Thin film solar cell and preparation method thereof

A solar cell and thin film technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high manufacturing cost, difficulty in large-scale production, and increased material cost, and achieve simple production and equipment, easy large-scale production, and reduced The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

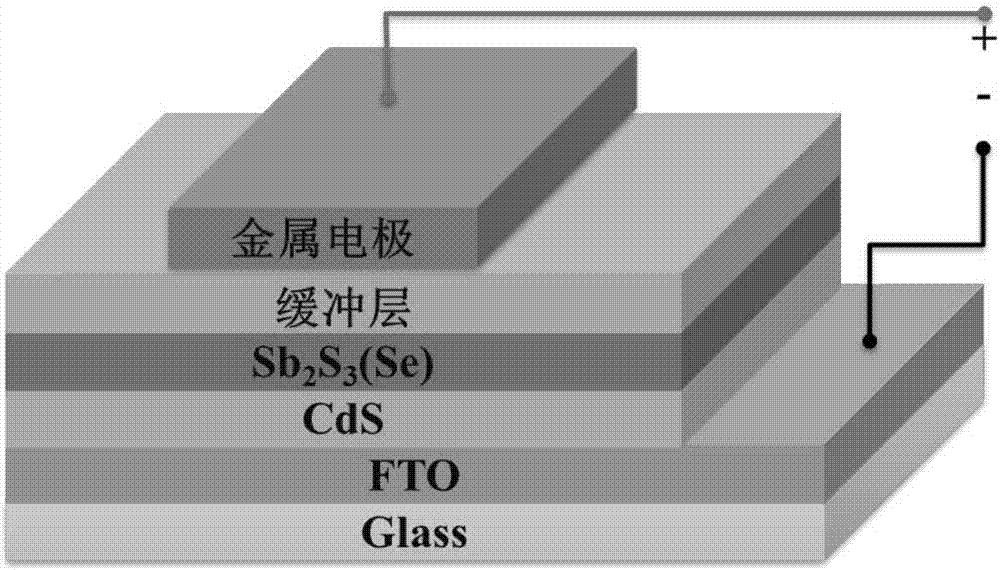

[0036]Thin film solar cells are basically as attached figure 1 as shown,

[0037] a Sb 2 S 3 The bottom layer of the structure of (Se) thin film solar cells is the substrate, and above the substrate are FTO, CdS, Sb 2 S 3 (Se), MoO 3 , Ag, the preparation steps are as follows:

[0038] (1) Substrate cleaning

[0039] Clean the FTO / glass substrate in deionized water, acetone, and isopropanol for 10 minutes with an ultrasonic cleaner, and then dry it.

[0040] (2) CdS film deposition

[0041] Thiourea and CdCl 2 Soluble in H 2 O, adding a certain amount of NH 4 ·H 2 O, CdCl 2 The concentration is 1.2mmol / L, thiourea and CdCl 2 The ratio of the amount of substance is: 100:7.2; NH 4 ·H 2 O is used to adjust the pH value of the solution to 11.5, the temperature of the water bath is 80° C., the deposition time is 30 min, and the thickness of CdS is 120 nm.

[0042] (3) Deposition of Sb on CdS film 2 S 3 (Se) thin film

[0043] i. Solution configuration

[0044] S...

Embodiment 2

[0055] The difference from Example 1 is: Sb in the precursor solution 3+ The concentration is 0.5mol / L, Sb 2 S 3 The film thickness is 500nm, the thickness of CdS is 150nm, and the buffer layer material is MoO 3 , MoO 3 The thickness is 3nm, the material of the metal electrode is Au, and the thickness of the metal electrode is 60nm. In step 3, the temperature at the high temperature end of selenization is controlled at 380°C, the temperature at the low temperature end is controlled at 350°C, and the selenization time is 5min.

Embodiment 3

[0057] The difference from Example 1 is: Sb in the precursor solution 3+ The concentration is 0.4mol / L, Sb 2 S 3 The thickness of the film is 1500nm, the thickness of CdS is 100nm, the material of the buffer layer is NiO, the thickness of NiO is 15nm, the material of the metal electrode is Pt, and the thickness of the metal electrode is 80nm. The temperature is controlled at 350°C, and the selenization time is 13 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com