High speed motor train unit roof assembly-welding device

A technology for high-speed EMUs and roofs, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of incompatibility with the assembly and welding of new car bodies and boxes, and improve the utilization rate of workshop space, reduce labor intensity, and save energy. effect of funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

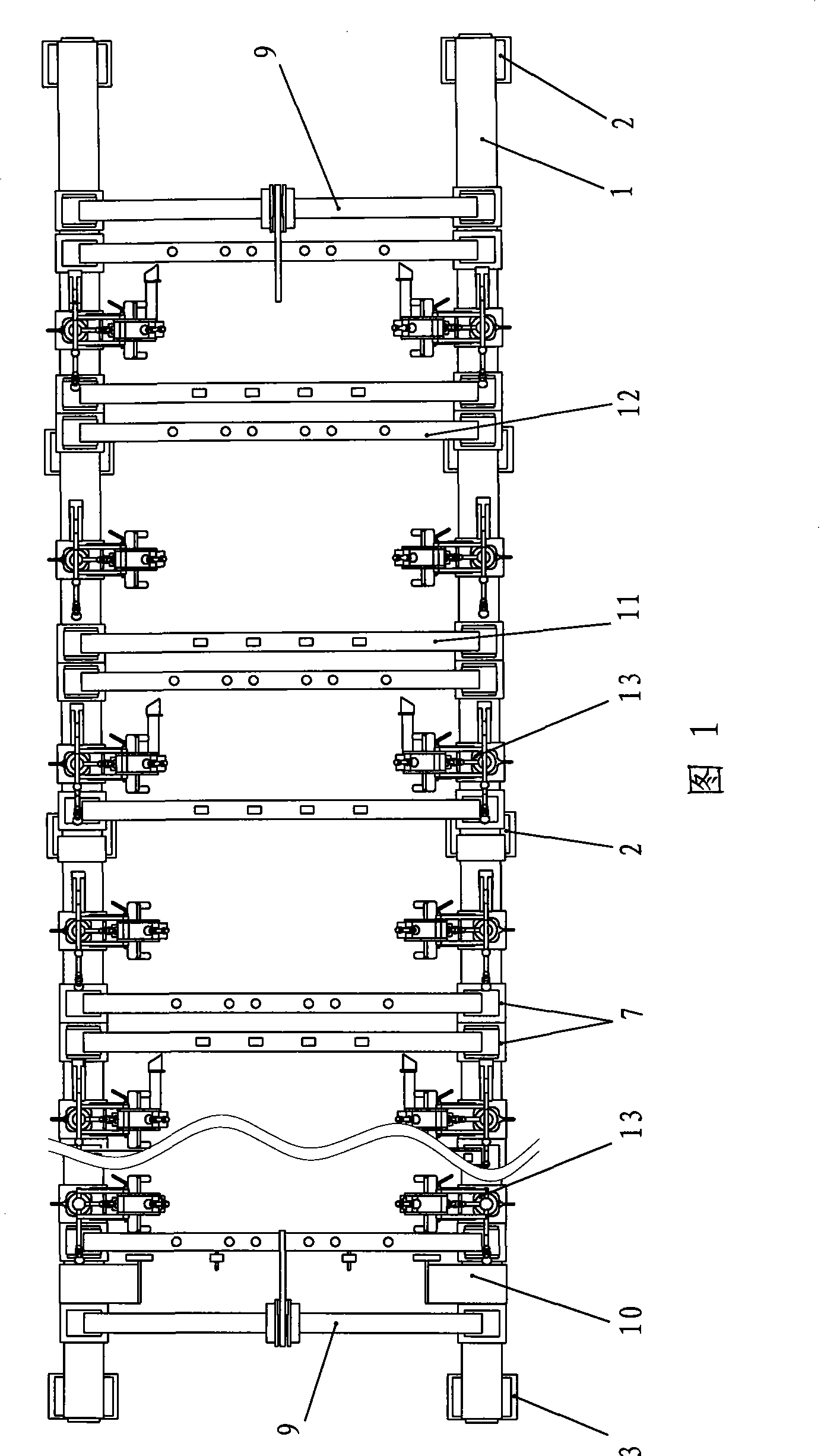

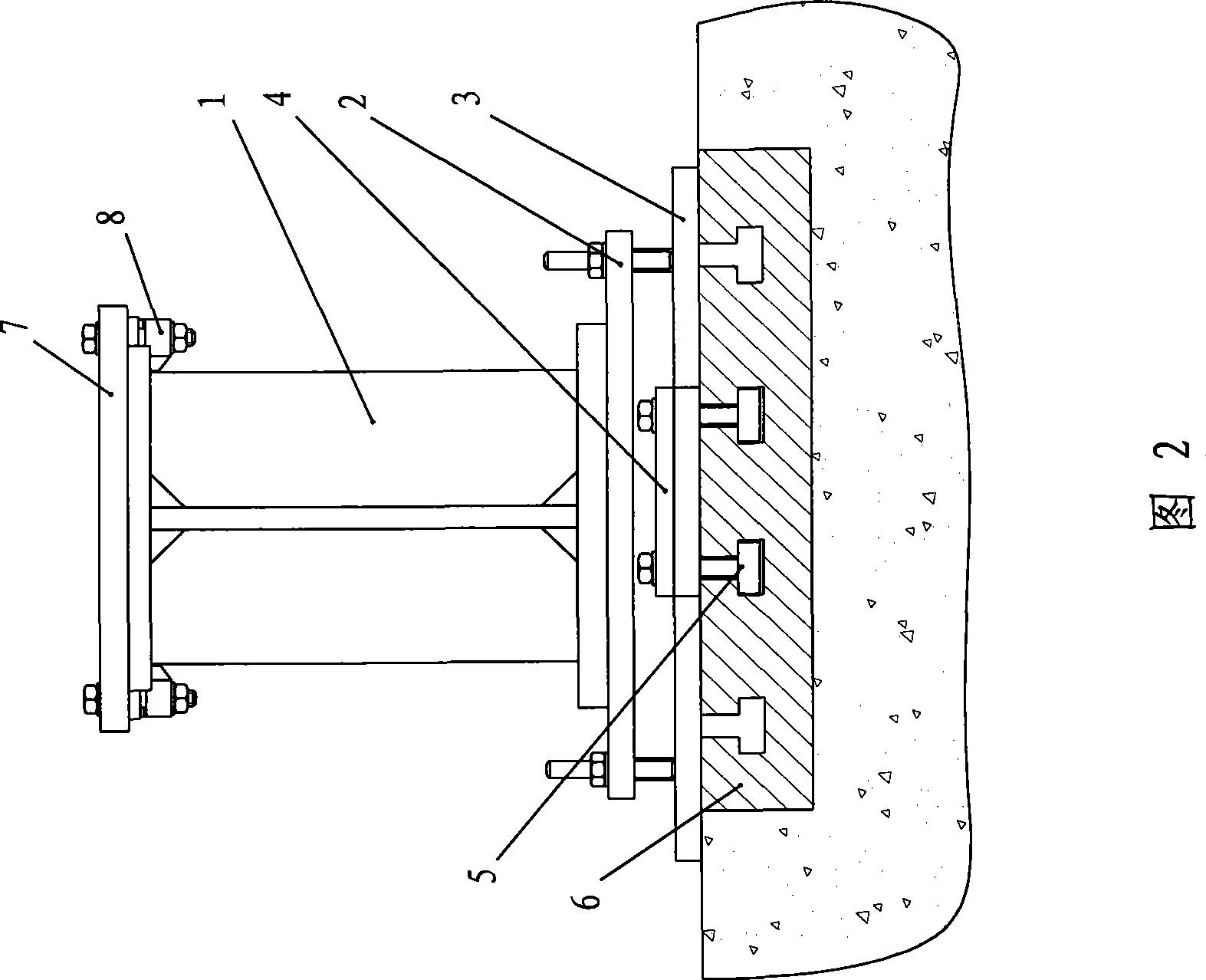

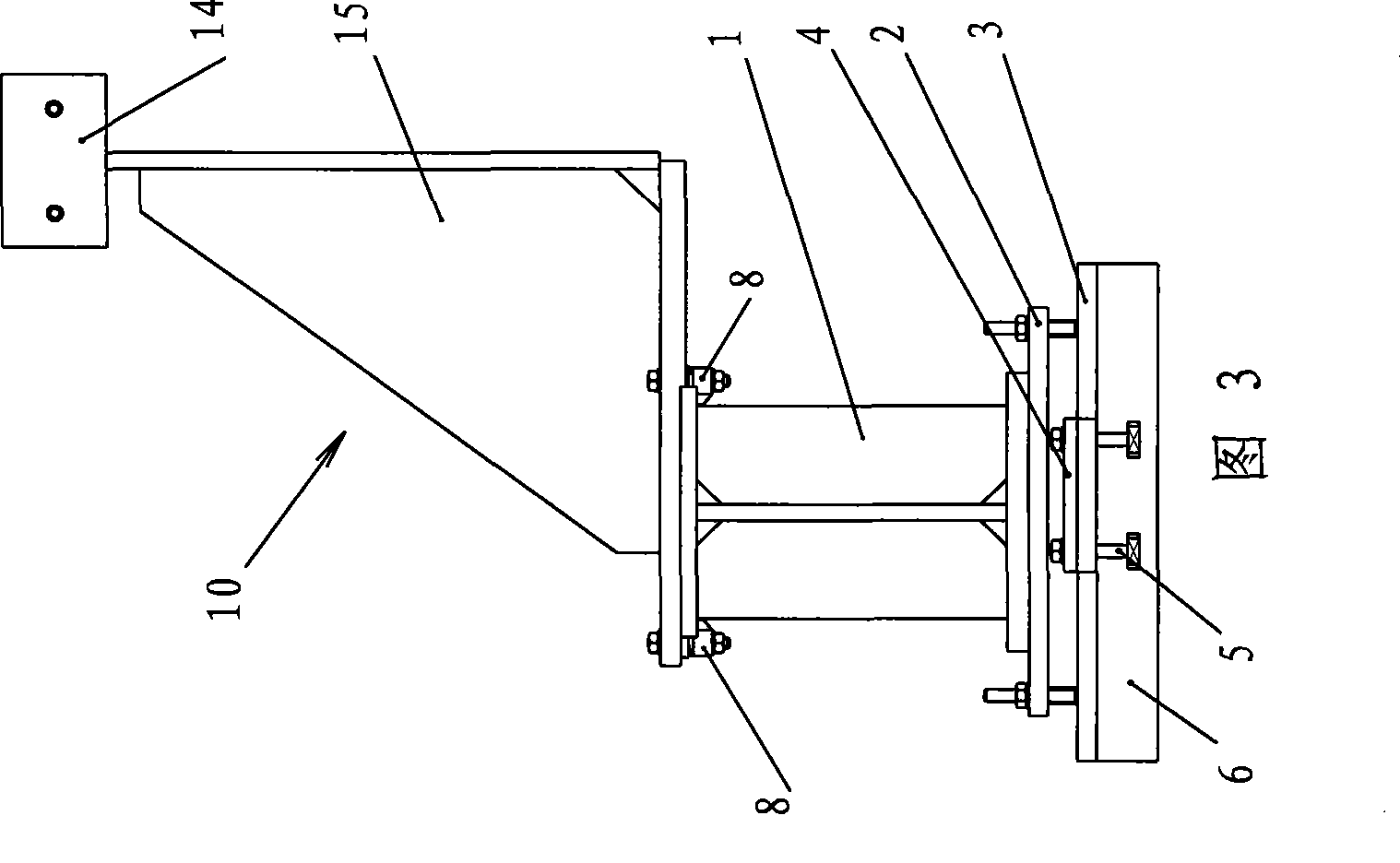

[0024] It can be seen from Fig. 1 and Fig. 2 that the high-speed EMU roof assembly welding device of the present invention includes two parallel foundation beams 1, and the foundation beam 1 is composed of several sections with I-shaped cross-sections connected in series by connectors. , the bottom surface of which is fixedly connected with several A boards 2, A board 2 is fixedly connected with B board 3 through bolts, B board 3 is embedded in the foundation with an inverted T groove through a pressure plate 4 and a T-head bolt 5. The C plate 6 is fixedly connected; several fixed plates 7 are installed on the foundation beam 1, and the clamping blocks 8 and fasteners placed along the two sides of the foundation beam 1 are fixedly connected to the foundation beam 1 under the fixed plate 7; The two ends on the beam 1 bridge the central positioning frame 9 respectively through the fixed plate 7, and a pair of top positioning frames 10 are installed symmetrically in the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com