Electrothermal asphalt concrete doped with graphite and carbon fibers

A technology of asphalt concrete and carbon fiber, which is applied in the field of asphalt pavement of road engineering to achieve the effect of fast heating of the pavement, low investment and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

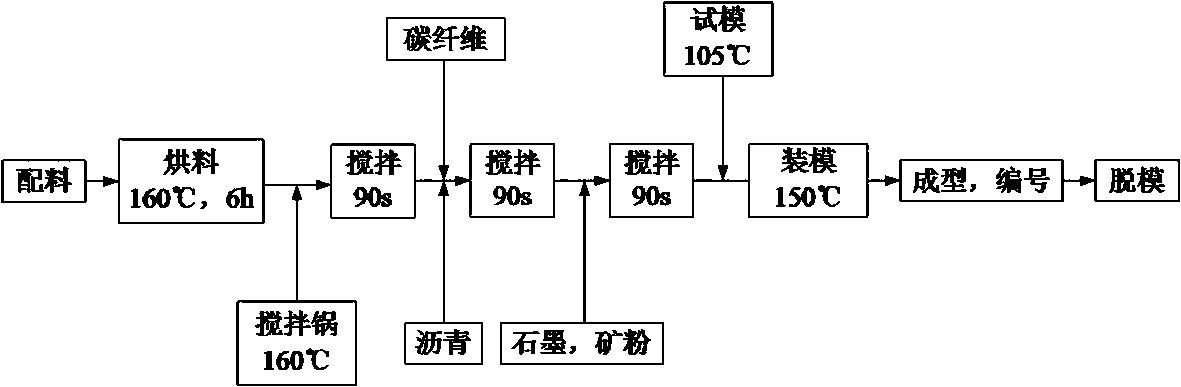

[0048] For the electrothermal asphalt concrete provided in this example, taking a Marshall test piece (cylindrical body with a diameter of 101.6 mm and a height of 63.5 mm ± 1.3 mm) weighing about 1200 g as an example, the relevant preparation process (the preparation process is as follows: figure 1 shown) are briefly introduced below.

[0049] (1) Aggregate pretreatment

[0050] Refer to the requirements of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTGE20-2011), set up the aggregate formula, take aggregate materials of different diameters in proportion, and pretreat them separately for later use; the pretreatment mainly refers to Dry each material. In this embodiment, it is specifically placed in an oven and dried for at least 6 hours to a constant weight. After cooling to room temperature, aggregate materials of different diameters are weighed in proportion for use (weighing according to the oil-stone ratio to be used) Aggregate required am...

experiment test example 1

[0121] On the basis of the test pieces prepared in the above examples, the inventors further tested the road performance of each test piece, including: water stability, high temperature stability, low temperature crack resistance, etc. The specific process is briefly introduced as follows.

[0122] (1) Water stability

[0123] Water is one of the main damage factors to the structural stability of asphalt pavement. Under the action of vehicle load, the presence of water and the effect of freezing and thawing make the water in the gaps on the surface of asphalt pavement continuously immerse into the interior of the asphalt pavement. At the same time, due to the dynamic load As a result, the water separates the asphalt from the aggregate, thereby causing damage to the interior of the pavement structure. If things go on like this, it will eventually lead to pits and other phenomena on the asphalt pavement, and the overall bearing capacity of the pavement will be reduced.

[0124]...

experiment test example 2

[0149] Ordinary asphalt concrete is made by mixing asphalt, aggregate and mineral powder. These materials do not have the ability to conduct electricity, so ordinary asphalt concrete has a large resistance value and is an insulator. One of the main purposes of this application is to incorporate conductive materials, so as to facilitate snow melting and deicing operations by means of electric heating. Therefore, this test example mainly tests the electrical conductivity of the test pieces prepared in this application. The specific process is briefly introduced as follows .

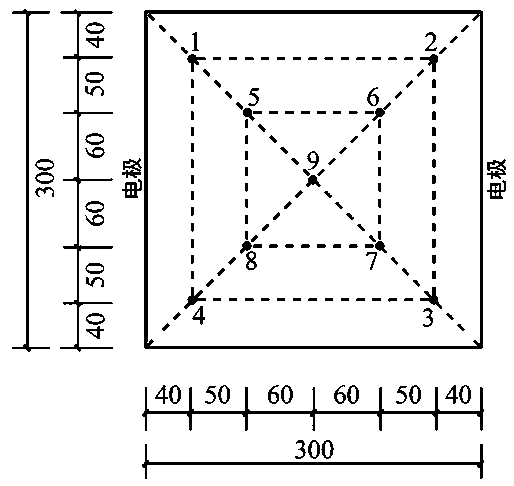

[0150] (1) Resistivity test

[0151] Using the two-electrode method, the resistance of the test piece was measured with a multimeter. During the test, a copper sheet was used as an electrode, fixed on both ends of the specimen with electric tape, and graphite powder was coated on the contact surface between the specimen and the electrode to fill the pores and reduce the contact resistance. Finally, use a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com