Method of welding dissimilar steel 10Cr9Mo1VNb and 1Cr18Ni9

A 1cr18ni9, welding method technology, applied in the field of special steel pipe welding, can solve the problems of difficult welding, brittle cold cracks of welded joints, and decreased impact toughness of welds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

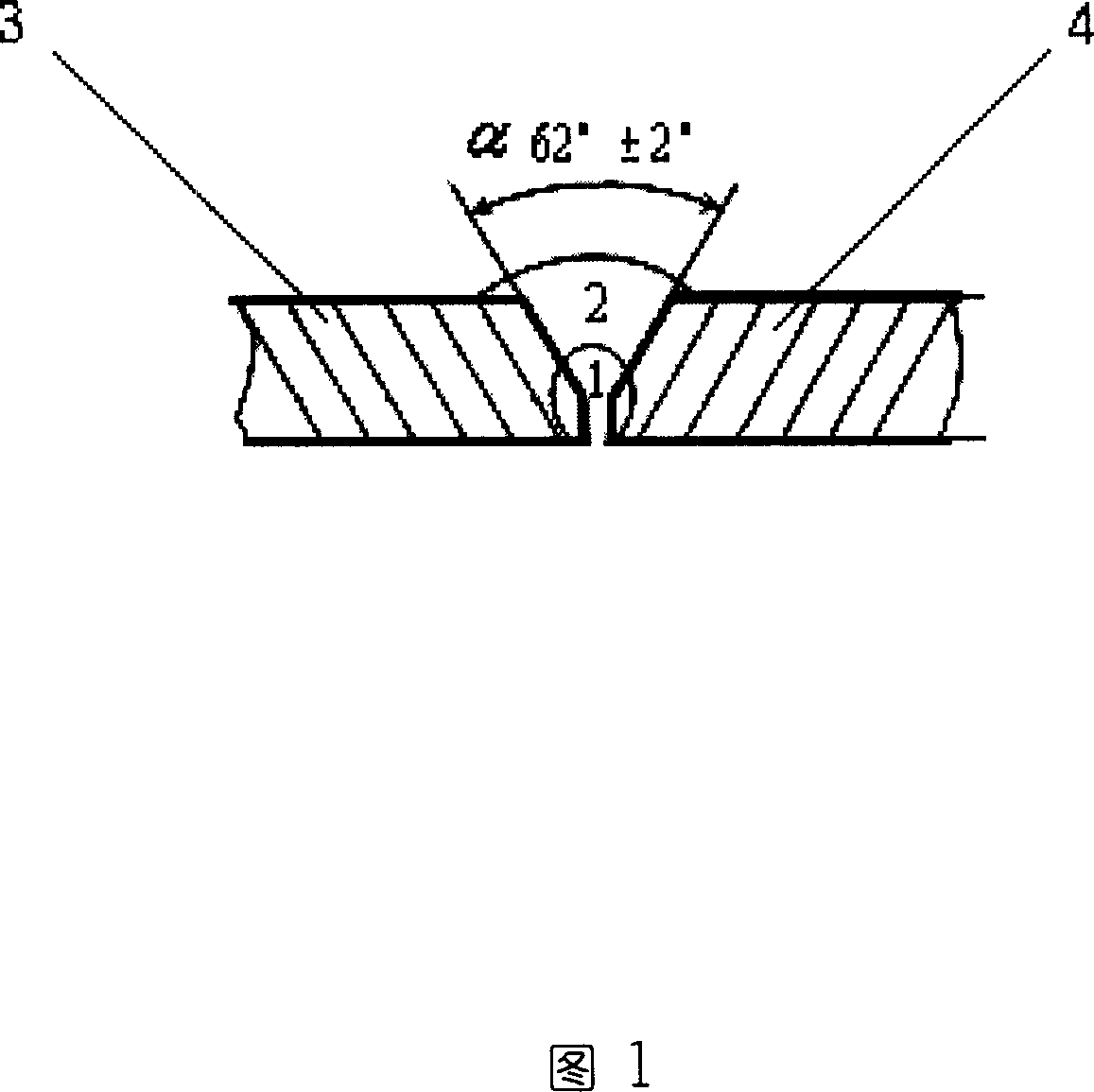

Image

Examples

Embodiment approach

[0014] 1. Welding method

[0015] The welding method adopts the combination of manual argon tungsten arc welding and the welding method of workpiece rotation with the installation of a welding positioner. The displacement pulse argon tungsten arc welding process has a beautiful appearance and is used for mass production; Dissimilar steel with flexible handling for narrow construction sites.

[0016] 2. Selection of welding process parameters

[0017] 2.1 preheating,

[0018] According to the data, the characteristics of the two steels are analyzed as follows:

[0019] ① 10Cr9Mo1VNb steel (T91) belongs to the air-cooled martensitic structure and is sensitive to cold cracks;

[0020] ②Due to reasons such as steel materials, welding materials, and manual welding processes, hydrogen may remain in the weld in a supersaturated state during martensitic transformation, making the area embrittled;

[0021] ③The phase transformation after welding, coupled with the structural restrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com