Vertical pultrusion process and device of multilayer fiber composite laminated section bar

A fiber composite, multi-layer fiber technology, applied to other household appliances and other directions, can solve the problems of process layout and fiber impregnation methods, which are difficult to achieve multi-layered and multi-oriented fiber bundles, easy oxidation of glue, and environmental pollution. Achieve the effect of overcoming the phenomenon of air bubbles attached to the wall, reducing traction and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

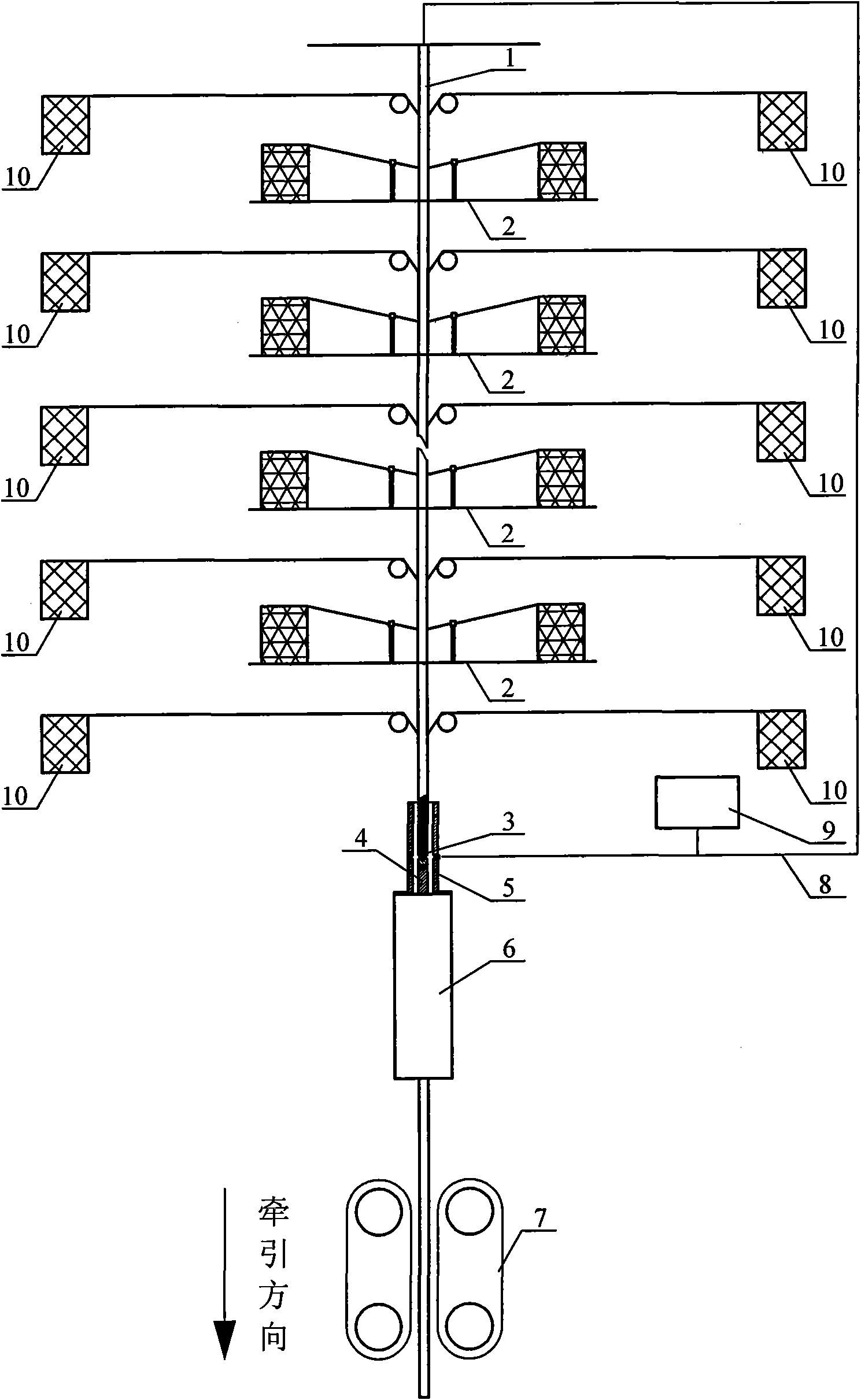

[0021] A vertical pultrusion forming process for multi-layer fiber composite laminated profiles. A tubular mandrel 1 is used to arrange longitudinal fiber bundle laminations on the tubular mandrel 1 first, and then arrange circumferential fiber bundle laminations on the longitudinal fiber bundle laminations. The method of fiber bundle layup alternately arranges longitudinal fibers and hoop fibers on the tubular mandrel 1, and the fiber composite layup is formed by stacking longitudinal fiber bundles and hoop fiber bundles, and is drawn by a tractor 7 traction movement;

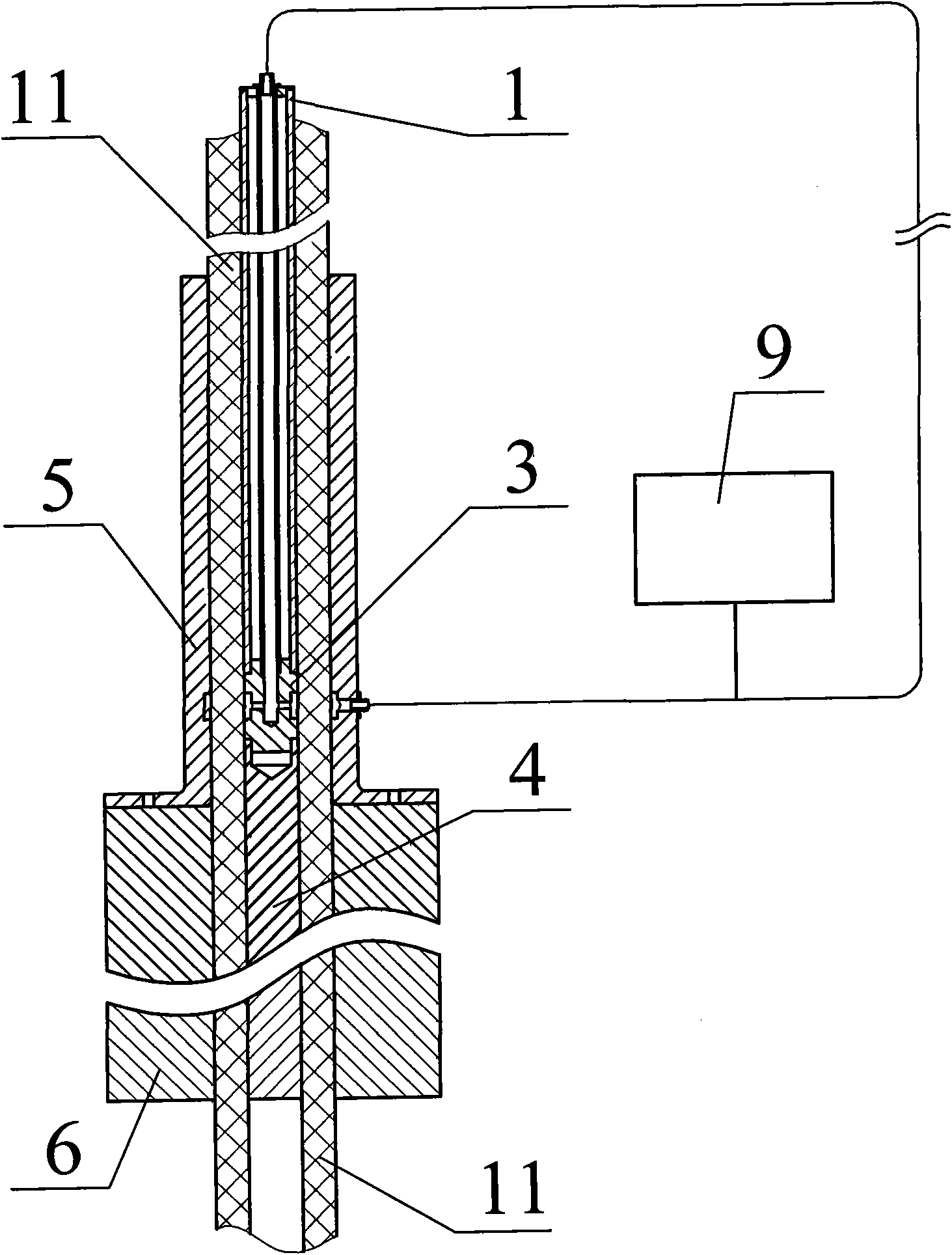

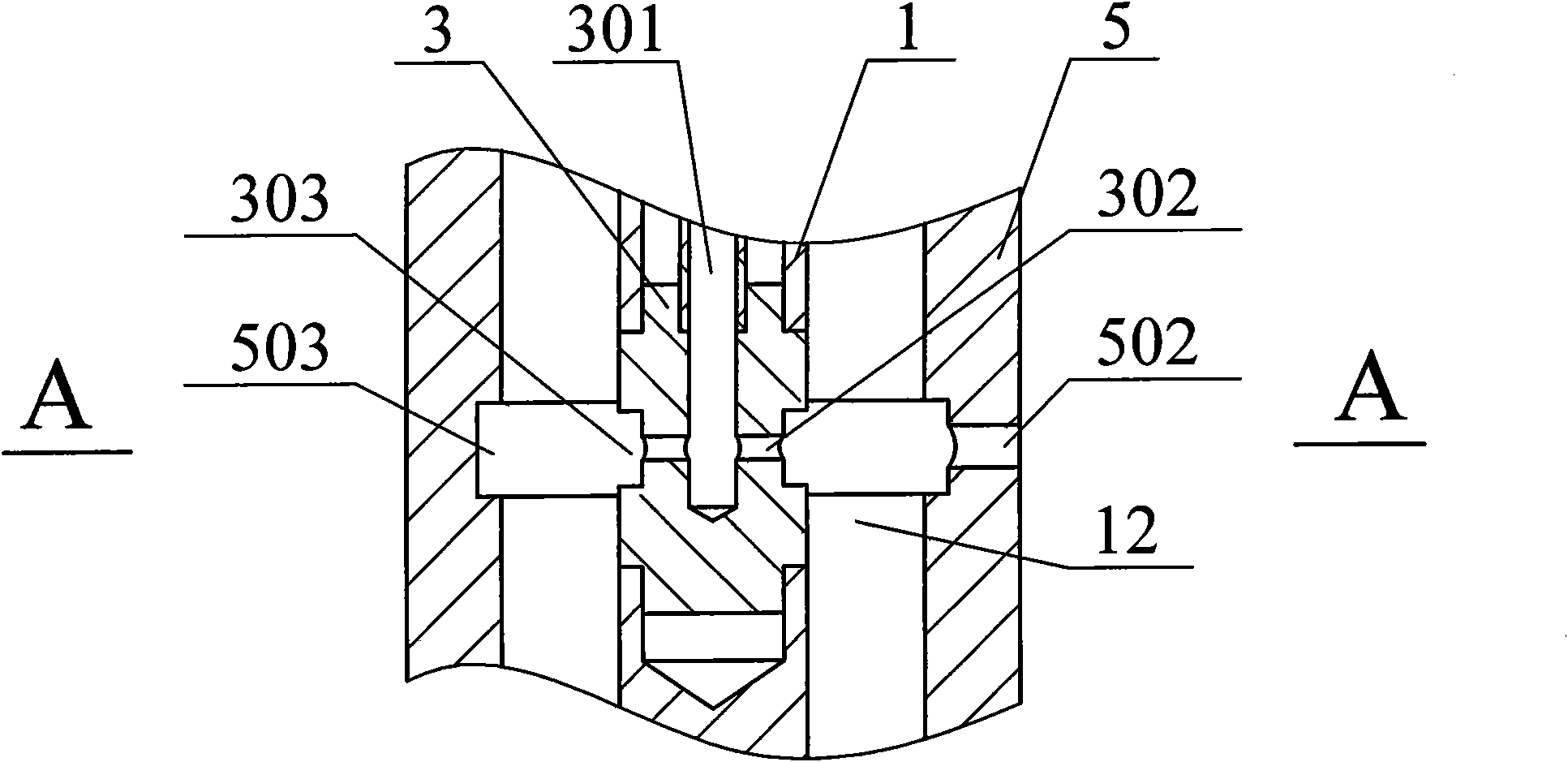

[0022] Introduce part of the glue into the interior of the tubular mandrel 1 and let the glue flow out of the tubular mandrel 1 into the interior of the fiber composite laminate and inject glue from the interior of the fiber composite laminate into the fiber composite laminate. At the same time, another part of the glue flows from the The fiber composite laminate is injected with glue to make the glue soak int...

Embodiment 2

[0025] A device for realizing a vertical pultrusion forming process, comprising: a tractor 7 for pulling fiber composite laminates and a heating molding die 6, an inner and outer glue injection device is arranged on the heating molding mold 6, and an inner and outer glue injection device A tubular mandrel 1 is provided, the internal glue injection port of the internal and external glue injection device is connected with a nozzle of the tubular mandrel 1, the other nozzle of the tubular mandrel 1 is connected with the external glue injection port of the internal and external glue injection device Connected to the glue injection pump, at least one set of yarn distributors is set on the tubular mandrel 1, said set of yarn distributors includes a longitudinal yarn roll 10 and a circumferential yarn winder 2, the longitudinal yarn roll 10 is in the direction of traction Located in front of the hoop winder 2.

[0026] In this example,

[0027] One set, two sets, five sets or more s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com