Suspended type pipe-jointing welding robot

A welding robot, hanging technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of small working space, difficult to achieve card installation, and unfavorable real-time observation and operation of operators, and achieve welding. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

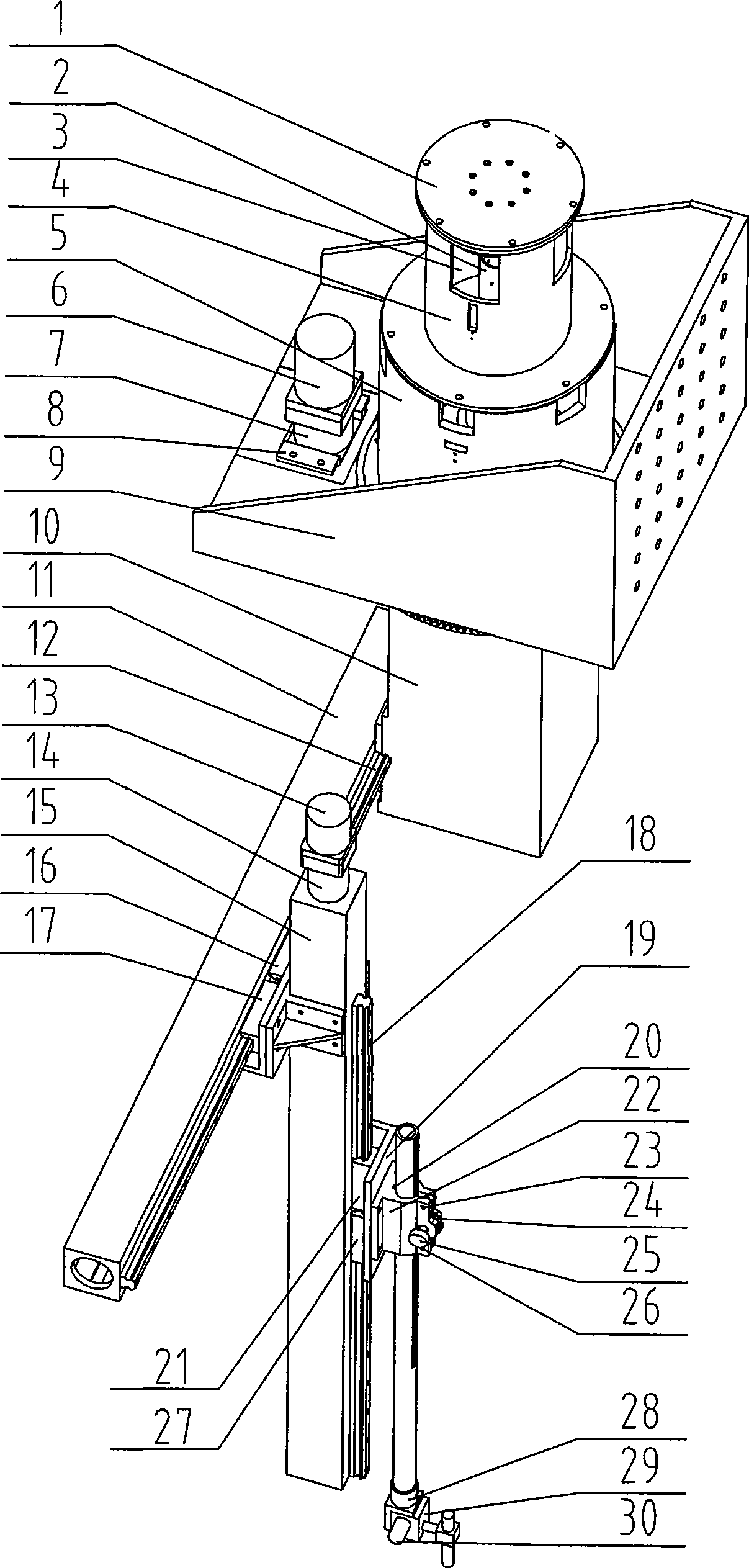

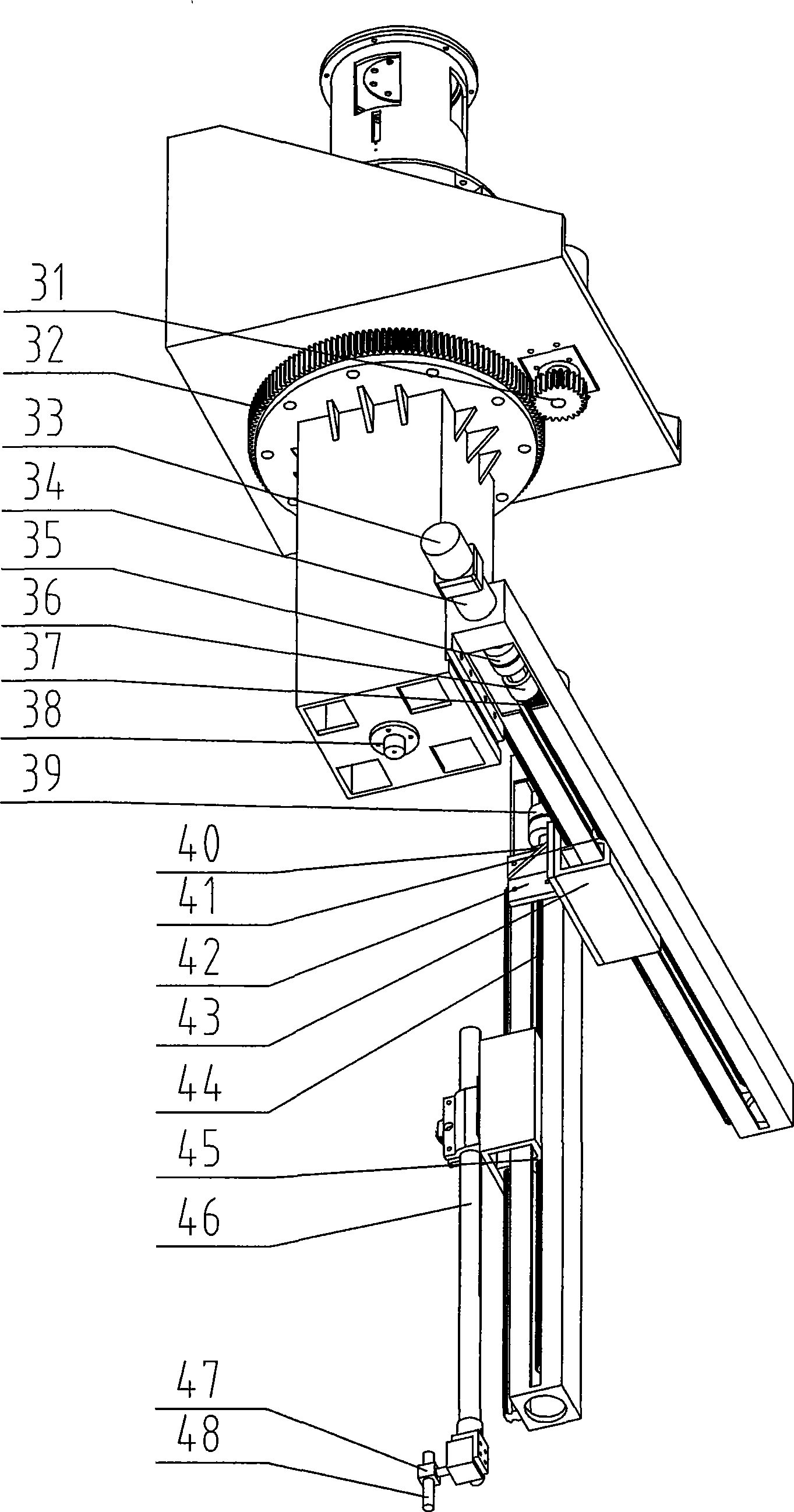

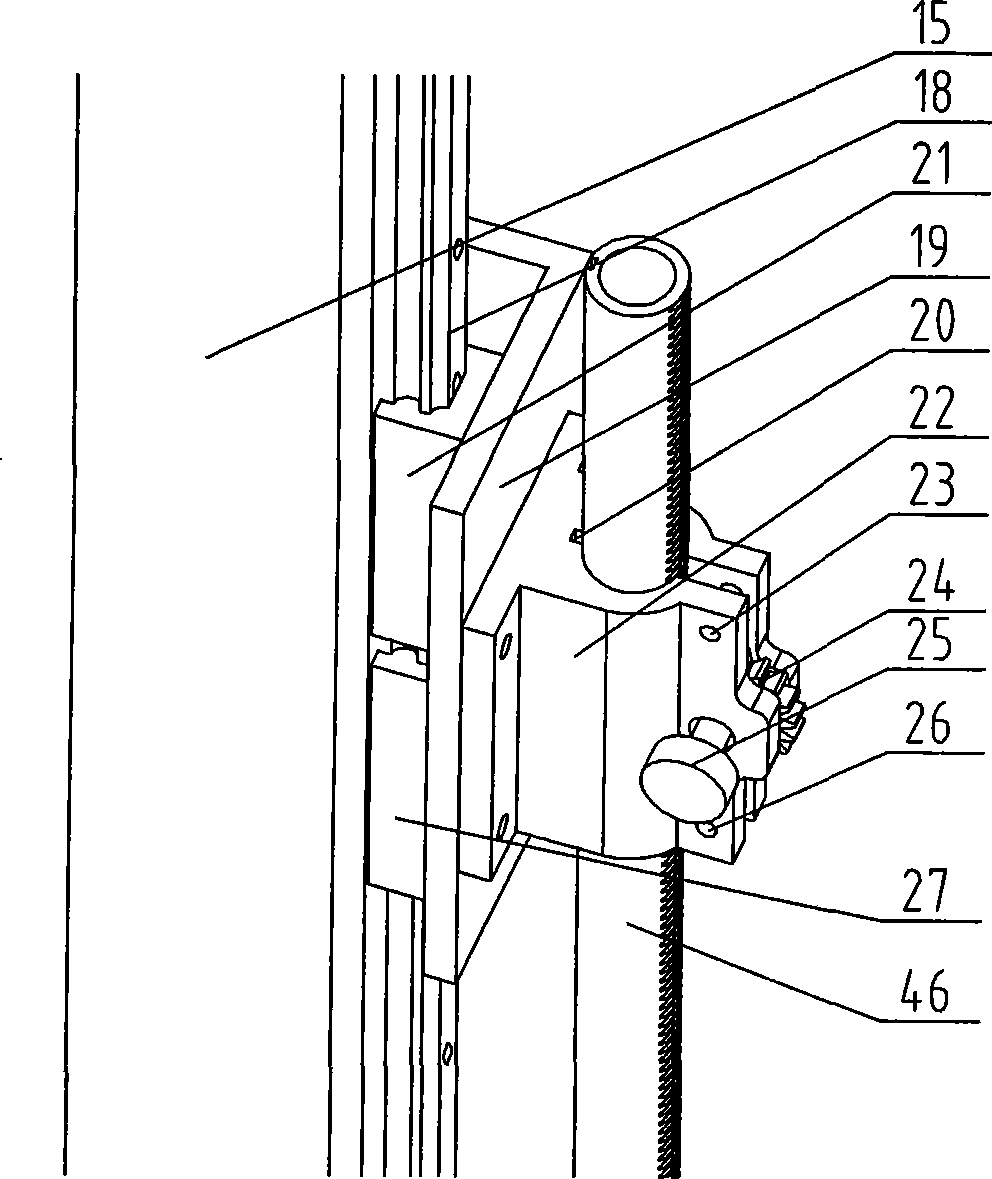

[0021] of the present invention Figure 1-Figure 6 The symbols of each part represent: 1. End cover, 2. Mandrel, 3. Circuit slip ring, 4. Shell I, 5. Shell II, 6. Servo motor, 7. Reducer, 8. Bracket, 9. Large hanger, 10. Rotating box, 11. Telescopic arm, 12. Linear slide rail, 13. Stepping motor, 14. Reducer, 15. Lifting arm, 16, 17. Slider, 18. Linear slide rail, 19. Lifting connection block, 20. Key, 21. Slider, 22. Clamper, 23, 26. Screw, 24. Lifting adjustment pinion, 25. Handwheel, 27. Slider, 28. End connecting block, 29. Worm gear reducer, 30. Stepping motor, 31. Rotating pinion, 32. Slewing ring, 33. Stepping motor, 34. Reducer, 35. Coupling, 36. Ball screw bracket, 37. Ball screw, 38. Laser, 39. Coupling, 40. Ball screw bracket, 41. Screw nut, 42. Two-arm connecting block, 43. Telescopic moving block, 44. Ball screw, 45. Lead screw Nut, 46. rack tube, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com