Intelligent shoveling bus controlling system of loader

A bus control, loader technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of large energy loss, poor leveling function, short service life, etc., achieve small energy loss, long service life, eliminate effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

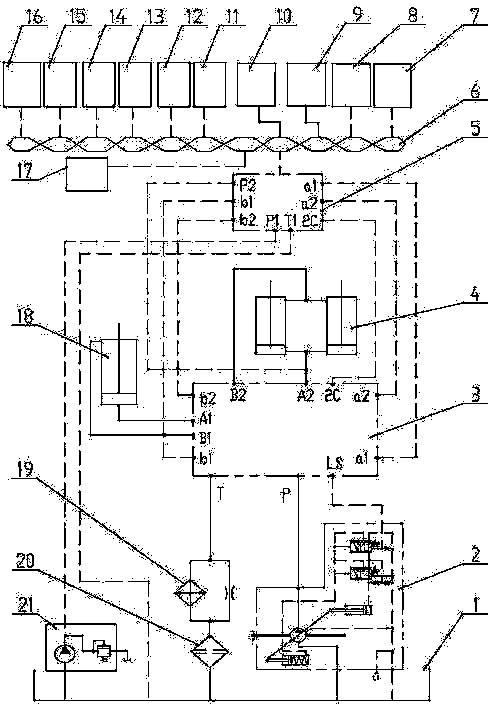

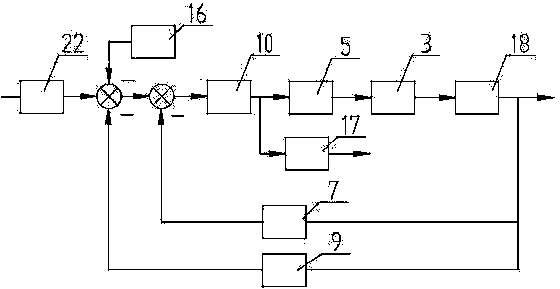

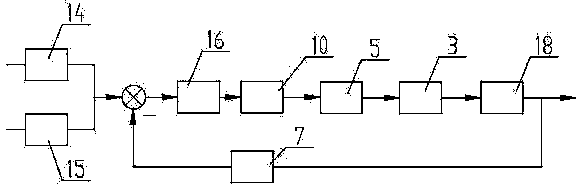

[0030] exist figure 1 Among them, the loader shovel intelligent bus control system includes a hydraulic oil tank 1 and a working pump 2, the oil inlet of the working pump 2 is connected to the hydraulic oil tank 1, and the oil outlet of the working pump 2 is connected to the oil inlet P of the electro-hydraulic proportional distribution valve 3 , the large chamber oil port A2 of the boom cylinder and the small chamber oil port B2 of the boom cylinder of the electro-hydraulic proportional distribution valve 3 are respectively connected with the large chamber and small chamber of the boom cylinder 4, and the large chamber of the tipping bucket cylinder of the electro-hydraulic proportional distribution valve 3 The oil port A1 and the small cavity B1 of the tipping bucket oil cylinder are respectively connected with the large cavity and the small cavity of the tipping bucket oil cylinder 18; The oil port b2 and the floating oil port 2C are respectively connected with the receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com