Vacuum electronic beam welding method for titanium-alloy rotor component

A vacuum electron beam and electron beam welding technology, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of high coaxiality requirements, weld seam porosity easily exceeds the standard, and the number of weld seams is large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

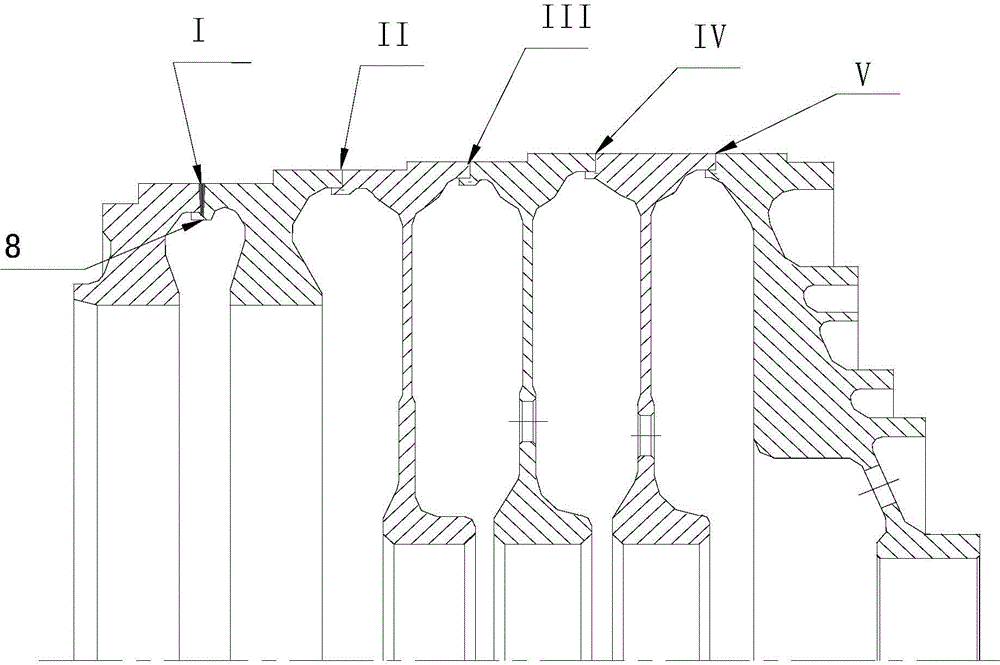

[0057] The compressor rotor of an aero engine is made of TC11 titanium alloy. This part is made up of six-stage compressor disks connected by five welds. The weld depth of weld I is required to be 7mm, and the weld of weld II to weld V The seam depth is required to be 5mm. And it is required that the coaxiality of the six-stage compressor disc after welding is ≤0.20mm, and the penetration depth is guaranteed, and the defects such as pores are excluded to the bottom of the liner. The inspection standard for pore defects is: CT inspection of the weld area , The entire weld is not allowed to have cracks, incomplete penetration, and no fusion, except for the liner area, no air holes are allowed, the size of a single air hole in the liner area is ≤1.5mm; the minimum distance between the air holes is 2D, where D It is the size of the largest pore; there are no more than 3 pores and unfused joints on a 100mm long weld; if any of the above indicators is not met, the welding is deemed t...

Embodiment approach

[0058] The specific implementation is as follows:

[0059] 1. Perform conventional pickling and dehydrogenation treatment on the compressor disk before electron beam welding, and perform electron beam welding within 24 hours;

[0060] 2. Load the compressor discs at all levels step by step, and the maximum gap between the welds after assembly is 0.05mm;

[0061] 3. Electron beam welding is used for tack welding at Ⅰ~Ⅴ. The process parameters of tack welding are shown in the following table:

[0062]

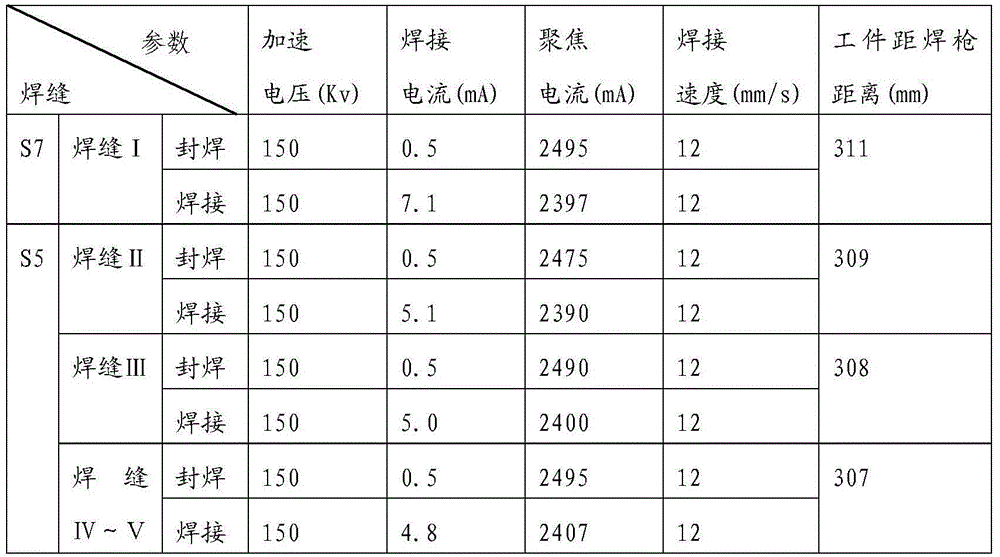

[0063] 4. Use electron beam welding to perform electron beam welding on the Ⅰ~Ⅴ positions. See Table 2 for sealing and welding parameters. The welding sequence is: firstly seal each weld in the order of weld Ⅰ→Ⅱ→Ⅲ→Ⅳ→Ⅴ; then perform formal welding in the order of weld Ⅱ→Ⅳ→Ⅰ→Ⅲ→Ⅴ, welding parameters As shown in the table below:

[0064]

[0065] 5. Perform conventional stress relief heat treatment after welding to eliminate stress;

[0066] 6. Perform CT inspection on the weld area. There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com