Copper coated aluminum bus bank production method and apparatus

A production method and technology of production equipment, applied in the field of copper-clad aluminum busbar production and equipment, can solve the problems of insufficient production method of copper-clad aluminum busbar, poor interphase diffusion effect of metals, insufficient strength of copper-aluminum joint surface, etc. , to achieve the effect of easy operation, high product quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

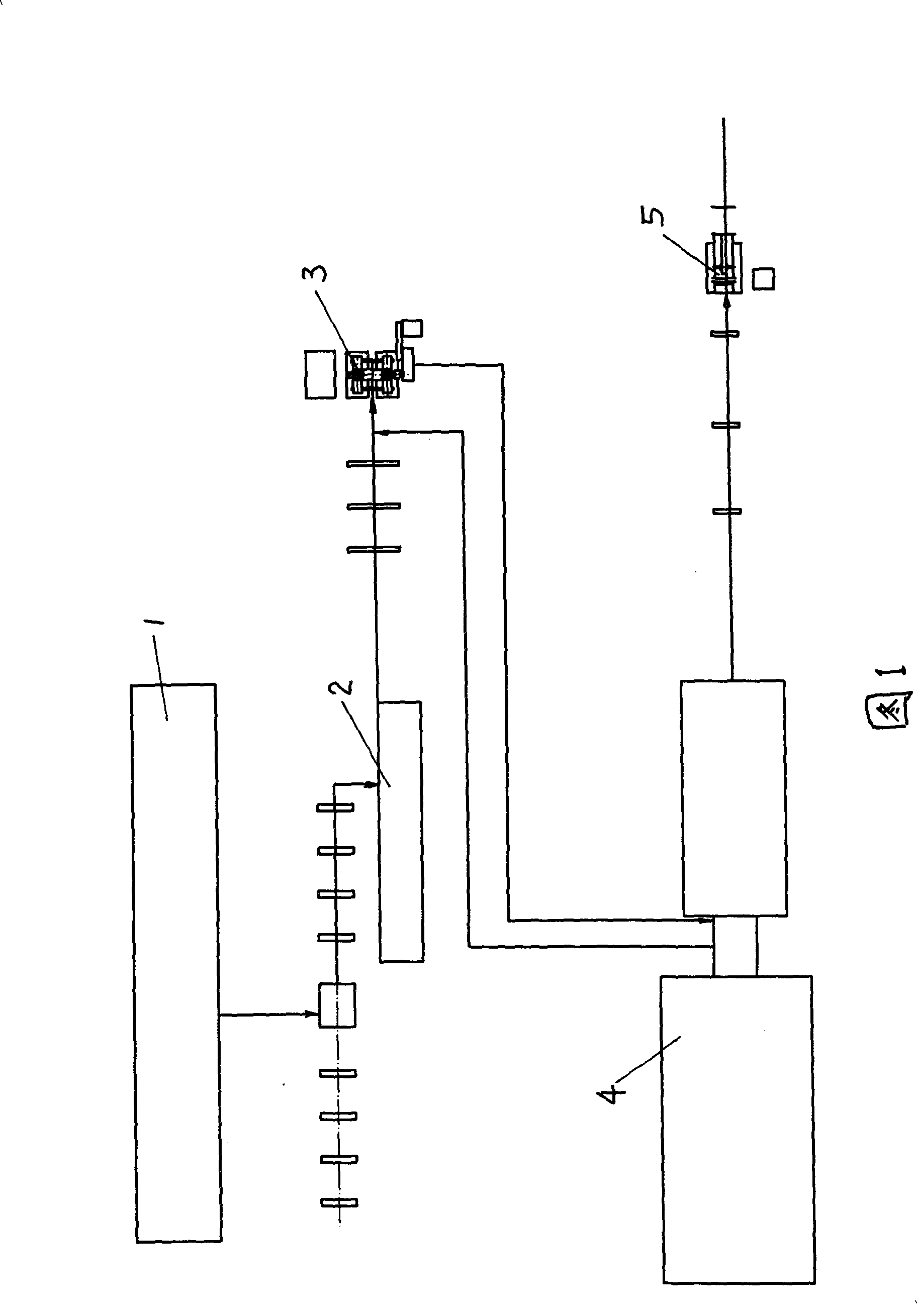

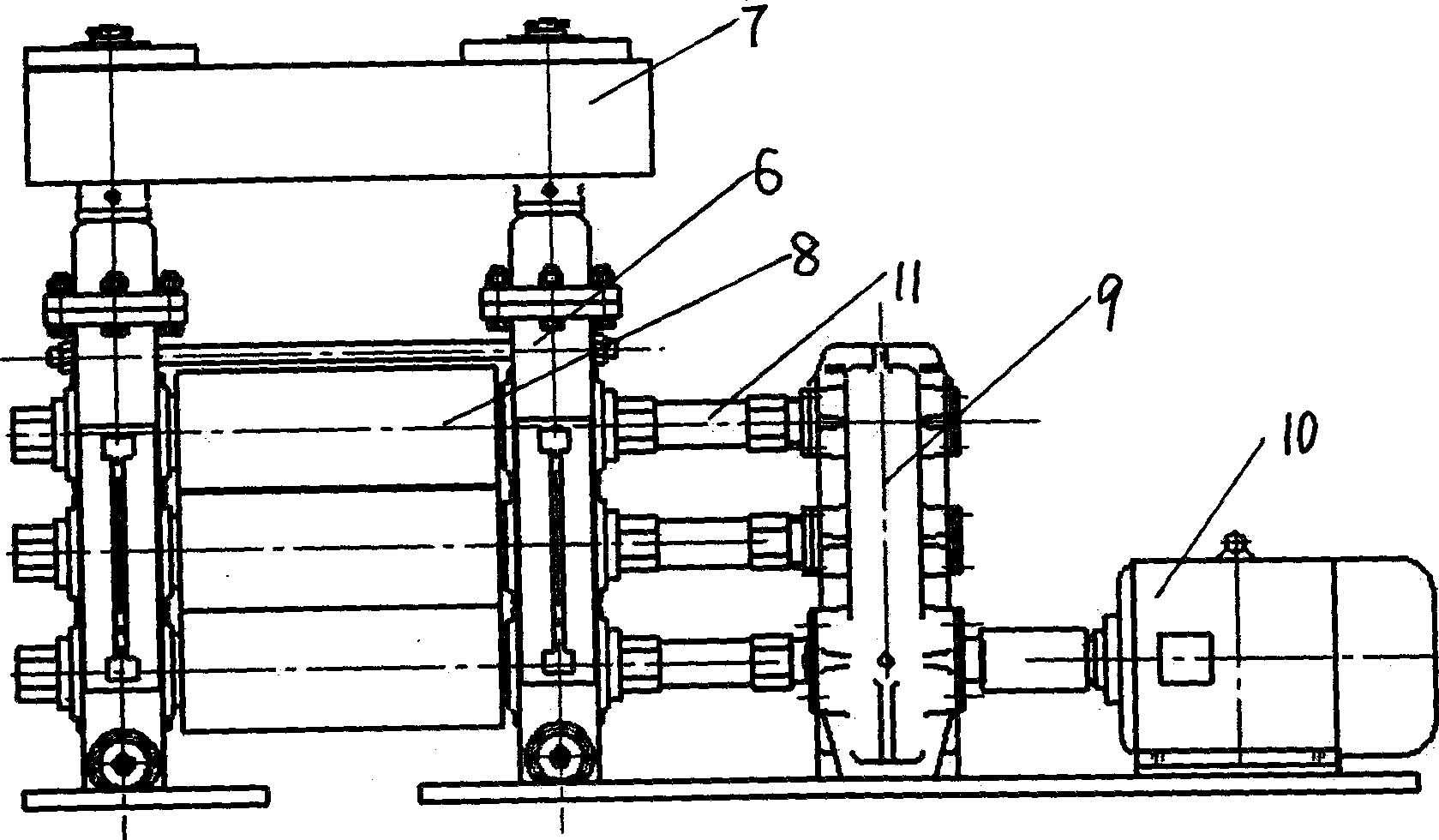

[0022] The production line shown in Figure 1 is composed of a grinding machine, a rolling mill, an annealing device, and a leveler. The cleaning equipment 1 is dynamically connected to the grinding machine 2, the grinding machine is dynamically connected to the rolling mill 3, the rolling mill is dynamically connected to the annealing furnace 4, and the annealing furnace is dynamically connected to the leveling machine. Flat machine 5. Among them, rolling mills such as figure 2 As shown, a pressing mechanism 7 and a roll system 8 are installed on the rolling stand 6, and the roll system is connected to the gearbox 9 and the motor 10 through the transmission shaft 11.

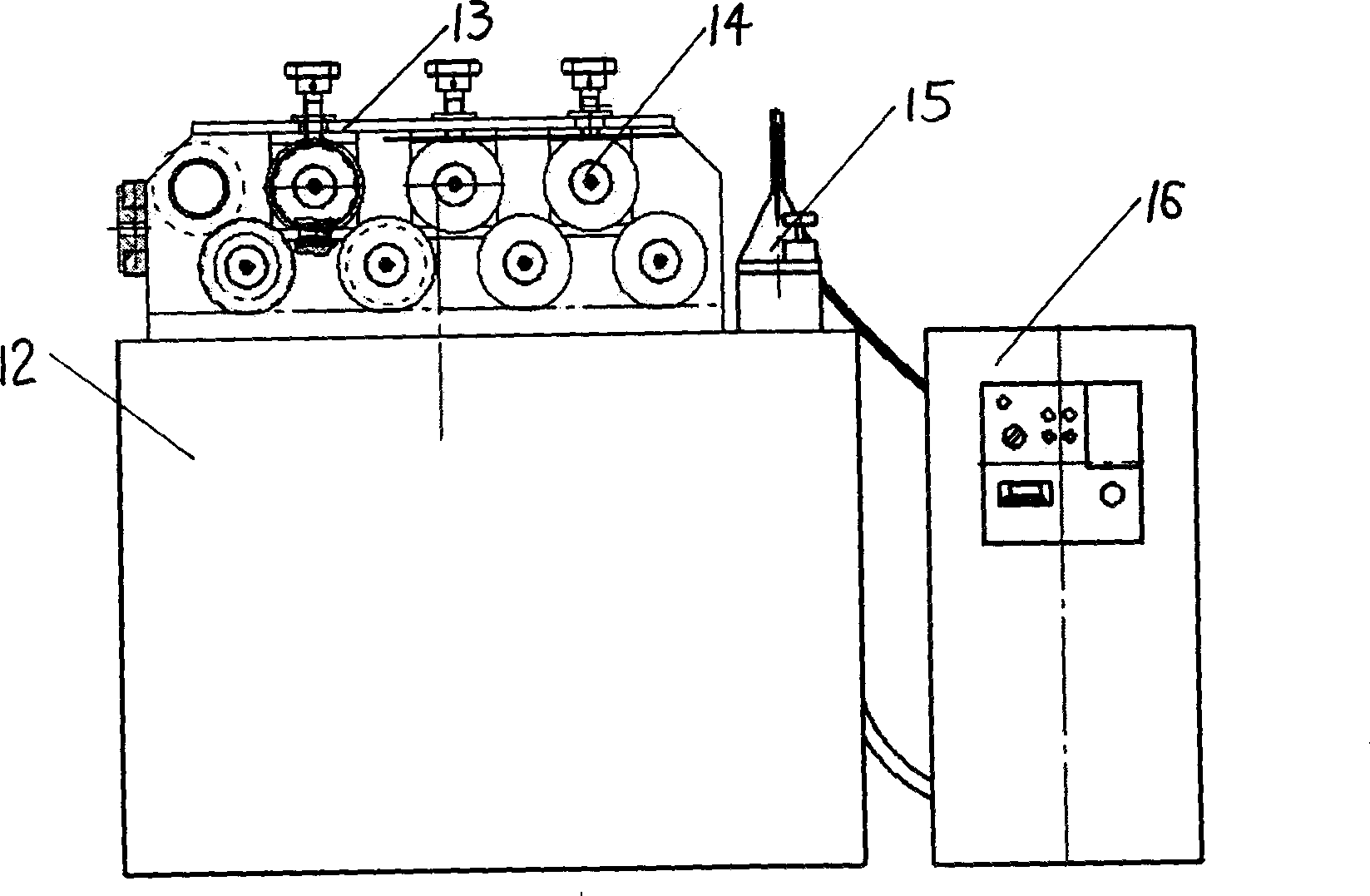

[0023] Leveling machine such as image 3 As shown, the electric control part 16 drives and connects the leveling roller 14 installed on the machine body 12, the pressing device 13 is installed above the leveling roller, and the discharge end of the leveling roller is dynamically connected with the guide device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com