Ultrahigh-performance-concrete prefabricated assembled-type arch rib and manufacturing and mounting method thereof

An ultra-high-performance concrete technology, applied in the direction of arch bridges, bridge forms, erection/assembly bridges, etc., to achieve the effect of reducing project cost, ensuring construction quality, and reducing requirements for geological conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

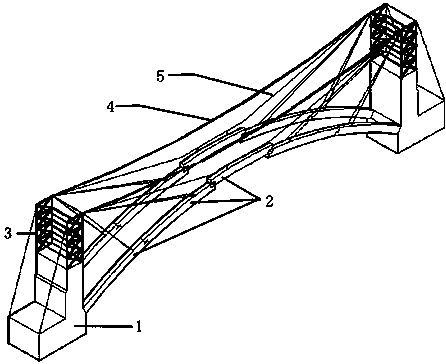

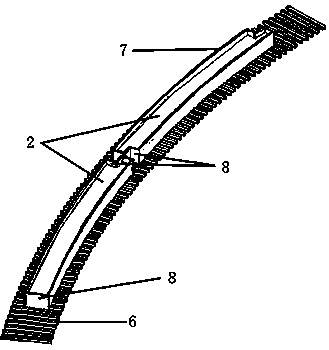

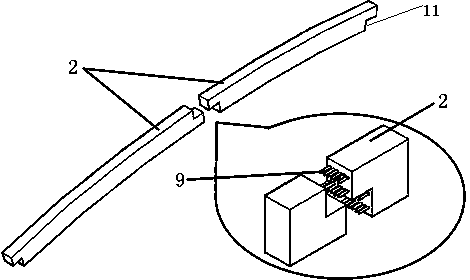

[0018] like figure 1 As shown, the rib arch bridge includes piers 1 and arch ribs. Pier 1 is made of ordinary concrete, and the arch rib is made of ultra-high performance concrete. The arch ring in the figure is composed of two separated arch ribs. The arch ribs are hoisted and assembled by cables. Towers 3 of a certain height are erected on both piers, and main cables 4 are anchored on corresponding piers 1 . Before hoisting the arch rib prefabricated component 2, first clean up the stains and sundries on the concrete surface of the component, apply epoxy resin glue on the interface of the arch rib prefabricated component 2 and the reserved hole 10, and then install the arch rib prefabricated component 2 in sequence Carry out symmetrical hoisting in place.

[0019] The inventive method comprises the following steps:

[0020] ① Concrete mix design. The water-cement ratio is 0.16-0.22, the sand-grain ratio is 0.8-2.0, and the ratio of cement: silica fume: finely ground fly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com