Method and system for automatic robot welding based on multilayer and multi-pass welding of curved surfaces

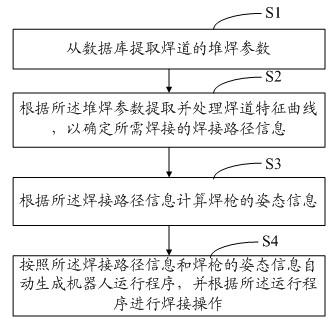

A multi-layer multi-pass welding and automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low work efficiency, welding quality depends on, multi-time, etc., to improve work efficiency and ensure welding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

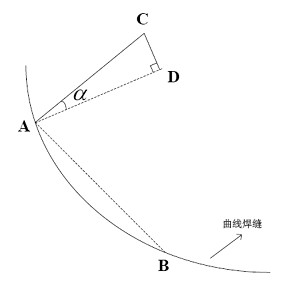

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

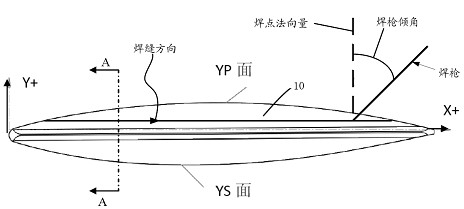

[0047] The technical solution of the present invention will be described in the following specific examples applied to the surfacing welding of guide vanes on hydraulic turbines. Of course, the technology of the present invention is not only applicable to the welding process of hydraulic turbine guide vanes, but also can be applied to curved surfaces in other industrial production. Multi-layer multi-pass welding to and from curved surfaces.

[0048] As we all know, as a hydraulic mechanical device that converts the energy of water flow into rotational mechanical energy to drive a generator, a water tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com