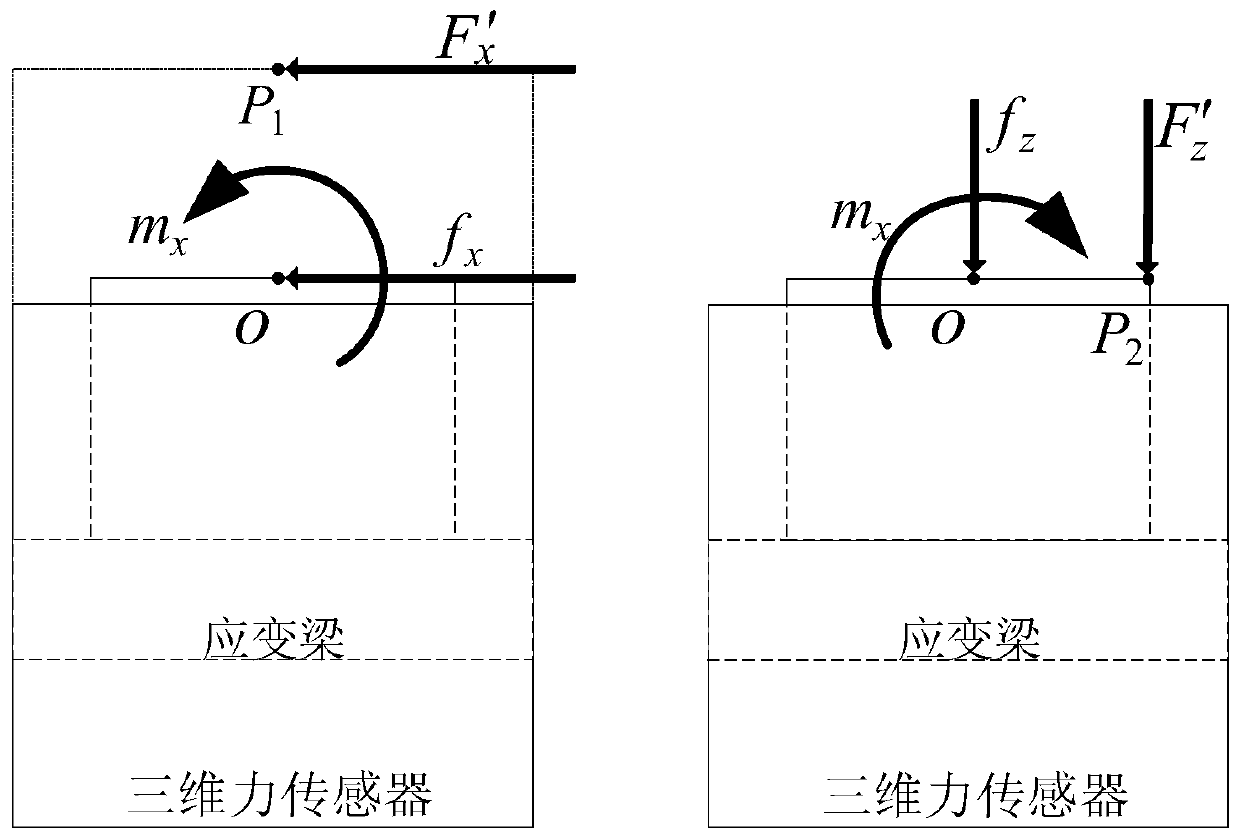

[0054] The device of the present invention is used in the working steps of the three-dimensional force sensor decoupling calibration and filtering method for constant force grinding:

[0055] (1) The three-dimensional force sensor used is A3D46-20kg force sensor with a measuring range of 20kg, its non-linearity is less than ±1% F.S., and the repeatability is less than ±0.5% F.S. Since the three-dimensional force sensor has no channel to detect torque information, it can only bear force at a fixed point. If the force point changes, it must be re-calibrated, otherwise force coupling will occur and the measured force value will be incorrect, resulting in robot misoperation. The force of the three-dimensional force sensor at different points is as follows: image 3 As shown, when at P 1 The point is subjected to a force F in the X direction x ’, the sensor is equivalent to being subjected to f at point O x force and m x torque. If a single force f is applied at point O x Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com